The global sinker market is experiencing steady growth, driven by rising demand in residential, commercial, and industrial construction sectors. According to a report by Mordor Intelligence, the global plumbing fixtures market—which includes sinkers—was valued at USD 65.8 billion in 2022 and is projected to grow at a CAGR of 4.8% from 2023 to 2028. Similarly, Grand View Research estimates that the global plumbing fixtures market will expand at a CAGR of 5.1% during the same period, fueled by urbanization, infrastructure development, and increasing focus on water-efficient fixtures. As demand for durable, aesthetically pleasing, and technologically advanced sink solutions rises, manufacturers are innovating in materials, design, and sustainability. In this evolving landscape, a select group of companies has emerged as leaders, combining engineering excellence with strong supply chain capabilities. Here are the top 8 sinker manufacturers shaping the industry in 2024.

Top 8 Sinker Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Grateful Lead Sinker Company, Fishing Sinkers, Fishing Weight …

Domain Est. 2008

Website: gratefullead.com

Key Highlights: We are a Florida based Direct-from-Manufacturer source for fine-quality, offshore lead fishing sinkers. We offer Egg fishing weights, Bank fishing sinkers, ……

#2 Om Fishing Sinkers

Domain Est. 2016

Website: omfishingsinkers.com

Key Highlights: We are Original manufacturer and professional wholesale from China for kinds of Fishing Tackle products. We have producing the tungsten fishing weight for ……

#3 The Grateful Lead Sinker Company

Website: thegratefulleadsinkercompany.com

Key Highlights: The Grateful Lead Sinker Company is your Direct-from-Manufacturer source for fine-quality, offshore lead fishing sinkers. We offer Egg, Bank, Deep Drop, ……

#4 Bullet Weights

Domain Est. 2000

Website: bulletweights.com

Key Highlights: Bullet Weights is reported to have the largest selection of fishing sinker products in the marketplace. Our unique weights are distributed worldwide….

#5 Lead Fishing Sinkers & Weights

Domain Est. 2006

Website: nuclead.com

Key Highlights: Rating 3.2 (17) Nuclead offers Lead Fishing Sinkers and Lead Fishing Weights. Lead fishing weights and cast net weights either custom or standard can be made….

#6 Reins Fishing

Domain Est. 2009

Website: reinsfishing.com

Key Highlights: Free delivery over $150Innovative designs and premium quality combine to make Reins lures and tungsten sinkers a necessity for your tackle box. View Products. Featured Products….

#7 Lead Fishing Weights & Sinkers, Cannonball Sinkers, Torpedo …

Domain Est. 2009

Website: ocean-angler.com

Key Highlights: 2–10 day deliveryAll of our products are 100% handcrafted in America. We offer some of the lowest prices available on lead sinkers for both fresh and saltwater fishing. From ……

