The global bread slicing machine market is experiencing robust growth, driven by rising demand for convenience foods and the expansion of industrial bakeries worldwide. According to Mordor Intelligence, the bakery equipment market—which includes slicing machines—is projected to grow at a CAGR of over 6.2% from 2023 to 2028, fueled by automation in commercial baking and increasing output requirements in both developed and emerging economies. Similarly, Grand View Research reports that the global bread and bakery products market exceeded USD 400 billion in 2022 and is expected to expand further, directly increasing the need for high-efficiency, precision slicing solutions. As manufacturers prioritize throughput, hygiene, and consistency, the adoption of advanced slicing machines has become a critical operational consideration. In this landscape, selecting the right equipment can significantly impact yield, waste reduction, and overall production efficiency. The following list highlights the top 8 slicing machines tailored for bread manufacturers, evaluated based on output capacity, blade technology, automation features, scalability, and real-world performance metrics.

Top 8 Slicing Machine For Bread Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 HOBA

Website: hoba.ws

Key Highlights: Specialized manufacturer of bread slicers, packaging and closing machines for the (semi-) industrial bakery….

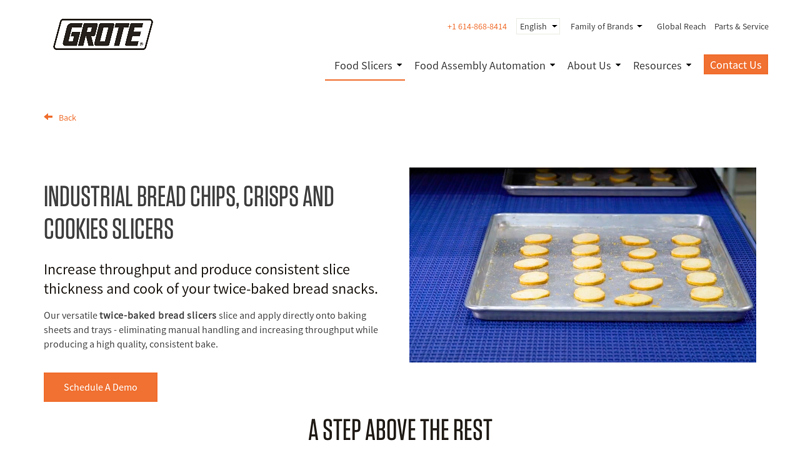

#2 Industrial Bread Chip, Crisp, & Cookie Slicers

Domain Est. 1997

Website: grotecompany.com

Key Highlights: Our versatile twice-baked bread slicers slice and apply directly onto baking sheets and trays – eliminating manual handling and increasing throughput….

#3 Bread Slicing

Domain Est. 2000

Website: hsiaolin.com

Key Highlights: Hsiao Lin provides a series of equipment that can be used for large-scale production of bread slicing. This type of equipment is usually used in restaurants, ……

#4 Bread Cutting Blades Manufacturer in Ludhiana, Slicing Machine …

Domain Est. 2024

Website: sohalslicers.com

Key Highlights: Sohal Engineers is a reputable and well-known manufacturer and supplier offering a wide selection of products including Bread Cutting Blades, Slicing Machine, ……

