The global fiber optic patch cord market is experiencing robust growth, driven by escalating demand for high-speed data transmission across data centers, telecommunications, and enterprise networks. According to a report by Mordor Intelligence, the Fiber Optic Cable Market—of which single mode patch cords are a critical component—is projected to grow at a CAGR of over 9.5% from 2024 to 2029. This expansion is fueled by the rapid deployment of 5G networks, increasing fiber-to-the-home (FTTH) adoption, and the continual scaling of hyperscale data centers. Similarly, Grand View Research valued the global fiber optic cable market at USD 10.5 billion in 2023 and forecasts a CAGR of 10.2% from 2024 to 2030, underscoring the escalating need for reliable, high-bandwidth connectivity solutions. As single mode patch cords—known for their long-distance transmission and low signal attenuation—become increasingly essential in backbone infrastructure, a select group of manufacturers have emerged as leaders in quality, innovation, and global reach. Below, we highlight the top 10 single mode patch cord manufacturers shaping the future of optical connectivity.

Top 10 Single Mode Patch Cord Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Fiber Optic Cable Assemblies

Domain Est. 1991

Website: corning.com

Key Highlights: Corning offers the most complete line of connectors and factory-terminated cables, from single-fiber patch cords to high-fiber-count assemblies….

#2 Singlemode Fiber Optic Patch Cord Cable Assembly Specifications

Domain Est. 1996

Website: fiberdyne.com

Key Highlights: Fiberdyne Labs, Inc. offers a complete line of premium quality Singlemode Fiber Optic Cable Assemblies….

#3 Fiber Optic Patch Cables

Domain Est. 2000

Website: fibertronics.com

Key Highlights: 2–12 day deliveryFibertronics Inc. offers a wide selection of high-quality fiber optic patch cables, with many models in stock and available for immediate shipment….

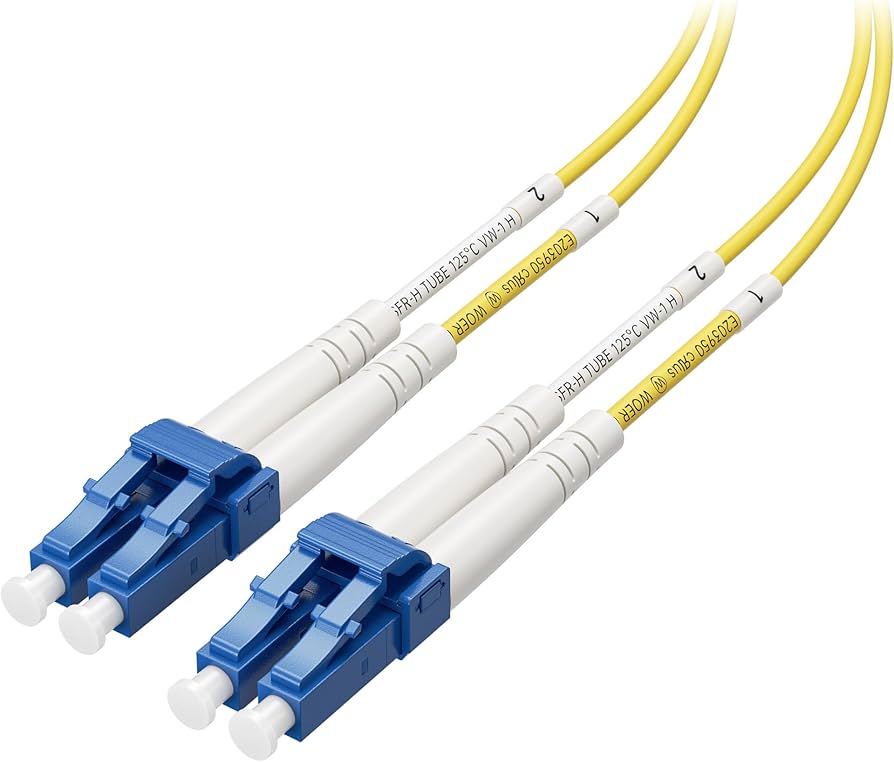

#4 040402G5Z20010M

Domain Est. 1991

Website: ecatalog.corning.com

Key Highlights: Professional 2.0 mm Single-mode Patch Cord, LSZH™, CPR Dca Corning® SMF-28® Ultra, Single-mode, LC UPC Duplex to LC UPC Duplex, 10 m. Typically ships in 14 day( ……

#5 Single Mode Standard Patch Cables

Domain Est. 1994

Website: newport.com

Key Highlights: Free delivery 30-day returnsNewport’s Single Mode Standard Patch cables are all-glass fibers supporting single-mode light propagation for many wavelength ranges….

