The global sewing machine market, valued at USD 4.5 billion in 2022, is projected to grow at a compound annual growth rate (CAGR) of 5.8% through 2030, driven by rising demand in both industrial and home textile sectors (Grand View Research, 2023). While modern innovations continue to shape the industry, a steady resurgence in vintage and classic sewing machines has fueled demand for authentic replacement parts—particularly for iconic brands like Singer. Enthusiasts, restorers, and repair specialists increasingly seek high-quality, historically accurate components to maintain the functionality and aesthetic integrity of older models. This niche, supported by a growing DIY culture and expanded access to e-commerce platforms, has revitalized interest in manufacturers that produce or supply original equipment manufacturer (OEM) and compatible vintage Singer sewing machine parts. As the after-sales ecosystem expands, a select group of companies has emerged as key players in preserving the legacy of these mechanical workhorses through precision-engineered old parts production and distribution.

Top 7 Singer Sewing Machine Old Parts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

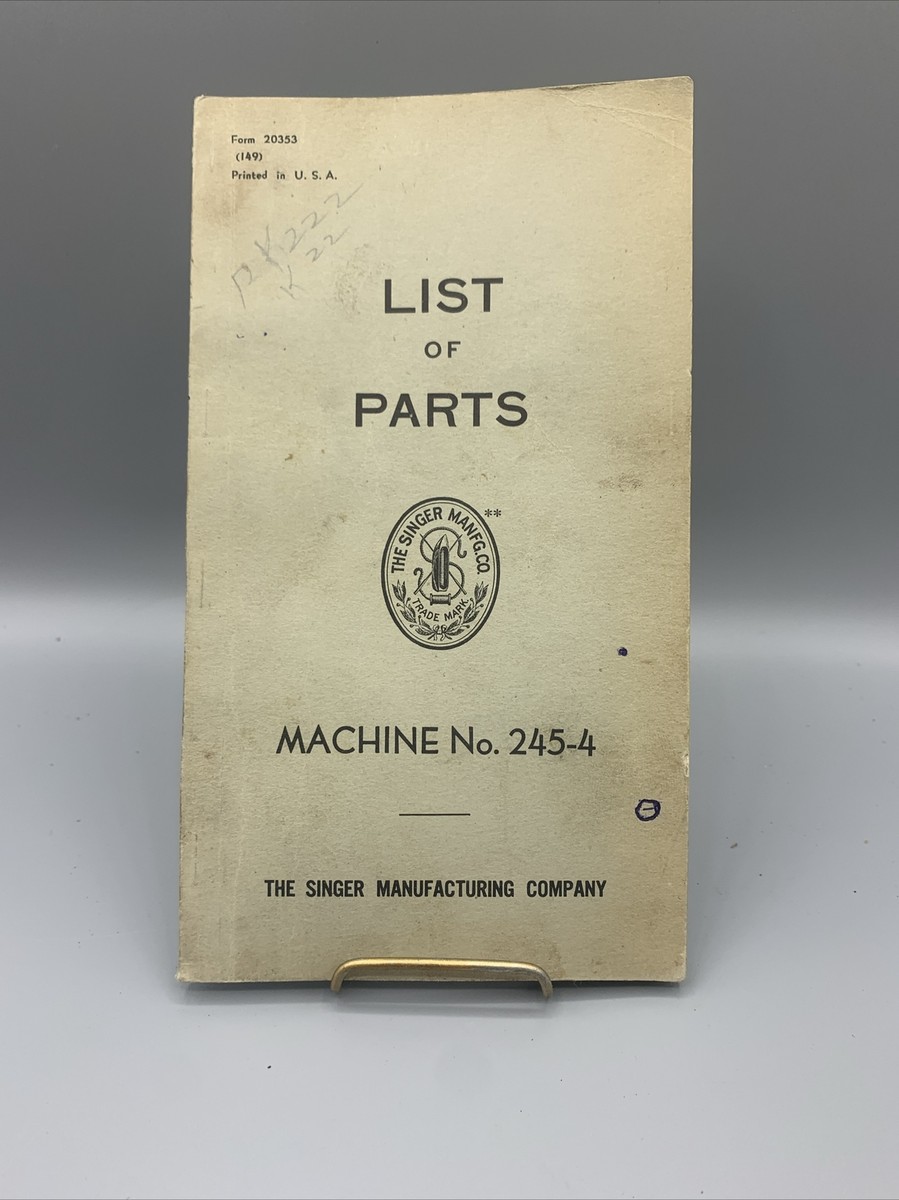

#1 Exploded Parts Views

Domain Est. 1998

Website: singeronline.com

Key Highlights: Sewing machine parts schematics for Singer, Kenmore, Baby Lock, Brother and more….

#2 Parts for Other Vintage & Antique Singer Machines

Domain Est. 2000

#3 Dating A Vintage Or Antique Sewing Machine, How Old Is It..?

