The global skylight ventilation market is experiencing steady growth, driven by rising demand for energy-efficient building solutions and increased focus on indoor air quality. According to a report by Mordor Intelligence, the global skylight market was valued at USD 3.8 billion in 2023 and is projected to grow at a CAGR of 5.2% from 2024 to 2029. This expansion is fueled by advancements in smart ventilation technologies, growing adoption in residential and commercial constructions, and supportive green building regulations worldwide. With natural light and passive ventilation becoming key considerations in sustainable architecture, manufacturers are innovating to meet performance, durability, and aesthetic demands. In this evolving landscape, eight leading skylight ventilation manufacturers have emerged as industry frontrunners, combining technological expertise, global reach, and product diversity to shape the future of daylighting and airflow solutions.

Top 8 Skylight Ventilation Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Thermally Broken Venting Unit Commercial Skylight Manufacturer

Domain Est. 1999

Website: americanskylights.com

Key Highlights: American Skylights’ venting units have a thermally broken aluminum frame construction with a 1″ insulated frame and condensation gutter….

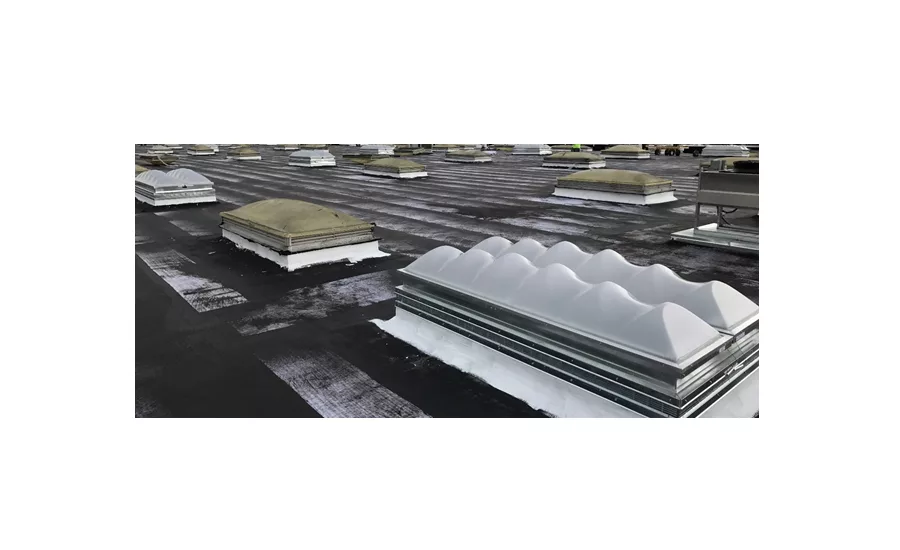

#2 Sunoptics

Domain Est. 1996

Website: sunoptics.com

Key Highlights: The patented Sunoptics Signature Series Skylights and Smoke Vents are designed to rise and stay risen across the apex of the skylight to capture the maximum ……

#3 Daylighting, Skylights and Ventilation Systems

Domain Est. 1997

Website: solatube.com

Key Highlights: Solatube, based in Vista, California, designs and manufactures a full line of daylighting systems and ventilation products….

