The global industrial sewing machine market is experiencing steady growth, driven by rising demand from the apparel, automotive, and home textiles sectors. According to a report by Mordor Intelligence, the market was valued at approximately USD 4.2 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. Similarly, Grand View Research reports expanding market dynamics due to automation in garment manufacturing and the increasing adoption of energy-efficient, high-speed machines. As industry leaders respond to the call for precision, durability, and smart manufacturing integration, Singer remains a prominent name in the landscape. This list highlights the top 10 Singer industrial sewing machine manufacturers, selected based on production capacity, technological innovation, global market presence, and customer reviews, reflecting companies shaping the future of industrial stitching solutions.

Top 10 Singer Industrial Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 , Commercial & Industrial Sewing Machines Chicago

Domain Est. 2007

Website: singerfactorydistributor.com

Key Highlights: Singer Factory Distributor Regional Sales & Service Center in Chicago offers great prices, award winning service and financing options….

#2 Singer Industrial Sewing Machine Models and Accessories

Domain Est. 1996

Website: ismacs.net

Key Highlights: Comprehensive reference guide to Singer industrial sewing machine models from 1900-1970, featuring specialized machines for manufacturing and their ……

#3 Industrial Sewing Machines, singeronline.com

Domain Est. 1998

Website: singeronline.com

Key Highlights: Free delivery over $35 · 30-day returns…

#4 About Us Company Page

Domain Est. 2000

Website: singermachines.co.uk

Key Highlights: We are singermachines.co.uk, the original Singer Sewing Machine online shop. We are not the manufacturer of Singer sewing machines (SVP Worldwide), nor are we ……

#5 Singer Industrial Sewing Machines

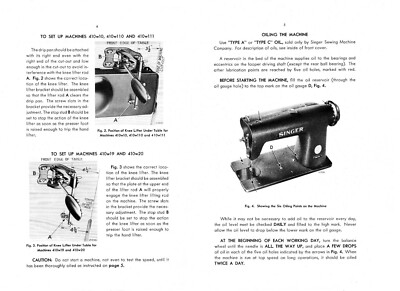

#6 Search Manuals

Domain Est. 1995

Website: support.singer.com

Key Highlights: Get expert support for your Singer, Pfaff, Husqvarna Viking sewing machines. Warranty, Terms & Conditions, Manuals, Machine Updates, and Stitch Guides to ……

#7 Singer Equipment Co.

Domain Est. 1999

Website: singerequipment.com

Key Highlights: From commercial kitchen design and construction to one-stop wholesale supply, Singer delivers a history of success across the foodservice industry….

#8 SINGER Sri Lanka

Domain Est. 1999

Website: singersl.com

Key Highlights: 7-day returnsBuy online and send home appliances and electronics to Sri Lanka and get delivered to your doorstep. An impressive array of products with multi brands to ……

#9 SVP Worldwide

Domain Est. 2006

Website: svpworldwide.com

Key Highlights: Since 1851, SINGER® has been one of the leading brands of consumer and artisan sewing machines, and one of the world’s most trusted and recognizable brands….

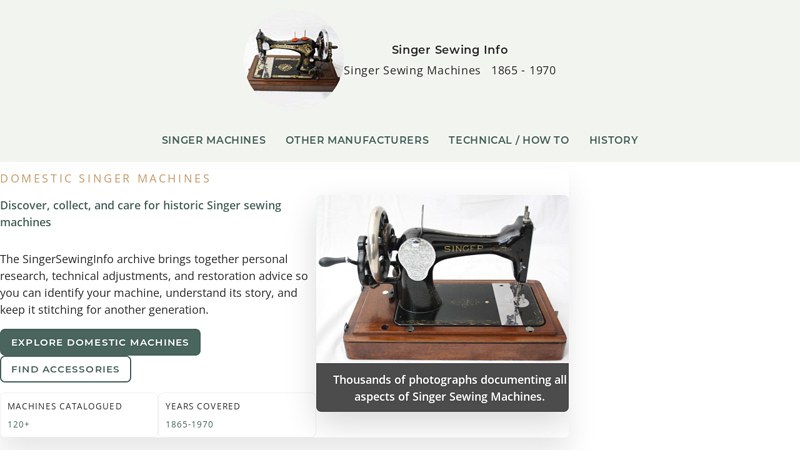

#10 Singer Sewing Info

Domain Est. 2011

Website: singersewinginfo.co.uk

Key Highlights: Singer sewing machine information site for sewing machines incl. 221, 222K. Also covers accessories, Toy sewing machines (TSM)and antique sewing machines….