Domain Est. 2000

Website: singermachines.co.uk

Key Highlights: Serial numbers on Singer sewing machines manufactured prior to 1900 have numbers only. After 1900 the machine serial numbers have a single or two-letter prefix….

#4 Singer Sewing Info

Domain Est. 2011

Website: singersewinginfo.co.uk

Key Highlights: Singer sewing machine information site for sewing machines incl. 221, 222K. Also covers accessories, Toy sewing machines (TSM)and antique sewing machines….

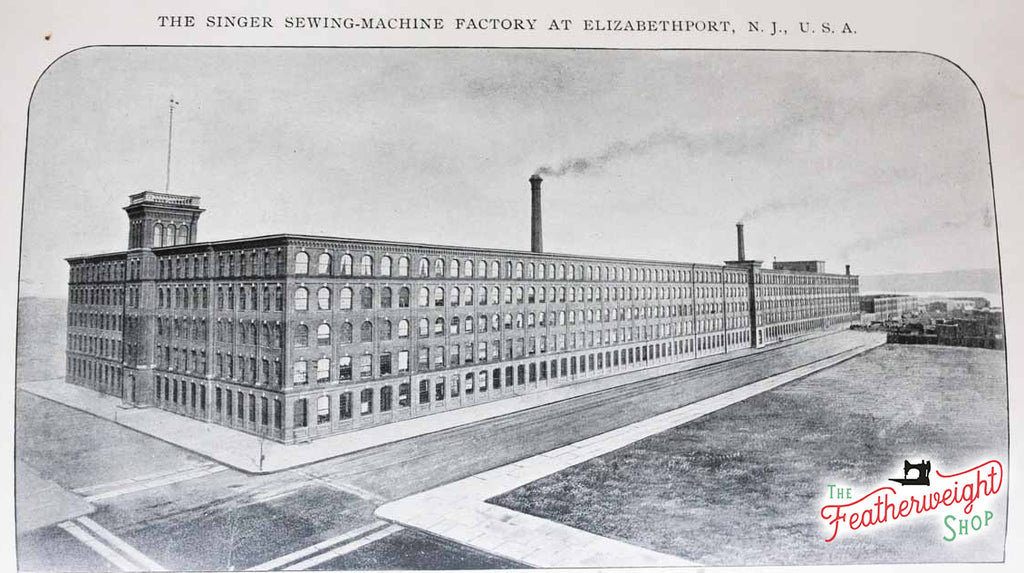

#5 Where was my Singer sewing machine made?

Domain Est. 2012

Website: oldsewingear.com

Key Highlights: Singer’s most prolific factories were located in Elizabeth, New Jersey (USA), Anderson, South Carolina (USA), Bridgeport, Connecticut (USA), Clydebank, ……

#6 Singer Sewing Machine Company

Domain Est. 2014

Website: historymuseumsb.org

Key Highlights: Isaac M. Singer established his Singer Company in 1851 in Boston. His operations were moved to New York City in 1853. In 1858, the plants in New York were ……

#7 Sewing Machine Parts

Domain Est. 2016

Website: twiceniceshoppe.com

Key Highlights: Out of Stock. Motor – Alpha Sew for Singer Featherweight 221/ 222 Quick View · Motor – Alpha Sew for Singer Featherweight 221/ 222 · $159.95 · Read more….

Expert Sourcing Insights for Singer Sewing Machine Old Parts

H2: 2026 Market Trends for Singer Sewing Machine Old Parts

The market for vintage Singer sewing machine parts is anticipated to experience notable shifts and sustained interest by 2026, driven by a convergence of cultural, economic, and technological factors. As consumer preferences increasingly favor sustainability, craftsmanship, and nostalgia, the demand for authentic, repairable, and historically significant sewing machine components continues to grow. Below are key trends expected to shape the market:

-

Rising Demand for Repair and Restoration

By 2026, more consumers are expected to embrace the “repair, don’t replace” ethos, especially in the context of sustainable fashion and DIY movements. Vintage Singer sewing machines—renowned for their durability and timeless design—are prime candidates for restoration. This trend fuels demand for original parts such as hand wheels, tension discs, bobbins, and gear assemblies, particularly from models produced between the 1920s and 1970s. -

Expansion of Online Marketplaces and Niche Platforms

E-commerce platforms like eBay, Etsy, and specialized vintage machinery forums are expected to play a dominant role in the distribution of old Singer parts. By 2026, enhanced search algorithms, AI-driven part identification tools, and improved global shipping logistics will make it easier for collectors and repair technicians to locate rare components, increasing market accessibility and competition. -

Growth of Collector and Enthusiast Communities

Online communities, YouTube restoration channels, and social media groups dedicated to vintage sewing machines are growing rapidly. These communities not only drive awareness but also create secondary markets for hard-to-find parts. The educational content they produce helps new users identify, source, and install original parts, sustaining long-term market demand. -

Increased Scarcity and Rising Prices

As original Singer parts become more scarce—due to decades of attrition, wear, and limited production—their value is projected to rise. By 2026, rare parts from iconic models like the Singer 66, 99, or Featherweight 221 are expected to command premium prices, especially those in good condition or with original finishes. This scarcity may also spur a market for high-quality reproductions, though purists will continue to seek authentic components. -

