The global signal relay market is experiencing robust growth, driven by rising demand for automation, industrial IoT integration, and advancements in telecommunications infrastructure. According to a 2023 report by Mordor Intelligence, the global relay market is projected to grow at a CAGR of over 6.8% from 2023 to 2028, reaching an estimated value of over $4.5 billion by the end of the forecast period. Similarly, Grand View Research valued the market at USD 3.2 billion in 2022, citing expanding deployment in automotive, energy, and manufacturing sectors as key growth catalysts. Within this expanding landscape, signal relays play a critical role in ensuring reliable control signal transmission across diverse industrial and electronic applications. As industries prioritize precision and operational efficiency, selecting from the leading signal relay manufacturers becomes essential. The following list highlights the top 10 manufacturers leveraging innovation, scalability, and technological expertise to lead the signal relay market forward.

Top 10 Signal Relay Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Forward Relay

Domain Est. 1997

Website: forward-relays.com

Key Highlights: Forward Relay is a leading manufacturer and supplier in China, specializing in the production of signal relay, industrial relay, power relay, etc….

#2 Relays and Contactors

Domain Est. 1990

Website: na.industrial.panasonic.com

Key Highlights: Panasonic manufactures a broad portfolio of Relays and Contactors. Relay options include Panasonic’s exclusive PhotoMOS® Semiconductor Relays….

#3 Relays

Domain Est. 1997

Website: components.omron.com

Key Highlights: Offering a range of relays designed to meet diverse needs, we provide reliable solutions for industrial and electronic applications….

#4 Relays & Contactors

Domain Est. 1992

Website: te.com

Key Highlights: Our types of switching devices include contactors, relays, and circuit breakers that offer cost-effective, reliable performance to enhance productivity….

#5 Signal Relay

Domain Est. 1997

Website: hongfa.com

Key Highlights: Signal relays have the characteristics of stable reliability, long service life, fast action response, high precision, small size and low power ……

#6 Pickering Electronics: The Reed Relay Leaders

Domain Est. 1997

Website: pickeringrelay.com

Key Highlights: Pickering Electronics – Design, manufacture and distribute high quality Reed Relays for Instrumentation, ATE and Semiconductor Test….

#7 Relays and Timers

Domain Est. 1997

Website: rockwellautomation.com

Key Highlights: Our relays and timers are designed, manufactured and tested to meet the most demanding worldwide standards and ratings….

#8 Signal Relay,Power Relay,Automotive Relay,Magnetic Latching …

Domain Est. 2021

Website: zhejianghke.com

Key Highlights: HKE mainly produces signal relays, power relays and automotive relays. They are widely used in air conditioners, refrigerators, microwave oven, OA equipment, ……

#9 Signal relays overview

Domain Est. 2021

Website: fcl-components.com

Key Highlights: FCL Components provides the industry with a wide range of signal relays, ranging from micro amp switching through to power circuit loads with high inrush ……

#10 Relays & Coax Switches

Domain Est. 2024

Website: teledyne-ade.com

Key Highlights: Teledyne Relays provides rugged, high-reliability relays for aerospace and defense, ensuring mission-critical performance in extreme conditions….

Expert Sourcing Insights for Signal Relay

H2: Market Trends for Signal Relay in 2026

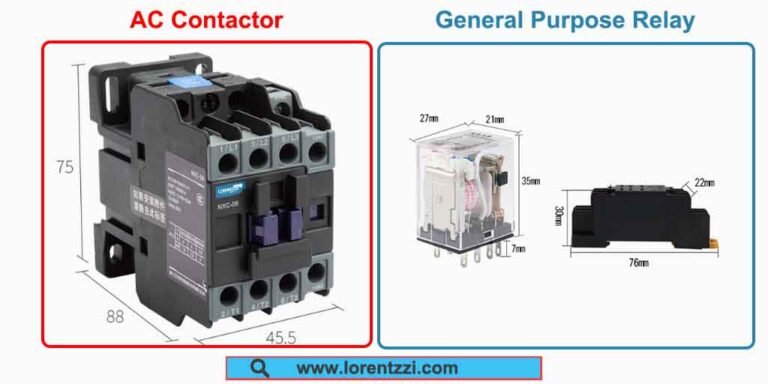

As we approach 2026, the signal relay market is undergoing significant transformation driven by advancements in automation, the proliferation of Industry 4.0 technologies, and the growing demand for reliable and efficient electrical control systems across various sectors. Signal relays—electromechanical or solid-state devices used to control circuits and transmit signals in industrial, automotive, telecommunications, and smart infrastructure applications—are benefiting from these macro trends. Below is an analysis of key market dynamics shaping the signal relay landscape in 2026.

