The global shrink wrap market is experiencing robust growth, driven by increasing demand for product branding, tamper-evident packaging, and supply chain efficiency across industries such as food and beverage, pharmaceuticals, and consumer goods. According to a report by Mordor Intelligence, the global shrink wrap market was valued at approximately USD 13.5 billion in 2023 and is projected to grow at a CAGR of over 5.2% through 2029. This expansion is fueled by rising e-commerce activity and the growing trend of brand differentiation through customized packaging—specifically, shrink wraps with integrated logos. As brands seek to enhance shelf appeal and build recognition, partnerships with specialized manufacturers capable of high-quality, brand-consistent print application have become critical. In this competitive landscape, identifying reliable shrink wrap with logo manufacturers who combine technical precision, sustainability, and scalability is essential for companies aiming to stand out in crowded markets.

Top 10 Shrink Wrap With Logo Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Mr. Shrinkwrap

Domain Est. 1997

Website: mrshrinkwrap.com

Key Highlights: Mr Shrinkwrap is the trusted source for shrink wrap, shrink wrap supplies and shrink wrapping equipment from top manufacturers including Ripack and Shrinkfast ……

#2 Nationwide Shrink Wrapping Services

Domain Est. 2008

Website: atlanticshrinkwrap.com

Key Highlights: Atlantic Shrink Wrapping Inc serves the United States with expert Shrink Wrapping Services for boats, marine, military, commercial, and construction ……

#3 Dr. Shrink

Domain Est. 1997

Website: dr-shrink.com

Key Highlights: Dr. Shrink is the global leader in shrink wrap, and it doesn’t stop at just the products to make it possible. Our extensive How-To library is always growing….

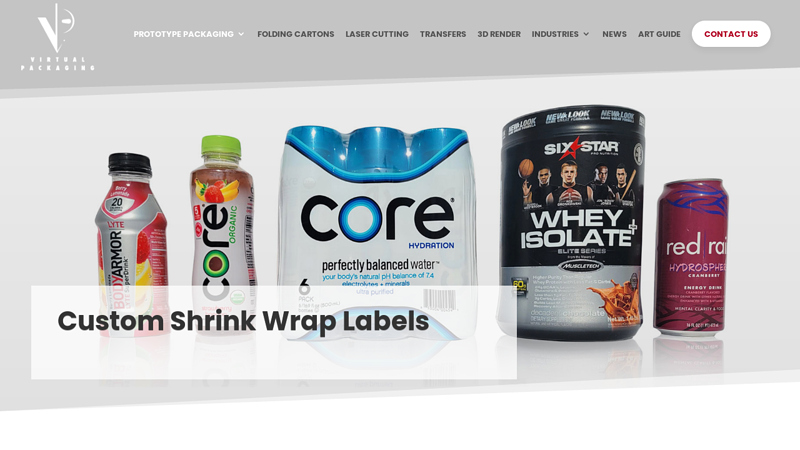

#4 Custom Shrink Wrap Labels

Domain Est. 1998

Website: virtualpackaging.com

Key Highlights: Shrink wrap is the perfect packaging option for products that need protection. Get vibrant, custom shrink wrap labels from Virtual Packaging today!…

#5 Texwrap

Domain Est. 1998

Website: texwrap.com

Key Highlights: Texwrap manufactures a full line of automatic standard and custom shrink wrapping systems, including shrink wrappers, shrink bundlers, L-bar sealers, side……

#6 Shrink Wrap Systems

Domain Est. 1999

Website: prempack.com

Key Highlights: Shrink wrapper systems can aid in multiple applications, and could be just the fit for you. Learn more about shrink wrap packaging benefits!…

#7 National ShrinkWrap

Domain Est. 2002

Website: nationalshrinkwrap.com

Key Highlights: They offer a variety of shrink wrap products, including their own national shrink wrap system, as well as biodegradable shrink wrap options….

#8 Custom Printed Heat Shrink Tubing

Domain Est. 2006

Website: buyheatshrink.com

Key Highlights: Both Text & Branded Logo Options · Very readable after shrinking · Gold & Silver ink available · Clear tube printing · Print on any diameter up to 3”….

