The global silencer market, a critical segment within the broader firearms and defense accessories industry, is experiencing steady growth driven by rising demand for noise suppression solutions in military, law enforcement, and civilian applications. According to a 2023 report by Mordor Intelligence, the global gun silencer market was valued at USD 2.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 7.8% from 2024 to 2029. This expansion is fueled by increasing firearm ownership, advancements in sound suppression technology, and evolving regulatory landscapes in regions such as North America and Europe. A key component of silencer performance lies in the design and durability of baffles—precision-engineered elements responsible for redirecting and cooling propellant gases to reduce noise. As innovation in materials, such as titanium and high-strength alloys, gains traction, the competitive landscape among baffle manufacturers is intensifying. Based on market reach, technological capability, and production scale, the following ten manufacturers have emerged as industry leaders in the development and supply of high-performance silencer baffles.

Top 10 Silencer Baffles Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

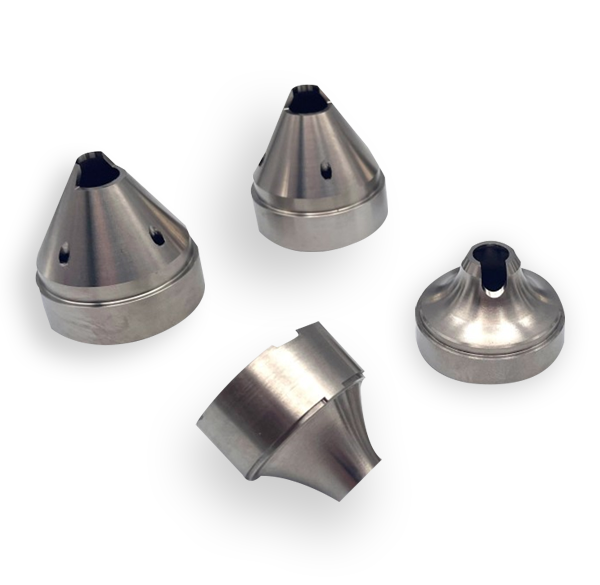

#1 Titanium Suppressor Baffles

Domain Est. 2011

Website: praxisti.com

Key Highlights: Praxis manufacturers titanium suppressor baffles using powder metallurgy, which makes parts lighter and cheaper than other methods….

#2 Silencers, Suppressors & Baffles for Defense Applications

Domain Est. 1995

Website: laube.com

Key Highlights: Suppressors, silencers, and baffles play an integral role in critical applications by reducing acoustic signatures, enhancing mission effectiveness, ……