1. Expansion of Industrial Automation and Smart Manufacturing

The continued adoption of smart factories and automated production lines is a primary growth driver for signal relays. As manufacturers integrate IoT-enabled sensors, programmable logic controllers (PLCs), and distributed control systems (DCS), the need for reliable signal transmission and circuit isolation increases. Signal relays play a critical role in ensuring seamless communication between control systems and actuators, especially in harsh industrial environments. In 2026, demand is expected to grow in emerging markets such as Southeast Asia and India, where industrial modernization is accelerating.

2. Rise of Solid-State Relays (SSRs) Over Electromechanical Relays (EMRs)

A notable trend is the shift from traditional electromechanical relays to solid-state relays. SSRs offer longer lifespans, faster switching speeds, silent operation, and greater resistance to vibration and shock—advantages highly valued in automation, renewable energy, and electric vehicle (EV) charging infrastructure. By 2026, SSRs are projected to capture a larger market share, particularly in high-reliability applications such as medical devices, data centers, and advanced robotics.

3. Growth in Renewable Energy and Grid Modernization

The global push toward sustainable energy is fueling demand for signal relays in solar inverters, wind turbines, and smart grid systems. Signal relays are essential for monitoring, protection, and control functions in power distribution networks. As countries upgrade aging electrical infrastructure and integrate decentralized energy sources, the need for precise signal management increases. In 2026, government investments in grid resilience and renewable integration will continue to boost the signal relay market, especially in North America and Europe.

4. Automotive Electrification and ADAS Development

The automotive sector remains a key end-user for signal relays, particularly with the rise of electric vehicles (EVs) and advanced driver assistance systems (ADAS). Signal relays are used in battery management systems, lighting control, HVAC, and safety circuits. With EV production expected to surpass 40 million units annually by 2026, demand for compact, high-efficiency relays will rise. Additionally, stringent safety standards are pushing automakers to adopt relays with enhanced reliability and diagnostic capabilities.

5. Miniaturization and Integration

As electronic devices become smaller and more complex, there is growing demand for miniaturized signal relays that offer high performance in limited space. In 2026, manufacturers are focusing on compact form factors, surface-mount designs, and integrated solutions that combine relays with sensors or microcontrollers. This trend is especially prominent in consumer electronics, medical equipment, and telecommunications hardware.

6. Supply Chain Resilience and Regionalization

Post-pandemic supply chain challenges have prompted a shift toward regional manufacturing and dual sourcing. In 2026, companies are investing in localized production of signal relays to reduce dependency on single geographies and improve delivery times. This trend benefits domestic suppliers in regions like North America and Europe while fostering innovation in automation-driven assembly processes.

7. Sustainability and Regulatory Compliance

Environmental regulations such as RoHS and REACH are driving the development of eco-friendly relays that use lead-free materials and consume less energy. In 2026, sustainability is becoming a competitive differentiator, with manufacturers emphasizing recyclability, energy efficiency, and reduced carbon footprints in their product offerings.

Conclusion

The signal relay market in 2026 is characterized by technological innovation, sector diversification, and increased demand from high-growth industries. Companies that invest in solid-state technologies, miniaturization, and sustainable manufacturing will be well-positioned to capitalize on these trends. As digitalization and electrification reshape global industries, signal relays will remain a foundational component in the infrastructure of the future.

