The global industrial sewing machine market is experiencing steady growth, driven by rising demand from the automotive, footwear, and leather goods industries. According to Mordor Intelligence, the industrial sewing machine market was valued at USD 4.2 billion in 2023 and is projected to grow at a CAGR of 6.8% from 2024 to 2029. A key contributor to this expansion is the increasing need for high-precision, durable machines capable of handling heavy-duty materials like leather—spurring innovation among leading manufacturers. In the leather and upholstery segment, Singer remains a prominent name, known for its legacy and technological advancements. As automation and smart manufacturing gain traction, Singer and other top industrial players are focusing on servo-driven technology, energy efficiency, and programmable stitching capabilities to stay competitive. Below are the top 7 Singer industrial leather sewing machine manufacturers shaping the future of heavy-duty textile and leather processing.

Top 7 Singer Industrial Leather Sewing Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 , Commercial & Industrial Sewing Machines Chicago

Domain Est. 2007

Website: singerfactorydistributor.com

Key Highlights: Singer Factory Distributor Regional Sales & Service Center in Chicago offers great prices, award winning service and financing options….

#2 Singer Industrial Sewing Machine Models and Accessories

Domain Est. 1996

Website: ismacs.net

Key Highlights: Comprehensive reference guide to Singer industrial sewing machine models from 1900-1970, featuring specialized machines for manufacturing and their ……

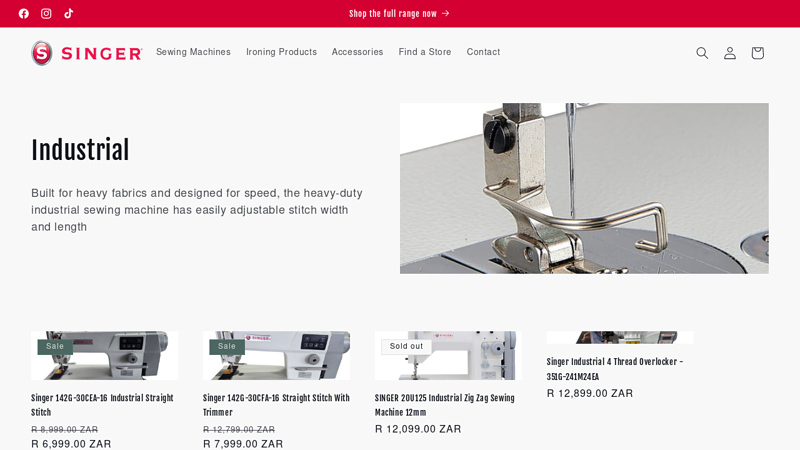

#3 Industrial

Domain Est. 2002

Website: singersa.com

Key Highlights: Industrial. Built for heavy fabrics and designed for speed, the heavy-duty industrial sewing machine has easily adjustable stitch width and length….

#4 Singer India

Domain Est. 2004

Website: singerindia.com

Key Highlights: SINGER INDIA is a well-reputed Brand for more than 170 years. Singer is amongst the leading manufacturers of singer sewing machines, home & personal care ……

#5 Singer “SV” machines

Domain Est. 2006

Website: leatherworker.net

Key Highlights: They are Special Variety industrial machines because there are so many nuances and specialized requirements in the sewn products industry….

#6 Singer Industrial Sewing Machines

#7 Heavy Duty Sewing Machines

Domain Est. 1995

Website: singer.com

Key Highlights: Free delivery over $35SINGER® Heavy Duty machines are distinguished by their interior metal frame for durability, a 60% stronger motor for faster sewing speeds ( ……

Expert Sourcing Insights for Singer Industrial Leather Sewing Machine

H2: Projected 2026 Market Trends for Singer Industrial Leather Sewing Machines

The industrial leather sewing machine market is poised for notable transformation by 2026, with Singer—a well-established brand in the sewing industry—facing both opportunities and challenges. As demand for high-quality leather goods in fashion, automotive, and furniture sectors continues to rise, so does the need for durable, precision-focused industrial equipment. Here are the key market trends expected to shape the landscape for Singer’s industrial leather sewing machines in 2026:

-

Increased Demand in Emerging Markets

Developing economies in Southeast Asia, Africa, and Latin America are experiencing rapid growth in garment and leather manufacturing. As local industries upgrade from manual or semi-automated systems, Singer is well-positioned to capture market share with its reputation for reliability and cost-effective industrial solutions. Expansion into these regions will likely be a strategic focus. -