3D Printing and Reproduction Parts

While original parts remain highly valued, the rise of 3D printing and precision machining presents a dual trend. Reproduction parts made from modern materials may fill gaps for unavailable originals. However, for restorers aiming for authenticity, especially in antique or show-quality machines, original Singer parts will remain irreplaceable, maintaining their premium status. -

Geographic Shifts in Market Activity

Although North America and Western Europe have traditionally dominated the vintage sewing machine market, interest is growing in Asia, particularly in Japan and South Korea, where craftsmanship and mechanical heritage are highly respected. By 2026, these regions may become significant sources of both demand and supply for original Singer parts.

In conclusion, the 2026 market for old Singer sewing machine parts is expected to remain robust, characterized by increasing demand, digital market expansion, and growing scarcity. Stakeholders—from collectors and repair specialists to resellers—must navigate a landscape where authenticity, provenance, and community engagement will be key to success.

Common Pitfalls When Sourcing Old Singer Sewing Machine Parts

Logistics & Compliance Guide for Singer Sewing Machine Old Parts

Overview

This guide outlines the essential logistics and compliance considerations for handling, transporting, storing, and disposing of old parts from vintage or discontinued Singer sewing machines. These components may include metal gears, motors, electrical wiring, cast iron housings, and plastic casings. Proper management ensures regulatory adherence, safety, and environmental responsibility.

Classification of Old Parts

Old Singer sewing machine parts are typically categorized as electronic waste (e-waste), scrap metal, or general waste, depending on their composition and condition. Proper classification is critical for correct handling and compliance with local and international regulations. Examples include:

– Metal components (e.g., cast iron bases, steel gears): Recyclable scrap metal.

– Electrical components (e.g., motors, foot pedals with wiring): Potential e-waste due to copper and plastic content.

– Plastic casings and knobs: May be recyclable depending on resin type.

– Wooden cabinets or drawers: Classified as general or bulky waste unless reusable.

Regulatory Compliance

Handling old sewing machine parts must comply with environmental and waste management regulations:

– WEEE Directive (EU): Applies if electrical components are present; mandates proper collection and recycling of e-waste.

– EPA Regulations (USA): Follow local and state rules for e-waste and scrap metal disposal; some states prohibit landfilling e-waste.

– RoHS Compliance: Ensure parts containing hazardous substances (e.g., lead solder) are handled accordingly.

– International Shipments: Exporting parts may require adherence to the Basel Convention if classified as hazardous waste.

Storage and Handling

To maintain safety and part integrity:

– Store in dry, secure areas to prevent rust and contamination.

– Segregate metal, plastic, and electrical components to simplify recycling.

– Label containers clearly (e.g., “Scrap Metal – Non-Hazardous”).

– Use protective gloves and tools when handling sharp or heavy parts.

Transportation Guidelines

When moving old parts:

– Secure loads to prevent shifting during transit.

– Use covered vehicles to avoid environmental contamination from oils or debris.

– For commercial shipments, ensure carriers are licensed for scrap metal or e-waste transportation.

– Maintain shipping manifests and waste transfer notes for traceability.

Recycling and Disposal

Prioritize recycling through certified facilities:

– Partner with licensed scrap metal recyclers for iron, steel, and copper.

– Use e-waste recyclers certified by R2 or e-Stewards standards for motors and wiring.

– Avoid landfill disposal unless parts are non-recyclable and legally permissible.

Documentation and Recordkeeping

Maintain records for compliance and audit readiness:

– Keep invoices from recyclers or disposal services.

– Document quantities, types, and destinations of parts shipped.

– Retain waste transfer notes for at least three years, as required by many jurisdictions.

Environmental and Safety Considerations

- Assess for residual lubricants or oils; clean or dispose of as hazardous waste if necessary.

- Train staff in safe handling practices and emergency procedures.

- Minimize dust and particulate exposure during disassembly or storage.

Conclusion

Managing old Singer sewing machine parts requires careful attention to classification, regulations, and environmental impact. By following this guide, businesses and collectors can ensure legal compliance, promote sustainability, and support responsible waste management practices.

In conclusion, sourcing parts for vintage Singer sewing machines requires patience, resourcefulness, and a strategic approach. Due to the age and discontinuation of many models, original components can be difficult to find, but various options are available to sewing enthusiasts and restorers. Online marketplaces such as eBay, Etsy, and specialized antique sewing machine forums often offer authentic used or NOS (New Old Stock) parts. Additionally, joining communities and networks of collectors can provide valuable leads and expert advice. Reproduction parts and 3D-printed solutions are increasingly viable alternatives for hard-to-find components. When restoring a classic Singer, verifying part compatibility through model numbers and serial codes is essential to ensure proper function. With careful research and the right resources, most vintage Singer sewing machine parts can be sourced, allowing these timeless machines to continue operating for generations to come.