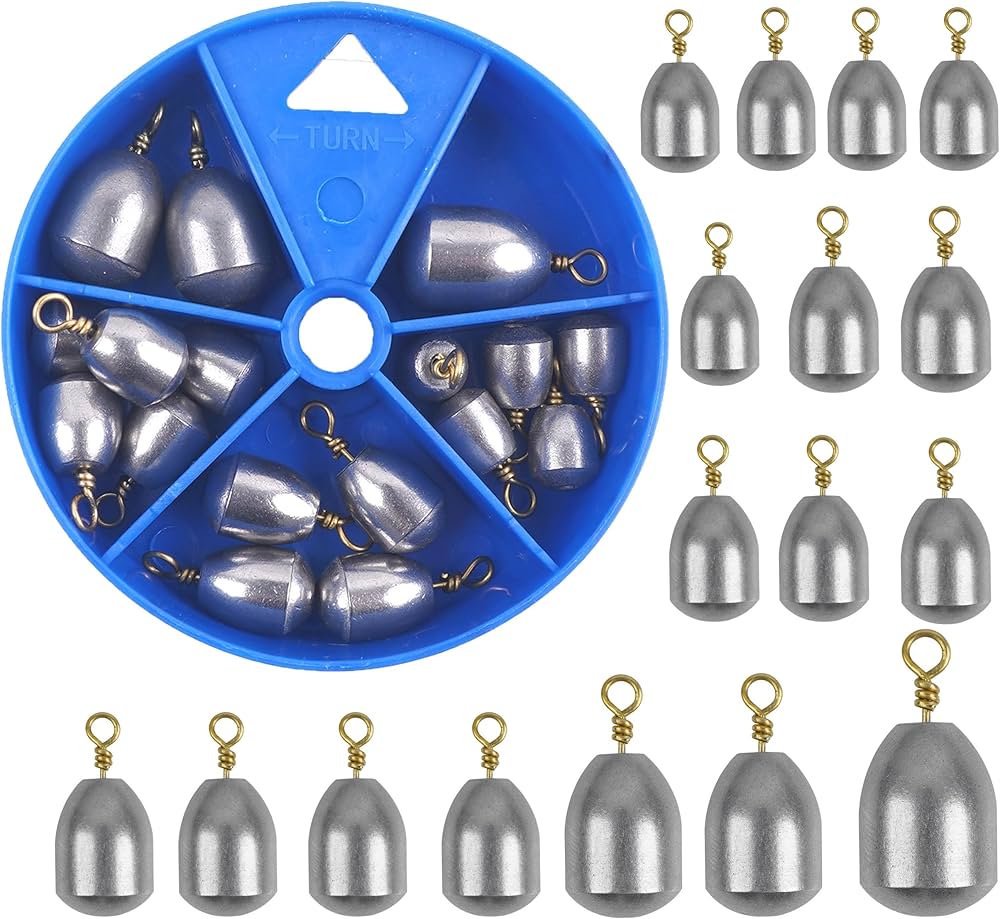

#8 Sinkers & Weights

Domain Est. 2022

Website: bluewingfishing.com

Key Highlights: Free delivery over $50 30-day returnsSinkers & Weights ; BLUEWING Tungsten Weight. $269.99 ; BLUEWING Split Shot Weight. $9.99 ; BLUEWING Egg Sinker with Plastic Core. $8.49 ; BLUE…

Expert Sourcing Insights for Sinker

H2 2026 Market Trends for Sinkers

While “Sinker” can refer to various products (fishing lures, marine anchors, or even industrial components), the most prevalent market context involves fishing sinkers. This analysis focuses on fishing sinkers, the dominant application, and outlines key H2 2026 market trends based on current trajectories, regulatory pressures, technological advancements, and consumer behavior.

1. Accelerated Shift Away from Lead: Regulatory and Environmental Dominance

- Stricter Regulations: H2 2026 will see the full implementation and enforcement of lead bans in key markets. The EU’s REACH restrictions are expected to be firmly in place, impacting all member states. Several US states (beyond California, New York, Maine) will likely have enacted or enforced their own bans. Canada’s phase-out will be more advanced. This is the single most significant driver.

- Environmental Awareness: Consumer demand for eco-friendly alternatives will surge, driven by conservation messaging from NGOs, government agencies, and responsible retailers. Anglers will increasingly view lead-free choices as a standard practice, not a niche.

- Market Impact: Demand for traditional lead sinkers will plummet in regulated regions. Retailers will heavily promote and stock compliant alternatives. Non-compliance risks significant penalties and reputational damage.