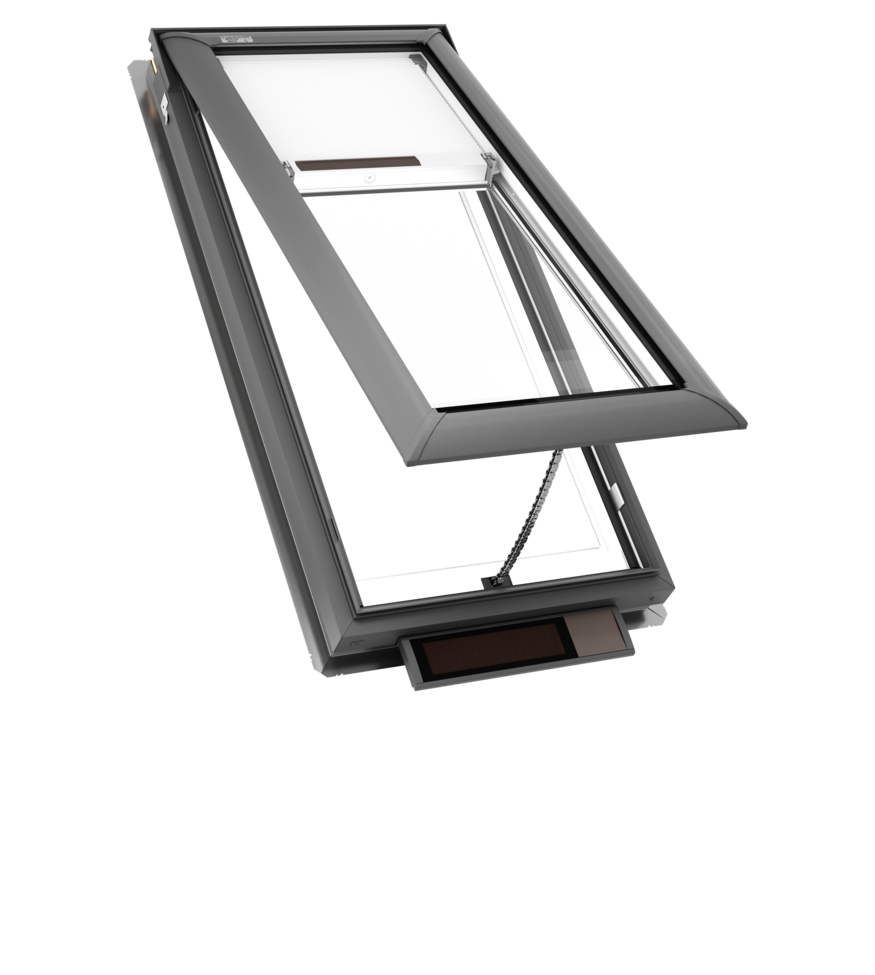

#4 VELUX Group

Domain Est. 1999

Website: velux.com

Key Highlights: Bring natural light and fresh air into your home through the roof. Create healthy homes with better indoor climate and save energy building active houses….

#5 LAMILUX

Domain Est. 2000

Website: lamilux.com

Key Highlights: Learn now more about our skylights and composites made in Germany! LAMILUX is a family run business in Rehau….

#6 Why Choose VELUX Skylights?

Domain Est. 2002

Website: veluxusa.com

Key Highlights: Discover why VELUX is the leading skylight brand—energy-efficient, durable, and designed for healthier indoor living….

#7 Kennedy Skylights and Solar Ventilation

Domain Est. 2004

Website: kennedyskylights.com

Key Highlights: Kennedy Skylights manufactures and distributes glass skylights, polycarbonate skylights, tubular skylights and solar attic fans and their accessories….

#8 Kingspan Light + Air

Domain Est. 2016

Website: kingspanlightandair.us

Key Highlights: Durable unit skylight solutions in a wide variety of sizes and configurations. smoke vent solutions. SMOKE VENTS AND NATURAL VENTILATION. Smoke Vents + Dropout ……

Expert Sourcing Insights for Skylight Ventilation

H2: 2026 Market Trends for Skylight Ventilation

The skylight ventilation market is poised for significant transformation by 2026, driven by converging forces in sustainability, technology, and evolving consumer demands. Key trends shaping this landscape include:

1. Dominance of Smart and Automated Systems:

Integration with smart home ecosystems (e.g., Alexa, Google Home, Apple HomeKit) will become standard. Expect widespread adoption of IoT-enabled skylights with sensors that automatically open/close based on temperature, humidity, air quality (VOC/CO2 monitoring), and weather forecasts. App-based control and voice activation will enhance user convenience and energy efficiency.

2. Focus on Energy Efficiency and Net-Zero Buildings:

As building codes tighten globally (e.g., California Title 24, EU Energy Performance of Buildings Directive), skylight ventilation will be critical for passive cooling and reducing HVAC loads. Products emphasizing high-performance glazing (low-e, spectrally selective), thermal breaks, and automated operation to minimize heat loss/gain will dominate. Skylight ventilation will be positioned as a key component in net-zero energy and LEED-certified projects.

3. Health, Well-being, and Indoor Air Quality (IAQ):

Post-pandemic awareness of IAQ will drive demand. Ventilating skylights will be marketed not just for light, but as essential tools for removing indoor pollutants, reducing moisture (mold prevention), and enhancing occupant health. Integration with whole-house ventilation systems and air quality sensors will be a key selling point.