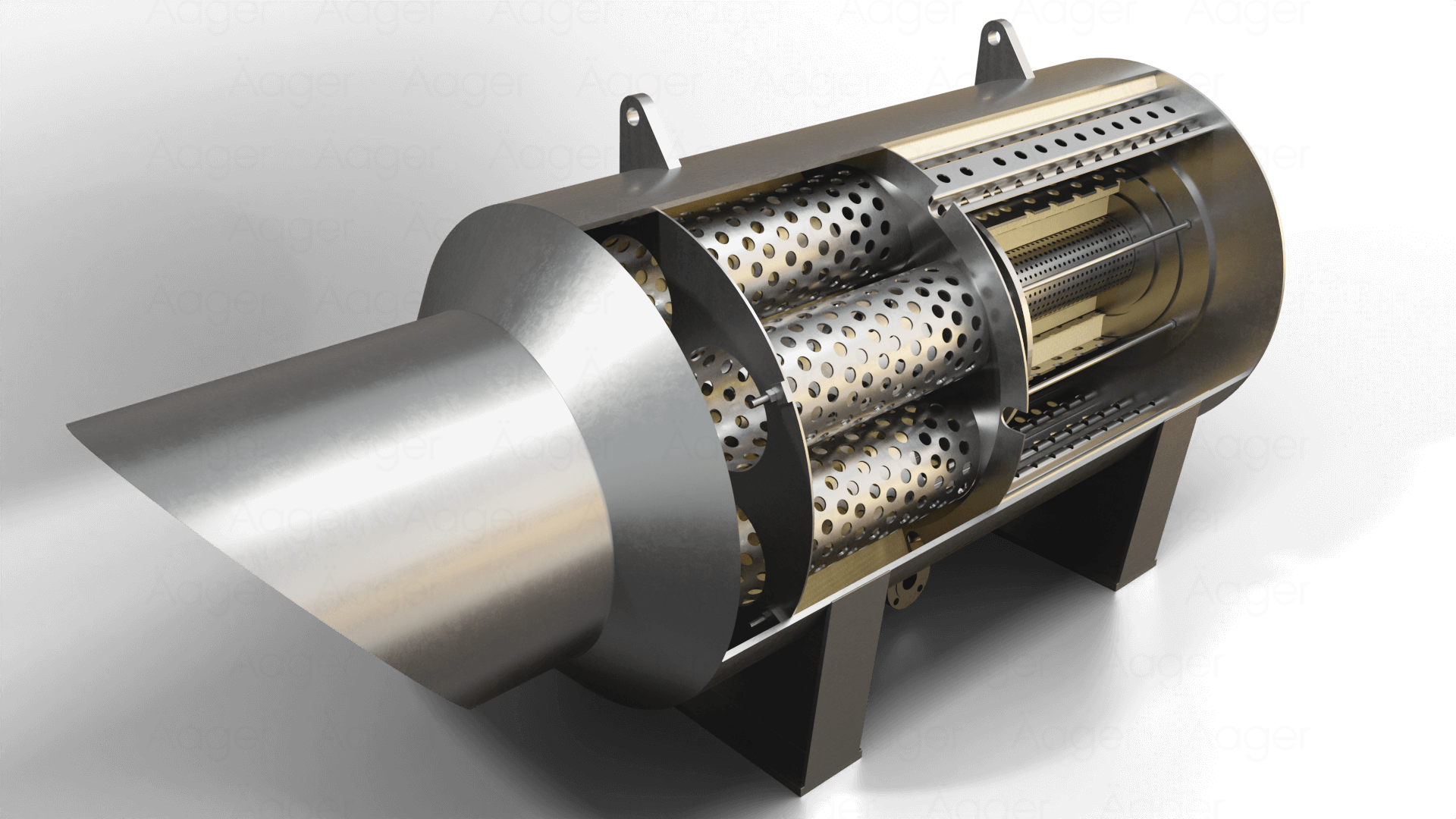

#3 [PDF] BAFFLE SILENCERS

Domain Est. 1996

Website: axces.com

Key Highlights: The official company name after this point will become Axces Steam and Flow Control B.V. while the trade name will remain Q.E. International. Axces Steam ……

#4 YHM Suppressors

Domain Est. 2000

Website: yhm.net

Key Highlights: YHM suppressors deliver industry-leading sound reduction, superior durability, and versatile mounting options across multiple firearms platforms….

#5 Suppressors

Domain Est. 2014

Website: amtacsuppressors.com

Key Highlights: AMTAC is the leader in over-barrel firearms suppressors for better sound reduction, balance, shorter overall length, and increased accuracy. See the lineup….

