The global bathroom fixtures and fittings market has seen steady expansion, driven by rising residential and commercial construction, increasing urbanization, and growing consumer focus on water efficiency and bathroom aesthetics. According to a 2023 report by Mordor Intelligence, the global shower door sealant market is projected to grow at a CAGR of approximately 4.8% from 2023 to 2028. Factors such as the proliferation of frameless glass shower enclosures—which require high-performance sealants to prevent leaks and mold—and the shift toward premium bathroom renovations in both developed and emerging markets are fueling demand. Additionally, innovations in silicone and non-silicone formulations, including mold-resistant and eco-friendly options, are redefining product standards. As competition intensifies, a handful of manufacturers have emerged as leaders, combining R&D investment, product reliability, and global distribution networks to capture significant market share. Based on market presence, product performance data, and industry reviews, here are the top 8 shower door sealant manufacturers shaping the current landscape.

Top 8 Shower Door Sealant Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Leading China Shower Door Seal Manufacturer

Domain Est. 2024

Website: glassseals.com

Key Highlights: SIMBA is a trusted China-based manufacturer of high-quality shower door seals, offering custom, OEM, and bulk solutions. Contact us for waterproof seals!…

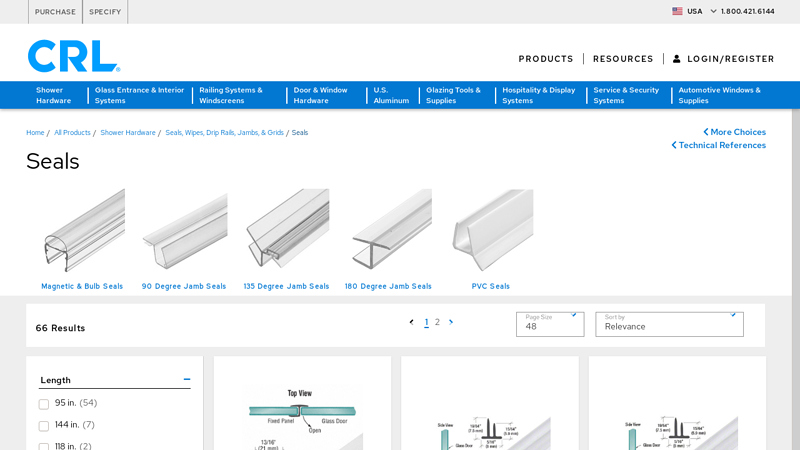

#2 Glass Shower Door Seals

Domain Est. 1995

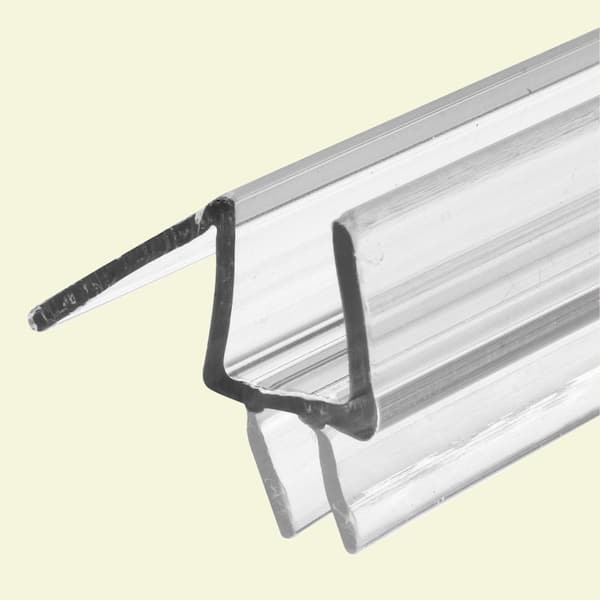

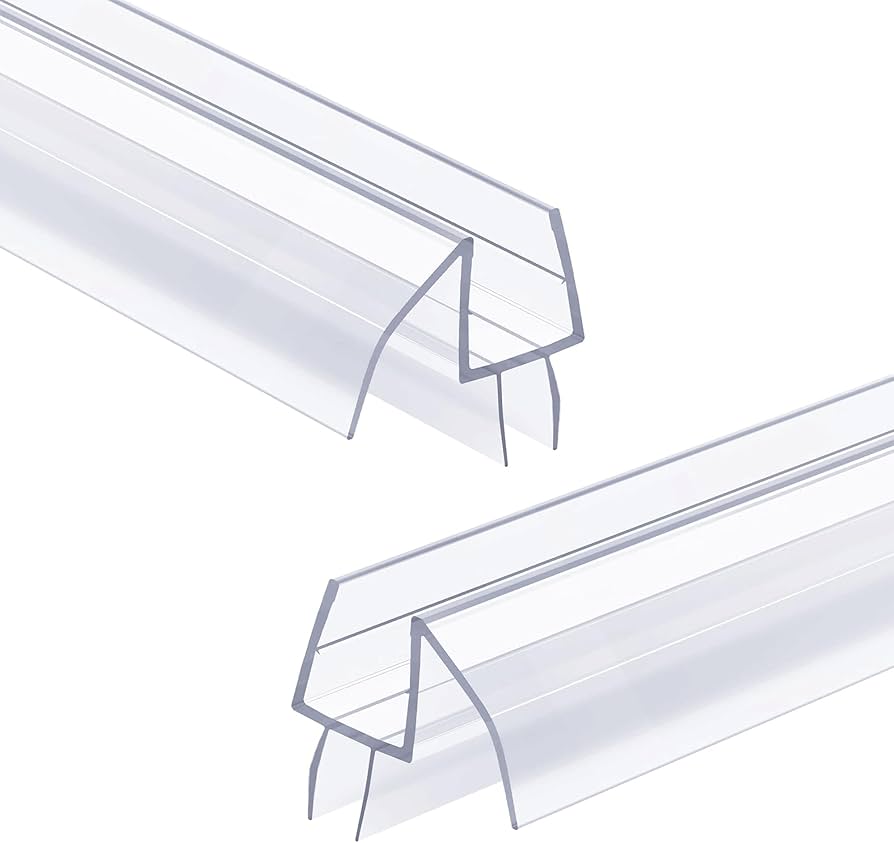

#3 Frameless Shower Door Seal (8 Different Available Types Now)

Domain Est. 2001

Website: framelessshowerdoors.com

Key Highlights: Interested in getting a frameless shower door seal? We got you covered with 8 different styles such as h jamb, bulb seal, angle jamb, and even glass gap ……

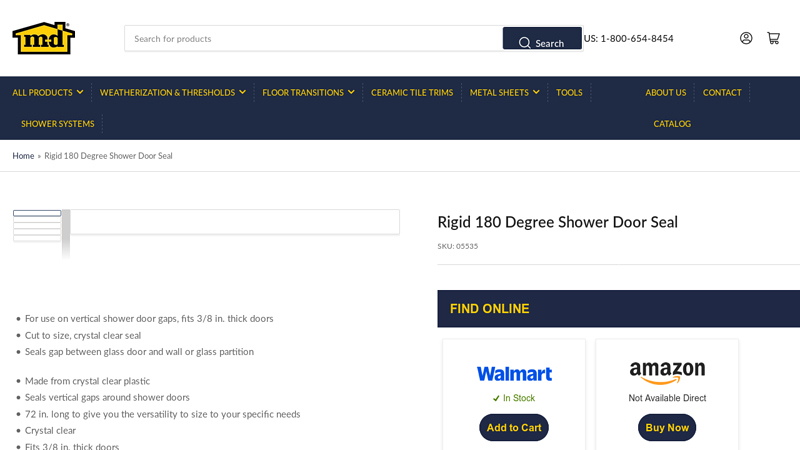

#4 Rigid 180 Degree Shower Door Seal

Domain Est. 2003

Website: mdbuildingproducts.com

Key Highlights: In stock Rating 1.0 1 For use on vertical shower door gaps, fits 3/8 in. thick doors · Cut to size, crystal clear seal · Seals gap between glass door and wall or glass partition….

#5 Shower Door Seals and Sweeps

Domain Est. 2004

#6 GE Sealants

Domain Est. 2016

Website: gesealants.com

Key Highlights: For more than 80 years, GE Sealants has led the caulk and sealants industry with a wide selection of hybrid, acrylic, and silicone caulk and sealants….

#7 FHC

Domain Est. 2019

Website: fhc-usa.com

Key Highlights: We provide a complete range of tools and supplies as well as innovative hardware product solutions for frameless shower doors, commercial storefronts….