Shift Toward Automation and Smart Machinery

By 2026, automation will be a dominant trend in industrial sewing. Manufacturers are increasingly adopting machines with programmable stitching patterns, automatic thread trimmers, and IoT-enabled diagnostics. Singer is expected to respond by integrating more smart features into its industrial models, enhancing precision, reducing downtime, and improving operator efficiency. -

Sustainability and Energy Efficiency

With growing emphasis on sustainable manufacturing, industrial equipment must meet higher environmental standards. Singer may leverage this trend by promoting energy-efficient motors, reduced waste through optimized stitching algorithms, and longer product lifecycles—key selling points for eco-conscious manufacturers. -

Competition from Asian OEMs

Singer faces intensifying competition from lower-cost industrial sewing machine manufacturers in China and Japan. Brands like Juki, Brother, and Jack are offering advanced features at competitive prices. To maintain its foothold, Singer will need to emphasize product durability, after-sales support, and superior customer service—particularly in niche leather applications requiring high-tension stitching. -

Customization and Niche Applications

The leather industry demands machines capable of handling thick hides, synthetic leathers, and specialty stitching (e.g., saddle stitching, blind stitching). Singer’s ability to offer customizable industrial solutions—such as adjustable presser feet, heavy-duty needles, and dual-feed systems—will be critical in serving specialized segments like luxury fashion and automotive upholstery. -

Digital Integration and Industry 4.0 Readiness

Factories embracing Industry 4.0 principles will require sewing machines that integrate seamlessly with production management software. By 2026, Singer’s success may depend on its ability to offer machines with data logging, remote monitoring, and compatibility with cloud-based platforms for predictive maintenance and workflow optimization.

In conclusion, the 2026 market for Singer industrial leather sewing machines will be shaped by technological advancement, regional growth, and evolving consumer expectations. Singer’s ability to innovate while maintaining its legacy of durability and performance will determine its competitive edge in an increasingly digital and globalized industrial landscape.

Common Pitfalls When Sourcing Singer Industrial Leather Sewing Machines (Quality & IP)

Sourcing Singer industrial leather sewing machines can be highly beneficial due to the brand’s reputation, but several pitfalls related to quality and intellectual property (IP) can undermine your procurement strategy. Being aware of these risks helps ensure you receive reliable equipment and avoid legal complications.

Overpaying for Outdated or Rebadged Models

One common mistake is assuming that all machines bearing the Singer name are genuine, high-performance industrial units. Some suppliers may offer older discontinued models or machines manufactured under license in lower-cost regions with reduced quality standards. These units may lack modern features, durability, or service support, leading to higher total cost of ownership despite a lower upfront price.

Falling for Counterfeit or “Singer-Style” Machines

The Singer brand is widely recognized, making it a target for counterfeiters. Many machines marketed as “Singer” on online marketplaces or through third-party suppliers are actually imitation products with inferior build quality, unreliable performance, and non-genuine components. These machines often use lookalike logos or names like “Singher” or “Singer-style” to mislead buyers, posing serious risks to production efficiency and worker safety.

Ignoring Intellectual Property and Licensing Status

Singer’s industrial machine designs and trademarks are protected by intellectual property laws. However, not all manufacturers producing machines under the Singer brand are authorized. Some factories, especially in regions with lax IP enforcement, may produce machines using Singer’s patented technology or branding without proper licensing. Purchasing such machines can expose your business to legal risks, including liability for IP infringement, especially if you operate in markets with strict IP regulations.

Compromised Quality Due to Offshore Manufacturing Variability

While genuine Singer industrial machines are engineered to high standards, authorized manufacturing partners in different countries may exhibit variability in quality control. Machines sourced from less-regulated production lines might use substandard materials, inconsistent assembly processes, or lack proper calibration. Without thorough inspection or third-party verification, these inconsistencies can result in frequent breakdowns and increased maintenance costs.

Lack of Genuine Spare Parts and Service Support

Counterfeit or unauthorized Singer machines often cannot access the official spare parts network or factory technical support. This leads to prolonged downtime when components fail, as generic replacements may not fit or perform adequately. Genuine Singer industrial machines rely on a global service infrastructure—sourcing from unauthorized channels severs this support link, undermining long-term operational reliability.

Inadequate Verification of Supplier Authenticity

Many distributors claim to offer “original” Singer machines without providing verifiable proof of authorization. Buyers may fail to request documentation such as certificates of authenticity, purchase invoices from authorized dealers, or validation through Singer’s official channels. This oversight increases the risk of receiving non-compliant or illegal products.