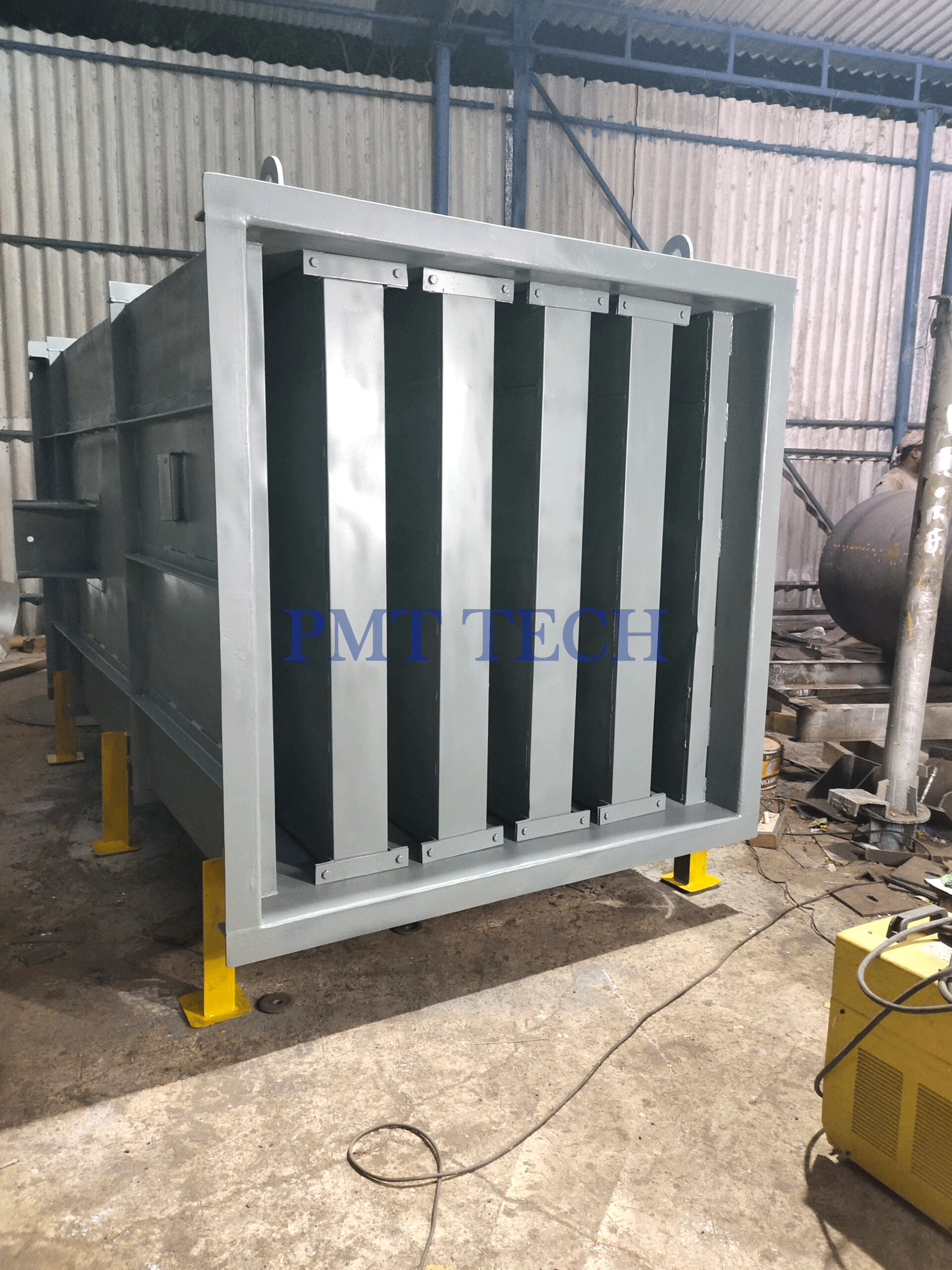

#6 Fan Silencer/ Silencer Baffle

Domain Est. 2015

Website: pmtacoustics.com

Key Highlights: These baffles are easily removable type and can do maintenance easily. It is an absorptive type silencer and is very effective for high frequency noise ……

#7 KGM Suppressors

Domain Est. 2020

Website: kgm-tech.com

Key Highlights: Our suppressors feature innovative baffle designs for managing gas-flow, utmost repeatability, and incredible durability….

#8 About Us

Domain Est. 2022

Website: blackopssuppressionsystems.com

Key Highlights: Black Ops Suppression Systems, or B.O.S.S. for short, was created as a vehicle to demonstrate the advanced baffle designs that we’ve been cooking up for years….

#9 Irregular Design Group

Domain Est. 2024

Website: irregulardesigngroup.com

Key Highlights: Every baffle is uniquely designed to optimize gas displacement between neighboring baffles. This method eliminates resonant harmonics, forcing gas to ……

#10 Acoustic Silencers and Baffles

Domain Est. 2024

Website: capstonedufrane.com

Key Highlights: Specializing in noise reduction solutions, our acoustic silencers and baffles contribute to a safer and more comfortable working environment….

Expert Sourcing Insights for Silencer Baffles

2026 Market Trends for Silencer Baffles

The market for silencer baffles is poised for significant evolution by 2026, driven by advancements in materials science, regulatory landscapes, and shifting consumer demands. As critical components within firearm suppressors responsible for sound attenuation and gas redirection, baffle performance directly impacts overall suppressor efficiency, durability, and safety. Key trends shaping the industry include:

Material Innovation and Lightweighting

A dominant trend through 2026 will be the accelerated adoption of advanced materials. While stainless steel and titanium remain staples, expect broader use of high-performance alloys and composites offering superior strength-to-weight ratios and enhanced heat resistance. Innovations in additive manufacturing (3D printing) will enable complex baffle geometries previously impossible with traditional machining, leading to optimized gas flow and noise reduction. Materials like Inconel and ceramic matrix composites may see increased R&D investment for extreme-duty applications, particularly in military and law enforcement segments.