#6 Custom Fiber Optic Patch Cables

Domain Est. 1995

Website: thorlabs.com

Key Highlights: Thorlabs stocks the largest selection of single mode and multimode optical fibers in the photonics industry. If our selection of stocked patch cables does ……

#7 2m (6.6ft) LC to LC (UPC) OS2 Single Mode Simplex Fiber Optic …

Domain Est. 1998

Website: startech.com

Key Highlights: In stock Free deliveryThis 9/125μm OS2 simplex single mode fiber patch cord is backward compatible with OS1 networks, ensuring a reliable connection in legacy fiber environments….

#8 Fiber Optic Cables

Domain Est. 2004

Website: fibercablesdirect.com

Key Highlights: Free delivery 30-day returnsWe stand behind the craftsmanship of every fiber optic product we deliver. From Indoor / Outdoor, Single mode & Multimode to Mode Conditioning and SFP ….

#9 Fiber Optic Patch Cables for Sale

Domain Est. 2004

Website: cablesondemand.com

Key Highlights: 30-day returns100% optically tested duplex single-mode 9/125 fiber optic patch cables by Amphenol meet and exceed industry standard specifications for insertion loss, return ……

#10 Fiber Optic Patch Cables

Domain Est. 2014

Expert Sourcing Insights for Single Mode Patch Cord

H2: Projected Market Trends for Single Mode Patch Cords in 2026

As the global demand for high-speed data transmission continues to accelerate, the market for Single Mode Patch Cords (SMPCs) is poised for significant evolution by 2026. These fiber optic cables, essential for long-distance and high-bandwidth applications, are expected to experience steady growth driven by advancements in telecommunications infrastructure, the proliferation of 5G networks, and the expansion of data centers. Below are the key market trends anticipated to shape the Single Mode Patch Cord landscape in 2026:

1. Increased Demand from 5G Network Deployments

The global rollout of 5G networks is a primary growth driver for SMPCs. With 5G requiring dense fiber backhaul networks to support low latency and high throughput, telecom operators are heavily investing in single-mode fiber infrastructure. Patch cords are critical for connecting baseband units to remote radio heads and interconnecting fiber distribution hubs. By 2026, 5G-related deployments are expected to account for a significant share of SMPC demand, particularly in Asia-Pacific and North America.

2. Growth in Hyperscale Data Centers

Hyperscale data centers are expanding rapidly to support cloud computing, artificial intelligence, and big data applications. These facilities rely on high-performance interconnects, where Single Mode Patch Cords enable efficient data transfer across long spans within and between data center campuses. The shift toward higher data rates (400G and beyond) is increasing the adoption of single-mode solutions over multimode, further boosting market demand.

3. Adoption of Advanced Connector Technologies

By 2026, there will be wider adoption of high-precision connectors such as LC, SC, and emerging SN and MDC connectors optimized for single-mode applications. Innovations in angled physical contact (APC) polishing and reduced insertion loss will enhance signal integrity, especially in dense network environments. Plug-and-play pre-terminated SMPC solutions are also expected to gain traction, reducing deployment time and costs.

4. Expansion in Enterprise and FTTx Applications

Beyond telecom and data centers, enterprises are upgrading internal networks to support bandwidth-intensive applications. Additionally, Fiber-to-the-Home (FTTH) and Fiber-to-the-X (FTTx) initiatives in emerging markets are contributing to SMPC demand. Governments and private ISPs are investing in fiber last-mile connectivity, where single-mode patch cords play a vital role in network termination points.

5. Regional Market Dynamics

Asia-Pacific is projected to lead global SMPC consumption by 2026, driven by China, India, and Southeast Asia’s aggressive digital infrastructure plans. North America will maintain strong demand due to cloud service expansion and 5G densification. Europe will see moderate growth, supported by EU digital agenda initiatives and green data center projects.

6. Sustainability and Supply Chain Optimization

Sustainability concerns are prompting manufacturers to develop eco-friendly cable materials and recyclable packaging. At the same time, supply chain resilience—impacted by past global disruptions—is driving regional manufacturing shifts and inventory diversification, influencing pricing and availability of SMPCs.