4. Sustainable Materials and Circular Economy:

Demand for eco-friendly manufacturing will rise. Brands using recycled aluminum, sustainably sourced wood, and low-impact production processes will gain market share. End-of-life recyclability and modular designs for easier repair/replacement will become important differentiators.

5. Design Integration and Aesthetic Innovation:

Architects and homeowners will prioritize seamless integration. Expect growth in flush-mounted, frameless designs, larger custom sizes, and options in diverse finishes (black, bronze, wood-look) to match modern aesthetics. Tubular skylights with ventilation kits will expand into residential retrofits for dark interior spaces.

6. Expansion in Retrofit and Renovation Markets:

As energy costs rise, homeowners will seek affordable ways to improve ventilation and reduce cooling bills. Easy-to-install retrofit kits and tubular ventilating skylights will see strong growth, supported by government incentives for energy-efficient upgrades.

7. Regional Regulatory Drivers:

Mandatory ventilation requirements in building codes (especially in Europe and North America) will directly boost demand. Fire safety regulations requiring smoke ventilation in commercial spaces will sustain the non-residential segment.

Conclusion:

By 2026, the skylight ventilation market will shift from a niche product to a mainstream, intelligent building component. Success will depend on innovation in automation, demonstrable energy/health benefits, sustainable practices, and seamless design. Companies that position their products as holistic solutions for comfort, efficiency, and well-being will lead the market.

Common Pitfalls When Sourcing Skylight Ventilation (Quality, IP)

Sourcing skylight ventilation systems requires careful attention to both quality and Ingress Protection (IP) ratings to ensure long-term performance, safety, and durability. Overlooking key factors can lead to system failures, water ingress, or reduced efficiency. Below are common pitfalls to avoid:

Overlooking IP Rating Suitability for Environment

One of the most frequent mistakes is selecting a skylight ventilation unit with an inappropriate IP rating for the installation environment. For example, using an IP44-rated unit in a high-humidity or outdoor-exposed industrial setting may lead to moisture and dust ingress, damaging internal components. Always match the IP rating (e.g., IP54 for dust and splash resistance, IP65 for dust-tight and water-jet protection) to the environmental conditions—particularly in harsh or variable climates.

Prioritizing Cost Over Build Quality

Sourcing based solely on the lowest price often results in substandard materials and poor craftsmanship. Low-quality skylight vents may use thin gauge metals, weak seals, or inferior motors, leading to premature failure, air leakage, or poor ventilation performance. Invest in reputable manufacturers known for robust construction, corrosion-resistant materials (e.g., powder-coated aluminum or stainless steel), and rigorous quality control.

Ignoring Third-Party Certifications and Testing

Failing to verify independent certifications (such as CE, UL, or VDE) and performance testing can expose projects to unreliable products. Reputable skylight ventilation units should come with documented test results for airflow efficiency, weather resistance, and electrical safety. Avoid suppliers who cannot provide certification or test data, as this raises red flags about product legitimacy and performance claims.

Misunderstanding IP Ratings: Confusing Dust and Water Protection Levels

Many buyers assume a higher IP rating automatically means better performance, but misinterpret what each digit represents. For instance, IP54 offers limited dust protection (not fully dust-tight) and splash resistance, while IP65 ensures complete dust protection and resistance to low-pressure water jets. Choosing the wrong level can result in inadequate protection—especially in dusty factories or areas exposed to rain-driven walls.

Neglecting Long-Term Maintenance Access and Design

Poorly designed skylight ventilation units may lack easy access for cleaning or servicing, leading to blocked vents, reduced airflow, and mold buildup. Units with inaccessible motors or filters increase maintenance costs and downtime. Ensure the design supports routine inspection and cleaning—especially critical in environments prone to debris or pollution.

Assuming All Suppliers Provide Genuine IP-Rated Products

Some suppliers may falsely claim IP ratings without actual testing or certification. This is particularly common with imported or off-brand products. Always request proof of IP testing from accredited laboratories and verify the rated conditions (e.g., duration of water exposure, particle size blocked). Conducting spot audits or sample testing can help validate supplier claims.

Overlooking Compatibility with Building Systems

Integrating skylight ventilation with existing HVAC, BMS (Building Management Systems), or fire safety systems is often underestimated. Units without proper control interfaces or fail-safe modes can compromise overall building performance. Ensure compatibility with control voltages, communication protocols (e.g., BACnet, Modbus), and emergency ventilation requirements.

