The global suppressor (silencer) market has seen steady expansion, driven by rising demand from defense, law enforcement, and civilian shooting sectors. According to a 2023 report by Mordor Intelligence, the global firearm silencer market was valued at USD 492.4 million in 2022 and is projected to grow at a CAGR of over 7.5% from 2023 to 2028. This growth is fueled by increased military modernization programs, expanded civilian firearm ownership, and technological advancements in noise suppression systems—fueling demand for high-performance silencer mounting solutions. As suppressors become more widely adopted, the reliability, durability, and quick-deploy capabilities of silencer mounts have become critical performance differentiators. With companies investing in advanced materials like titanium and hardened steel, and adopting modular designs for enhanced compatibility, the competitive landscape among silencer mount manufacturers is intensifying. The following list highlights the top nine manufacturers leading innovation, precision engineering, and market presence in the silencer mounting ecosystem.

Top 9 Silencer Mounts Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Manufacturer of High Quality Suppressors & Firearm Accessories

Domain Est. 2012

Website: wittmachine.net

Key Highlights: Manufacturer of High Quality Suppressors & Firearm Accessories, Witt Machine. … The Big Body Tu-Tu-Three Ultra Compact Suppressor $299….

#2 YHM Suppressors

Domain Est. 2000

Website: yhm.net

Key Highlights: YHM suppressors deliver industry-leading sound reduction, superior durability, and versatile mounting options across multiple firearms platforms….

#3 SilencerCo Suppressors

Domain Est. 2007

Website: silencerco.com

Key Highlights: Here’s How To Mount It. Here’s the breakdown on how to mount your new silencer, from checking barrel threads to finding the right mounting system….

#4 Griffin Armament

Domain Est. 2007 | Founded: 2005

Website: griffinarmament.com

Key Highlights: ENGINEERED SILENCE – Since 2005, Griffin Armament has been manufacturing high quality sound suppressors, firearms, and accessories….

#5 Allen Arms Tactical

Domain Est. 2010

Website: allenarmstactical.com

Key Highlights: Allen Arms Tactical is centered on NFA Distribution (commonly called ‘Class 3’). While specializing in silencers, mounts and accessories we also carry Daniel ……

#6 Dead Air Silencers

Domain Est. 2014

Website: deadairsilencers.com

Key Highlights: Engineered for precision and durability, our rifle silencers reduce noise and recoil, delivering exceptional performance for every shot….

#7 Rugged Suppressors

Domain Est. 2014

Website: ruggedsuppressors.com

Key Highlights: Our suppressors are machined from top of the line materials to not only last a lifetime, but withstand any rate of fire….

#8 Silencer Central: Shop Suppressors Online

Domain Est. 2018

Website: silencercentral.com

Key Highlights: Silencer Central is the easiest way to own a suppressor, handling everything from product recommendations and ATF paperwork to delivery at your front door….

#9 Otter Creek Labs

Domain Est. 2021

Website: ottercreeklabs.com

Key Highlights: OTTER CREEK LABS LLC · Mounts & Muzzle Devices · SILENCERS · MERCH · UPGRADE….

Expert Sourcing Insights for Silencer Mounts

H2: Market Trends for Silencer Mounts in 2026

The global silencer mounts market is poised for significant transformation by 2026, driven by technological advancements, increasing demand from defense and civilian sectors, and evolving regulatory landscapes. As a critical component in firearm sound suppression systems, silencer mounts ensure secure attachment between suppressors and firearms, directly impacting performance, accuracy, and user safety. Below is an analysis of key market trends expected to shape the silencer mounts industry in 2026:

1. Rising Demand in Civilian and Law Enforcement Markets

The civilian firearms market, particularly in North America, continues to expand due to growing interest in recreational shooting, hunting, and personal defense. This trend is fueling demand for high-performance suppressor systems, which in turn increases the need for reliable silencer mounts. Simultaneously, law enforcement agencies are increasingly adopting suppressors for tactical operations to reduce auditory risk and improve communication—further boosting the need for durable, quick-detach (QD) silencer mount solutions.

