The global automotive brake system market is experiencing steady expansion, driven by rising vehicle production, stringent safety regulations, and increased demand for high-performance braking components. According to a report by Mordor Intelligence, the automotive brakes market was valued at USD 27.5 billion in 2023 and is projected to grow at a CAGR of over 4.8% through 2029. A key segment within this growth is the demand for reliable, cost-effective caliper solutions—particularly single piston calipers, which are widely used in passenger vehicles and light commercial vehicles due to their simplicity, efficiency, and lower manufacturing costs. As original equipment manufacturers (OEMs) and aftermarket suppliers focus on lightweight design and improved thermal management, leading caliper manufacturers are scaling innovation and production capacity. This list highlights the top 9 single piston caliper manufacturers shaping the industry through technological advancement, global supply chain reach, and alignment with evolving vehicle safety standards.

Top 9 Single Piston Caliper Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Brake Calipers

Domain Est. 1996

Website: apracing.com

Key Highlights: AP Racing, the Coventry, UK-based company is a key supplier and the leading manufacturer of performance brake and clutch systems for road and race cars….

#2 Baer Brakes

Domain Est. 1996

Website: baer.com

Key Highlights: Baer, Inc is a leader in the performance brake industry that challenges the status quo by focusing on engineering design and innovative technology….

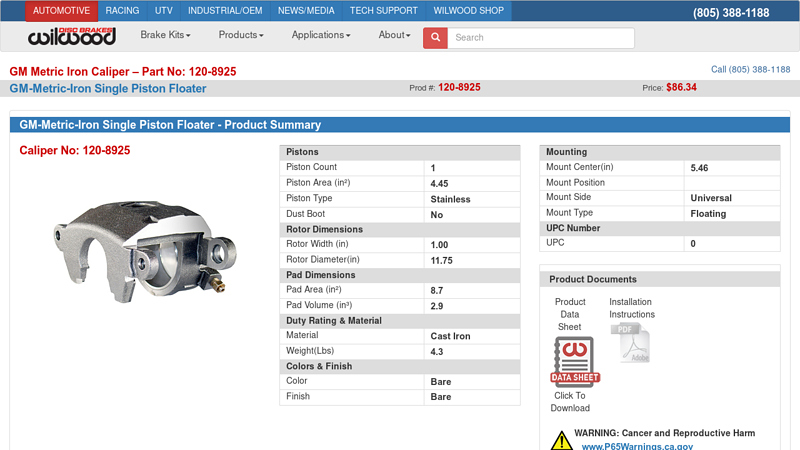

#3 GM

Domain Est. 1997

#4 Innovation and Safety in Braking Systems for Cars and Bike …

Domain Est. 1997

Website: brembo.com

Key Highlights: Discover the latest innovations in braking systems and mobility. Brembo ensures safety, performance, and sustainability. Explore our products on the ……

