The global railing systems market is experiencing steady growth, driven by rising urbanization, increasing infrastructure development, and stringent building safety regulations. According to a report by Mordor Intelligence, the global railing systems market was valued at USD 3.5 billion in 2023 and is projected to grow at a CAGR of over 6.2% from 2024 to 2029. This growth is particularly fueled by demand in commercial and residential construction segments, where sidewalk railings play a critical role in pedestrian safety and architectural design. Metal railings—especially those made from stainless steel and aluminum—dominate the market due to their durability, low maintenance, and aesthetic versatility. As cities prioritize accessible and secure public spaces, the demand for high-quality sidewalk railing solutions continues to rise. In this evolving landscape, a select group of manufacturers have distinguished themselves through innovation, material excellence, and compliance with international safety standards. Below are the top 9 sidewalk railing manufacturers shaping the industry’s future.

Top 9 Sidewalk Railing Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Outdoor Living Products & Accessories

Domain Est. 1998

Website: diggerspecialties.com

Key Highlights: As a leading Westbury railing manufacturer, we offer a wide selection of aluminum railing systems and vinyl railing options designed to upgrade ……

#2 RDI Railing

Domain Est. 2003

Website: rdirail.com

Key Highlights: Explore our full collection of railing products, complementary accents — including privacy panels and pergolas — along with outdoor lighting and ADA handrail.Missing: sidewalk man…

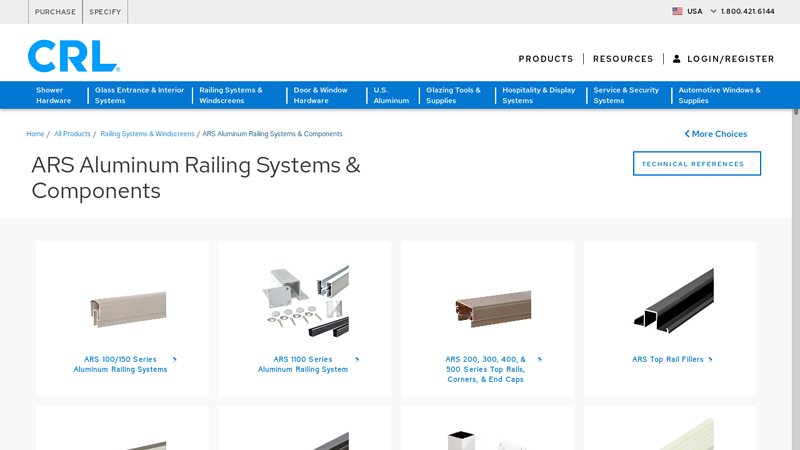

#3 ARS Aluminum Railing Systems & Components

Domain Est. 1995

Website: crlaurence.com

Key Highlights: Choose CRL’s ARS Aluminum Railing Systems to create a customized, modern railing design. These metal railings are ideal for stairways and balconies….

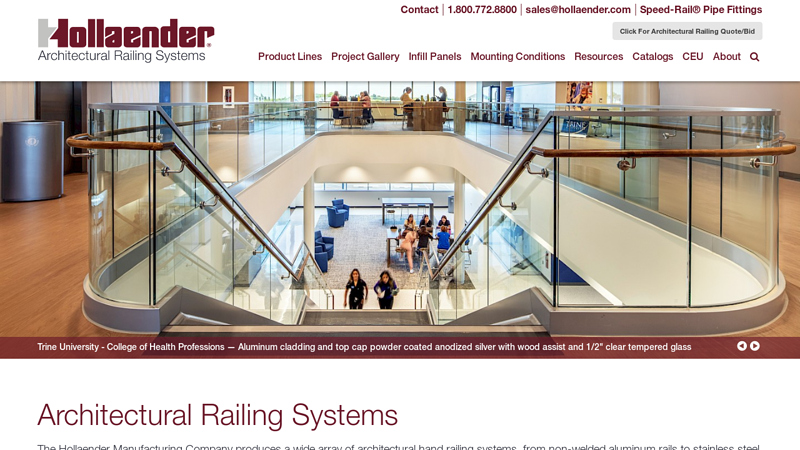

#4 Architectural Railing Systems

Domain Est. 1996

Website: architecturalhandrail.hollaender.com

Key Highlights: The Hollaender Manufacturing Company produces a wide array of architectural hand railing systems, from non-welded aluminum rails to stainless steel ……

#5 Easy Install, High Quality, Cable Railing

Domain Est. 2003

Website: ultra-tec.com

Key Highlights: Ultra-tec cable railing is high quality and provides an elegant look to your railing project. Easiest install cable railing products….