Common Pitfalls Sourcing Signal Relays (Quality, IP)

Sourcing signal relays—especially for applications requiring high reliability or use in harsh environments—can be fraught with challenges. Two critical areas where issues frequently arise are quality and Ingress Protection (IP) rating. Overlooking these can lead to premature failure, safety risks, and increased maintenance costs. Below are common pitfalls to avoid:

Poor Quality Components and Counterfeits

One of the biggest risks when sourcing signal relays is receiving substandard or counterfeit components. This often occurs when purchasing from unauthorized distributors or low-cost suppliers. Poor-quality relays may use inferior materials such as weak contact alloys, low-grade plastics, or undersized coils, leading to:

- Premature contact wear or welding

- Inconsistent switching performance

- Reduced lifespan under rated loads

- Higher failure rates in high-cycle applications

To mitigate this, always source from authorized distributors or directly from reputable manufacturers. Verify certifications (e.g., UL, CE, RoHS) and request detailed component datasheets and test reports.

Misunderstanding or Misrepresenting IP Ratings

Ingress Protection (IP) ratings define a relay’s resistance to dust and moisture, which is critical for industrial, outdoor, or high-humidity environments. Common pitfalls include:

- Assuming all relays are sealed: Many signal relays are not IP-rated and are intended for use inside protected enclosures.

- Confusing IP ratings with general “sealed” claims: A relay marketed as “sealed” may not meet any official IP standard. Genuine IP ratings (e.g., IP67) must be tested and certified.

- Overlooking installation impact: Even an IP67-rated relay can lose protection if the associated socket or wiring is not properly sealed.

Always confirm the exact IP rating from the manufacturer’s datasheet and ensure the entire assembly (relay, socket, housing) maintains the required environmental protection.

Inadequate Electrical and Mechanical Specifications

Signal relays are often selected based on basic parameters like coil voltage and contact rating, but critical details are missed:

- Contact material and load type: Gold-plated contacts are suited for low-level signals, while silver alloy is better for higher loads. Using the wrong type leads to arcing or contact resistance issues.

- Mechanical life vs. electrical life: A relay may have a high mechanical cycle rating, but its electrical life (under load) could be significantly lower.

- Bounce time and switching speed: Critical in precision or high-frequency applications; overlooked in general sourcing.

Ensure the relay’s full specifications align with the application’s electrical, thermal, and switching demands.

Lack of Environmental and Regulatory Compliance Verification

Signal relays used in regulated industries (medical, automotive, rail) must meet specific standards (e.g., IEC, AEC-Q200, EN). Pitfalls include:

- Assuming compliance without documentation

- Using relays not rated for the required temperature range

- Ignoring flammability ratings (e.g., UL94 V-0) for plastic housings

Always request compliance documentation and ensure the relay meets regional and industry-specific requirements.

Conclusion

Avoiding these pitfalls requires due diligence: source from trusted suppliers, verify specifications and certifications, and validate both quality and IP ratings against your application needs. Investing time upfront prevents costly failures and downtime later.

Logistics & Compliance Guide for Signal Relay

This guide outlines the essential logistics and compliance considerations for the distribution, handling, and use of Signal Relay devices. Adherence to these guidelines ensures regulatory compliance, operational safety, and efficient supply chain management.

Regulatory Compliance

Signal Relay products must comply with relevant international, national, and regional regulations. Key compliance areas include:

- Electromagnetic Compatibility (EMC): Devices must meet applicable EMC standards such as IEC/EN 61000-6 series to prevent interference with other electronic equipment.

- Safety Standards: Conformity with electrical safety standards such as IEC/EN 61010-1 is required for industrial control equipment.

- RoHS & REACH Compliance: Signal Relay devices must comply with EU directives restricting hazardous substances (RoHS) and regulating chemical substances (REACH).

- CE & UKCA Marking: Devices placed on the European Economic Area (EEA) and UK markets must carry valid CE or UKCA marks, indicating conformity with health, safety, and environmental protection standards.

- UL/cUL Certification: For North American markets, products may require UL listing or recognition under relevant standards (e.g., UL 508 for industrial control equipment).

Ensure all product documentation includes up-to-date compliance declarations and certification marks.

