The commercial kitchen equipment market has experienced steady expansion, driven by rising demand from restaurants, hotels, and foodservice operators seeking high-performance cooking solutions. According to Grand View Research, the global commercial kitchen equipment market size was valued at USD 9.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2023 to 2030. This growth is fueled by the proliferation of full-service and quick-service restaurants, particularly in emerging economies, alongside a shift toward modular and energy-efficient kitchen setups. Within this landscape, six-burner commercial stoves have become a staple in mid-to-high volume kitchens, offering chefs enhanced cooking capacity and versatility. As demand intensifies, manufacturers are focusing on durability, thermal efficiency, and compliance with commercial safety standards. Based on market presence, innovation, and product reliability, the following eight manufacturers have emerged as leading suppliers of six-burner commercial stoves worldwide.

Top 8 Six Burner Commercial Stove Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Blodgett Ovens

Domain Est. 2001

Website: blodgett.com

Key Highlights: Blodgett is the leading manufacturer of commercial convection, Hydrovection, baking & roasting and pizza deck and Combi ovens in the world….

#2 Cook

Domain Est. 1996

Website: vikingrange.com

Key Highlights: 2-day deliveryExplore high-end Viking cook ranges. Choose options that fit your culinary needs and elevate your kitchen experience, from start to finish….

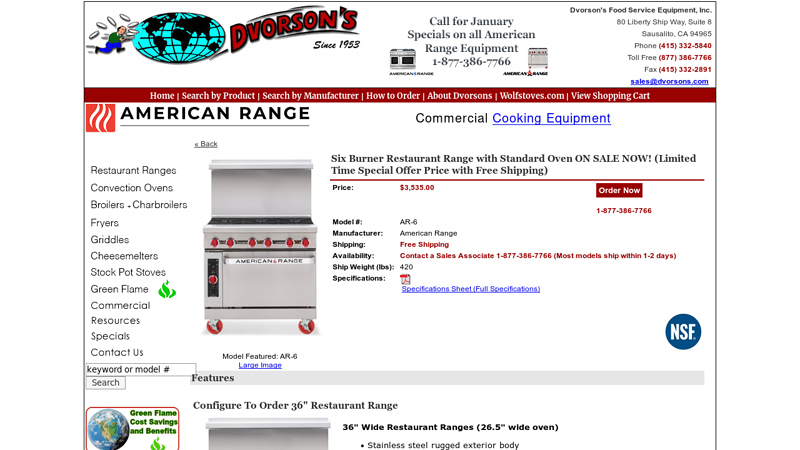

#3 Six Burner Restaurant Range with Standard Oven ON SALE NOW …

Domain Est. 2005

Website: americanstoves.com

Key Highlights: In stock36″ Wide Restaurant Ranges (26.5″ wide oven). Stainless steel rugged exterior body; 6″ deep front stainless steel bullnose landing ledge/work space….

