The global skid steer loader market, a key segment within the broader construction and agricultural machinery industry, is experiencing steady expansion driven by rising infrastructure development and demand for compact, versatile equipment. According to Grand View Research, the global skid steer loader market was valued at USD 6.2 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2024 to 2030. This growth trajectory is mirrored in the increasing demand for specialized attachments—particularly buckets—where performance, capacity, and durability are critical. As machines become more powerful and applications more diverse, manufacturers are innovating to deliver higher-capacity, task-optimized buckets that enhance productivity across industries. In this competitive landscape, nine manufacturers have emerged as leaders in skid steer bucket capacity innovation, combining engineering precision with data-informed design to meet the evolving needs of contractors, landscapers, and material handlers worldwide.

Top 9 Skid Steer Bucket Capacity Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Skid Steer Attachments, Buckets, Skid Loader Attachments

Domain Est. 2000

Website: berlon.com

Key Highlights: Berlon Industries is a manufacturer and distributor of highly durable buckets, augers, trenchers, grapples and attachments for skid steers….

#2 Skid Steer Buckets

Domain Est. 1993

Website: cat.com

Key Highlights: 2-day deliveryCat® provides a comprehensive line of machine-matched buckets for Cat Skid Steer Loaders and Compact Track Loaders. Equipment Type (16 items)….

#3 Compact skid loader

Domain Est. 1995

Website: gehl.com

Key Highlights: Whatever your needs, the compact skid loader helps you get your work done. Discover GEHL machines, with radial or vertical lifting….

#4 Skid Steer Loaders

Domain Est. 1995

Website: casece.com

Key Highlights: From job-crushing attachments to swift, smooth, smart product features, CASE skid steer loaders will help you ingeniously command the jobsite….

#5 Skid

Domain Est. 1997

Website: bobcat.com

Key Highlights: Discover the entire Bobcat® skid-steer loader lineup and explore pricing, specs, features, benefits, compare models and more to find the perfect machine for ……

#6 Buckets

Domain Est. 2005

Website: cidattachments.com

Key Highlights: The Skid Steer Standard (45 HP) and Heavy Duty (65 HP) Grapple Buckets are perfect for picking up logs, rocks, supplies, and various other types of debris….

#7 Skid Steer Utility Bucket

Domain Est. 2009

Website: skidsplitter.com

Key Highlights: With 96″ of capacity, our skid steer bucket is made from the highest quality, powder coated steel. Our bucket for skid steer equipment is made to last….

#8 Buckets

Domain Est. 2022

Website: ironcraftusa.com

Key Highlights: The Mini Skid Steer Grapple Bucket allows you to easily pick up rocks, logs and other materials on the job site exceeding the lifting capacity of the machine….

#9 THE ULTIMATE GUIDE TO SKID STEER BUCKETS

Domain Est. 2002

Website: virnigmfg.com

Key Highlights: Use this guide to find a quality skid steer bucket that best fits your needs, while getting the most out of your investment….

Expert Sourcing Insights for Skid Steer Bucket Capacity

H2: 2026 Market Trends for Skid Steer Bucket Capacity

The skid steer loader market is poised for continued evolution in 2026, with bucket capacity trends reflecting broader shifts in construction, landscaping, agriculture, and material handling sectors. Driven by demand for efficiency, versatility, and operator productivity, key trends shaping skid steer bucket capacity include:

1. Dominance of Mid-Range Capacity Buckets (0.5 – 1.25 cu yd): The core market segment will remain focused on buckets ranging from half a cubic yard to 1.25 cubic yards. This capacity range offers the optimal balance between machine compatibility (especially with popular 80–120 hp radial and vertical lift models), maneuverability in tight spaces, and sufficient material handling capability for the vast majority of tasks – from digging and loading to grading and light demolition. Manufacturers will continue to optimize designs within this range for maximum fill efficiency and breakout force.

2. Growth in Larger Capacity Buckets (1.25 – 2.0+ cu yd): Driven by demand for higher productivity on larger job sites and in agricultural applications, there will be a noticeable increase in the use of high-capacity and super-sized buckets. These buckets (often 1.5 cu yd and above) are best suited for compact track loaders (CTLs) and high-flow skid steers. They excel in bulk material handling (e.g., mulch, gravel, manure) and earthmoving, reducing cycle times. The trend is supported by the growing power and hydraulic flow of newer machine models enabling effective use of these larger attachments.

3. Emphasis on Specialized, Task-Specific Bucket Designs (Variable Effective Capacity): While nominal capacity is important, the 2026 market will see heightened focus on effective capacity and functionality. This means:

* Optimized Geometry: Buckets designed with specific profiles (e.g., high dump, rock, skeleton, root rakes) that maximize usable capacity for their intended purpose, even if nominal capacity is standard.

* Material-Specific Features: Wear-resistant steels, bolt-on cutting edges, and tailored bucket widths/depths ensure the bucket maintains its capacity and integrity when handling abrasive or challenging materials, preserving long-term value.

