The global printed circuit board (PCB) market continues to expand, driven by rising demand in consumer electronics, automotive, and industrial applications. According to Mordor Intelligence, the PCB market was valued at USD 80.21 billion in 2023 and is projected to reach USD 109.59 billion by 2029, growing at a CAGR of approximately 5.3% during the forecast period. A significant portion of this growth is attributed to single-sided PCBs, which remain a cost-effective and reliable solution for low-complexity electronic devices. Their widespread use in applications such as power supplies, LED lighting, and basic consumer electronics ensures ongoing demand, particularly in emerging markets. As manufacturers seek efficiency, scalability, and quality compliance, the need for reliable single-sided PCB suppliers has become more critical. Based on production capacity, global reach, certifications, and customer reviews, the following are the top 10 single-sided PCB manufacturers leading the industry today.

Top 10 Single Side Pcb Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 to American Standard Circuits

Domain Est. 1996

Website: asc-i.com

Key Highlights: Explore top-tier printed circuit board manufacturing with American Standard Circuits. Your USA-based solution for quality PCBs and circuit boards….

#2 Printed Circuit Board Manufacturer

Domain Est. 1998

Website: pcbnet.com

Key Highlights: Imagineering is a trusted printed circuit board manufacturer, offering precision PCB assembly, fabrication, & protoype services with quick turnaround….

#3 PCB Manufacturer, PCB Prototype & PCB Assembly

Domain Est. 2004

Website: rushpcb.com

Key Highlights: RUSH PCB is your one-stop shop for all types of PCBs – Printed Circuit Board Manufacturing, PCB Design, PCB Fabrication and Full Turnkey PCB Assemblies in the ……

#4 China PCB Prototype & Fabrication Manufacturer

Domain Est. 2012

#5 AdvancedPCB

Domain Est. 2018

Website: advancedpcb.com

Key Highlights: Prototype to Production PCBs from AdvancedPCB. Choose us as your trusted PCB board manufacturer and circuit board manufacturer….

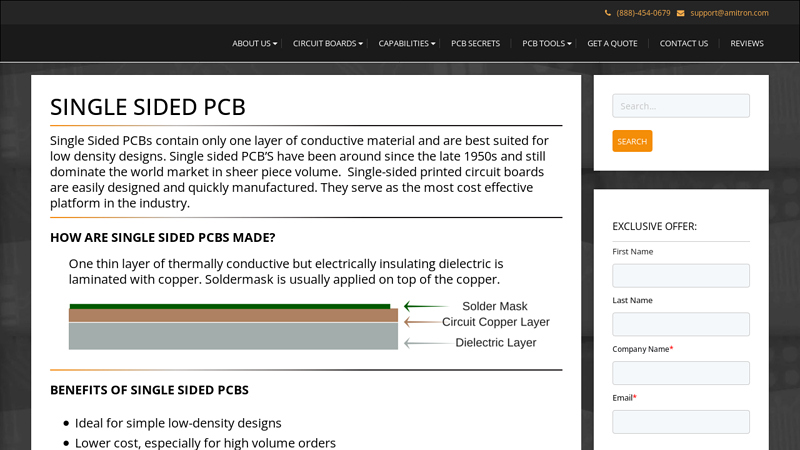

#6 SINGLE SIDED PCB

Domain Est. 1995

Website: amitron.com

Key Highlights: Amitron manufactures high quality single sided printed circuit boards (PCBs) at low prices with excellent customer service….

#7 Sierra Circuits

Domain Est. 1997 | Founded: 1986

Website: protoexpress.com

Key Highlights: Since 1986, Sierra Circuits has been an industry leader in PCB prototype manufacturing, optimization, and assembly….

#8 PCBCart

Domain Est. 2005

Website: pcbcart.com

Key Highlights: Expert of PCB manufacturing, we proudly offer PCB making & assembly services with certified quality standards for all your needs. Free online quote!…