Customization and Performance Optimization

Consumer demand for personalized firearm accessories will drive growth in customizable baffle systems. Modular baffle stacks allowing end-users to reconfigure internal layouts for different calibers or sound profiles will gain popularity. This trend is supported by digital design tools and faster prototyping, enabling manufacturers to offer tailored solutions. Performance metrics beyond decibel reduction—such as recoil mitigation, flash suppression, and backpressure management—will become key differentiators in baffle design.

Regulatory and Legal Influences

The regulatory environment, especially in the United States under the National Firearms Act (NFA), will continue to impact market dynamics. Potential legislative changes or state-level restrictions could influence consumer purchasing behavior and distribution channels. However, sustained advocacy efforts and growing public acceptance of suppressors for hearing protection may lead to incremental deregulation, expanding market access and stimulating baffle innovation.

Expansion in Commercial and Recreational Use

The recreational shooting and hunting markets are expected to drive baffle demand as suppressor ownership becomes more mainstream. Increased awareness of hearing conservation, coupled with marketing that emphasizes improved shooting comfort and accuracy, will broaden the user base. This shift will favor baffle designs that balance performance, reliability, and affordability for civilian applications.

Sustainability and Manufacturing Efficiency

Environmental and production cost considerations will push manufacturers toward more sustainable practices. This includes minimizing material waste through precision machining and recycling scrap metals. Energy-efficient production methods and lifecycle assessments of baffle materials may become competitive advantages, particularly among environmentally conscious consumers and institutional buyers.

In summary, the 2026 silencer baffle market will be characterized by technological sophistication, greater personalization, and responsiveness to both regulatory frameworks and end-user needs. Companies investing in R&D, agile manufacturing, and compliance expertise are likely to lead this evolving landscape.

Common Pitfalls Sourcing Silencer Baffles (Quality, IP)

Sourcing silencer baffles—critical components in firearm suppressors—comes with significant challenges, particularly concerning quality consistency and intellectual property (IP) risks. Overlooking these pitfalls can lead to product failure, legal disputes, or reputational damage.

Poor Material Quality and Manufacturing Tolerances

Low-grade materials (e.g., substandard stainless steel or inconel) or imprecise machining can compromise baffle integrity under repeated high-pressure, high-temperature conditions. Inconsistent tolerances result in poor gas flow control, reduced sound suppression, and increased risk of baffle strike or catastrophic failure.

Lack of Performance Testing and Certification

Many suppliers fail to provide verifiable performance data or durability testing (e.g., rounds-to-failure, heat cycling). Without certified test results, buyers risk acquiring baffles that degrade quickly or fail to meet advertised noise reduction claims.

Inadequate Traceability and Documentation

Missing material certifications (e.g., mill test reports), heat numbers, or manufacturing logs makes it difficult to ensure consistency across batches or investigate failures. This lack of traceability also complicates regulatory compliance.

Intellectual Property Infringement Risks

Sourcing baffles from unauthorized manufacturers or copying patented baffle designs (e.g., Nielsen devices, monocore layouts) exposes buyers to IP litigation. Some offshore suppliers replicate proprietary geometries without licensing, creating legal exposure for end-users and integrators.

Counterfeit or Non-Spec Components

Unverified suppliers may deliver baffles that appear genuine but deviate from design specifications. These counterfeits often use inferior alloys or incorrect geometries, posing safety risks and undermining product reliability.

Supply Chain Opacity and Lack of Oversight

Relying on intermediaries or offshore vendors without direct quality audits increases the risk of undetected defects or IP violations. Limited visibility into manufacturing practices makes it hard to enforce quality standards or ensure ethical compliance.

Mitigating these pitfalls requires rigorous supplier vetting, contractual IP protections, independent quality validation, and ongoing compliance monitoring.

Logistics & Compliance Guide for Silencer Baffles

Silencer baffles are critical components in firearm suppressors (commonly referred to as silencers), designed to slow and cool escaping propellant gases to reduce noise. Due to their role in regulated devices, the logistics and compliance requirements for silencer baffles are strict and governed by federal law in the United States. This guide outlines key considerations for legal handling, transportation, manufacturing, and compliance.