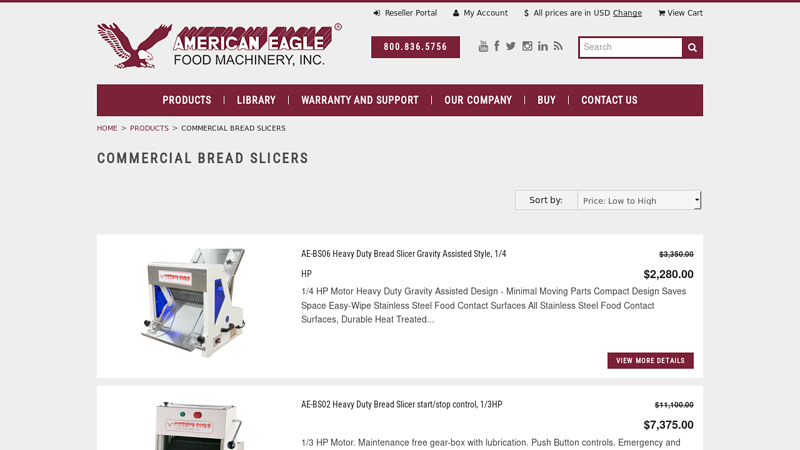

#5 Commercial Bread Slicer

Domain Est. 1997

#6 Bizerba takes over startup in the field of bread slicing

Domain Est. 1999

Website: bizerba.com

Key Highlights: The machines from the North Rhine-Westphalian bread slicing specialist clearly stand out from the competition with their clear functionality and elegant design….

#7 Bread slicers

Domain Est. 2000

Website: jac-machines.com

Key Highlights: JAC offers a broad array of bread slicer machines and loaf slicers to meet every requirement. Among these is the adjustable bread slicer….

#8 Commercial Bread Slicers for Every Bakery

Domain Est. 2009

Website: oliverquality.com

Key Highlights: Our machines are designed to handle high-volume slicing needs, making them perfect for bakeries and grocery stores seeking optimal efficiency and productivity….

Expert Sourcing Insights for Slicing Machine For Bread

2026 Market Trends for Slicing Machines for Bread: Key Developments and Drivers

Growing Demand for Convenience and Consistency in Commercial Baking

By 2026, the global market for bread slicing machines is expected to be significantly driven by the rising demand for convenience foods and the need for uniformity in commercial bakeries, supermarkets, and foodservice operations. Consumers continue to favor pre-sliced bread for its ease of use, prompting bakeries and large-scale producers to invest in high-efficiency slicing machines that ensure consistent thickness and presentation. Automation in this segment will be a critical focus, with manufacturers prioritizing machines that reduce labor costs and human error while increasing throughput.

Adoption of Smart and Automated Slicing Technologies

A major trend shaping the 2026 market is the integration of smart technologies into bread slicing equipment. Advanced slicing machines are increasingly incorporating Internet of Things (IoT) connectivity, real-time monitoring, predictive maintenance, and AI-driven controls. These features allow operators to remotely manage slicing parameters, monitor blade wear, and optimize performance. Fully automated in-line slicers that integrate seamlessly with baking and packaging lines are gaining traction, especially among high-volume producers aiming to improve operational efficiency and reduce downtime.

Emphasis on Hygiene, Safety, and Easy Maintenance

Food safety regulations are becoming stricter worldwide, pushing manufacturers to design slicing machines with improved hygiene standards. By 2026, equipment featuring sanitary designs—such as stainless steel construction, minimal crevices, and tool-free disassembly—will dominate the market. Additionally, safety mechanisms like automatic blade guards, emergency stops, and touchless operation will be standard features, aligning with global workplace safety norms and reducing the risk of injury in fast-paced environments.

Expansion in Emerging Markets and Artisan Bakery Segments

While established markets in North America and Europe continue to modernize their slicing infrastructure, significant growth is anticipated in Asia-Pacific, Latin America, and the Middle East. Rising urbanization, expanding retail chains, and the popularity of Western-style bread are fueling demand in these regions. Concurrently, the artisanal and specialty bread movement is creating demand for versatile, mid-range slicing machines capable of handling diverse bread types—from sourdough to gluten-free loaves—without compromising texture or structural integrity.

Sustainability and Energy Efficiency as Competitive Advantages

Environmental concerns are influencing equipment design, with a growing emphasis on energy-efficient motors, reduced material waste, and recyclable components. By 2026, manufacturers offering eco-friendly slicing machines with lower power consumption and longer lifespans will gain a competitive edge. Additionally, modular designs that allow for part replacement instead of full-machine disposal will appeal to sustainability-conscious buyers across the food production chain.

In summary, the 2026 bread slicing machine market will be characterized by technological innovation, automation, and a strong focus on hygiene and sustainability, driven by evolving consumer preferences and industrial efficiency demands.