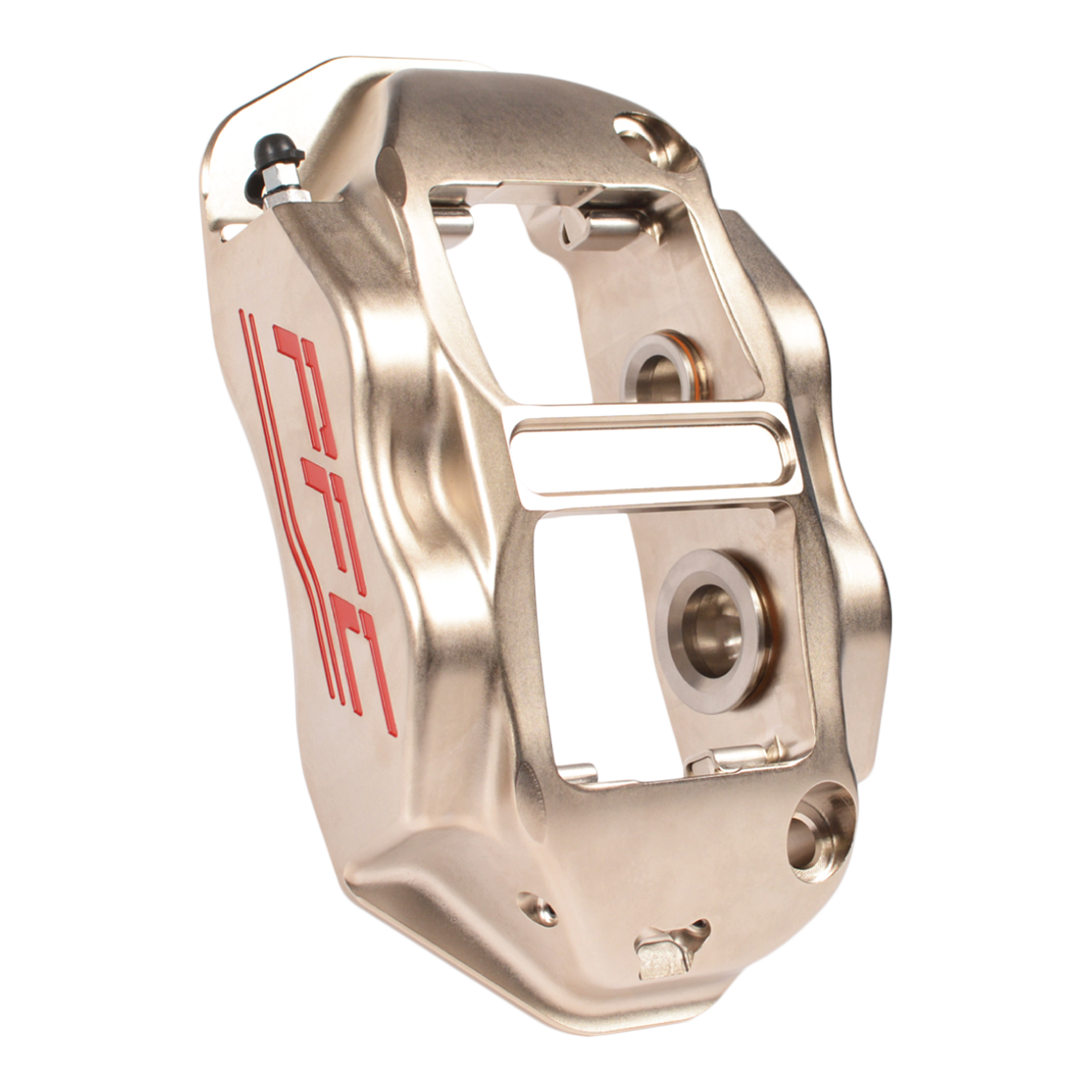

#5 PFC Brakes

Domain Est. 2000

Website: pfcbrakes.com

Key Highlights: We’ve built a culture of performance, crafting high-performance brake calipers, discs, and pads in our state-of-the-art facility located in Clover, South ……

#6 EBC Brakes

Domain Est. 2000

Website: ebcbrakes.com

Key Highlights: EBC Brakes are a leading brake company offering brakes, pads, calipers, brake lines, discs & rotors for Automotive, Motorcycle, Mountain Bike & Racing….

#7 Cleveland Wheel & Brake Systems

Domain Est. 2002

Website: clevelandwheelandbrake.com

Key Highlights: Cleveland Wheel and Brake Systems (CWBS) provides aircraft braking systems and key system components including wheels, brakes, and hydraulic components….

#8 Beringer Brakes

Domain Est. 2006

Website: beringer-brakes.com

Key Highlights: Beringer is the specialist in high performance braking for motorcycles, cars and quads: caliper, brake disc, master cylinder……

#9 Disc Brakes for Off-Road & Other Specialty Applications

Domain Est. 2012

Website: hayesperformance.com

Key Highlights: Custom dry disc brakes for off-road vehicles & unique applications. Livelihoods, and lives, depend on brakes configured to precise specifications….