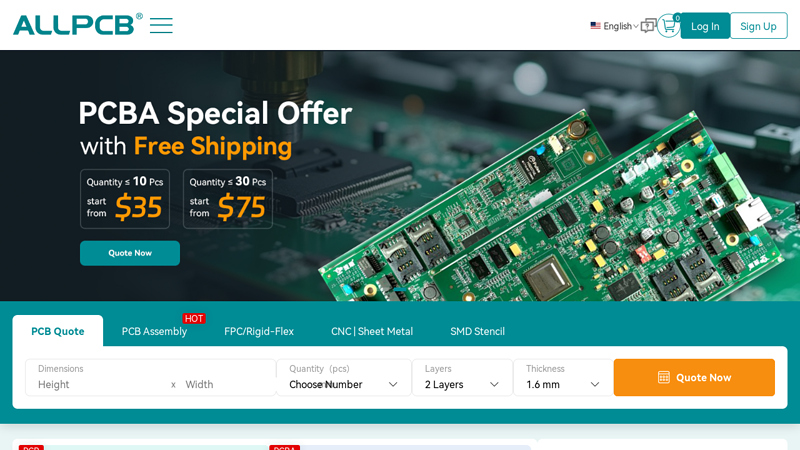

#9 ALLPCB

Domain Est. 2011

Website: allpcb.com

Key Highlights: Explore the ALLPCB approach to PCB manufacturing and assembly: From prototype to production, we’ve got you covered….

#10 OSH Park ~

Domain Est. 2011

Website: oshpark.com

Key Highlights: We produce high quality bare printed circuit boards, focused on the needs of prototyping, hobby design, and light production….

Expert Sourcing Insights for Single Side Pcb

H2 2026 Market Trends for Single-Sided PCBs

The global market for single-sided printed circuit boards (PCBs) is expected to experience moderate but strategic growth during the second half of 2026 (H2 2026), driven by sustained demand in cost-sensitive and high-volume applications despite increasing competition from more advanced PCB technologies. Below is an analysis of key market trends shaping the single-sided PCB segment during this period.

1. Continued Demand in Consumer Electronics and Industrial Applications

Single-sided PCBs remain a preferred choice in low-complexity consumer electronics such as calculators, LED lighting, and basic household appliances due to their low manufacturing cost and simple design. In H2 2026, demand is expected to remain steady, particularly in emerging markets where affordability is a key purchasing factor. Additionally, industrial applications—including power supplies, relay systems, and sensors—continue to adopt single-sided PCBs for non-critical control modules, supporting consistent market demand.

2. Growth in Automotive and Automotive Aftermarket Segments

While high-end vehicles increasingly use multilayer and flexible PCBs, single-sided PCBs maintain relevance in automotive lighting systems, dashboard components, and aftermarket accessories. With the global push toward electrification and smart vehicle features, even entry-level models in developing regions are incorporating more electronics, creating opportunities for cost-effective single-sided solutions. In H2 2026, this trend is expected to bolster regional production, especially in Southeast Asia and India.

3. Pressure from Advanced PCB Technologies

The market share of single-sided PCBs is under gradual pressure from double-sided and HDI (High-Density Interconnect) PCBs, which offer better functionality in compact form factors. As electronics continue to shrink and integrate more features, the limitations of single-sided designs—such as limited routing space and lower component density—are becoming more apparent. However, their cost advantage ensures continued usage in applications where performance requirements are less stringent.

4. Regional Manufacturing Shifts and Supply Chain Optimization

Asia-Pacific, particularly China, India, and Vietnam, remains the dominant manufacturing hub for single-sided PCBs. In H2 2026, regional governments are expected to further incentivize domestic PCB production through subsidies and infrastructure development, reducing reliance on imports. This localization trend supports faster turnaround times and lower costs, benefiting OEMs in price-sensitive sectors.

5. Sustainability and Regulatory Considerations

Environmental regulations, particularly in the EU and North America, are pushing manufacturers to adopt lead-free assembly and recyclable materials. Single-sided PCBs, often simpler in composition, are easier to recycle than multilayer counterparts. In H2 2026, eco-conscious design and compliance with RoHS and REACH standards are becoming competitive differentiators, encouraging manufacturers to invest in greener production processes.

6. Price Stability Amid Raw Material Fluctuations

Copper and substrate material prices have shown moderate volatility in 2026 due to global supply chain adjustments post-pandemic and geopolitical factors. However, the relatively low material usage in single-sided PCBs buffers them from severe cost swings. Most suppliers are expected to maintain price stability in H2 2026 through long-term contracts and process efficiencies.

Conclusion

While single-sided PCBs are no longer at the forefront of technological innovation, they remain a vital component in numerous established and emerging applications. In H2 2026, the market will be characterized by steady demand, geographic diversification of manufacturing, and incremental improvements in sustainability. For stakeholders, success will depend on cost optimization, regional market adaptation, and strategic positioning within low-to-mid complexity electronics ecosystems.

Common Pitfalls When Sourcing Single-Sided PCBs (Quality, IP)

Sourcing single-sided printed circuit boards (PCBs) can be cost-effective, but it comes with several risks—especially related to quality control and intellectual property (IP) protection. Being aware of these pitfalls helps ensure reliable production and safeguards your designs.

