The global silicone filament market is experiencing robust growth, driven by increasing demand across industries such as healthcare, electronics, and industrial manufacturing. According to Mordor Intelligence, the global silicone resins market—closely aligned with silicone-based 3D printing materials—is projected to grow at a CAGR of over 5.8% from 2023 to 2028, fueled by advancements in additive manufacturing and the material’s superior thermal stability, flexibility, and chemical resistance. Parallel insights from Grand View Research indicate that the broader silicone materials market is expected to expand at a CAGR of 4.8% from 2023 to 2030, underpinned by rising adoption in high-performance applications. As 3D printing continues to evolve beyond prototyping into end-part production, silicone filament has emerged as a critical material for creating durable, flexible, and biocompatible components. This growing demand has spurred innovation among manufacturers, positioning several key players at the forefront of silicone filament development. Below, we spotlight the top 10 silicone filament manufacturers leading this transformation through technological expertise, product quality, and market reach.

Top 10 Silicone Filament Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Industrial 3D Printing Materials and Resins

Domain Est. 1996

Website: 3dsystems.com

Key Highlights: Partner with 3D Systems’ Application Innovation Group to transform your ideas into reality with cutting-edge 3D printing and tailored manufacturing solutions….

#2 Siraya Tech 3D Printing UV Resin for Elegoo,Anycubic & SLA 3d …

Domain Est. 2019

Website: siraya.tech

Key Highlights: Free delivery 30-day returnsSiraya Tech: Leading manufacturer of high-performance UV resins and platinum silicones for best 3D printing. Specializing in engineering-grade UV resins…