Expert Sourcing Insights for Single Piston Caliper

2026 Market Trends for Single Piston Caliper

The single piston caliper market is poised for moderate transformation by 2026, influenced by evolving automotive technologies, regulatory standards, and shifts in consumer demand. While traditionally favored for cost-effective and lightweight braking solutions—especially in entry-level vehicles, scooters, and certain bicycle applications—single piston calipers face both challenges and opportunities in the broader transportation ecosystem.

Growing Demand in Two-Wheeler and Light Electric Vehicles

One of the main growth drivers for single piston calipers through 2026 is the expanding two-wheeler and light electric vehicle (LEV) market, particularly in Asia-Pacific and emerging economies. With increasing urbanization and demand for affordable personal mobility, scooters, e-bikes, and electric mopeds are adopting single piston calipers for their simplicity, lower manufacturing costs, and adequate performance in low-speed environments. In regions such as India, Southeast Asia, and parts of Africa, the proliferation of electric two-wheelers is expected to sustain demand for cost-efficient braking systems like single piston calipers.

Additionally, the rise of micro-mobility solutions—including electric scooters and shared bikes—further supports the relevance of single piston designs due to their ease of maintenance and reliability under moderate use.

Pressure from Advanced Braking Technologies

Despite their cost advantages, single piston calipers face increasing competition from multi-piston and advanced braking systems, especially in the automotive and high-performance segments. By 2026, original equipment manufacturers (OEMs) are expected to prioritize enhanced safety and braking performance, driven by stricter global safety regulations (e.g., NCAP standards) and consumer expectations. This trend favors dual or multi-piston calipers, which offer superior heat dissipation, balanced clamping force, and better modulation.

In electric vehicles (EVs), regenerative braking reduces reliance on friction brakes, but when mechanical braking is required, more efficient and durable systems are often preferred. As a result, single piston calipers may remain confined to non-performance and economy segments rather than mainstream passenger EVs.

Material and Design Innovations

To remain competitive, manufacturers of single piston calipers are investing in lightweight materials and improved thermal management. Innovations such as aluminum alloy bodies, enhanced piston seals, and better pad compounds are extending the performance envelope of single piston systems. By 2026, expect to see more engineered single piston calipers that bridge the gap between cost and performance, especially in niche applications like light commercial vehicles and recreational off-road vehicles.

Consolidation and Regional Manufacturing Shifts

The market is likely to witness consolidation among braking component suppliers, with larger Tier-1 companies acquiring specialized caliper manufacturers to streamline supply chains. Regional shifts in automotive production—especially in Southeast Asia, Eastern Europe, and Mexico—will influence where single piston calipers are manufactured and deployed. Localization strategies aimed at reducing logistics costs will benefit suppliers with flexible production capabilities.

Sustainability and Circular Economy Considerations

By 2026, environmental regulations will increasingly affect brake component design and materials. Single piston calipers, often simpler to disassemble and recycle, may gain favor in circular economy initiatives. Moreover, reduced material usage compared to multi-piston systems aligns with sustainability goals, potentially enhancing their appeal in eco-conscious markets.

Conclusion

While the single piston caliper is unlikely to dominate high-performance or premium vehicle segments by 2026, it will maintain a strong foothold in cost-sensitive, lightweight, and urban mobility applications. Continued innovation, regional market dynamics, and sustainability trends will shape its trajectory, ensuring its relevance in a diversified and evolving braking technology landscape.

Common Pitfalls Sourcing Single Piston Calipers (Quality, IP)

Sourcing single piston calipers, especially for cost-sensitive or high-volume applications, presents several critical challenges related to quality consistency and intellectual property (IP) risks. Being aware of these pitfalls is essential to avoid performance issues, safety concerns, and legal complications.