7. Price Pressure and Competitive Landscape

Increased competition among fiber optic component suppliers may lead to price stabilization or slight declines. However, premium SMPCs with enhanced performance (e.g., low bend loss, high reliability) are expected to command higher margins, creating a bifurcated market.

In conclusion, the Single Mode Patch Cord market in 2026 will be shaped by technological innovation, infrastructure modernization, and evolving connectivity demands. Stakeholders who align with high-growth sectors like 5G, cloud, and smart cities will be best positioned to capitalize on these trends.

Common Pitfalls When Sourcing Single Mode Patch Cords (Quality, IP)

Sourcing high-quality Single Mode patch cords is critical for maintaining signal integrity, minimizing loss, and ensuring long-term network reliability. However, several pitfalls related to quality and intellectual property (IP) can lead to performance issues, security risks, and legal complications. Being aware of these can help avoid costly mistakes.

Poor Optical Quality and Performance

One of the most frequent issues is receiving patch cords that do not meet optical performance standards. Inferior connectors, improper polishing, or low-grade fiber can result in high insertion loss, excessive back reflection, and unreliable connections. Always verify compliance with IEC or Telcordia standards and request test reports for key parameters like insertion loss and return loss.

Use of Counterfeit or Non-Compliant Components

Some suppliers offer patch cords using counterfeit connectors or fiber that mimic reputable brands but fail to meet specifications. These components may look identical but degrade quickly under real-world conditions. Ensure traceability and request manufacturer certifications to avoid substandard or non-compliant parts.

Inadequate Connector Polish and End-Face Inspection

Single Mode fiber requires precise end-face geometry and polishing (typically UPC or APC). Poorly polished connectors lead to signal loss and contamination risks. Avoid suppliers that do not provide end-face inspection reports or use automated inspection systems. A clean, scratch-free ferrule is essential for high-performance links.

Misrepresentation of Fiber Specifications

Some vendors falsely claim their patch cords use ITU-T G.652.D or G.657.A1 single-mode fiber when, in reality, they use lower-grade or multimode fiber. This misrepresentation can cause compatibility issues and signal degradation. Always verify fiber type through third-party testing or detailed product specifications.

Lack of Intellectual Property Due Diligence

Using patch cords that infringe on patented connector designs (e.g., LC, SC, MTP®) can expose your organization to legal risk. Some low-cost suppliers replicate protected designs without licensing. Source from reputable vendors who respect IP rights and can provide documentation of legal compliance.

Insufficient Testing and Quality Control

Budget suppliers may skip critical testing steps such as 100% optical testing or environmental stress screening. This increases the chance of field failures. Insist on suppliers with documented quality management systems (e.g., ISO 9001) and full test traceability for each patch cord.

Inconsistent Labeling and Documentation

Poor labeling—such as missing model numbers, fiber type, or test data—makes inventory management and troubleshooting difficult. Incomplete or falsified documentation can also hinder compliance audits. Choose suppliers who provide clear, consistent labeling and full traceability.

Supply Chain Transparency and Traceability Gaps

Without transparent sourcing, it’s difficult to verify the origin of materials or ensure ethical manufacturing practices. This lack of traceability can introduce quality or security vulnerabilities. Prioritize vendors who disclose their manufacturing processes and supply chain controls.

Logistics & Compliance Guide for Single Mode Patch Cord

Product Overview

A Single Mode Patch Cord is a fiber optic cable designed to carry a single ray of light over long distances with minimal signal loss. It is commonly used in high-bandwidth data transmission applications such as telecommunications, data centers, and enterprise networks. These patch cords typically feature LC, SC, or other standard connectors on each end and comply with industry standards for performance and safety.

Packaging & Labeling Requirements

- Primary Packaging: Each patch cord must be individually wrapped in anti-static polybags to prevent electrostatic discharge (ESD) damage.

- Secondary Packaging: Group multiple units in rigid cardboard boxes with internal dividers to prevent tangling and physical damage during transit.

- Labeling: Each unit must display a permanent label including:

- Product name (e.g., “Single Mode Patch Cord”)

- Model number and part number

- Fiber type (e.g., OS2)

- Connector type (e.g., LC-LC, SC-LC)

- Length (e.g., 2m, 5m)

- Manufacturer name and date of production

- Compliance markings (e.g., RoHS, CE)

Storage Conditions

- Temperature: Store in a dry environment with temperatures between -10°C to +50°C.

- Humidity: Maintain relative humidity below 85% to prevent corrosion and insulation damage.

- Shelving: Store in upright positions on shelves, avoiding direct sunlight and sources of electromagnetic interference.