Expert Sourcing Insights for Singer Industrial Sewing Machine

H2 2026 Market Trends for Singer Industrial Sewing Machines

As we approach the second half of 2026, the industrial sewing machine market—particularly for established brands like Singer—reflects a dynamic landscape shaped by technological innovation, shifting manufacturing demands, and evolving global supply chains. Singer, traditionally known for its strong presence in the home sewing segment, has been strategically expanding its foothold in the industrial sector. Here’s an analysis of key market trends influencing Singer industrial sewing machines during H2 2026:

1. Increased Adoption of Automation and Smart Technology

Singer has accelerated the integration of smart features into its industrial models, such as IoT-enabled machines that monitor performance, predict maintenance needs, and optimize stitch quality in real time. These advancements align with broader industry demands for automation in apparel and textile manufacturing. In H2 2026, factories are increasingly investing in interconnected sewing systems, and Singer’s push toward digitization positions its industrial line as competitive against rivals like Juki and Brother.

2. Surge in Nearshoring and Onshoring Manufacturing

Geopolitical disruptions and supply chain vulnerabilities have driven North American and European apparel brands to bring production closer to home. This trend fuels demand for reliable, mid-tier industrial machines like those offered by Singer. Singer’s cost-effective yet durable machines are gaining traction among small-to-mid-sized manufacturers in the U.S. and EU, especially in fast-fashion and custom apparel segments.

3. Focus on Sustainability and Energy Efficiency

Environmental regulations and corporate ESG goals are influencing equipment procurement. Singer has responded by launching energy-efficient industrial models with reduced noise output and lower power consumption. These eco-friendly features are becoming a key differentiator in H2 2026, particularly in markets with strict environmental standards.

4. Growth in Niche and Customization Markets

There is rising demand for industrial machines capable of handling specialty fabrics (e.g., technical textiles, sustainable materials, and smart fabrics). Singer has introduced modular industrial machines that support quick changeovers and customization, catering to manufacturers in athletic wear, medical textiles, and protective gear industries.

5. Competitive Pricing and After-Sales Support

Singer maintains a competitive edge through aggressive pricing and expanded service networks. In H2 2026, the company has enhanced its technician training programs and launched remote diagnostics support, improving uptime and customer retention—critical factors in industrial purchasing decisions.

6. Challenges from Emerging Market Brands

While Singer benefits from brand recognition, it faces growing competition from Chinese and Indian manufacturers offering lower-cost industrial alternatives. To counter this, Singer is emphasizing reliability, warranty coverage, and compatibility with global spare parts networks.

Conclusion

In H2 2026, Singer industrial sewing machines are successfully navigating a transformative market by leveraging digital innovation, sustainability, and strategic positioning in reshoring economies. While challenges remain, especially in price-sensitive segments, Singer’s focus on smart, serviceable, and adaptable industrial solutions is strengthening its market presence and long-term competitiveness.

Common Pitfalls When Sourcing Singer Industrial Sewing Machines (Quality and Intellectual Property)

Sourcing Singer industrial sewing machines can be beneficial due to the brand’s reputation, but buyers often encounter significant challenges related to quality consistency and intellectual property (IP) misuse. Being aware of these pitfalls is essential to avoid costly mistakes and operational disruptions.

Inconsistent Quality Due to Manufacturing Variability

One of the most frequent issues when sourcing Singer industrial machines is inconsistent product quality. While Singer is a well-known brand, its industrial equipment is often produced under license by third-party manufacturers in various countries. This decentralized production can lead to wide variations in build quality, material standards, and performance. Buyers may receive machines that differ substantially in durability and precision, even within the same model line, impacting production efficiency and increasing maintenance costs.

Misrepresentation of Genuine Singer Products

Another critical pitfall is the prevalence of mislabeled or counterfeit machines. Many suppliers falsely advertise generic industrial sewing machines as authentic Singer products to capitalize on the brand’s credibility. These machines may carry logos or model numbers that resemble genuine Singer equipment but lack the engineering, quality control, and warranty support of true Singer industrial units. Without proper verification, buyers risk investing in substandard equipment that fails prematurely.

Lack of After-Sales Support and Warranty Coverage

Even when sourcing what appears to be a genuine Singer industrial machine, buyers may discover that the warranty is invalid or unsupported in their region. Licensed manufacturers or unauthorized distributors often cannot provide manufacturer-backed service, technical support, or spare parts. This lack of after-sales infrastructure leads to extended downtime and higher total cost of ownership, undermining the initial savings from a lower purchase price.

Intellectual Property Infringement Risks

Purchasing from unauthorized suppliers may expose businesses to intellectual property (IP) risks. Machines that illegally use the Singer name, trademarks, or patented designs violate IP laws. Companies found using or distributing such products—knowingly or not—could face legal action, fines, or reputational damage. Ensuring that the supplier is authorized by the trademark holder (currently SVP Worldwide, which owns the Singer brand) is crucial to avoid IP complications.

Supply Chain Transparency Issues

Many suppliers do not disclose the actual manufacturer or country of origin for Singer-branded industrial machines. This lack of transparency makes it difficult to assess quality standards, compliance with safety regulations, or adherence to ethical manufacturing practices. Without clear supply chain information, businesses cannot conduct proper due diligence or ensure long-term reliability.