#8 Top 10 Shower Door Seals Suppliers in the World

Domain Est. 2024

Website: shower-seals.com

Key Highlights: Top 10 Shower Door Seals Suppliers in the World · 1. C.R. Laurence (CRL) · 2. Frameless Hardware Company (FHC) · 3. The Original Frameless Shower Doors · 4. Shower- ……

Expert Sourcing Insights for Shower Door Sealant

H2: 2026 Market Trends for Shower Door Sealant

The global shower door sealant market is poised for steady growth and transformation by 2026, driven by evolving consumer preferences, advancements in materials, and increased focus on bathroom hygiene and water conservation. Key trends shaping the industry include:

-

Rise in Demand for Mold-Resistant and Antimicrobial Formulations

Homeowners and commercial developers are increasingly prioritizing health and hygiene, especially post-pandemic. In response, manufacturers are innovating with sealants infused with antimicrobial additives that inhibit mold and mildew growth—a common issue in humid bathroom environments. By 2026, products touting long-term resistance to microbial buildup are expected to dominate shelves and online marketplaces. -

Growth in Renovation and Bathroom Remodeling Activities

The residential renovation sector, particularly in North America and Europe, continues to expand. As consumers upgrade bathrooms for aesthetic appeal and functionality, the demand for reliable, easy-to-install sealants rises. Shower door sealants that offer a clean, seamless look while ensuring watertight integrity are becoming essential components in modern bathroom designs. -

Shift Toward Eco-Friendly and Low-VOC Sealants

Environmental regulations and consumer awareness are pushing the market toward sustainable solutions. Sealants with low volatile organic compound (VOC) content, recyclable packaging, and bio-based ingredients are gaining traction. By 2026, green-certified products are expected to capture a significant market share, especially in regions with strict environmental standards like the EU and California. -

Increased Adoption of Pre-Attached and Self-Adhesive Sealant Strips

Convenience and DIY-friendly installation are major selling points. Pre-attached brush or rubber seals and peel-and-stick silicone strips are becoming popular due to their ease of application and minimal maintenance. These products appeal to both homeowners and contractors looking to reduce labor time and costs. -

Expansion in Emerging Markets

Rapid urbanization and rising disposable incomes in Asia-Pacific, Latin America, and the Middle East are fueling demand for modern bathroom fixtures and accessories. As housing developments incorporate glass shower enclosures more frequently, the need for high-performance sealants grows, presenting growth opportunities for international brands. -

Integration with Smart Bathroom Ecosystems

While still in early stages, there is growing interest in smart bathroom technologies. By 2026, we may see sealants developed with moisture-sensing indicators or compatibility with humidity-control systems, providing proactive maintenance alerts and enhancing overall bathroom performance. -

Consolidation and Brand Differentiation

The market is witnessing increased competition, prompting key players to differentiate through product innovation, extended warranties, and aesthetic customization (e.g., color-matched seals). Strategic partnerships with shower door manufacturers are also becoming common to offer bundled, performance-optimized solutions.

In summary, the 2026 shower door sealant market will be defined by innovation in materials, a strong emphasis on health and sustainability, and alignment with broader trends in home improvement and smart living. Companies that adapt to these dynamics will be well-positioned to capture growing consumer demand globally.

Common Pitfalls When Sourcing Shower Door Sealant (Quality, IP)

Sourcing the right shower door sealant is critical for preventing water damage, mold growth, and ensuring long-term bathroom integrity. However, several common pitfalls related to quality and IP (Ingress Protection) ratings can compromise performance if not carefully addressed.

Overlooking Material Quality and Durability

Low-quality sealants often degrade quickly due to constant exposure to moisture, temperature fluctuations, and cleaning chemicals. Using inferior silicone or non-UV-stable materials can result in cracking, yellowing, or loss of adhesion within months. Always verify the sealant is made from high-grade, mold-resistant silicone specifically formulated for bathroom environments.

Ignoring IP Rating Requirements

Many buyers assume all sealants offer adequate water protection, but true water ingress protection requires attention to IP ratings. For shower doors, an appropriate IPX4 (splash-resistant) or higher rating is essential. Failing to confirm the sealant’s compatibility with required IP standards can result in inadequate sealing, leading to water leakage around door edges and track systems.

Assuming All Sealants Are Mold and Mildew Resistant

Not all sealants contain effective antimicrobial additives. In humid environments like showers, standard sealants can become breeding grounds for mold and mildew. Ensure the product explicitly states mold and mildew resistance and has been tested under real-world bathroom conditions.

Poor Fit and Design Compatibility

Even high-quality sealants fail if they’re not dimensionally suited to the shower door profile. Using generic or ill-fitting strips can leave gaps, allowing water to escape. Always match the sealant’s shape (e.g., D-shape, P-shape) and size precisely to the door and frame design.

Neglecting Installation Best Practices

High performance depends on proper installation. Contaminated surfaces, inadequate curing time, or incorrect application techniques can undermine even the best sealant. Ensure installers are trained and follow manufacturer guidelines for surface preparation and application.

Selecting Based Solely on Price

Opting for the cheapest option often leads to higher long-term costs due to premature failure and rework. Prioritize total cost of ownership by evaluating lifespan, maintenance needs, and warranty support rather than initial price alone.