Quality Inconsistencies and Non-Compliance

One of the most prevalent issues when sourcing single piston calipers—particularly from low-cost or less-regulated suppliers—is inconsistent manufacturing quality. Poor casting integrity, incorrect metallurgy, substandard surface finishes, and inadequate heat treatment can lead to premature wear, brake fade, or even catastrophic failure under stress. Many suppliers may not adhere strictly to OEM specifications or international standards (e.g., ISO, SAE, or ECE regulations), resulting in calipers that fail durability and safety testing. Buyers often discover these shortcomings only after field failures or during rigorous quality audits, leading to costly recalls or reputational damage.

Intellectual Property (IP) Infringement Risks

Another significant pitfall is the risk of sourcing calipers that infringe on existing intellectual property. Some manufacturers produce calipers that are direct copies or close derivatives of patented OEM designs, especially for popular vehicle models. These “replica” or “pattern” parts may appear identical and function adequately but expose the buyer to legal liability for IP violations. Even if the supplier claims the design is generic, subtle design elements—such as piston geometry, mounting interface, or internal fluid passages—may still be protected by patents. Sourcing such components can lead to cease-and-desist orders, customs seizures, or litigation, especially when importing into regions with strong IP enforcement (e.g., the EU or North America).

Lack of Traceability and Certification

Many suppliers, particularly in unregulated markets, provide insufficient documentation or traceability. This includes missing material certifications, test reports, or ISO/TS quality management system compliance. Without proper traceability, it becomes nearly impossible to verify batch consistency or conduct root cause analysis during failure investigations. This lack of transparency also complicates compliance with automotive industry requirements such as IATF 16949, which mandates rigorous process controls and documentation.

Inadequate Testing and Validation

Suppliers may claim compliance with performance standards but have not conducted or validated third-party testing. For example, a caliper might pass basic visual inspection but fail under thermal cycling or long-term corrosion resistance tests. Without access to comprehensive validation data—including pressure testing, leak testing, and environmental exposure—the buyer assumes significant risk that the product will underperform in real-world conditions.

Hidden Costs from Rework and Warranty Claims

Poor-quality calipers often result in higher downstream costs, including assembly line rework, increased warranty claims, and customer dissatisfaction. The initial cost savings from sourcing low-cost calipers are quickly eroded when accounting for field failures and service replacements. Additionally, inconsistent dimensions or tolerances can cause fitment issues during installation, leading to delays and additional labor costs.

To mitigate these pitfalls, buyers should conduct thorough due diligence on suppliers, require full technical documentation, perform independent quality audits, and ensure IP clearance through legal or technical review. Engaging with reputable, certified manufacturers—even at a higher initial cost—ultimately reduces risk and ensures long-term reliability and compliance.

Logistics & Compliance Guide for Single Piston Caliper

This guide outlines the essential logistics and compliance considerations for the transportation, storage, handling, and regulatory adherence related to single piston calipers—commonly used in automotive braking systems. Adhering to these guidelines ensures product integrity, safety, and compliance with international and regional standards.

Product Overview

A single piston caliper is a vital component of a disc brake system, typically used in passenger vehicles and light trucks. It utilizes one hydraulic piston to clamp brake pads against a rotor, enabling vehicle deceleration. Due to its metallic construction and potential residual fluids (e.g., brake fluid), proper handling and regulatory compliance are critical throughout the supply chain.

Packaging Requirements

- Protective Packaging: Calipers must be individually wrapped in anti-corrosion paper or vapor corrosion inhibitors (VCI) to prevent rust, especially during maritime transport.

- Secure Boxing: Pack in rigid corrugated cardboard or wooden crates with internal cushioning (foam inserts or edge protectors) to prevent mechanical damage.

- Labeling: Each package must display:

- Part number and description

- Net weight and gross weight

- Handling symbols (e.g., “Do Not Stack,” “This Side Up”)

- Manufacturer and destination details

Storage Conditions

- Environment: Store in a dry, temperature-controlled warehouse (10°C to 30°C; 50°F to 86°F) with relative humidity below 60% to prevent corrosion.