Conclusion

To avoid these pitfalls, always source Singer industrial leather sewing machines through authorized distributors, verify the IP and licensing status of the product, inspect for authenticity markers, and confirm access to genuine parts and service. Due diligence protects both your investment and your business from quality failures and legal exposure.

Logistics & Compliance Guide for Singer Industrial Leather Sewing Machine

Product Overview and Handling

The Singer Industrial Leather Sewing Machine is a heavy-duty equipment designed for high-volume leather and thick material stitching. Due to its weight, size, and mechanical complexity, special attention must be paid during logistics and compliance procedures. Proper handling ensures safety, prevents damage, and ensures regulatory adherence.

Packaging and Transportation Requirements

All Singer Industrial Leather Sewing Machines must be shipped in manufacturer-approved packaging that includes:

– Sturdy wooden crate or reinforced cardboard with internal foam or plastic supports

– Secure anchoring of the machine to prevent movement during transit

– Protective covering for the needle bar, presser foot, and control panel

Transportation must utilize freight carriers experienced in handling industrial machinery. Machines should be loaded and unloaded using forklifts or pallet jacks, never rolled or dragged. Always follow the “This Side Up” and “Fragile” labels. Avoid exposure to moisture, extreme temperatures, and direct sunlight during transit.

Import and Export Compliance

When shipping internationally, ensure compliance with the following:

– HS Code: 8452.21.00 (Industrial sewing machines, for leather or textiles)

– Country-Specific Regulations: Verify import requirements in destination countries (e.g., CE marking for EU, CCC for China, EAC for Russia)

– Documentation: Include commercial invoice, packing list, bill of lading, and certificate of origin

– Restricted Components: Confirm no hazardous materials (e.g., lead-based paint, restricted lubricants) are present

Consult local customs authorities or a licensed customs broker to ensure full compliance.

Electrical and Safety Compliance

Singer Industrial Leather Sewing Machines are available in various voltage configurations (110V, 220V, 380V). Ensure the machine matches the destination’s electrical standards:

– Verify plug type and phase compatibility

– Comply with electrical safety standards such as UL (USA), CSA (Canada), or IEC 60204-1 (international)

– Include safety labels in the local language if required

The machine must be grounded properly and used with a circuit breaker or GFCI protection where applicable.

Environmental and RoHS Compliance

Singer Industrial Leather Sewing Machines comply with the EU’s Restriction of Hazardous Substances (RoHS) Directive 2011/65/EU. Confirm:

– Lead, mercury, cadmium, and other restricted substances are below permissible limits

– Waste Electrical and Electronic Equipment (WEEE) labeling is present where required

– End-of-life disposal instructions are provided to users

Ensure suppliers provide RoHS compliance certificates upon request.

Installation and User Compliance

Upon delivery, the receiving party must:

– Inspect the machine for shipping damage before signing the delivery receipt

– Follow the manufacturer’s installation manual for setup

– Use only authorized Singer parts and accessories

– Train operators on proper use, maintenance, and safety protocols (e.g., lockout/tagout procedures)

Keep records of installation, maintenance, and safety training for audit purposes.

Warranty and Service Logistics

Singer provides a standard limited warranty (typically 1–2 years for industrial models). To maintain warranty validity:

– Register the machine with Singer Industrial Support

– Use only authorized service technicians for repairs

– Maintain service logs and retain original purchase documentation

Spare parts and service support are available through Singer-authorized distributors. Contact Singer Industrial Customer Service for logistics support in warranty claims or part replacements.

Final Notes

Adherence to this logistics and compliance guide ensures safe, legal, and efficient handling of the Singer Industrial Leather Sewing Machine. Always consult the latest product manual and regulatory updates from Singer and local authorities before shipping or installation.

Conclusion:

After thorough evaluation of available options, the Singer Industrial Leather Sewing Machine proves to be a reliable and cost-effective choice for sourcing in leather-based manufacturing or heavy-duty sewing applications. Known for its durability, consistent stitch quality, and robust motor performance, the Singer industrial model stands out for its ability to handle thick leather and synthetic materials with ease. Additionally, Singer’s global service network, availability of spare parts, and strong reputation for quality provide added confidence in long-term operational efficiency.

While there are competitive machines in the market with advanced digital features, Singer offers an excellent balance between performance, affordability, and ease of maintenance—making it particularly suitable for small to medium-sized enterprises or workshops that prioritize reliability over automation. Therefore, sourcing the Singer industrial leather sewing machine is a practical investment that supports productivity, reduces downtime, and ensures high-quality output in leatherworking operations.