The global crane market is experiencing robust growth, driven by rising infrastructure development, urbanization, and industrial expansion—particularly in emerging economies. According to Mordor Intelligence, the global crane market was valued at USD 38.67 billion in 2023 and is projected to reach USD 55.89 billion by 2029, growing at a CAGR of 6.4% during the forecast period. A key segment within this market is skyhook cranes—specialized suspended lifting systems increasingly adopted in high-rise construction, bridge building, and modular construction projects due to their precision, safety, and space efficiency. As demand for innovative lifting solutions intensifies, several manufacturers have emerged as leaders in designing and engineering advanced skyhook crane systems. Below are the top 5 skyhook crane manufacturers shaping the future of vertical transportation and construction logistics.

Top 5 Skyhook Crane Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SKYHOOK INC.

Domain Est. 1999

Website: skyhook-inc.com

Key Highlights: Skyhook, Inc. is currently offering crane rental and rigging services. We started business in 1977 and have done work in all aspects of the Communications ……

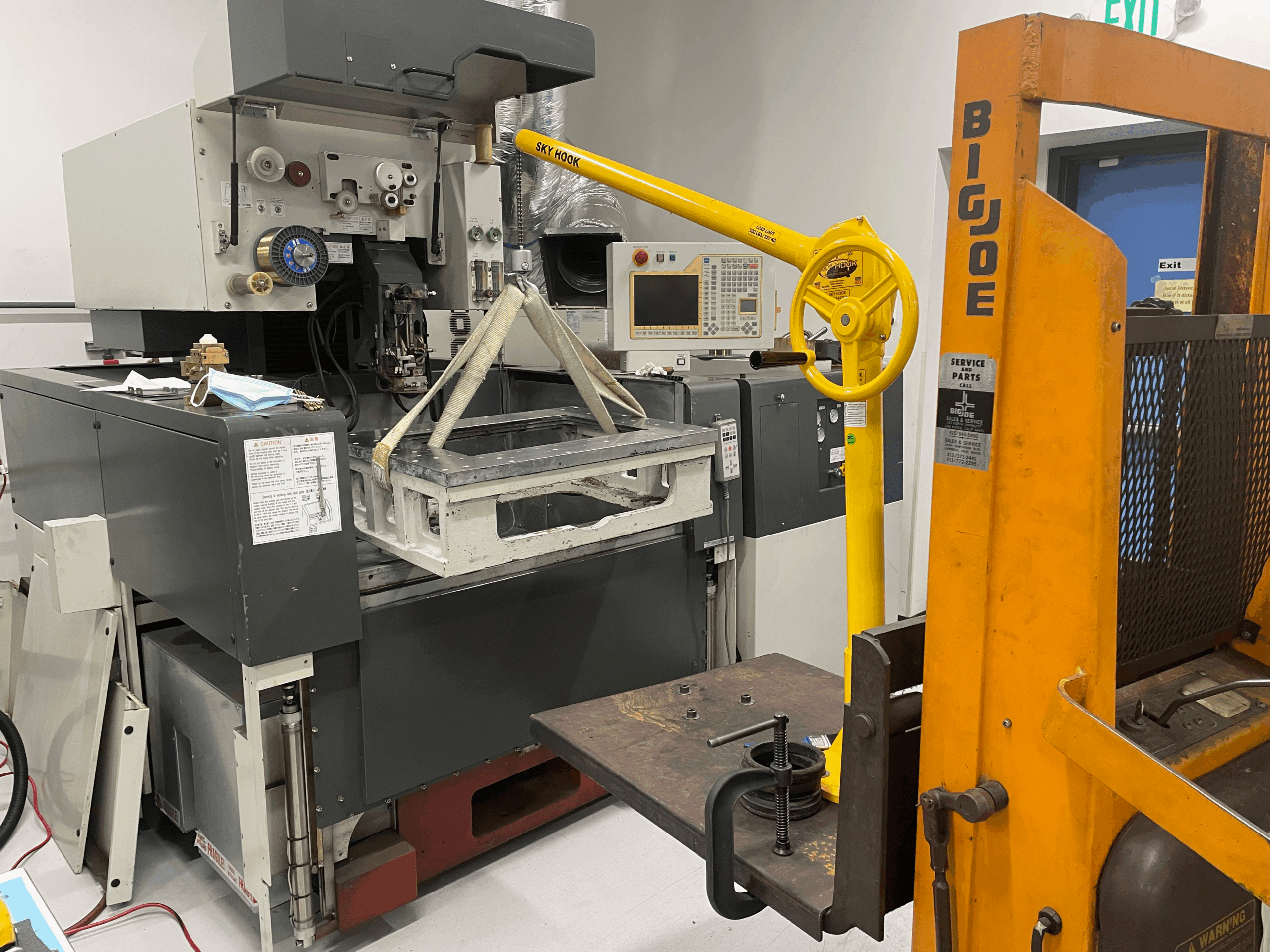

#2 Sky Hook Ergonomic Lifting Devices

Domain Est. 2000

Website: skyhook.cc

Key Highlights: The Sky Hook is a small, portable, ergonomic lifting device designed to provide a safe, high quality lifting solution that can prevent lifting injuries….