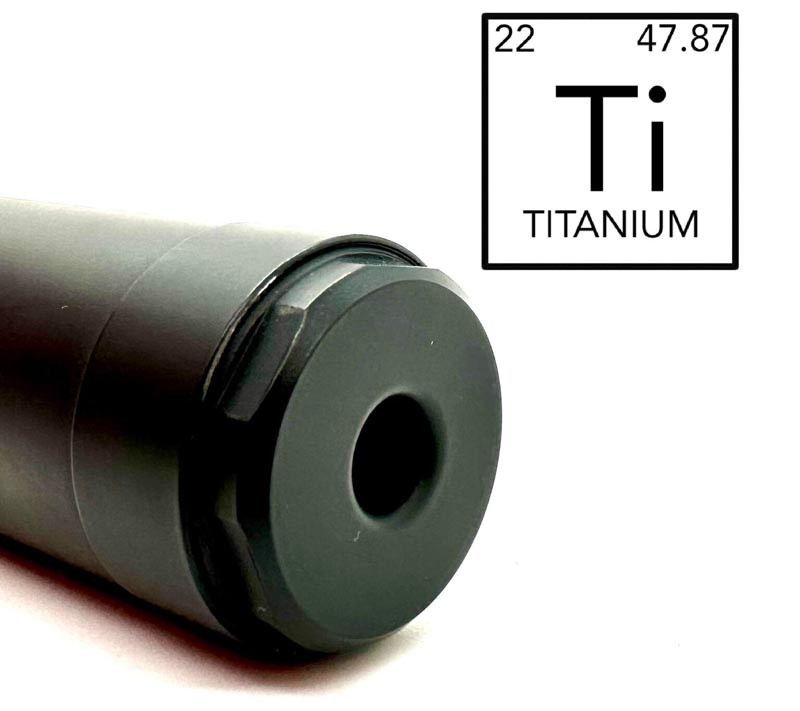

2. Technological Innovation and Material Advancements

By 2026, manufacturers are expected to prioritize innovation in materials and design. The use of advanced alloys such as titanium and high-grade stainless steel is becoming more common, offering improved heat resistance, corrosion protection, and weight reduction. Additionally, precision engineering via CNC machining and modular designs—such as those compatible with multiple thread patterns (e.g., 1/2×28, 5/8×24)—will enhance versatility across firearm platforms.

3. Growth in Direct Thread and Quick-Detach (QD) Mounts

QD silencer mounts are gaining popularity due to their ease of use and rapid deployment, especially among tactical users and competitive shooters. The market will likely see increased adoption of patented QD systems (e.g., Nielsen devices, muzzle brake-integrated mounts) that provide consistent alignment and reduced point-of-impact shift. However, direct-thread mounts will maintain strong demand due to their cost-effectiveness and reliability in civilian applications.

4. Regulatory Environment and Standardization

Regulatory frameworks, particularly in the U.S. under the National Firearms Act (NFA), continue to influence market dynamics. Although suppressor ownership remains tightly controlled, ongoing legislative efforts to deregulate or streamline suppressor acquisition—such as the proposed Hearing Protection Act—could significantly expand the consumer base by 2026. This would likely drive demand for standardized, ATF-compliant silencer mounts.

5. Expansion in International Markets

While North America dominates the current market, Europe and the Asia-Pacific region are expected to see growth due to rising defense spending and increasing civilian firearm ownership in select countries. This expansion will necessitate region-specific silencer mount designs that comply with local firearm standards and threading conventions.

6. Integration with Smart Firearm Technologies

Emerging smart gun technologies and digital shooting ecosystems may lead to integrated suppressor systems with performance feedback. While still in early stages, silencer mounts could evolve to include sensors or alignment calibration features, especially in high-end tactical or competitive shooting markets.

7. Sustainability and Manufacturing Localization

Environmental concerns and supply chain resilience are prompting manufacturers to explore sustainable production methods and localized manufacturing. By 2026, companies may increasingly adopt green machining practices and reshoring strategies to reduce lead times and tariff exposure—especially in the U.S. and EU markets.

Conclusion

The silencer mounts market in 2026 will be characterized by innovation, diversification, and regulatory sensitivity. As demand grows across civilian, law enforcement, and military sectors, manufacturers that invest in high-quality materials, modular designs, and compliance-ready solutions will be best positioned to capture market share. The trend toward QD systems, combined with the potential for regulatory liberalization, suggests a robust growth trajectory for the silencer mounts industry over the coming years.

Common Pitfalls Sourcing Silencer Mounts: Quality and Intellectual Property (IP) Concerns

Sourcing silencer mounts—critical components that attach suppressors to firearms—can be fraught with risks, particularly concerning quality control and intellectual property (IP) violations. Avoiding these pitfalls is essential for ensuring performance, safety, and legal compliance.

Poor Quality Control and Material Deficiencies

One of the most significant risks when sourcing silencer mounts is inconsistent or substandard quality, especially with overseas or uncertified manufacturers. Low-quality mounts may be made from inferior materials such as sub-grade steel or aluminum alloys, leading to premature wear, thread stripping, or catastrophic failure under repeated firing. Poor machining tolerances can result in misalignment between the suppressor and barrel, negatively impacting accuracy and potentially damaging the host firearm. Additionally, inadequate heat treatment or improper threading can compromise the mount’s ability to withstand high-pressure environments. Without proper quality assurance processes like ISO certification or in-house testing, buyers risk receiving components that fail in the field, endangering users and damaging reputations.