Packaging & Labeling Requirements

Proper packaging and labeling are critical for safe handling and regulatory traceability:

- Packaging: Use anti-static, shock-resistant packaging suitable for electronic components. Inner packaging must prevent movement and protect terminals.

- Labeling: Each unit or package must include:

- Product name and model number

- Manufacturer details (Signal Relay or authorized partner)

- Lot or serial number

- Compliance markings (CE, UKCA, UL, etc.)

- Electrostatic-sensitive device (ESD) warning symbol where applicable

- Country of origin

- Barcode/QR Codes: Include scannable identifiers for inventory tracking and traceability.

Shipping & Transportation

Follow these guidelines to ensure safe and compliant shipment:

- Mode of Transport: Signal Relay devices may be shipped via air, sea, or ground. Confirm compliance with IATA, IMDG, or ADR regulations if transporting in bulk.

- Temperature & Humidity: Store and transport within the recommended environmental conditions (typically -25°C to +70°C, non-condensing humidity).

- ESD Protection: Use ESD-safe containers and handling procedures during packing and shipping.

- Hazard Classification: Signal Relay products are generally non-hazardous. However, confirm classification under UN/DOT regulations if batteries or other components are included.

- Documentation: Include commercial invoices, packing lists, and certificates of compliance. For international shipments, ensure Harmonized System (HS) codes are accurate.

Import & Export Controls

Adhere to trade compliance requirements when moving products across borders:

- Export Classification: Determine the correct Export Control Classification Number (ECCN) under the U.S. Commerce Control List (CCL) or equivalent. Most Signal Relay relays fall under EAR99 (low-risk, non-controlled items).

- Sanctions & Embargoes: Verify destination countries are not subject to trade restrictions (e.g., OFAC-sanctioned countries).

- Customs Declarations: Provide accurate product descriptions, values, and origin information to avoid delays.

- Incoterms: Use appropriate Incoterms (e.g., FOB, DDP) in contracts to define responsibilities for shipping, insurance, and customs clearance.

Inventory & Storage Management

Maintain product integrity through proper storage practices:

- Environment: Store in clean, dry, temperature-controlled areas away from direct sunlight and corrosive atmospheres.

- Shelf Life: Observe manufacturer-recommended shelf life; inspect older stock before deployment.

- Handling: Use ESD-safe workstations and wrist straps when unpacking or testing devices.

- Traceability: Maintain lot-level traceability through warehouse management systems (WMS) to support recalls or audits.

End-of-Life & Environmental Responsibility

Support sustainable practices and regulatory disposal requirements:

- WEEE Compliance: In the EU, Signal Relay products are subject to the Waste Electrical and Electronic Equipment (WEEE) directive. End users must dispose of products via authorized take-back systems.

- Recycling Guidance: Provide customers with information on proper recycling channels.

- Product Take-Back: Participate in or facilitate manufacturer return programs where available.

Compliance Monitoring & Audits

Maintain ongoing compliance through:

- Supplier Audits: Ensure all manufacturing and distribution partners adhere to quality and compliance standards (e.g., ISO 9001, ISO 14001).

- Internal Audits: Conduct regular reviews of logistics processes, documentation, and regulatory updates.

- Regulatory Updates: Monitor changes in standards (e.g., new EMC requirements) and update product certifications as needed.

By following this guide, stakeholders in the Signal Relay supply chain can ensure safe, legal, and efficient operations from manufacturing to end use.

Conclusion for Sourcing Signal Relays:

In conclusion, sourcing signal relays requires a comprehensive evaluation of technical specifications, application requirements, supplier reliability, and cost-effectiveness. It is essential to select relays that match the electrical and environmental demands of the intended system—considering factors such as switching capacity, contact configuration, coil voltage, signal integrity, and durability. Additionally, prioritizing components from reputable manufacturers ensures consistent quality, regulatory compliance, and long-term performance. By balancing technical needs with supply chain stability and lifecycle costs, organizations can make informed sourcing decisions that enhance system reliability and operational efficiency. Ultimately, a strategic and well-researched approach to sourcing signal relays contributes significantly to the overall success and maintenance of electronic and control systems.