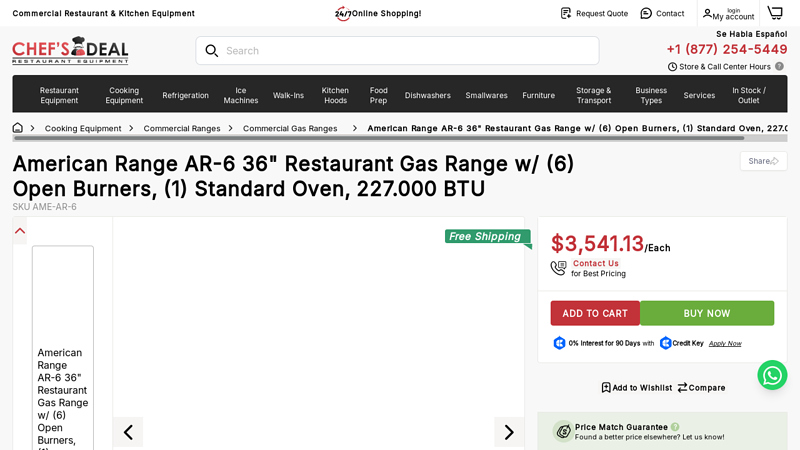

#4 American Range AR

Domain Est. 2007

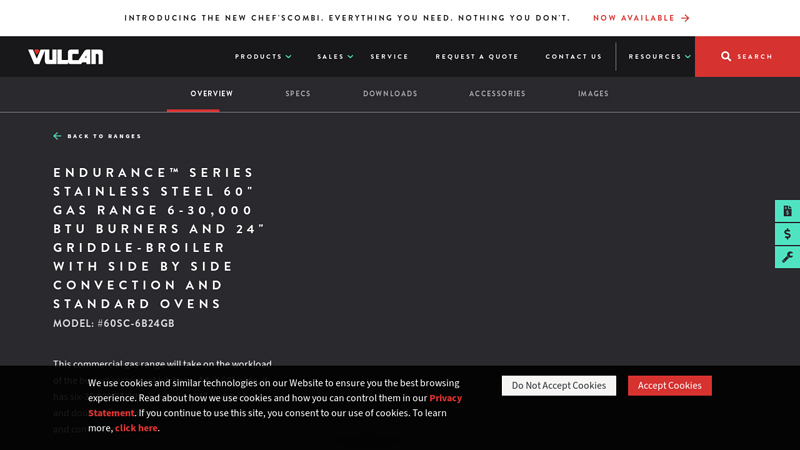

#5 Commercial 60 Inch Gas Range, 6 Burners and 24″ Griddle

Domain Est. 2009

Website: vulcanequipment.com

Key Highlights: A full 60” wide, it has six-30,000 BTU/hr. burners, a 24” griddle-broiler, and double ovens that do double duty—standard and convection. Feel ……

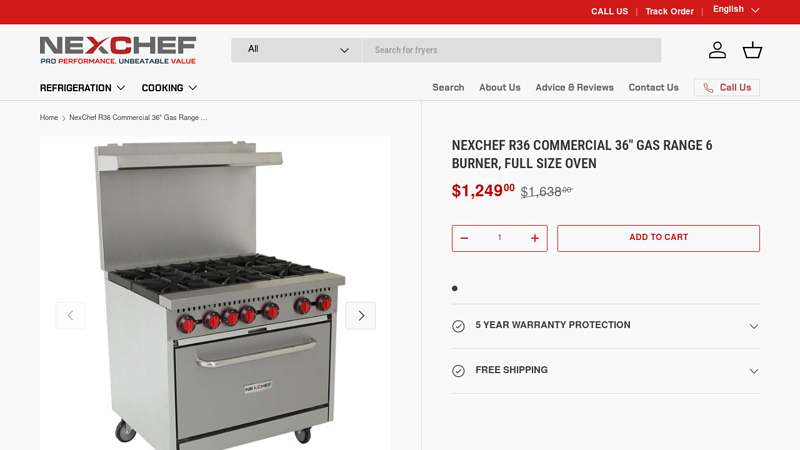

#6 NexChef R36 Commercial 36″ Gas Range 6 Burner, Full Size Oven

Domain Est. 2018

Website: nex-chef.com

Key Highlights: Free delivery 30-day returnsThis powerful 6-burner range is designed for optimal performance, featuring a total of 210,000 BTU to meet the demands of any busy kitchen. Enjoy peace …

#7 EasyRose 36 Inch Gas Range 6 Burner Heavy …

Domain Est. 2021

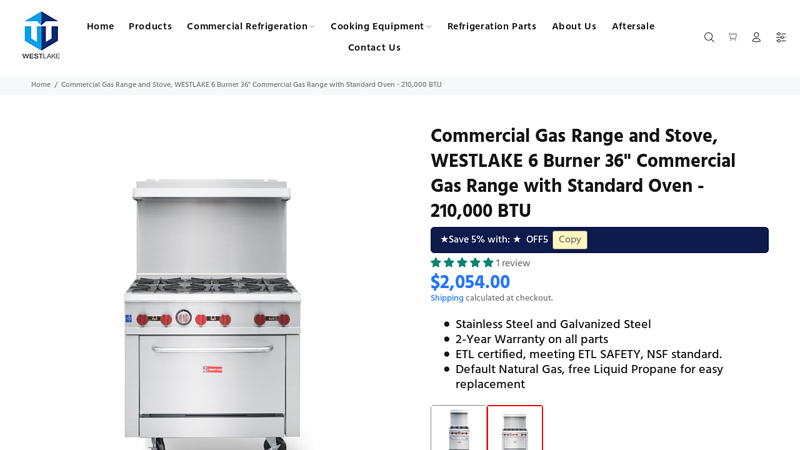

#8 Commercial Gas Range and Stove, WESTLAKE 6 Burner 36

Domain Est. 2021

Website: westlakechef.com

Key Highlights: Product Overview: This commercial gas range with oven is suitable for both natural gas and propane, featuring 6 burners and a large-capacity oven to meet ……

Expert Sourcing Insights for Six Burner Commercial Stove

2026 Market Trends for Six Burner Commercial Stove

The commercial kitchen equipment industry is undergoing significant transformation, driven by technological innovation, evolving culinary demands, and a heightened focus on sustainability. Among the most essential appliances in foodservice operations, the six burner commercial stove remains a staple in restaurants, catering kitchens, and institutional facilities. As we approach 2026, several key trends are shaping the market for six burner commercial stoves, influencing design, functionality, and purchasing decisions.