- Handling: Avoid bending below the minimum bend radius (typically 30mm for patch cords) and prevent crushing or excessive tension.

Transportation Guidelines

- Domestic & International Shipping: Use UN-certified packaging if shipping in bulk. Follow IATA/IMDG regulations if transporting by air or sea.

- Shock & Vibration Protection: Include cushioning materials such as foam inserts to minimize impact.

- Temperature Control: Avoid exposure to extreme temperatures during transit; use climate-controlled vehicles if necessary.

- Documentation: Include a commercial invoice, packing list, and bill of lading. Clearly mark packages with “Fragile” and “This Side Up” labels.

Regulatory Compliance

International Standards

- IEC 61300-3-35: Fiber optic interconnecting devices and passive components – Inspection and measurement procedures.

- TIA-492: American National Standard for optical fibers and cables.

- ISO/IEC 11801: Generic cabling for customer premises.

Environmental & Safety Regulations

- RoHS (Directive 2011/65/EU): Restricts the use of hazardous substances (e.g., lead, mercury, cadmium). Ensure compliance with maximum concentration values.

- REACH (EC 1907/2006): Registration, Evaluation, Authorization, and Restriction of Chemicals. Confirm all materials are registered and safe.

- CE Marking: Required for sale in the European Economic Area (EEA), indicating conformity with health, safety, and environmental standards.

- FCC Part 15 (USA): While fiber is non-conductive, any accompanying hardware must comply with electromagnetic interference standards.

Import/Export Considerations

- HS Code: Typically classified under 8544.70.00 (Optical fiber cables) for customs declarations.

- Country-Specific Requirements:

- USA: FCC compliance for packaging and labeling; no radiation emission concerns for passive fiber.

- EU: CE marking and EU Declaration of Conformity must be available.

- China: Requires CCC certification only if active components are included; passive patch cords generally exempt.

- India: BIS certification not required for passive fiber patch cords as of current regulations.

- Documentation: Prepare Certificate of Origin, Test Reports (e.g., insertion loss, return loss), and Material Declarations (e.g., RoHS, REACH).

Quality Assurance & Testing

- Factory Testing: Each batch must undergo:

- Insertion Loss (IL): ≤ 0.3 dB typical

- Return Loss (RL): ≥ 55 dB (APC connectors), ≥ 40 dB (UPC connectors)

- Continuity and polarity verification

- Certification: Provide test reports (e.g., IEC 61300-3-4) with shipment where required by customer or regulation.

- Traceability: Maintain lot numbers and test data for a minimum of 5 years.

End-of-Life & Disposal

- Recycling: Coordinate with certified e-waste recyclers. Fiber optic cables contain glass and plastic components that can be separated and recycled.

- Disposal Compliance: Follow local regulations (e.g., WEEE in the EU) for electronic waste. Do not dispose of in regular landfill if regulated.

- Hazardous Materials: Confirm absence of restricted substances per RoHS; documentation must support safe disposal.

Summary

To ensure seamless logistics and regulatory compliance for Single Mode Patch Cords:

– Adhere to standardized packaging, labeling, and storage protocols.

– Comply with international safety and environmental directives (RoHS, REACH, CE).

– Maintain proper documentation for import/export.

– Conduct routine quality testing and ensure full traceability.

Following this guide ensures product integrity, regulatory adherence, and customer satisfaction across global markets.

Conclusion on Sourcing Single-Mode Patch Cords

In conclusion, sourcing single-mode patch cords requires careful consideration of several critical factors to ensure optimal network performance, reliability, and long-term cost-efficiency. Key elements such as fiber type (OS2), connector polish (preferably UPC or APC to minimize return loss), cable construction (tight-buffered or loose-tube), and compliance with industry standards (e.g., TIA/EIA, ISO/IEC) must be thoroughly evaluated. Additionally, selecting reputable suppliers with demonstrated quality assurance practices, proper certifications, and consistent product traceability is essential.

Single-mode patch cords are vital for high-bandwidth, long-distance applications in telecommunications, data centers, and enterprise networks. Therefore, investing in high-quality cords from trusted manufacturers not only enhances signal integrity and reduces attenuation but also minimizes downtime and maintenance costs. Factors such as warranty, technical support, and scalability for future network upgrades should also influence the sourcing decision.

Ultimately, a strategic sourcing approach—balancing performance requirements, quality standards, and total cost of ownership—will ensure reliable, high-performance connectivity and support the evolving demands of modern optical networks.