2. Maturation and Diversification of Lead-Free Alternatives

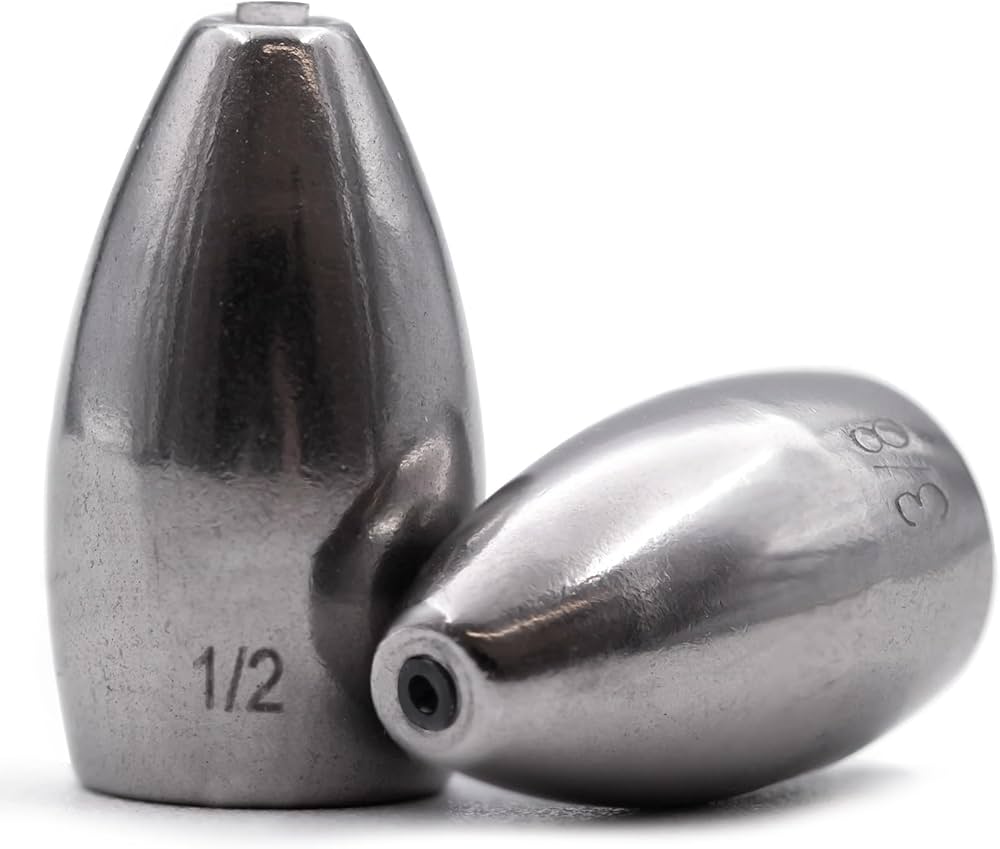

- Material Dominance Shift: Tungsten, particularly for smaller, high-density applications (e.g., drop-shot, finesse jig heads), will solidify its position as the premium choice due to its density, compact size, and perceived environmental safety. Iron and steel will dominate the mid-to-large weight, budget-friendly segment.

- Bismuth & Composites: Bismuth-based alloys will find a niche in specific applications requiring non-magnetic properties or unique casting characteristics. Composite materials (e.g., tungsten-polymer mixes) will gain traction, offering a balance of performance, cost, and environmental profile, especially for irregular shapes.

- Innovation Focus: R&D will focus on improving the cost-effectiveness of tungsten and enhancing the density and casting performance of iron/steel and composites to better compete with lead’s historical advantages.

3. Increased Demand for Specialized and Performance-Oriented Sinkers

- Niche Application Growth: Demand for sinkers tailored to specific techniques will grow:

- Finesse Fishing: Ultra-compact tungsten and high-density composite weights for Ned rigs, drop-shot, and shakey heads.

- Flippin’ & Pitching: Denser materials (tungsten) allowing for smaller, more discreet jig heads and weights that penetrate cover better.

- Carolina/Slip Rigs: High-quality, smooth-running tungsten or composite bullet weights; specialized no-roll designs.

- Trolling & Deep Water: Large, streamlined weights (often steel or iron) designed for depth and stability.

- “Smart” Features: Integration of features like built-in swivels, weed guards, or specialized coatings (e.g., non-reflective, noise-reducing) will become more common, adding value beyond just weight.

4. Supply Chain Consolidation and Sourcing Challenges

- Tungsten Volatility: Geopolitical factors (primarily China’s dominance in supply and potential export controls) could lead to price fluctuations and supply constraints for tungsten, impacting costs for premium sinkers.

- Cost Pressures: While iron/steel is cheaper, the overall shift to alternative materials and potential tungsten costs will keep pressure on manufacturers to optimize production. This may lead to consolidation among smaller players unable to achieve economies of scale or invest in new tooling.

- Sustainable Sourcing: Increased scrutiny on the mining and processing of alternative materials (e.g., tungsten, bismuth) will emerge, pushing larger manufacturers towards more transparent and sustainable sourcing practices.

5. E-commerce and Direct-to-Consumer (DTC) Growth

- Online Dominance: Sales through specialized fishing e-commerce platforms and brand DTC websites will continue to grow faster than traditional brick-and-mortar retail. This allows for wider product selection (especially niche/specialized sinkers) and direct consumer engagement.