Poor Manufacturing Quality

One of the most frequent issues when sourcing single-sided PCBs, especially from low-cost suppliers, is inconsistent or substandard manufacturing quality. This can manifest as incorrect trace widths, poor etching leading to shorts or opens, inconsistent copper thickness, or inaccurate drilling. These defects can lead to circuit failure, reduced performance, or early product returns. Low-quality solder masks and silkscreens may also degrade over time, affecting both usability and aesthetics.

Inadequate Material Specifications

Single-sided PCBs often use FR-1 or FR-2 substrates instead of the more robust FR-4, especially in budget options. While acceptable for low-power or non-critical applications, these materials have lower thermal resistance, mechanical strength, and moisture tolerance. Sourcing without verifying material specs can result in boards that fail under normal operating conditions or during soldering processes.

Lack of Quality Assurance and Testing

Many overseas or budget PCB suppliers skip essential quality assurance steps such as electrical testing (e.g., continuity and isolation checks), automated optical inspection (AOI), or sample validation. Without these checks, defective boards may go undetected until assembly or field use, increasing overall costs and delaying time-to-market.

Intellectual Property Exposure

Sharing your PCB design files (typically Gerber and drill files) with third-party manufacturers inherently risks IP exposure. In regions with weak IP enforcement, there’s a real danger of design theft, unauthorized production, or counterfeit versions entering the market. This is particularly concerning for innovative or proprietary products.

No Legal Recourse for IP Infringement

Even if IP theft is suspected, pursuing legal action against overseas manufacturers can be costly and ineffective due to jurisdictional challenges and lack of enforceable contracts. Many suppliers operate in countries where IP laws are either poorly enforced or not aligned with international standards, leaving innovators with little protection.

Hidden Costs from Rework and Failures

Initially low pricing can be misleading. Poor quality may lead to high failure rates during assembly, requiring costly rework or scrapping of components. These hidden costs often outweigh the savings from choosing a cheaper PCB supplier, especially at scale.

Limited Traceability and Documentation

Lower-tier suppliers may not provide full traceability for materials or processes. In regulated industries or for failure analysis, the lack of documentation—such as copper thickness certifications, laminate batch numbers, or process logs—can be a significant drawback.

Best Practices to Mitigate Risks

To avoid these pitfalls, vet suppliers thoroughly, request samples before bulk orders, use non-disclosure agreements (NDAs), consider working with manufacturers in IP-respectful regions, and specify material and testing requirements clearly in contracts. Using trusted procurement channels or intermediaries with quality oversight can also enhance security and reliability.

Logistics & Compliance Guide for Single-Side PCB

This guide outlines the essential logistics and compliance considerations for the manufacturing, shipping, and use of single-side printed circuit boards (PCBs). Adhering to these standards ensures product quality, regulatory compliance, and smooth operations across the supply chain.

Manufacturing and Material Compliance

Single-side PCBs must be produced using materials and processes that meet international environmental and safety standards. Key compliance areas include:

- RoHS (Restriction of Hazardous Substances): Ensure all components and materials comply with RoHS directives (e.g., EU Directive 2011/65/EU), restricting lead, mercury, cadmium, and other hazardous substances.

- REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals): Confirm that all chemical substances used in production are registered and compliant under REACH regulations.

- IPC Standards: Follow IPC-6011 and IPC-6012 standards for performance and qualification of rigid PCBs, including single-side variants, to maintain quality and reliability.

- UL Recognition: Where applicable, use base materials (e.g., FR-4) with UL94 flammability ratings and ensure the PCB is marked with UL certification if required.

Packaging and Handling

Proper packaging protects single-side PCBs from electrostatic discharge (ESD), moisture, and physical damage during storage and transit:

- ESD Protection: Package boards in static-dissipative or conductive shielding bags (e.g., pink poly or metallized shielding bags) to prevent ESD damage.

- Moisture Barrier: Use moisture barrier bags (MBBs) with desiccant and humidity indicator cards, especially for boards with moisture-sensitive components (per IPC/JEDEC J-STD-033).

- Mechanical Protection: Employ rigid corrugated cardboard, foam inserts, or stackable trays to prevent warping, scratching, or breakage.

- Labeling: Clearly label packages with ESD warnings, handling instructions, product ID, revision, quantity, and date of manufacture.

Shipping and Transportation

Logistics for single-side PCBs must ensure timely, secure, and compliant delivery:

- Regulatory Documentation: Include commercial invoices, packing lists, and certificates of compliance (e.g., RoHS, REACH) for international shipments.