#9 Printed Shrink Wrap and Stretch Film Products For Marketing

Domain Est. 2011

Website: uspackagingandwrapping.com

Key Highlights: Printed Pallet Shrink Wrap. Custom printed stretch film in a variety of sizes and thicknesses! Call 1-800-441-5090 or click here for a custom quote!…

#10 Shrink Wrap Rolls

Domain Est. 2023

Website: filmsourcepackaging.com

Key Highlights: We can print your unique designs, logos, and messages directly onto the shrink wrap film, helping you stand out and reinforce brand recognition….

Expert Sourcing Insights for Shrink Wrap With Logo

2026 Market Trends for Shrink Wrap With Logo

Increasing Demand for Brand-Centric Packaging Solutions

By 2026, the demand for shrink wrap with logos is projected to grow significantly as brands intensify their focus on distinctive, recognizable packaging. With rising competition across e-commerce and retail sectors, companies are leveraging branded shrink wrap to enhance shelf appeal, build customer loyalty, and reinforce brand identity. Custom logos and vibrant designs on shrink films serve as cost-effective marketing tools, turning every packaged product into a brand touchpoint.

Sustainability and Eco-Friendly Materials Driving Innovation

Environmental concerns will continue shaping the shrink wrap market in 2026. Consumers and regulators are pushing for sustainable packaging, prompting manufacturers to develop recyclable, biodegradable, and compostable shrink films. Brands incorporating logos into eco-friendly shrink wraps will gain a competitive edge by aligning with green consumer values. Expect increased adoption of plant-based polymers and water-based inks for logo printing, supporting circular economy goals.

Growth in E-Commerce and Product Protection Needs

The expansion of online retail will fuel demand for durable, tamper-evident shrink wrap with branding capabilities. Shrink wrap with logos not only protects products during shipping but also provides an unboxing experience that reinforces brand trust. In 2026, more e-commerce businesses will use branded shrink wrap to differentiate their deliveries, reduce returns, and create a premium customer experience.

Advancements in Printing Technology and Customization

Digital and flexographic printing technologies will enable higher-resolution, full-color logo application on shrink films by 2026. These advancements allow for intricate designs, variable data printing, and short-run customization—ideal for limited editions or regional marketing campaigns. Enhanced print durability ensures logos remain intact after shrinking, even under heat and stress.

Regional Market Expansion and Regulatory Compliance

Emerging markets in Asia-Pacific, Latin America, and Africa will see increased use of branded shrink wrap, driven by rising consumerism and modern retail infrastructure. However, regional packaging regulations—especially concerning plastic usage and labeling—will require brands to adapt logo shrink wrap materials and designs. Compliance with local standards will be critical for multinational companies expanding their reach.

Integration with Smart Packaging and Digital Engagement

By 2026, shrink wrap with logos may incorporate smart features such as QR codes, NFC tags, or augmented reality (AR) markers embedded within the design. These interactive elements can link consumers to brand stories, promotions, or product authenticity verification, transforming static logos into dynamic engagement tools and enhancing customer retention.

Common Pitfalls When Sourcing Shrink Wrap With Logo: Quality and Intellectual Property Issues

Logistics & Compliance Guide for Shrink Wrap With Logo

Product Overview

Shrink wrap with logo refers to heat-shrinkable plastic film customized with a company’s branding, logo, or messaging. Commonly used for packaging consumer goods, food items, electronics, and promotional products, it serves both protective and marketing purposes. This guide outlines the logistics and compliance considerations for sourcing, transporting, and using branded shrink wrap in commercial operations.

Material & Environmental Compliance

Ensure that the shrink wrap material complies with regional and international environmental and safety standards. Common materials include PVC, Polyolefin (POF), and PET. Key compliance points include:

– REACH (EU): Confirm that chemical substances used in the film are registered and do not include restricted substances.

– RoHS (EU/Global): Applicable if used in electronics packaging; verifies absence of hazardous substances.

– FDA Compliance (USA): Required if in direct contact with food; ensure the material is food-grade and complies with 21 CFR regulations.