- Shelving: Keep off the floor on pallets or metal shelving; avoid direct contact with concrete.

- Ventilation: Ensure adequate airflow to minimize condensation.

- Shelf Life: Inspect for corrosion or seal degradation if stored over 12 months. Reapply protective coating if necessary.

Transportation Guidelines

- Mode Selection: Suitable for road, rail, air, and sea freight. Air and sea shipments require enhanced moisture protection.

- Stacking: Do not stack more than three layers high unless using reinforced pallets. Use dunnage between layers if needed.

- Securing Loads: Palletized shipments must be stretch-wrapped and banded to prevent shifting during transit.

- Hazardous Materials: If calipers contain residual brake fluid (DOT 3, 4, or 5.1), classify and declare as ORM-D (Other Regulated Material – Domestic) or UN3082 (Environmentally Hazardous Substance) if applicable. Consult SDS before shipping.

Regulatory Compliance

- International Trade:

- HS Code: Typically classified under 8708.30 (Braking equipment for vehicles). Confirm locally as codes vary by country.

- Customs Documentation: Include commercial invoice, packing list, certificate of origin, and bill of lading/air waybill.

- Environmental Regulations:

- REACH (EU): Ensure no restricted substances (e.g., lead, cadmium) exceed permissible limits in metallic components.

- RoHS (if applicable): Although primarily for electronics, verify compliance if caliper includes electronic parking brake components.

- Safety Standards:

- FMVSS 105/121 (USA): Calipers must meet U.S. Federal Motor Vehicle Safety Standards for braking performance.

- ECE R13 (Europe): Compliance with UN Regulation 13 for braking systems is mandatory for OEM applications.

- Waste Disposal (End-of-Life):

- Follow local WEEE or ELV (End-of-Life Vehicles) directives for proper recycling and disposal.

- Remove residual fluids before scrapping.

Documentation & Traceability

- Maintain batch/lot traceability through serialized part numbers or QR codes.

- Retain material test reports, compliance certificates (e.g., ISO 9001, IATF 16949), and shipping records for a minimum of 10 years for automotive components.

Special Handling Precautions

- Wear gloves when handling to prevent fingerprint-induced corrosion on polished surfaces.

- Avoid exposure to saltwater, acidic cleaners, or abrasive materials.

- Do not disassemble or modify calipers during storage or transit.

Emergency Procedures

- Leakage (Brake Fluid): In case of fluid spill, contain with absorbent pads. Dispose of as hazardous waste per local regulations.

- Injury Risk: Sharp edges may be present; use cut-resistant gloves during unpacking.

Adherence to this guide ensures safe, compliant, and efficient movement of single piston calipers across the global supply chain. Always consult local regulations and customer-specific requirements before shipment.

Conclusion for Sourcing Single Piston Caliper

In conclusion, sourcing a single piston caliper requires a comprehensive evaluation of several key factors including performance requirements, cost-efficiency, compatibility with existing braking systems, durability, and supplier reliability. Single piston calipers offer advantages such as simplicity in design, lighter weight, easier maintenance, and cost-effective production, making them suitable for light to moderate-duty applications such as passenger vehicles, scooters, and entry-level motorcycles.

When selecting a supplier, it is essential to consider quality certifications, manufacturing capabilities, logistical support, and after-sales service to ensure consistent product performance and long-term supply chain stability. Additionally, balancing initial procurement costs with total cost of ownership—factoring in maintenance, lifespan, and warranty—will contribute to a more sustainable and efficient sourcing decision.

Ultimately, choosing the right single piston caliper and supplier involves aligning technical specifications with application needs while maintaining a focus on quality, reliability, and value. A strategic sourcing approach will not only optimize braking performance but also enhance overall vehicle safety and operational efficiency.