By addressing these common pitfalls—particularly around accurate IP rating application and quality verification—buyers can ensure reliable, efficient, and durable skylight ventilation solutions tailored to their specific environmental and operational needs.

Logistics & Compliance Guide for Skylight Ventilation

This guide outlines the essential logistics and compliance considerations for the manufacturing, distribution, installation, and maintenance of skylight ventilation systems. Adhering to these standards ensures product safety, regulatory compliance, and efficient operations across the supply chain.

Product Classification and Regulatory Standards

Skylight ventilation systems are subject to multiple building, safety, and energy codes depending on the region of installation. Key standards include:

- International Building Code (IBC) and International Residential Code (IRC): Govern structural performance, wind load resistance, and emergency egress requirements.

- International Energy Conservation Code (IECC): Regulates U-factor, Solar Heat Gain Coefficient (SHGC), and overall thermal performance to meet energy efficiency goals.

- UL 1422 / UL 1423: Standard for fire-resistance tests of window and skylight assemblies.

- ASTM E283 / E330: Air leakage and structural load testing for fenestration products.

- FM 4432: Approval standard for smoke and heat venting equipment used in commercial applications.

Manufacturers must ensure that all skylight ventilation units are third-party certified where required and carry appropriate labeling (e.g., NFRC, UL, FM).

Manufacturing and Quality Assurance

All production facilities must comply with ISO 9001 quality management standards and maintain traceability of raw materials and components. Key steps include:

- Implementing documented quality control procedures for glazing, framing, seals, and mechanical actuators.

- Conducting routine performance testing on sample units for air/water infiltration, structural integrity, and thermal performance.

- Ensuring all electrical components (e.g., motorized openers, sensors) meet UL or CE electrical safety standards.

- Providing detailed product specifications, installation manuals, and compliance documentation with each unit.

Packaging and Shipping Requirements

Proper packaging is critical to prevent damage during transit:

- Units must be crated or palletized with protective corner guards and weather-resistant wrapping.

- Label all packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include model numbers, batch/lot codes, and destination details.

- Use climate-controlled transport when shipping to extreme environments to avoid seal degradation or condensation damage.

- Confirm carrier compliance with hazardous materials regulations if shipping units with lithium batteries or pressurized components.

Import/Export Compliance

For international shipments, ensure adherence to the following:

- Classify products under the correct Harmonized System (HS) code (e.g., 7007 for safety glass, 8481 for ventilation actuators).

- Prepare accurate commercial invoices, packing lists, and certificates of origin.

- Comply with destination country regulations such as CE marking (EU), CCC (China), or RCM (Australia/NZ).

- Verify compliance with REACH, RoHS, and other chemical/environmental directives affecting materials used.

Installation and Field Compliance

Installers must follow manufacturer instructions and local building codes:

- Verify roof load capacity and framing compatibility prior to installation.

- Ensure proper flashing integration to prevent water intrusion—comply with ASTM D226 or equivalent.

- For motorized units, connect only to approved power sources and include surge protection.

- Document completed installations with inspection checklists and provide operation/maintenance guides to building owners.

Maintenance and Recalls

Establish a service protocol to support long-term compliance:

- Recommend annual inspections for seal integrity, actuator operation, and debris clearance.

- Register all installed units in a service database for recall management and warranty tracking.

- Report any safety-related defects to regulatory bodies (e.g., CPSC in the U.S.) and initiate corrective actions promptly.

By following this guide, Skylight Ventilation ensures safe, compliant, and efficient delivery of high-performance ventilation solutions across global markets.

In conclusion, sourcing skylight ventilation systems requires careful consideration of factors such as energy efficiency, climate compatibility, building design, and ventilation needs. High-quality skylights with integrated ventilation offer numerous benefits, including improved indoor air quality, reduced moisture buildup, enhanced thermal comfort, and lower energy costs. When selecting a supplier or product, it is essential to evaluate durability, ease of maintenance, compliance with building codes, and available automation features such as rain sensors and remote controls. By partnering with reputable manufacturers and considering both passive and active ventilation options, builders and property owners can ensure optimal performance and long-term sustainability. Ultimately, investing in well-sourced skylight ventilation contributes to healthier indoor environments and greater overall building efficiency.