Rising Demand for Energy-Efficient and Eco-Friendly Models

Energy efficiency continues to be a top priority for foodservice operators aiming to reduce utility costs and meet sustainability goals. In 2026, manufacturers are increasingly offering six burner stoves with advanced combustion systems, improved heat retention, and ENERGY STAR® certification. Induction-powered six burner units are gaining traction, especially in urban and eco-conscious markets, due to their precise temperature control and lower carbon footprint compared to traditional gas models. Regulatory pressures and green building standards (such as LEED) are further accelerating the shift toward energy-efficient stoves.

Growth in Modular and Smart Kitchen Integration

The integration of smart technology into commercial kitchens is a defining trend for 2026. Six burner stoves are now being designed with IoT (Internet of Things) capabilities, allowing remote monitoring of usage, performance diagnostics, and energy consumption tracking via cloud-based platforms. These smart stoves can be part of a larger modular kitchen system, enabling operators to customize layouts and streamline kitchen workflows. Touchscreen controls, automatic shut-off features, and connectivity with kitchen management software are becoming standard in premium models.

Expansion in Emerging Markets and Urban Food Hubs

Emerging economies in Asia-Pacific, Latin America, and Africa are experiencing rapid growth in the foodservice sector, driven by urbanization and rising disposable incomes. In 2026, demand for durable, mid-to-high range six burner stoves is increasing in these regions, particularly among fast-casual restaurants and cloud kitchens. Localized manufacturing and distribution partnerships are helping global brands penetrate these markets with cost-effective, region-specific models that meet local fuel and safety standards.

Shift Toward Multi-Fuel and Hybrid Capabilities

Flexibility in fuel sources is becoming a competitive advantage. In 2026, many six burner commercial stoves are being designed with dual-fuel or hybrid capabilities—offering combinations of gas, electric, and induction burners on a single unit. This adaptability allows kitchens to optimize performance based on menu requirements and energy availability. For instance, induction burners may be used for precision cooking, while gas burners handle high-heat searing. Such hybrid models are particularly popular in multi-concept restaurants and hotel kitchens.

Focus on Ergonomics and Kitchen Safety

Operator safety and ergonomic design are gaining prominence. The 2026 market sees an increase in six burner stoves with enhanced safety features such as flame failure devices, auto-reignition systems, cool-to-touch exteriors, and improved ventilation integration. Additionally, manufacturers are prioritizing user-friendly layouts, with intuitive control placement, reduced footprint designs, and anti-slip surfaces to minimize strain and accidents in high-pressure environments.

Increased Customization and Aesthetic Appeal

As restaurant branding becomes more experiential, the visual design of kitchen equipment is receiving greater attention. Six burner stoves in 2026 are available in a range of finishes—including stainless steel, matte black, and custom colors—to match modern kitchen aesthetics. Customizable configurations, such as added griddles, ovens, or storage compartments beneath the cooktop, allow operators to tailor units to specific culinary needs, enhancing both functionality and presentation.

Conclusion

The 2026 market for six burner commercial stoves is defined by innovation, sustainability, and adaptability. As foodservice operators face increasing pressure to improve efficiency, reduce environmental impact, and support diverse cooking techniques, the evolution of this essential appliance reflects broader industry shifts. Manufacturers who embrace smart technology, energy efficiency, and user-centric design will be best positioned to lead in this dynamic and competitive market.

Common Pitfalls When Sourcing a Six-Burner Commercial Stove (Quality & IP Considerations)

Sourcing a six-burner commercial stove is a significant investment for any foodservice operation. While focusing on price and capacity is common, overlooking quality and intellectual property (IP) aspects can lead to long-term operational issues, safety risks, and legal exposure. Here are key pitfalls to avoid:

Overlooking Build Quality and Material Durability

Many buyers focus solely on upfront cost, opting for stoves made with thin-gauge stainless steel or inferior materials. Low-quality surfaces scratch easily, warp under high heat, and are prone to corrosion—especially in high-moisture kitchen environments. Poorly constructed burners may deliver inconsistent flame patterns, leading to uneven cooking and reduced efficiency. Always verify material thickness (e.g., 16- or 18-gauge stainless steel), weld quality, and component durability to ensure longevity and hygiene compliance.