#3 Skyhook Operators

Domain Est. 2020

Website: skyhookops.com

Key Highlights: Skyhook Operators is a gulf coast commercial crane operator company, that specializes in providing seasoned tower crane operators to help build your next high ……

#4 Sky Hook Cranes

Domain Est. 2022

Website: skyhookcranes.com

Key Highlights: Call Us For All Your Crane Needs. We specialize in all types of lifts, from HVAC units to backyard spas. What do you need help moving? Sky Hook is here!…

#5 Skyhook Crane Services

Website: skyhookcraneservice.com

Key Highlights: Reliable and experienced crane rental and rigging experts serving Texas. Skyhook Crane Services offers CCO-certified operators, heavy haul transport, ……

Expert Sourcing Insights for Skyhook Crane

H2: Market Trends for Skyhook Crane in 2026

As the construction, infrastructure, and industrial sectors evolve through technological innovation and shifting economic dynamics, Skyhook Crane—a hypothetical or specialized crane manufacturer or service provider—is poised to experience significant market shifts by 2026. The following analysis outlines key trends shaping the crane and lifting equipment industry, with specific implications for Skyhook Crane’s strategic positioning.

1. Increased Demand for Automation and Smart Cranes

By 2026, automation will be a dominant trend in heavy machinery. Skyhook Crane is likely to see growing demand for smart cranes equipped with IoT sensors, real-time monitoring, remote operation capabilities, and predictive maintenance systems. These features enhance safety, reduce downtime, and improve operational efficiency—key selling points for large construction firms and logistics operators. Integration with Building Information Modeling (BIM) platforms will also become standard, enabling seamless project coordination.

2. Expansion in Renewable Energy Infrastructure

The global push toward renewable energy—especially offshore and onshore wind farms—will drive demand for specialized heavy-lift cranes. Skyhook Crane can capitalize on this trend by developing or adapting models suited for wind turbine installation, which requires high-reach, high-capacity cranes capable of operating in challenging environments. Government incentives for green energy projects in North America, Europe, and parts of Asia will further fuel this demand.

3. Urbanization and High-Rise Construction Growth

Rapid urbanization, particularly in emerging markets such as India, Southeast Asia, and parts of Africa, will boost construction activity. Skyhook Crane can benefit from the rising need for tower cranes and mobile cranes in dense urban environments. Compact, modular, and quick-assembly crane designs will be in higher demand to accommodate tight city spaces and fast-paced project timelines.

4. Sustainability and Electrification of Equipment

Environmental regulations and corporate ESG (Environmental, Social, and Governance) goals will push construction companies to adopt low-emission machinery. By 2026, electric and hybrid-powered cranes are expected to gain market share. Skyhook Crane that invests in electrification technologies—such as battery-powered or hydrogen-fueled cranes—will gain a competitive edge and align with sustainability mandates in public and private sector contracts.

5. Growth in Rental and Equipment-as-a-Service (EaaS) Models

Many construction firms are shifting from ownership to rental models to reduce capital expenditure and increase flexibility. The Equipment-as-a-Service (EaaS) trend is expected to expand, offering pay-per-use or subscription-based crane services. Skyhook Crane could diversify its revenue by offering leasing, maintenance packages, and digital fleet management platforms to rental partners.

6. Supply Chain Resilience and Localization

Post-pandemic disruptions and geopolitical tensions have emphasized the need for resilient supply chains. By 2026, there will be a greater push toward regional manufacturing and localized service networks. Skyhook Crane may need to establish regional assembly hubs or partner with local distributors to reduce lead times and improve after-sales support.

7. Labor Shortages Driving Technological Adoption

The construction industry faces a persistent shortage of skilled crane operators and technicians. This labor gap will accelerate the adoption of AI-assisted operation, automated load handling, and augmented reality (AR) for training and maintenance. Skyhook Crane that embeds user-friendly interfaces and training tools into its systems will appeal to operators and contractors seeking efficiency.

Conclusion

By 2026, Skyhook Crane must navigate a dynamic landscape shaped by digitalization, sustainability, and infrastructure transformation. To remain competitive, the company should prioritize innovation in automation and electrification, expand into high-growth sectors like renewable energy, and embrace flexible business models such as equipment leasing and smart service platforms. Strategic investments in R&D and regional partnerships will be critical to capturing emerging opportunities in a rapidly evolving global market.

Common Pitfalls When Sourcing a Skyhook Crane

Quality Inconsistencies and Substandard Components

One of the most significant risks when sourcing a Skyhook crane—especially from overseas or less-regulated manufacturers—is encountering inconsistent quality and substandard components. Buyers may receive cranes with inferior steel alloys, improperly welded joints, or underperforming hydraulic systems that compromise safety and longevity. These issues often stem from cost-cutting measures and lack of rigorous quality control processes. Without thorough third-party inspections or adherence to recognized engineering standards (such as ISO or ASME), the crane may fail under operational stress, leading to costly downtime or safety hazards.