- Export Controls: Verify if PCBs fall under export control regulations (e.g., EAR in the U.S.) based on technical specifications or end-use applications.

- Temperature and Humidity Control: Avoid extreme conditions during transit; maintain ambient storage conditions (typically 15–30°C, 30–60% RH).

- Carrier Requirements: Use reputable carriers experienced in handling electronic components and ensure packages meet dimensional and weight guidelines.

Import and Customs Compliance

For cross-border shipments, ensure adherence to destination country regulations:

- HS Code Classification: Use the correct Harmonized System (HS) code (e.g., 8534.00 for printed circuits) to determine duties and taxes.

- Country-Specific Requirements: Check for local certifications (e.g., CE in Europe, CCC in China, KC in South Korea) based on end-product integration.

- Duty and Tax Optimization: Leverage free trade agreements or bonded warehouses where applicable to reduce costs.

Traceability and Documentation

Maintain full traceability throughout the supply chain:

- Lot Tracking: Record batch numbers, material certifications, and manufacturing dates for each production run.

- Compliance Records: Retain test reports, material declarations (e.g., IPC-1752), and audit trails for at least 10 years as per industry best practices.

- Customer Documentation: Provide compliance datasheets, IPC documentation, and safety data sheets (SDS) upon request.

End-of-Life and Environmental Responsibility

Support sustainable practices in line with environmental directives:

- WEEE Compliance: Design and document PCBs to support recycling under the Waste Electrical and Electronic Equipment (WEEE) directive.

- Recycling Guidelines: Provide disposal and recycling instructions to end users or OEM partners.

By following this logistics and compliance guide, manufacturers and distributors can ensure that single-side PCBs meet global standards, reduce risks, and support reliable integration into end products.

Conclusion for Sourcing Single-Sided PCBs:

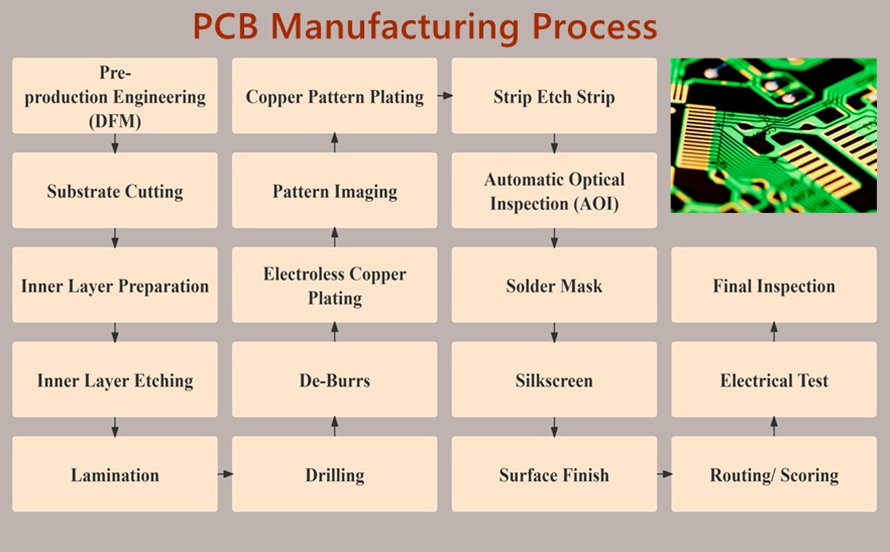

Sourcing single-sided PCBs is a cost-effective and practical solution for simple electronic applications that do not require complex circuitry. These boards are ideal for prototyping, educational projects, and low-density designs due to their straightforward manufacturing process, shorter lead times, and lower production costs compared to multi-layer PCBs.

When sourcing single-sided PCBs, it is essential to select a reliable manufacturer that ensures quality in materials, etching precision, and surface finish. Key factors to consider include turnaround time, minimum order quantities, compliance with industry standards (such as IPC), and the ability to meet specific design requirements like copper thickness, solder mask, and silkscreen options.

Additionally, leveraging online PCB fabrication platforms can streamline the sourcing process, offering instant quoting, design validation, and global shipping options. However, for larger volumes or specialized applications, direct engagement with manufacturers may provide better pricing and customization.

In summary, single-sided PCBs remain a viable and efficient choice for basic electronic assemblies. By carefully evaluating suppliers and balancing cost, quality, and lead time, businesses and designers can successfully integrate single-sided PCBs into their product development workflow.