- Content-Driven Marketing: Brands will leverage video (YouTube, social media) to demonstrate sinker performance, fishability, and environmental benefits, influencing purchasing decisions heavily in the online space.

6. Consumer Education and Brand Loyalty

- Knowledge Gap Bridging: Brands and retailers will invest heavily in educating consumers about the performance benefits of lead-free alternatives (not just environmental), overcoming the lingering perception that lead is superior.

- Brand Differentiation: Trust in brands known for consistent quality, innovation in lead-free materials, and environmental responsibility will become crucial. Performance consistency (e.g., true weight, smooth finish) will be a key differentiator, especially for premium tungsten.

- “Green” Branding: Environmental responsibility will be a core marketing pillar for successful brands, appealing to the increasingly eco-conscious angler.

Conclusion for H2 2026:

The sinker market in H2 2026 will be overwhelmingly defined by the post-lead era. Regulatory enforcement and consumer demand will make lead-free options the absolute standard in major markets. Tungsten will lead in performance and premium segments, while iron/steel dominates value and larger weights. Success will hinge on innovation in alternative materials, cost management, supply chain resilience, specialized product development, effective online marketing, and strong brand trust built on quality and environmental responsibility. The market will be more mature, segmented, and driven by performance and sustainability than ever before.

Common Pitfalls When Sourcing Sinker (Quality, IP)

Sourcing sinker—typically referring to high-density, high-quality wood like African Blackwood or other dense hardwoods used in precision applications such as musical instruments, luxury turnery, or industrial components—can present significant challenges, particularly concerning material quality and intellectual property (IP) risks. Below are key pitfalls to avoid:

Quality-Related Pitfalls

1. Inconsistent Material Density and Grain Structure

Sinker wood, especially reclaimed or salvaged timber, often varies in density and grain due to prolonged submersion, decay, or environmental exposure. Buyers may receive boards that appear premium but lack the structural integrity needed for precision work, leading to product failure or machining difficulties.

2. Undisclosed Rot, Insect Damage, or Fungal Infection

Even wood labeled as “premium sinker” may harbor internal defects invisible to surface inspection. Without proper kiln drying and certification, hidden rot or insect damage can compromise the usability and longevity of the material.

3. Mislabeling of Species or Origin

Suppliers may falsely represent lower-grade wood as rare sinker varieties (e.g., passing off regular ebony as African Blackwood). This misrepresentation undermines product authenticity and performance, especially in sensitive applications like instrument making.

4. Inadequate Drying and Stabilization

Poorly dried sinker wood is prone to warping, cracking, or movement after shaping. Buyers often overlook moisture content documentation, leading to costly post-production issues.

Intellectual Property (IP)-Related Pitfalls

1. Unauthorized Use of Proprietary Designs or Grades

Some suppliers market their sinker wood using branded grading systems or proprietary names (e.g., “Grade A Sinker Ebony™”) without proper licensing. Sourcing such materials may inadvertently expose buyers to IP infringement claims, particularly if the branding is trademarked.

2. Copying of Unique Product Specifications

When custom specifications (e.g., moisture content targets, cut dimensions, or stabilization methods) are shared with suppliers, there’s a risk these are replicated and sold to competitors. Lack of non-disclosure agreements (NDAs) or IP clauses in procurement contracts increases this exposure.

3. Sourcing from Unverified or Informal Supply Chains

In regions with weak IP enforcement, reclaimed sinker wood may be processed or sold by entities that lack legal rights to distribute the material. This raises concerns about the legitimacy of ownership and potential downstream liability.

4. Lack of Traceability and Certification

Without verifiable documentation—such as chain-of-custody certification, CITES permits (for endangered species), or supplier audits—buyers risk unintentionally supporting illegal logging or trafficking, which can result in reputational damage and legal consequences tied to environmental and IP regulations.

Mitigation Strategies

- Require third-party certification for quality and species verification (e.g., FSC, PEFC, or independent lab testing).

- Implement supplier audits and demand transparency in sourcing practices.

- Use legal agreements that include IP protection, confidentiality, and compliance clauses.

- Insist on detailed moisture reports, kiln-drying documentation, and defect disclosure.

Avoiding these pitfalls ensures consistent quality and reduces legal and reputational risks when sourcing premium sinker materials.