* Quick-Change Integration: Compatibility with universal skid steer quick-attach systems allows operators to rapidly switch between buckets of different capacities and types, maximizing machine utilization across diverse tasks.

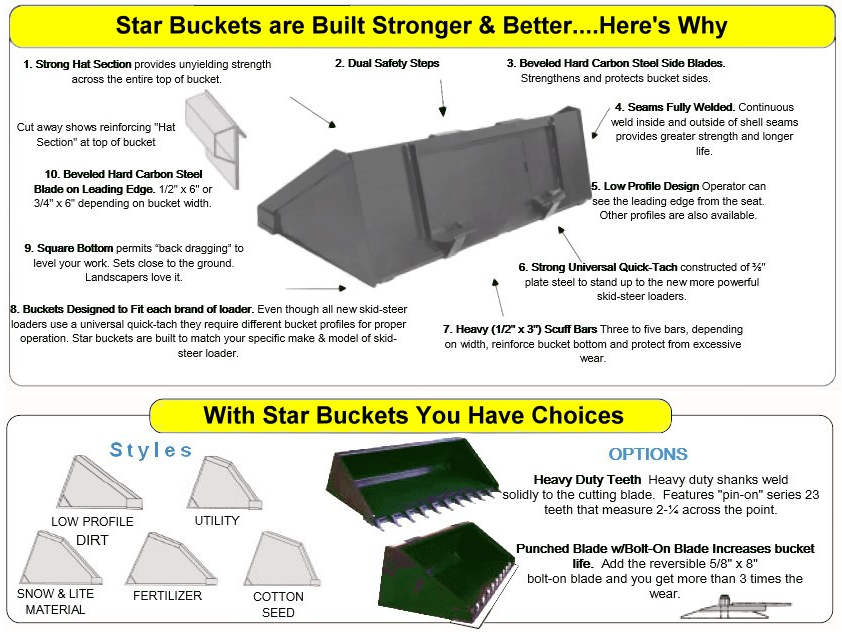

4. Demand for Enhanced Durability and Reduced Maintenance: Operators and fleet managers prioritize buckets that maintain their rated capacity over time. Trends include:

* Increased Use of High-Strength Steels: Buckets built with AR400/AR500 steel resist wear and deformation, especially on cutting edges and sidewalls, ensuring consistent capacity and reducing downtime for repairs.

* Reinforced Designs: Strategic reinforcement in high-stress areas (like the hinge and heel) prevents structural failure and capacity loss under heavy loads.

* Improved Edge Technology: Bolt-on, reversible, and replaceable wear packages extend bucket life and maintain optimal cutting and filling performance.

5. Sustainability and Efficiency Drivers: While not directly altering capacity numbers, sustainability trends influence bucket design:

* Lightweighting: Using advanced materials or design optimization to reduce bucket weight without sacrificing capacity or durability, improving fuel efficiency and machine responsiveness.

* Longer Lifespan: Durable, repairable buckets reduce waste and the environmental impact associated with frequent replacements, aligning with ESG goals.

In summary, the 2026 skid steer bucket capacity market will be characterized by the sustained importance of mid-range capacities, growth in larger options for productivity gains, and a significant shift towards specialized, durable designs that maximize effective capacity and total cost of ownership. The focus will be less on simply increasing raw cubic yardage and more on delivering the right capacity, with the right features, for the right job.

Common Pitfalls When Sourcing Skid Steer Bucket Capacity (Quality, IP)

When selecting a skid steer bucket, focusing solely on bucket capacity can lead to inefficiencies and operational issues. Overlooking quality and impact protection (IP) can result in premature wear, safety hazards, and higher long-term costs. Below are key pitfalls to avoid:

Overestimating Effective Capacity

Many buyers focus on the nominal bucket capacity advertised by manufacturers, but this often reflects a heaped or level load under ideal conditions. In real-world applications—especially with dense materials like wet soil or gravel—the effective capacity may be significantly lower. This mismatch can lead to underperformance and reduced productivity.

Ignoring Material-Specific Design

Not all buckets are created equal. Using a general-purpose bucket for heavy-duty applications like rock or demolition increases wear and reduces effective capacity over time. Buckets designed for specific materials (e.g., rock buckets with reinforced edges) maintain capacity longer and offer better durability.

Underestimating the Importance of Build Quality

Low-cost buckets may use thinner steel or inferior welding techniques, leading to warping, cracking, or hinge failure under stress. Poor build quality reduces the bucket’s usable lifespan and can compromise safety. Always verify steel gauge, weld integrity, and component tolerances.

Neglecting Impact Protection (IP) Features

Impact protection—such as bolt-on cutting edges, side protectors, and wear strips—is critical for maintaining bucket capacity and structural integrity. Without proper IP, edges wear quickly, increasing the gap between the bucket and the ground and reducing effective capacity. Skimping on IP leads to frequent replacements and downtime.