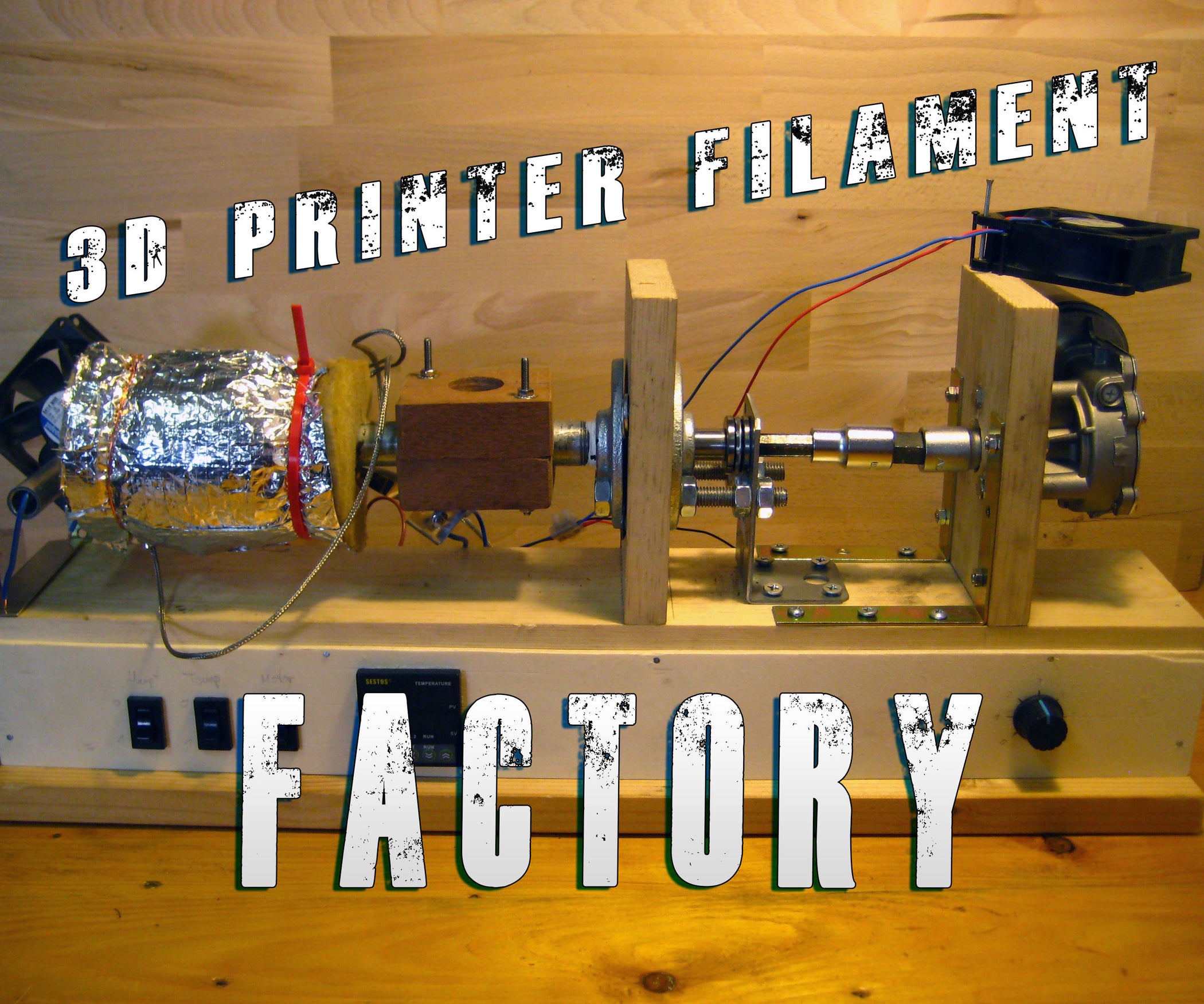

#3 3D printer filament

Domain Est. 2004

#4 High

Domain Est. 2012

#5 Polymaker

Domain Est. 2013

Website: polymaker.com

Key Highlights: Polymaker is an international team passionate about 3D printing. We produce the very best 3D printing materials by controlling every stage of production….

#6 Top 3D Printing Service and Additive Manufacturing

Domain Est. 2013

Website: carbon3d.com

Key Highlights: From rapid prototyping to end-use parts, the Carbon Digital Light Synthesis Process is the dream of Additive Manufacturing realized….

#7 ZYLtech Engineering LLC

Domain Est. 2015

#8 Spectrum Filaments

Domain Est. 2015

Website: spectrumfilaments.com

Key Highlights: Spectrum Filaments to firma specjalizująca się w produkcji materiałów do druku 3D wykorzystywanych w drukarkach 3D klasy FDM / FFF….

#9 Flexible 3D Printing Filament

Domain Est. 2019

Website: bambulab.com

Key Highlights: Free delivery · 14-day returnsExplore Bambu Lab’s flexible 3D printing filaments. Perfect for soft and bendable prints. Shop now and discover the best flexible filaments….

#10 Filament2

Domain Est. 2024

Website: filament2.com

Key Highlights: Filament2 makes Liquid Filaments for standard FDM printers, enabling silicone 3D printing that is fast, clean, and reliable for prototypes and production….

Expert Sourcing Insights for Silicone Filament

H2: 2026 Market Trends for Silicone Filament

By 2026, the silicone filament market is poised for significant transformation, driven by technological advancements, expanding applications, and evolving industrial demands. Key trends shaping the landscape include:

1. Accelerated Adoption in Healthcare and Wearables

Silicone filament will see robust growth in medical and wearable technology sectors due to its biocompatibility, flexibility, and skin-safe properties. By 2026, expect increased use in:

– Custom prosthetics and orthotics with patient-specific designs enabled by 3D printing.

– Soft robotics for rehabilitation devices and minimally invasive surgical tools.

– Smart wearable sensors for health monitoring, leveraging silicone’s durability and comfort.

2. Innovation in Material Formulations

Manufacturers will focus on enhancing material performance through:

– Hybrid composites combining silicone with conductive fillers (e.g., graphene or carbon nanotubes) for integrated electronics.

– Improved thermal and UV resistance for outdoor and industrial applications.

– Faster-curing and higher-resolution formulations compatible with advanced extrusion-based 3D printers.

3. Expansion in Industrial and Automotive Applications

The automotive and aerospace industries will adopt silicone filament for rapid prototyping and end-use parts requiring:

– High-temperature resistance (e.g., gaskets, seals, and under-hood components).

– Vibration damping and noise reduction.

– Lightweight, customizable solutions that reduce production lead times.

4. Growth of Desktop and Industrial 3D Printing Ecosystem

As 3D printer manufacturers develop better support for flexible materials, accessibility will increase. By 2026:

– More desktop printers will offer reliable silicone printing capabilities.

– Industrial additive manufacturing platforms will integrate silicone into multi-material workflows.

– Open-source communities and CAD software will expand design libraries for silicone-based parts.

5. Sustainability and Circular Economy Initiatives

Environmental concerns will drive:

– Development of bio-based or recyclable silicone filaments.