Common Pitfalls When Sourcing a Slicing Machine for Bread (Quality and IP)

Sourcing a bread slicing machine requires careful consideration to ensure consistent product quality and to avoid intellectual property (IP) complications. Overlooking key factors can lead to operational inefficiencies, legal risks, and compromised product integrity. Below are some common pitfalls to watch out for:

Poor Build Quality and Material Selection

Many budget-friendly slicing machines use substandard materials such as non-food-grade stainless steel or components prone to corrosion. This compromises hygiene, increases maintenance costs, and may introduce contamination risks. Always verify that construction materials meet food safety standards (e.g., FDA or EU 1935/2004) and are suitable for high-moisture environments typical in bakery settings.

Inconsistent Slice Uniformity

Low-quality machines often lack precision engineering, leading to uneven slicing—particularly problematic for pre-packaged bread where consistency affects branding and consumer satisfaction. Check for adjustable blade tension, reliable feed mechanisms, and servo-driven controls to ensure uniform thickness across every loaf.

Inadequate Blade Design and Durability

Using generic or poorly tempered blades results in tearing, crushing, or premature dulling—especially when slicing crusty or artisanal breads. Ensure the machine uses high-carbon or ceramic-coated blades designed specifically for bread, and confirm whether replacements are readily available and comply with original equipment specifications.

Overlooking IP-Restricted Technologies

Some advanced slicing machines incorporate patented technologies—such as automated loaf alignment, anti-jam systems, or digital thickness calibration. Sourcing clones or reverse-engineered models from unverified suppliers may lead to IP infringement, resulting in legal action, shipment seizures, or forced equipment removal. Always verify that the manufacturer holds legitimate rights to the technology or has proper licensing.

Lack of Compliance Documentation

Suppliers may fail to provide necessary certifications (e.g., CE, UL, or IP ratings for dust and water resistance). Without proper documentation, you risk non-compliance with local safety regulations and difficulty obtaining insurance or passing health inspections. Confirm all compliance certificates are valid and machine-specific.

Insufficient After-Sales Support and Spare Parts Availability

Many overseas suppliers offer attractive upfront pricing but provide limited technical support or long lead times for replacement parts. This can result in costly downtime. Evaluate the supplier’s service network, warranty terms, and spare parts inventory before purchasing.

Misaligned Machine Capacity and Production Needs

Selecting a machine based solely on price rather than throughput can lead to bottlenecks. Under-capacity machines slow production, while over-spec’d models waste capital and space. Accurately assess your daily loaf volume, loaf sizes, and future scalability needs to match the right machine specifications.

Ignoring Sanitation and Cleanability

Machines with complex crevices, inaccessible blades, or non-removable parts hinder thorough cleaning, increasing the risk of microbial growth. Choose designs with open structures, quick-release components, and IP65 or higher ingress protection for washdown environments.

By proactively addressing these pitfalls—especially those related to quality consistency and intellectual property—you can source a reliable, compliant, and efficient bread slicing machine that supports long-term operational success.

Logistics & Compliance Guide for Slicing Machine For Bread

Conclusion: Sourcing a Slicing Machine for Bread

After careful evaluation of technical specifications, production capacity, budget constraints, and operational requirements, sourcing a bread slicing machine is a crucial investment to enhance efficiency, ensure product consistency, and meet growing demand. Automated slicing machines offer significant advantages in terms of precision, speed, hygiene, and labor cost reduction, particularly for bakeries operating at medium to large scale.

Key considerations such as blade quality, slice thickness adjustability, throughput capacity, ease of cleaning, and compliance with food safety standards (e.g., FDA, CE) must guide the final selection. Additionally, after-sales support, warranty, and spare parts availability from the supplier play a vital role in minimizing downtime and ensuring long-term reliability.

Based on the assessment, sourcing a reliable, high-performance bread slicing machine from a reputable manufacturer—either domestically or internationally—will not only improve product quality but also strengthen competitiveness in the market. It is recommended to obtain quotes from shortlisted suppliers, conduct performance demonstrations if possible, and select a machine that best aligns with current operations and future scalability needs.