Ignoring BTU Output and Burner Performance

Not all six-burner stoves deliver the same heating power. Some budget models use underpowered burners that struggle to maintain consistent temperatures, especially during peak service. Conversely, excessively high BTUs without proper control can lead to energy waste and fire hazards. Ensure each burner provides appropriate BTU output (typically 20,000–35,000 BTU for commercial use) and features precise, reliable control valves for temperature management.

Failing to Verify Safety Certifications

A major quality red flag is the absence of recognized safety certifications such as UL (Underwriters Laboratories), NSF (National Sanitation Foundation), or CE (for international models). Stoves lacking these certifications may not meet gas safety, electrical, or sanitation standards, posing operational risks and potentially voiding insurance. Always request certification documentation before purchase.

Assuming All “Stainless Steel” Stoves Are Equal

Be cautious of misleading labeling—some manufacturers use “stainless steel” for only visible surfaces while using mild steel or coated metals underneath. This can lead to rust, structural weakness, and non-compliance with health codes. Confirm that the entire chassis, legs, and internal frame are constructed from commercial-grade stainless steel.

Neglecting Intellectual Property (IP) Risks in Sourcing

Sourcing from unverified suppliers, especially overseas, increases the risk of purchasing stoves that infringe on patented designs or trademarks. Counterfeit or cloned equipment may mimic popular branded models but lack performance, safety features, and manufacturer support. Using such equipment could expose your business to legal liability, especially if the original IP holder pursues action against distribution or use of infringing products.

Relying on Unverified Suppliers Without IP Due Diligence

When sourcing from third-party manufacturers or new market entrants, conduct due diligence on whether the design is licensed or original. Request proof of IP ownership or licensing agreements, particularly for proprietary burner systems, control panels, or ergonomic features. Lack of transparency here may indicate IP infringement, which could result in shipment seizures, recalls, or reputational damage.

Skipping Warranty and After-Sales Support Verification

Low-cost stoves often come with limited or voidable warranties, especially if IP issues arise. Confirm the warranty covers both parts and labor, and ensure the supplier offers accessible technical support and spare parts. Brands that respect IP are more likely to stand behind their products with reliable service networks.

By prioritizing verified quality standards and conducting proper IP due diligence, you protect your investment, ensure kitchen safety, and avoid potential legal complications when sourcing a six-burner commercial stove.

H2: Logistics & Compliance Guide for Six Burner Commercial Stove

H2.1 Pre-Shipment Preparation

- Documentation Checklist:

- Commercial Invoice (accurate description, quantity, HTS code, value).

- Packing List (detailed contents, weights, dimensions, package count).

- Bill of Lading (Air Waybill for air freight) – correct shipper, consignee, notify party.

- Certificate of Origin (required by many countries for tariff determination).

- Manufacturer’s Declaration of Conformity (stating compliance with origin country standards).

- Technical Specifications Sheet (including voltage, fuel type, dimensions, weight, certifications).

- Required Import Permits/Licenses (if applicable to destination country).

- Risk Assessment (if shipping hazardous materials like residual fuel – rare for stoves).

- Packaging & Marking:

- Use robust, export-grade packaging (wooden crate or heavy-duty cardboard with internal bracing).

- Clearly mark packages with:

- Shipper & Consignee (full addresses, contact details).

- Purchase Order Number.

- Item Description (“Six Burner Commercial Stove – FRAGILE”).

- Net & Gross Weight, Dimensions (LxWxH).

- Handling Symbols (Fragile, This Way Up, Do Not Stack).

- Country of Origin.

- Compliance Verification:

- Confirm stove meets origin country safety standards (e.g., UL 197 in USA, CSA B149.1/CSA C22.2 No. 62 in Canada, CE for EU if shipped from there).

- Verify correct Harmonized System (HS) Code (e.g., 7321.11 or 7321.19 for gas stoves, 8516.60 for electric – verify specific code based on fuel type and region). This is critical for customs clearance.

- Ensure all required origin certifications are obtained and ready.

H2.2 Transportation & Freight Forwarding

- Mode Selection:

- Ocean Freight (FCL/LCL): Most economical for heavy items like stoves. Ideal for large quantities. Requires palletization/crating. Longer transit times.

- Air Freight: Faster but significantly more expensive. Used for urgent shipments or very small quantities. Weight limits apply.

- Land Freight (Truck): Primary method for domestic or regional (e.g., NAFTA/USMCA) shipments. Requires coordination with trucking company.

- Freight Forwarder: Engage a reputable forwarder experienced in commercial kitchen equipment. They manage:

- Booking space with carriers.

- Cargo insurance procurement.

- Customs documentation preparation.

- Inland transportation to/from ports/airports.

- Tracking and communication.