Mismatching Bucket Size to Machine Capacity

A bucket that exceeds the skid steer’s rated operating capacity can strain the hydraulic system, reduce lift height, and create tipping hazards. Always match bucket size and expected load to the machine’s lift capacity and tipping load specs.

Overlooking Attachment Compatibility and Fit

Poorly manufactured buckets may not align correctly with the skid steer’s quick-attach system, causing play or binding. This misalignment accelerates wear on both the bucket and machine, reduces efficiency, and can void warranties.

Failing to Consider Future Maintenance and Repair

Buckets with non-standard or proprietary wear parts can be difficult and costly to repair. Opt for buckets with readily available, industry-standard IP components to minimize downtime and maintenance costs.

Relying Solely on Price

The cheapest bucket often ends up being the most expensive due to frequent repairs, downtime, and reduced productivity. Invest in a high-quality bucket with robust impact protection to ensure long-term value and consistent performance.

By addressing these pitfalls, operators can select a skid steer bucket that delivers reliable capacity, withstands job site demands, and provides optimal return on investment.

Logistics & Compliance Guide for Skid Steer Bucket Capacity

Understanding and adhering to proper logistics and compliance standards for skid steer loader bucket capacity is essential for operational safety, equipment longevity, and regulatory adherence. This guide outlines key considerations related to bucket capacity, load handling, transportation, and regulatory compliance.

Understanding Bucket Capacity Ratings

Skid steer bucket capacities are typically measured in heaped and level (struck) cubic yards or liters. It is critical to distinguish between these two measurements:

– Level (Struck) Capacity: The volume of material even with the top edge of the bucket.

– Heaped Capacity: The total volume when material is piled above the bucket’s sides at a standard angle (usually 2:1 slope).

Always refer to the manufacturer’s specifications for accurate capacity ratings. Overloading beyond the rated capacity can compromise machine stability and lead to accidents.

Matching Bucket to Machine Capacity

Each skid steer has a maximum rated operating capacity (ROC), usually stated in pounds or kilograms. This ROC determines the maximum weight the machine can safely lift and carry at full extension.

– Ensure the bucket size and the material density (e.g., soil, gravel, mulch) do not result in loads exceeding the ROC.

– Use the formula:

Load Weight = Bucket Capacity × Material Density

Example: A 0.75 yd³ bucket with dry sand (approx. 2,700 lbs/yd³) = 2,025 lbs load.

Regulatory Compliance and Safety Standards

Compliance with OSHA (Occupational Safety and Health Administration) and ANSI (American National Standards Institute) standards is mandatory in the United States:

– OSHA 29 CFR 1926.602: Requires that powered equipment be operated only by trained personnel and used within manufacturer specifications.

– ANSI/SAE J1178: Standard for skid steer loader performance and test codes, including lift capacity and stability.

– Conduct regular inspections and operator training to ensure adherence.

Load Securement During Transport

When transporting a skid steer with or without an attached bucket:

– Retract the bucket fully and lower it to the travel position to minimize overhang.

– Secure the machine using appropriate tie-down straps or chains (minimum of four points for trailers).

– Comply with FMCSA (Federal Motor Carrier Safety Administration) regulations for cargo securement (49 CFR Part 393, Subpart I).

– Ensure the total vehicle weight, including the skid steer and bucket, remains within legal limits.

Environmental and Site Compliance

- Avoid overloading buckets with heavy or abrasive materials that can increase wear and emissions.

- Follow local environmental regulations when handling hazardous or contaminated materials (e.g., lead soil, asbestos).

- Use proper containment methods to prevent material spillage during transport or operation.

Documentation and Record Keeping

Maintain accurate records for compliance and audit purposes:

– Equipment manuals and capacity charts on file.

– Operator certification and training logs.

– Daily inspection checklists including bucket condition and attachment security.

Best Practices Summary

- Always use the correct bucket size for the job and machine.

- Never exceed the manufacturer’s rated operating capacity.

- Train operators on load estimation and material density.

- Secure the machine and attachments during transit.

- Stay updated on local, state, and federal regulations.

By following this logistics and compliance guide, operators and fleet managers can ensure safe, efficient, and legally compliant use of skid steer loaders and their bucket attachments.

In conclusion, determining the appropriate skid steer bucket capacity is essential for maximizing efficiency, productivity, and equipment performance on the job site. The ideal bucket size depends on various factors, including the type of material being handled, the machine’s operating capacity, lift path configuration, and specific application requirements. Selecting a bucket that matches the skid steer’s rated operating capacity ensures optimal performance while minimizing wear and safety risks. Additionally, considering attachments and job site constraints can further refine bucket selection. By carefully evaluating these factors and consulting manufacturer specifications, operators and contractors can source a skid steer bucket that delivers the right balance of capacity, durability, and versatility for their operational needs.