– Closed-loop recycling programs for silicone waste in manufacturing.

– Regulatory pressure and consumer demand for eco-friendly materials in consumer goods.

6. Regional Market Expansion

Asia-Pacific will emerge as a key growth region due to:

– Rising investments in additive manufacturing in China, Japan, and South Korea.

– Strong electronics and automotive manufacturing bases.

– Government support for advanced materials R&D.

In conclusion, the 2026 silicone filament market will be characterized by deeper integration into high-value industries, enhanced material performance, and broader accessibility—positioning it as a critical enabler of next-generation 3D printed solutions.

Common Pitfalls When Sourcing Silicone Filament (Quality & IP)

Sourcing silicone filament for 3D printing presents unique challenges due to its emerging nature and specialized properties. Buyers often encounter significant pitfalls related to quality inconsistencies and intellectual property (IP) concerns. Understanding these issues is critical to ensuring reliable supply, product performance, and legal compliance.

Quality-Related Pitfalls

1. Inconsistent Material Composition and Performance

Silicone filaments vary widely in base polymer formulation, filler content (e.g., silica), and additives. Poorly sourced materials may exhibit batch-to-batch variability in flexibility, thermal stability, and printability. This inconsistency can lead to failed prints, dimensional inaccuracies, or compromised mechanical properties in end-use parts.

2. Poor Printability and Processing Issues

Low-quality filaments often suffer from inconsistent diameter tolerances, poor surface finish, or inadequate thermal behavior. These flaws result in nozzle clogging, stringing, warping, or delamination during printing—especially problematic given silicone’s already challenging extrusion requirements.

3. Lack of Certification and Testing Data

Many suppliers, especially smaller or offshore manufacturers, fail to provide comprehensive technical data sheets (TDS), biocompatibility certifications (e.g., USP Class VI), or flame resistance ratings (e.g., UL 94). Without these, verifying suitability for medical, automotive, or consumer applications becomes risky.

4. Substandard Curing and Post-Processing Requirements

High-performance silicone prints often require post-curing (e.g., thermal or UV) to achieve final properties. Low-quality filaments may not fully cure or may degrade during this process, resulting in weak or unstable parts. Suppliers may not clearly disclose or support required post-processing steps.

Intellectual Property (IP) Pitfalls

1. Risk of Infringing Patented Formulations

Several companies hold patents on specific silicone filament chemistries, extrusion methods, or curing processes (e.g., Wacker Chemie, Dow, or specialized 3D printing material developers). Sourcing generic or unbranded filaments from unknown manufacturers increases the risk of using IP-protected formulations without licensing, exposing buyers to legal liability.

2. Unverified “White-Label” or Repackaged Materials

Many suppliers sell rebranded silicone filament with unclear origins. These products may falsely claim compatibility or performance based on copied specifications, hiding the true manufacturer and potentially infringing on trademarks or patented material systems.

3. Lack of Transparency in Supply Chain

Opaque supply chains make it difficult to trace material origin or verify IP compliance. Buyers may inadvertently support suppliers using reverse-engineered or pirated formulations, jeopardizing not only legal standing but also product reliability.

4. Misleading Marketing and Performance Claims

Some vendors exaggerate properties such as elongation at break, temperature resistance, or chemical stability—claims that may be derived from IP-protected benchmark studies rather than actual testing of their own product. This misrepresentation complicates due diligence and validation.

Mitigation Strategies

- Demand full material traceability and compliance documentation (e.g., CoA, RoHS, REACH, patent licenses).

- Engage only with reputable suppliers that openly disclose manufacturing processes and IP status.

- Conduct independent material testing before scaling production.

- Consult legal counsel to assess IP risks, especially for commercial or medical applications.

Avoiding these pitfalls requires diligence in supplier vetting, material validation, and IP awareness—ensuring both performance integrity and legal safety in silicone filament sourcing.

Logistics & Compliance Guide for Silicone Filament

Introduction

Silicone filament, a flexible 3D printing material known for its heat resistance, elasticity, and biocompatibility, requires specialized handling and regulatory oversight throughout the supply chain. This guide outlines critical logistics and compliance considerations for the safe and legal transportation, storage, and use of silicone filament in industrial and commercial applications.