Intellectual Property (IP) Infringement and Counterfeit Designs

Sourcing a Skyhook crane can also expose buyers to intellectual property risks, particularly if the supplier replicates patented designs or uses proprietary technology without authorization. Some manufacturers may offer “compatible” or “inspired by” models that closely mimic branded Skyhook cranes, potentially violating patents, trademarks, or design rights. Purchasing such equipment not only exposes the buyer to legal liability but may also result in unreliable performance due to reverse-engineered components. Ensuring suppliers provide proper documentation, design licenses, and freedom-to-operate assurances is essential to mitigate IP-related pitfalls.

Logistics & Compliance Guide for Skyhook Crane Operations

This guide outlines the essential logistics and compliance considerations for safe, efficient, and legally compliant operations involving Skyhook cranes. Adherence to these standards ensures operational integrity, worker safety, and regulatory alignment.

Equipment Specifications and Pre-Use Inspection

Prior to any operation, verify that the Skyhook crane model meets project-specific requirements, including lifting capacity, reach, and mobility. Conduct a comprehensive pre-use inspection covering structural integrity, hydraulic systems, control functions, wire ropes, and safety mechanisms. Document all inspections and address any deficiencies before operation.

Regulatory Compliance and Permits

Ensure all crane operations comply with local, state, and federal regulations, including OSHA (Occupational Safety and Health Administration) standards in the U.S., or equivalent bodies internationally. Secure necessary permits for crane setup, road closures, and worksite access. Maintain up-to-date certifications for operators and signal persons as required by regulation.

Operator Certification and Training

Only certified and trained personnel may operate Skyhook cranes. Operators must hold valid credentials from accredited programs and undergo regular refresher training. Training should include load dynamics, emergency procedures, equipment limitations, and site-specific hazards.

Site Assessment and Risk Management

Perform a thorough site assessment before crane deployment. Evaluate ground conditions, overhead obstructions (e.g., power lines), wind conditions, and proximity to public areas. Develop a site-specific lift plan that includes load weight, center of gravity, rigging configuration, and exclusion zones. Implement risk mitigation strategies for identified hazards.

Load Handling and Rigging Procedures

Use only certified slings, shackles, and rigging hardware rated for the intended load. Ensure proper load attachment and balance to prevent shifting or tipping. Never exceed the crane’s rated capacity—refer to load charts specific to boom length and radius. Conduct trial lifts when necessary to verify stability.

Communication Protocols

Establish clear communication between crane operators, signal persons, and ground crews using standardized hand signals or two-way radios. Ensure all personnel understand and adhere to the communication plan. Use spotters when visibility is limited.

Transportation and Mobilization

When transporting Skyhook cranes, comply with Department of Transportation (DOT) regulations regarding weight, dimensions, and securing of equipment. Use appropriate trailers and follow route planning to avoid low bridges or weak infrastructure. Ensure proper demobilization and securing procedures after operations.

Environmental and Safety Compliance

Minimize environmental impact by preventing fuel or hydraulic fluid spills and managing noise levels, especially in urban or sensitive areas. Implement spill containment measures and maintain spill response kits on-site. Conduct regular safety audits and maintain incident reporting logs.

Documentation and Recordkeeping

Maintain detailed records of inspections, maintenance, operator certifications, lift plans, incident reports, and compliance permits. Store records securely and ensure they are accessible for audits or regulatory reviews. Retain documentation per legal requirements, typically for a minimum of five years.

Emergency Response and Incident Reporting

Develop and communicate an emergency response plan covering crane malfunctions, dropped loads, injuries, or structural failures. Train personnel on evacuation procedures and first aid. Report all incidents immediately to supervisors and regulatory authorities as required. Conduct post-incident reviews to prevent recurrence.

Adherence to this guide ensures Skyhook crane operations are conducted safely, efficiently, and in full compliance with applicable laws and industry best practices. Regular review and updates to procedures are recommended to reflect changes in regulations or operational scope.

Conclusion for Sourcing Skyhook Crane

In conclusion, sourcing a Skyhook crane requires a comprehensive evaluation of technical specifications, lifting capacity, mobility, safety features, and compliance with industry standards. After assessing multiple suppliers, considering budget constraints, and reviewing long-term operational needs, it is evident that selecting a reputable manufacturer with a strong service network and proven reliability is crucial. The chosen Skyhook crane should align with project requirements, offer scalability for future needs, and ensure operator safety and efficiency. Additionally, factoring in maintenance support, warranty terms, and ease of spare parts availability will contribute to minimizing downtime and maximizing return on investment. Ultimately, a well-informed sourcing decision will enhance operational productivity and support the successful execution of lifting operations across various worksite conditions.