Conclusion

To avoid these pitfalls, buyers should verify supplier authorization, request documentation for warranty and origin, inspect machines thoroughly before purchase, and consider sourcing through official distributors or directly from SVP-authorized channels. Due diligence is key to ensuring both product quality and IP compliance when investing in Singer industrial sewing equipment.

Logistics & Compliance Guide for Singer Industrial Sewing Machines

Overview

This guide outlines key logistics considerations and compliance requirements for the international shipping, import, and use of Singer Industrial Sewing Machines. Adhering to these guidelines ensures efficient delivery, regulatory compliance, and safe operation.

Packaging and Handling Requirements

- Secure Packaging: Machines must be shipped in robust, factory-approved crates or cartons with internal bracing to prevent movement during transit.

- Moisture Protection: Use moisture-resistant wrapping or desiccants to prevent corrosion, especially in high-humidity environments.

- Fragile Labeling: Clearly mark packages as “Fragile,” “This Side Up,” and “Do Not Stack” to prevent mishandling.

- Weight and Dimensions: Confirm machine weight and dimensions for accurate freight classification and handling instructions.

Transportation and Shipping

- Freight Classification: Industrial sewing machines typically fall under machinery (Harmonized System code 8452.21 or similar). Accurate classification is essential for customs clearance.

- Mode of Transport: Suitable for road, sea, and air freight. Sea freight is most common for bulk shipments due to cost efficiency.

- Incoterms: Clearly define responsibilities using standard Incoterms (e.g., FOB, CIF, DDP) to allocate costs and risks between buyer and seller.

- Tracking and Documentation: Ensure all shipments include tracking numbers and complete shipping documentation (commercial invoice, packing list, bill of lading/air waybill).

Import and Export Compliance

- Export Licenses: Verify if export licenses are required based on destination country (e.g., embargoed regions). Most industrial sewing machines do not require special licensing under U.S. EAR or similar regulations.

- Customs Documentation:

- Accurate commercial invoice with product description, value, country of origin (typically Vietnam, China, or Thailand for Singer industrial models), and HS code.

- Certificate of Origin, if required by the importing country.

- Import Declaration, as per local customs authority requirements.

- Duties and Taxes: Research applicable import duties, VAT, or GST based on the destination country’s tariff schedule. Use preferential trade agreements where eligible.

Regulatory and Safety Compliance

- Electrical Standards: Ensure machines comply with voltage and frequency standards of the destination country (e.g., 110V/60Hz in North America, 220–240V/50Hz in Europe). Include adapters or specify motor compatibility.

- CE Marking: Required for entry into the European Economic Area (EEA), indicating conformity with health, safety, and environmental protection standards.

- UL/CSA Certification: Required for sale in the United States and Canada. Verify compliance with UL 1563 (Standard for Electric Sewing Machines).

- RoHS Compliance: Confirm that electrical components comply with Restriction of Hazardous Substances directives (EU and similar regulations).

- EMC Compliance: Ensure electromagnetic compatibility to prevent interference with other devices (required under EU EMC Directive).

Installation and Operational Compliance

- User Manuals: Provide manuals in the local language of the destination country, including safety instructions, maintenance schedules, and troubleshooting.

- Training Requirements: Recommend operator training to ensure safe and efficient use, particularly in industrial environments.

- Warranty and Service Support: Confirm availability of local service centers or technical support for repairs and spare parts.

Environmental and Disposal Regulations

- WEEE Compliance (EU): Industrial sewing machines may fall under Waste Electrical and Electronic Equipment directives. Provide information on proper disposal and recycling.

- Battery and Oil Handling: If applicable, ensure compliance with regulations for lubricants or backup batteries (e.g., proper disposal under local environmental laws).

Record Keeping and Audits

- Maintain records of shipping documents, compliance certificates, and import/export filings for a minimum of 5–7 years, depending on jurisdiction.

- Conduct periodic audits to ensure ongoing compliance with evolving trade and safety regulations.

Contact and Support

For compliance inquiries or logistics support, contact Singer Industrial Customer Service or your authorized distributor with product model number and region of operation.

Conclusion for Sourcing Singer Industrial Sewing Machines

Sourcing Singer industrial sewing machines presents a reliable and cost-effective solution for manufacturers and garment businesses seeking durable, high-performance equipment. Singer’s long-standing reputation for quality, innovation, and global support makes its industrial models a trusted choice in the textile and apparel industry. These machines are engineered for heavy-duty use, offering consistency, precision, and efficiency in high-volume production environments.

When sourcing, it is essential to consider factors such as production needs, machine specifications, availability of spare parts, after-sales service, and warranty options. Purchasing through authorized distributors or directly from Singer ensures authenticity, technical support, and access to training resources. Additionally, comparing pricing, lead times, and shipping logistics will help optimize procurement decisions.

In conclusion, investing in Singer industrial sewing machines supports long-term operational efficiency and product quality. With the right sourcing strategy, businesses can leverage Singer’s proven technology and global service network to enhance productivity and maintain a competitive edge in the market.