Classification & Hazard Identification

Silicone filament is typically non-toxic and non-hazardous in its solid, ready-to-print form. However, classification depends on formulation and additives. Most formulations fall under non-regulated materials for transport under UN and IATA standards when unprocessed. Always verify the Safety Data Sheet (SDS) to confirm classification. If containing flammable solvents or reactive components, classification may shift to hazardous goods (e.g., Class 9 – Miscellaneous Dangerous Goods).

Regulatory Compliance

Ensure compliance with regional and international regulations:

– REACH (EU): Register all chemical substances above 1 ton/year; provide SVHC (Substances of Very High Concern) disclosure if applicable.

– RoHS (EU & Global): Confirm absence of restricted substances (e.g., lead, cadmium, phthalates) especially in filaments intended for consumer electronics or medical devices.

– FDA (USA): Required if filament is marketed for food-contact or medical applications. Use only FDA-compliant grades (e.g., USP Class VI or NSF-51 certified).

– Proposition 65 (California): Label products containing listed carcinogens or reproductive toxins.

Packaging & Labeling

Use moisture-resistant, sealed packaging (e.g., vacuum-sealed bags with desiccants) to prevent humidity absorption, which degrades print quality. Outer packaging must include:

– Product name and batch/lot number

– Manufacturer or supplier details

– Storage conditions (e.g., “Store in a cool, dry place”)

– Compliance marks (e.g., CE, RoHS)

– SDS reference or QR code linking to safety documentation

Transportation & Shipping

Silicone filament is generally classified as non-hazardous for transport when in solid form and properly packaged. However:

– Use durable, crush-resistant boxes to prevent spool deformation.

– Avoid extreme temperatures during transit; prolonged exposure above 40°C (104°F) may cause premature curing or deformation.

– For international shipments, provide commercial invoices with accurate HS codes (typically 3916.20 or 3916.90 for plastic rods/shape stock).

– Declare material composition clearly to avoid customs delays.

Storage Conditions

Store in a climate-controlled environment:

– Temperature: 15–25°C (59–77°F)

– Humidity: Below 50% RH

– Keep away from direct sunlight and UV exposure to prevent degradation

– Rotate stock using FIFO (First In, First Out) to prevent aging

Handling & Worker Safety

While low-risk, best practices include:

– Use nitrile gloves when handling to avoid skin oils transferring to filament

– Wear safety glasses if cutting or machining printed parts

– Ensure adequate ventilation in printing areas; avoid inhalation of fumes during high-temperature extrusion

– Follow SDS guidelines for first aid and spill response (rare, but wipe up with dry cloth if debris occurs)

End-of-Life & Environmental Compliance

Silicone is not biodegradable but can be incinerated safely at high temperatures with proper emission controls. Recycling options are limited; consult specialized polymer recyclers. Comply with local waste disposal regulations (e.g., WEEE, EPA guidelines). Encourage take-back programs or industrial reuse where feasible.

Documentation & Traceability

Maintain full traceability through:

– Batch-specific SDS and Certificates of Analysis (CoA)

– Regulatory compliance documentation (REACH, RoHS, FDA)

– Shipping records with temperature logs if applicable

– Supplier audits to ensure upstream compliance

Conclusion

Effective logistics and compliance management for silicone filament ensures product integrity, regulatory adherence, and operational safety. Always consult the manufacturer’s specifications and update procedures in line with evolving chemical and transportation regulations. Regular training for logistics and procurement teams is recommended to maintain compliance across the supply chain.

Conclusion for Sourcing Silicone Filament

Sourcing silicone filament requires careful consideration of material quality, supplier reliability, technical specifications, and application requirements. Due to its unique properties—such as high flexibility, thermal resistance, and biocompatibility—silicone filament is ideal for specialized applications in industries like healthcare, automotive, and consumer goods. However, its availability is more limited compared to conventional 3D printing materials, and not all filament manufacturers produce true silicone-based filaments (some offer silicone-infused TPE/TPU blends instead).

To ensure successful integration into manufacturing or prototyping processes, it is crucial to partner with reputable suppliers who provide verifiable material data sheets (MDS), consistent batch quality, and technical support. Evaluating factors such as elongation at break, Shore hardness, printability, and post-processing needs will further aid in selecting the right product. Additionally, considering regional supply chain resilience, lead times, and customization options can enhance long-term sourcing sustainability.

In conclusion, while sourcing genuine silicone filament presents challenges, a strategic and informed procurement approach—grounded in technical due diligence and supplier vetting—enables organizations to leverage the full advantages of this advanced material for innovative and high-performance applications.