#6 Your specialist for railing systems

Domain Est. 2004

Website: q-railing.com

Key Highlights: Top quality and easy installation: at Q-railing you will find the largest selection of glass railings, handrails, handrail brackets, glass clamps and much ……

#7 Safety Railing Solutions

Domain Est. 2007

Website: keesafety.com

Key Highlights: Our high-quality safety railing solutions are constructed using slip-on pipe fittings and standard pipe. They are a cost-effective alternative to traditional ……

#8 Feeney

Domain Est. 2008

Website: feeneyinc.com

Key Highlights: Discover the combination of beauty, functionality and durability of Feeney luxury cable and aluminum railings, awnings, architectural rods and more….

#9 Westbury Railing Collections

Domain Est. 2016

Website: deckandrailsupply.com

Key Highlights: 8-day delivery 30-day returnsWestbury aluminum power-coated deck railing systems offer code-approved, easy-level aluminum posts, signature top rail, and railing infill choices….

Expert Sourcing Insights for Sidewalk Railing

2026 Market Trends for Sidewalk Railing

The sidewalk railing market is poised for significant evolution by 2026, driven by urbanization, safety regulations, smart city initiatives, and sustainability demands. Key trends shaping the industry include:

Urbanization and Infrastructure Investment

Rapid urban population growth, particularly in emerging economies and secondary cities, is fueling demand for improved public infrastructure. Governments worldwide are increasing investments in pedestrian safety and walkability as part of broader smart city and sustainable development goals. This includes retrofitting aging sidewalks and constructing new urban corridors, directly boosting demand for compliant and durable sidewalk railings.

Emphasis on Accessibility and Universal Design

Regulatory frameworks such as the Americans with Disabilities Act (ADA) and international accessibility standards are becoming more rigorously enforced. By 2026, sidewalk railings will increasingly need to meet stringent accessibility requirements, including proper height, continuous gripping surfaces, and integration with ramps and tactile paving. Universal design principles will gain traction, ensuring railings are usable by people of all ages and abilities.

Adoption of Smart and Multifunctional Railings

Smart city integration is driving innovation in railing systems. By 2026, expect growth in railings embedded with sensors for crowd monitoring, air quality detection, or emergency alerts. Some systems may incorporate LED lighting, solar panels, or Wi-Fi hotspots, transforming railings from passive safety features into active components of urban digital infrastructure.

Sustainable and Low-Carbon Materials

Environmental regulations and corporate ESG goals are pushing demand for eco-friendly materials. Recycled metals (especially aluminum and steel), low-carbon concrete, and composite materials made from recycled plastics will see increased adoption. Life cycle assessments (LCA) will become standard in procurement decisions, favoring railings with lower embodied carbon and longer service lives.

Design Aesthetics and Community Identity

Municipalities and developers are prioritizing aesthetics to enhance public spaces and reflect local culture. Customizable railing designs—featuring regional motifs, color options, or artistic elements—will become more prevalent. This trend supports placemaking efforts and fosters community pride, making railings a subtle yet impactful design feature.

Advanced Manufacturing and Modular Systems

Prefabricated and modular railing systems will gain market share due to faster installation, reduced labor costs, and improved quality control. Technologies like robotic welding and 3D modeling (BIM integration) will enhance precision and enable complex designs. These systems also facilitate easier maintenance and replacement, appealing to municipal planners.

Resilience and Climate Adaptation

With rising concerns over extreme weather and climate resilience, sidewalk railings will be designed to withstand flooding, high winds, and temperature fluctuations. Corrosion-resistant coatings, elevated foundations, and materials suitable for coastal or high-moisture environments will be prioritized, especially in vulnerable urban areas.

In summary, the 2026 sidewalk railing market will be defined by smarter, greener, and more inclusive solutions that align with the broader transformation of urban environments. Stakeholders who embrace innovation, sustainability, and user-centered design will lead the next phase of growth in this essential infrastructure segment.

Common Pitfalls When Sourcing Sidewalk Railings (Quality and Intellectual Property)

Sourcing sidewalk railings involves more than just selecting a design and placing an order. Buyers often encounter challenges related to product quality, compliance, and intellectual property (IP) rights. Avoiding these pitfalls is essential to ensure safety, durability, and legal compliance. Below are key issues to watch for:

1. Compromised Material Quality

One of the most frequent pitfalls is receiving railings made from substandard materials. Suppliers may use low-grade steel, inferior powder coatings, or non-compliant alloys to cut costs. This results in railings that corrode quickly, lack structural integrity, or fail to meet local building codes.

Prevention Tip: Always request material certifications (e.g., mill test reports) and conduct third-party inspections before shipment.

2. Inconsistent Fabrication and Welding Standards

Poor welding techniques or inconsistent fabrication can compromise the safety and aesthetics of sidewalk railings. Defects such as incomplete welds, misaligned joints, or rough finishes are common with unqualified manufacturers.

Prevention Tip: Specify welding standards (e.g., AWS D1.1) in your purchase agreement and require sample submissions for approval.

3. Non-Compliance with Local Safety and Accessibility Codes

Railings must meet jurisdiction-specific requirements for height, spacing, load capacity, and accessibility (e.g., ADA in the U.S.). Sourcing from overseas or non-specialized suppliers increases the risk of non-compliant designs.