– Recyclability & Labeling: Use recyclable materials where possible (e.g., POF over PVC). Clearly label the resin type (e.g., #4 LDPE) to support waste sorting.

– Plastic Packaging Tax (UK): If shipping to or operating in the UK, verify whether your shrink wrap contains less than 30% recycled content, which may trigger tax liability.

Custom Printing & Branding Regulations

Logos and branding printed on shrink wrap must adhere to intellectual property and labeling laws:

– Trademark Clearance: Verify that logos, brand names, and designs do not infringe on existing trademarks.

– Ink Compliance: Use non-toxic, food-safe inks if the packaging contacts consumable products. Comply with FDA 21 CFR §175.300 or EU Framework Regulation (EU) No 10/2011 for food contact materials.

– Country-Specific Labeling: Some markets require additional text (e.g., recycling symbols, manufacturer info) in local language—confirm requirements for each target country.

Packaging & Shipping Logistics

Efficient handling and transport of shrink wrap rolls or bundles require attention to:

– Storage Conditions: Store in a cool, dry place away from direct sunlight and heat sources to prevent premature shrinking or deformation.

– Palletization & Protection: Secure rolls on pallets using stretch wrap or banding. Use edge protectors and corner boards to prevent damage during transit.

– Weight & Dimensions: Optimize roll size and core diameter (commonly 3″, 6″, or 9″) to balance shipping efficiency and machine compatibility.

– Hazard Classification: Shrink wrap is typically non-hazardous, but confirm classification under IATA, IMDG, or ADR regulations if shipping internationally.

– Import/Export Documentation: Provide commercial invoices, packing lists, and material safety data sheets (MSDS) if requested. Include HTS codes (e.g., 3920.10 for plastic films) for customs clearance.

Sustainability & Waste Management

Environmental responsibility is increasingly critical in packaging logistics:

– Reduce Over-Packaging: Optimize film thickness (gauge) to minimize material use while ensuring product protection.

– Recycling Programs: Partner with suppliers offering take-back or recycling programs for used film.

– Carbon Footprint: Choose suppliers with local manufacturing to reduce transport emissions. Consider bio-based or compostable films where technically feasible.

Quality Assurance & Supplier Compliance

Establish clear quality standards with suppliers:

– Pre-Production Samples: Request printed samples to verify logo accuracy, color matching (Pantone standards), and film clarity.

– Batch Testing: Require certificates of conformance (CoC) for thickness, shrink ratio, tensile strength, and seal integrity.

– Audit Suppliers: Evaluate supplier compliance with ISO 9001 (quality management) and ISO 14001 (environmental management).

End-User Application & Safety

Ensure safe and compliant use by your customers or production teams:

– Heat Application Safety: Provide guidelines for shrink tunnel temperatures and conveyor speeds to prevent overheating or fire hazards.

– Ventilation: Use in well-ventilated areas, especially with PVC film, which can release HCl gas if overheated.

– Machine Compatibility: Confirm that the shrink wrap width, thickness, and core size are compatible with the user’s packaging equipment.

Recordkeeping & Traceability

Maintain documentation to support compliance and operational efficiency:

– Batch Tracking: Record lot numbers, production dates, and supplier information for traceability.

– Compliance Files: Archive test reports, CoCs, and regulatory approvals for audits or customer requests.

– Change Management: Document any material or design changes that could affect compliance or performance.

By following this logistics and compliance guide, businesses can ensure that their use of shrink wrap with logo is safe, legally compliant, environmentally responsible, and operationally efficient across the supply chain.

Conclusion:

Sourcing shrink wrap with a custom logo is a strategic investment that enhances brand visibility, protects products during transit, and adds a professional touch to packaging. By partnering with a reliable supplier that offers high-quality materials, consistent print accuracy, and customization options, businesses can effectively strengthen their brand identity while ensuring product integrity. It is essential to evaluate factors such as material durability, printing technique, lead times, and cost-effectiveness to make an informed decision. Ultimately, branded shrink wrap not only serves a functional purpose but also acts as a mobile marketing tool, leaving a lasting impression on customers and contributing to overall brand recognition and customer satisfaction.