- Insurance: Obtain comprehensive cargo insurance covering loss, damage, and delay during transit. Specify coverage value (typically invoice value + freight + 10%).

- Inland Transportation: Arrange secure trucking from manufacturer to port/airport (origin) and from port/airport to final destination (destination). Ensure vehicles are suitable for heavy, bulky items.

H2.3 Import Clearance & Destination Compliance

- Customs Broker: Hire a licensed customs broker in the destination country.

- They file import declarations using provided documentation.

- Calculate and pay applicable duties, taxes (VAT/GST), and fees.

- Liaise with customs authorities to resolve queries.

- Ensure compliance with import regulations.

- Destination Country Requirements (CRITICAL):

- Technical Standards & Certification: The stove MUST comply with the destination country’s safety and performance standards. Common requirements include:

- Electrical: Voltage (110V/120V, 220V/240V, 380V), Plug Type, Frequency (50Hz/60Hz). Certification (e.g., CE, UKCA, CCC, INMETRO, S-Mark).

- Gas: Fuel Type (Natural Gas, Propane/LPG), Gas Pressure, Pipe Thread Type (NPT, BSP). Certification (e.g., CSA, AGA, DVGW, TÜV, JIS).

- Safety: Flame failure devices, ventilation requirements, material safety (food contact surfaces if applicable). Specific local codes (e.g., NFPA 96 in USA).

- Emissions & Environmental: Potential regulations on NOx emissions or energy efficiency (increasingly common).

- Labeling: Permanent labels showing voltage, fuel type, serial number, safety warnings, manufacturer, country of origin in the local language.

- Technical Standards & Certification: The stove MUST comply with the destination country’s safety and performance standards. Common requirements include:

- Duties & Taxes: Be prepared for:

- Import Duty: Based on HS code and origin (check for free trade agreements like USMCA, CPTPP).

- Value Added Tax (VAT) / Goods and Services Tax (GST): Applied to the landed cost (Product Value + Freight + Insurance + Duty).

- Other Fees: Harbor fees, customs processing fees, inspection fees.

H2.4 Final Delivery & Installation Readiness

- Final Mile Logistics:

- Coordinate with the consignee for delivery appointment.

- Ensure the delivery location has:

- Adequate access (doorway width, elevator capacity, ramp).

- Proper utility connections (gas line size/pressure, electrical circuit capacity, ventilation hood clearance).

- Sufficient personnel/equipment (dolly, liftgate truck) for unloading and positioning.

- Compliance Handover:

- Provide the end-user with all relevant compliance documentation (CoC, manuals, local certification copies).

- Clearly communicate any modifications required before use (e.g., orifice change for different gas type, voltage transformer).

- Critical: Emphasize that local, licensed professionals (plumber, electrician) must perform final gas/electrical connections and inspection to meet local code requirements. The manufacturer’s compliance does not override local installation codes.

H2.5 Key Risks & Mitigation

- Non-Compliance at Destination: Mitigation: Thoroughly research destination regulations before shipment. Obtain necessary certifications in advance. Work with experts (broker, agent).

- Customs Delays: Mitigation: Ensure perfect documentation. Use a competent broker. Pay duties/taxes promptly. Consider pre-clearance if feasible.

- Damage in Transit: Mitigation: Robust packaging. Adequate insurance. Clear handling marks. Careful loading/unloading.

- Incorrect Specifications: Mitigation: Double-check voltage, fuel type, and plug/gas connection compatibility with the end-user’s location before manufacturing/shipping.

- Installation Issues: Mitigation: Provide clear installation manuals. Specify need for licensed local technicians. Verify site readiness before delivery.

Disclaimer: This guide provides general information. Always consult with specialized logistics providers, customs brokers, and legal/compliance experts familiar with the specific origin and destination countries’ regulations for the definitive requirements. Regulations change frequently.

In conclusion, sourcing a six-burner commercial stove is a strategic investment for any high-volume food service operation seeking efficiency, consistency, and reliability in the kitchen. When selecting the right model, key factors such as burner power (BTU output), build quality, energy source (gas or electric), safety features, and ease of maintenance must be carefully evaluated. Additionally, considering the available space, ventilation requirements, and compliance with local health and safety regulations ensures seamless integration into the kitchen environment.

Comparing reputable brands, warranty options, and total cost of ownership—beyond the initial purchase price—will help identify a stove that delivers long-term value and performance. By prioritizing durability, precise temperature control, and energy efficiency, operators can enhance productivity, reduce downtime, and support high-quality food preparation. Ultimately, a well-chosen six-burner commercial stove not only meets current operational needs but also supports scalability and success in a competitive culinary environment.