Regulatory Classification and Legal Status

Silencer baffles are classified as “firearms” under the National Firearms Act (NFA) of 1934 when they are designed or intended to be used in a silencer. This classification is upheld by the Bureau of Alcohol, Tobacco, Firearms and Explosives (ATF). Specifically:

- Baffles are considered “firearms” because they are essential components of a suppressor.

- Manufacturing, selling, or transferring silencer baffles without proper ATF registration and tax payment is a federal offense.

- Even unfinished or raw baffle components may be considered “firearms” if they are in a form that can readily be converted into a functional baffle.

Manufacturing Compliance

Entities involved in manufacturing silencer baffles must adhere to strict ATF regulations:

- Federal Firearms License (FFL): A Type 07 FFL is required for manufacturing firearms, including silencer components.

- Special Occupational Tax (SOT): Manufacturers must also hold a Class 2 SOT specifically for NFA firearms manufacturing.

- Serialization: Every baffle or baffle core must be serialized if it is considered a regulated firearm component. This includes engraving a unique serial number, manufacturer name, and model.

- Recordkeeping: All manufacturing activities must be documented in the company’s Acquisition and Disposition (A&D) records.

Transportation and Logistics

Transporting silencer baffles—whether domestically or internationally—requires adherence to federal, state, and (if applicable) international laws.

- Domestic Shipping: Baffles must be shipped only to authorized recipients (e.g., FFL/SOT holders). Common carriers like FedEx or UPS may require special NFA-compliant packaging and documentation.

- Interstate Transfers: All transfers between FFLs must be reported to the ATF using Form 3 (for government agencies) or Form 4 (for private transfers), which require ATF approval prior to shipment.

- International Export/Import: Requires a license from the Directorate of Defense Trade Controls (DDTC) under the International Traffic in Arms Regulations (ITAR), as silencer components are listed on the U.S. Munitions List (USML).

Storage and Security

- Silencer baffles must be stored in a secure gun vault or container that meets ATF standards when not in use.

- Access should be restricted to authorized personnel only.

- Facilities must comply with local and federal storage regulations to prevent theft or unauthorized access.

Compliance Best Practices

- Conduct regular internal audits to ensure adherence to FFL and SOT requirements.

- Maintain meticulous records of all baffle production, sales, transfers, and disposals.

- Stay informed on ATF rulings and guidance (e.g., recent advisory opinions on unfinished components).

- Consult ATF directly or through legal counsel when uncertain about the regulatory status of a component.

Penalties for Noncompliance

Violations of NFA regulations related to silencer baffles can result in:

- Criminal prosecution

- Fines up to $250,000

- Imprisonment for up to 10 years

- Revocation of FFL and SOT licenses

Conclusion

Silencer baffles are subject to the same stringent regulations as complete suppressors under U.S. federal law. Any entity involved in their manufacturing, sale, or distribution must ensure full compliance with the NFA, ATF guidelines, and recordkeeping requirements. Proper licensing, serialization, secure storage, and legal transfer protocols are essential to avoid severe legal consequences. Always consult with legal experts or the ATF for clarification on compliance matters.

Conclusion for Sourcing Silencer Baffles

In conclusion, sourcing silencer baffles requires a strategic approach that balances performance, durability, regulatory compliance, and cost-effectiveness. High-quality materials such as stainless steel, titanium, or advanced alloys are essential to ensure longevity and optimal sound suppression under repeated firing conditions. Precision engineering and tight manufacturing tolerances are critical to maintain consistency, safety, and compatibility with specific firearm platforms.

Whether sourcing domestically or internationally, evaluating suppliers based on certifications, quality control processes, and proven track record in aerospace or firearms manufacturing is vital. Additionally, adherence to ITAR, ATF, and other relevant regulations cannot be overlooked, particularly when dealing with controlled components.

Ultimately, the ideal sourcing strategy involves partnering with reliable, compliant manufacturers who offer technical expertise, scalability, and consistent quality assurance. By prioritizing these factors, organizations can ensure reliable supply chains, enhanced product performance, and long-term success in the design and production of effective firearm suppression systems.

![[PDF] BAFFLE SILENCERS](https://www.sohoinchina.com/wp-content/uploads/2026/01/pdf-baffle-silencers-895.png)