Prevention Tip: Verify that the supplier is familiar with the target market’s regulatory standards and provide exact specifications upfront.

4. Inadequate Surface Protection and Finishing

Poor powder coating, galvanization, or painting processes lead to premature rust and degradation, especially in outdoor or coastal environments. Some suppliers use thin coatings or skip pre-treatment steps.

Prevention Tip: Define minimum coating thickness (e.g., ASTM A123 for galvanizing) and insist on salt spray test reports.

5. Intellectual Property Infringement

Using or sourcing railings based on patented designs, ornamental patterns, or proprietary engineering without authorization can lead to legal disputes, shipment seizures, or financial liability.

Prevention Tip: Conduct an IP due diligence check. Require suppliers to confirm that their designs do not infringe on existing patents or registered designs.

6. Copycat or Counterfeit Designs

Some manufacturers replicate popular architectural railing designs protected by design patents or copyrights. Purchasing such items—even unknowingly—can expose the buyer to legal risk.

Prevention Tip: Work with reputable suppliers who develop original designs or have licensing agreements for branded products.

7. Lack of Traceability and Documentation

In the event of a failure or audit, missing documentation—such as test reports, compliance certificates, or IP clearances—can complicate liability and remediation efforts.

Prevention Tip: Include documentation requirements in contracts and treat them as deliverables.

By recognizing and addressing these common pitfalls, buyers can ensure they source sidewalk railings that are safe, durable, compliant, and free from intellectual property risks.

Logistics & Compliance Guide for Sidewalk Railing

This guide outlines the key logistical considerations and regulatory compliance requirements for the manufacturing, transportation, installation, and maintenance of sidewalk railing systems. Adhering to these standards ensures safety, durability, and legal conformity in public infrastructure projects.

Manufacturing & Material Standards

Sidewalk railings must be fabricated using materials that meet industry standards for strength, corrosion resistance, and longevity. Common materials include stainless steel, powder-coated aluminum, and galvanized steel. All materials should comply with ASTM (American Society for Testing and Materials) standards such as ASTM A36 for structural steel or ASTM A53 for pipe and tubing. Manufacturers must provide material test reports (MTRs) and ensure consistent quality control throughout production.

Structural & Safety Compliance

Railings must comply with local, state, and federal safety codes, including the International Building Code (IBC) and the Americans with Disabilities Act (ADA). Key requirements include:

– Minimum height of 42 inches (1067 mm) for public areas.

– Ability to withstand a horizontal load of 50 pounds per linear foot.

– No openings greater than 4 inches to prevent entrapment hazards.

– Smooth, non-protruding surfaces to prevent injury.

Designs must be stamped by a licensed professional engineer where required and submitted for approval during permitting.

Transportation & Handling

Due to the length and weight of railing sections, logistics planning is essential:

– Use flatbed trucks or enclosed trailers with protective padding to prevent damage.

– Secure loads with straps and corner protectors to avoid bending during transit.

– Coordinate delivery schedules with installation timelines to minimize on-site storage.

– Handle components with lifting slings or forklifts equipped with soft grips to preserve finishes.

Installation & Site Compliance

Installation must follow engineered drawings and local permitting requirements:

– Verify site measurements and alignment with curb lines, sidewalks, and ADA ramps.

– Anchor railings to concrete footings or existing structures using approved fasteners (e.g., epoxy-set anchors).

– Ensure proper spacing and continuity across sections, including expansion joints where needed.

– Conduct post-installation inspections to confirm alignment, stability, and compliance with design specs.

Inspection & Certification

Before public use, completed railing installations must undergo inspection by the relevant authority (e.g., city building department or DOT). Documentation should include:

– Approved shop drawings and engineering certifications.

– Installation records and as-built photos.

– Third-party load test reports, if required.

A Certificate of Compliance or Notice of Completion may be issued upon passing inspection.

Maintenance & Long-Term Compliance

To maintain compliance and safety, implement a routine maintenance program:

– Inspect railings annually for corrosion, loose fasteners, or structural damage.

– Clean surfaces to preserve finish and prevent grime buildup.

– Repair or replace damaged sections promptly in accordance with original specifications.

– Retain maintenance logs for audit or liability purposes.

Following this logistics and compliance guide ensures sidewalk railing systems remain safe, durable, and in full regulatory compliance throughout their service life.

In conclusion, sourcing sidewalk railing involves a comprehensive evaluation of material quality, durability, compliance with local building codes and safety standards, cost efficiency, and aesthetic compatibility with the surrounding environment. Whether choosing materials such as stainless steel, aluminum, or iron, it is essential to partner with reputable suppliers or manufacturers who provide reliable products, timely delivery, and professional installation support. Conducting thorough research, obtaining multiple quotes, and considering long-term maintenance requirements will ensure a cost-effective and sustainable solution. Ultimately, properly sourced sidewalk railing enhances public safety, improves urban accessibility, and contributes to the overall visual appeal of pedestrian pathways.