Intellectual Property (IP) Infringement and Counterfeit Designs

Another major pitfall is the risk of sourcing silencer mounts that infringe on protected intellectual property. Many reputable manufacturers hold patents or trademarks on proprietary mounting systems (e.g., ASR, Ultra, or muzzle device-specific designs). Sourcing from suppliers offering look-alike or reverse-engineered products may expose the buyer to legal liability, including cease-and-desist orders, fines, or product seizures. Furthermore, counterfeit mounts often lack the engineering rigor and reliability of original designs, increasing safety risks. Buyers should verify that suppliers have proper licensing agreements or offer non-infringing, independently developed designs. Due diligence—such as reviewing patent databases and requesting documentation—can help avoid costly IP disputes and ensure compliance with U.S. and international regulations.

Logistics & Compliance Guide for Silencer Mounts

Silencer mounts, also known as muzzle devices or suppressor mounts, are critical components in firearm accessory systems. Due to their association with NFA (National Firearms Act) regulated items like silencers, their logistics and compliance requirements are strictly governed by federal and, in some cases, state laws. This guide outlines key considerations for legal handling, transportation, and regulatory compliance.

Regulatory Classification

Silencer mounts themselves are generally not classified as NFA-regulated items unless they are permanently attached to a silencer or function as an integral part of the suppressor. However, they are often treated as controlled accessories due to their exclusive use with regulated devices. Always confirm the specific design and function with a qualified legal expert or the ATF.

Federal Compliance (ATF Regulations)

- No Separate Registration Required: Muzzle mounts sold independently (not affixed to a silencer) typically do not require Form 1 or Form 4 registration under the NFA, provided they are not designed or intended to function as part of a suppressor.

- ITAR/EAR Considerations: If the silencer mount is made from ITAR-controlled materials or exported internationally, compliance with the International Traffic in Arms Regulations (ITAR) or Export Administration Regulations (EAR) may apply. Consult with an export compliance officer before shipping outside the U.S.

- Recordkeeping: Maintain detailed sales records including purchaser information, date of transaction, and product details. Though not always mandated for non-NFA items, good recordkeeping supports compliance audits.

Shipping & Transportation

- Domestic Shipping: Silencer mounts can generally be shipped via common carriers (e.g., FedEx, UPS) without special licensing if not attached to a suppressor. Clearly label packages without reference to NFA items to avoid scrutiny.

- Carrier Policies: Confirm with carriers that they allow shipment of firearm-related accessories. Some have restrictions on items associated with NFA-regulated goods.

- State-Level Restrictions: Several states (e.g., California, New Jersey, New York) impose additional regulations on firearm accessories. Verify recipient state laws before shipping to ensure compliance.

State & Local Compliance

- Restricted Jurisdictions: Some states regulate or ban the possession of certain muzzle devices or quick-detach mounts. Research local laws thoroughly prior to sale or transfer.

- Age Requirements: While federal law does not set a minimum age for silencer mounts alone, many dealers enforce a 21-year minimum consistent with firearm accessory standards.

- Local Ordinances: Municipalities may have additional restrictions. Always verify compliance at all jurisdictional levels.

Best Practices for Sellers & Distributors

- Verify Intended Use: Ensure the product is marketed and sold only for lawful purposes.

- Customer Verification: Confirm buyer eligibility and maintain transaction records.

- Legal Review: Have all product descriptions, marketing materials, and sales processes reviewed by legal counsel familiar with firearms regulations.

- Training: Educate staff on compliance protocols, red flags, and reporting obligations.

Conclusion

While silencer mounts are not inherently NFA items, their close association with regulated suppressors demands careful attention to logistics and compliance. Adhering to federal guidelines, respecting state laws, and maintaining rigorous internal controls will help ensure lawful and responsible distribution. When in doubt, consult the ATF or a firearms attorney for clarification.

Conclusion for Sourcing Silencer Mounts:

After evaluating various suppliers, material options, production capabilities, and cost structures, it is concluded that sourcing silencer mounts requires a strategic balance between quality, durability, cost-efficiency, and supply chain reliability. The optimal supplier should demonstrate proven expertise in manufacturing vibration-dampening components, utilize high-grade materials (such as rubber-metal composites or advanced polymers), and adhere to industry-specific standards (e.g., ISO/TS 16949 for automotive applications).

Local suppliers offer advantages in lead time and logistics, while overseas manufacturers may provide cost savings, provided quality control measures are rigorously enforced. Additionally, collaboration with suppliers capable of customization and prototyping support ensures compatibility with specific vehicle or engine designs.

In conclusion, selecting a trusted supplier with strong technical capabilities, consistent quality assurance, and responsive service will ensure reliable performance of silencer mounts, contributing to reduced noise, vibration, and overall improved end-product satisfaction. It is recommended to establish long-term partnerships with 1–2 key suppliers to ensure continuity, innovation, and scalability in future production needs.