Logistics & Compliance Guide for Sinker

This guide outlines the key logistics and compliance considerations for Sinker, ensuring smooth operations, legal adherence, and efficient supply chain management.

Overview

Sinker, as a product or component used in industrial, fishing, or manufacturing applications, must be managed with attention to transportation regulations, safety standards, and import/export compliance. This guide covers essential practices for handling, storing, shipping, and complying with relevant regulations.

Product Classification & Specifications

- Material Type: Typically lead, steel, or environmentally safe alternatives

- Hazardous Status: May contain regulated materials (e.g., lead); check local and international regulations

- UN Number (if applicable): UN3077 (for certain lead-containing sinkers) or similar

- Proper Shipping Name: “Environmentally hazardous substance, solid, n.o.s.” (if applicable)

- HS Code: 7806.00 (Lead waste and scrap) or 7326.20 (Other articles of iron or steel), depending on composition

Packaging & Labeling Requirements

- Use durable, leak-proof packaging to prevent environmental contamination

- Clearly label packages with:

- Product name and weight

- Handling instructions (e.g., “Keep Dry”, “Do Not Drop”)

- Hazard communication labels (if containing regulated substances)

- GHS pictograms if classified as hazardous

- Include Safety Data Sheets (SDS) with shipments when required

Transportation & Shipping

- Domestic Shipments:

- Comply with DOT (U.S.) or equivalent national regulations for ground transport

- Use certified carriers for hazardous materials (if applicable)

- International Shipments:

- Adhere to IMDG Code (maritime), IATA DGR (air), or ADR (road in Europe) as applicable

- Declare proper UN number, hazard class, and packaging group

- Ensure export documentation (commercial invoice, packing list, certificate of origin) is accurate

- Weight & Dimension Limits: Optimize packaging to meet carrier restrictions and reduce freight costs

Storage & Handling

- Store in dry, ventilated areas away from food, water sources, and incompatible materials

- Stack securely to prevent collapse or damage

- Use PPE (gloves, masks) when handling lead-based sinkers to prevent exposure

- Implement spill containment procedures if storing in bulk

Environmental & Regulatory Compliance

- RoHS/REACH (EU): Ensure compliance if shipping to the European Union; restrict use of lead and other hazardous substances

- EPA Regulations (U.S.): Follow EPA guidelines for lead content and disposal; some states restrict lead sinkers due to environmental impact on wildlife

- Canada: Comply with CEPA and provincial regulations restricting toxic substances in fishing gear

- UK REACH: Post-Brexit compliance required for shipments to the UK

Import/Export Documentation

- Accurate commercial invoice indicating value, quantity, and country of origin

- Bill of Lading or Air Waybill

- Export declaration (e.g., AES filing in the U.S.)

- Import permits (if required by destination country)

- Certificates of compliance (e.g., ISO, RoHS, or material safety)

Recordkeeping & Audits

- Maintain records of SDS, shipping documents, compliance certifications, and training logs for at least 5 years

- Conduct annual compliance audits to verify adherence to regulations

- Train logistics and warehouse staff on hazardous material handling and emergency procedures

Sustainability & Alternatives

- Consider offering non-toxic sinkers (e.g., tungsten, bismuth, steel) to meet environmental standards

- Promote recycling programs for used lead sinkers

- Monitor regulatory trends toward banning lead in fishing and industrial applications

Emergency Response

- In case of spill or exposure:

- Isolate area and prevent spread

- Follow SDS emergency procedures

- Report incidents per local and federal requirements

- Maintain spill kits and first aid supplies in storage and transport areas

By following this guide, Sinker operations can ensure regulatory compliance, reduce environmental impact, and maintain efficient logistics across global markets.

Conclusion for Sourcing Sinker:

Sourcing a reliable sinker requires a strategic approach that balances quality, cost, and supply chain sustainability. After evaluating potential suppliers, conducting due diligence, and assessing material specifications, it is evident that selecting a sinker supplier demands attention to production capabilities, material consistency, delivery reliability, and compliance with industry standards. By prioritizing long-term partnerships with vetted suppliers and maintaining clear communication on technical and logistical requirements, organizations can ensure a steady supply of high-performance sinkers that meet their operational needs. Ultimately, effective sourcing not only enhances product quality and performance but also contributes to cost efficiency and supply chain resilience.