By avoiding these pitfalls and focusing on verified quality, appropriate IP ratings, and correct application, you can ensure reliable, long-lasting performance from shower door sealants.

Logistics & Compliance Guide for Shower Door Sealant

Product Classification and Regulatory Overview

Shower door sealant is typically classified as a construction sealant or bathroom sealant, often based on silicone or polyurethane formulations. It may contain antimicrobial agents to resist mold and mildew. Regulatory oversight primarily involves volatile organic compound (VOC) emissions, chemical safety, and labeling requirements. Key regulations include those from the U.S. Environmental Protection Agency (EPA), Occupational Safety and Health Administration (OSHA), and state-level authorities such as the California Air Resources Board (CARB). Internationally, compliance with REACH (EU), CLP Regulation, and other regional standards is essential for market access.

Packaging and Labeling Requirements

All shower door sealant products must be packaged in containers that prevent leakage and maintain product integrity during transport and storage. Primary packaging (e.g., caulk tubes) must be clearly labeled with:

– Product name and intended use

– Manufacturer or distributor information

– Batch or lot number

– Expiration date

– Net quantity

– Hazard pictograms and signal words (per GHS standards)

– Precautionary statements and first aid measures

– VOC content (if applicable)

– Compliance with local labeling laws (e.g., TSCA in the U.S., CLP in the EU)

Ensure bilingual labeling where required (e.g., English and French in Canada).

Transportation and Storage Guidelines

Transport sealants in accordance with Department of Transportation (DOT) Hazard Class 9 (Miscellaneous Hazardous Materials) if applicable, particularly for flammable formulations. Use temperature-controlled environments when possible; store between 40°F and 90°F (4°C to 32°C) to prevent premature curing or separation. Avoid direct sunlight and ensure containers are upright and sealed. Segregate from oxidizers and incompatible materials. For international shipping, comply with IMDG Code (maritime), IATA DGR (air), or ADR (road) as appropriate.

VOC and Environmental Compliance

Silicone-based sealants are generally low in VOCs, but formulations with solvents may be subject to VOC limits. In the U.S., ensure compliance with EPA Method 24 and regional standards such as SCAQMD Rule 1168 or CARB Architectural Coatings Regulation. In the EU, adhere to the EU Ecolabel criteria for indoor sealants and REACH SVHC (Substances of Very High Concern) disclosure requirements. Maintain updated VOC test reports and Safety Data Sheets (SDS) reflecting accurate emissions data.

Safety Data Sheet (SDS) and Hazard Communication

Provide a GHS-compliant SDS (16-section format) for each product variant. The SDS must include:

– Identification of the substance/mixture

– Hazard(s) identification

– Composition/information on ingredients

– First-aid and firefighting measures

– Accidental release measures

– Handling and storage recommendations

– Exposure controls and PPE

– Physical and chemical properties

– Stability and reactivity

– Toxicological and ecological information

– Disposal considerations

– Transport information

– Regulatory information

– Other relevant data

Review and update SDS every 3–5 years or when formulation changes occur.

Import/Export Considerations

For international trade, verify import regulations in destination countries. Key documentation includes:

– Commercial invoice

– Packing list

– Bill of lading or air waybill

– SDS and product specification sheets

– Certificate of Origin

– VOC compliance certification (e.g., CARB, EU Ecolabel)

– REACH pre-registration or authorization (if applicable)

Ensure proper Harmonized System (HS) code classification—typically under 3506.91 or 3506.99 for sealants. Consult customs brokers to confirm tariff and duty requirements.

Sustainable Practices and End-of-Life Management

Promote recycling where packaging is recyclable (e.g., aluminum caulk tubes). Advise consumers and contractors on proper disposal: uncured sealant should be treated as hazardous waste if flammable or toxic; cured sealant may be disposed of as non-hazardous solid waste. Offer take-back programs or partner with waste management services to support responsible disposal. Explore low-VOC, bio-based, or recyclable packaging innovations to enhance sustainability credentials.

Regulatory Monitoring and Updates

Assign responsibility for ongoing regulatory monitoring to a compliance officer or team. Subscribe to regulatory updates from EPA, OSHA, CARB, ECHA, and other relevant agencies. Conduct annual compliance audits and maintain a compliance management system to track changes in labeling, VOC limits, and chemical restrictions. Participate in industry associations (e.g., ASC – Adhesive and Sealant Council) to stay informed on best practices and upcoming regulations.

In conclusion, sourcing the right shower door sealant is essential for maintaining a water-tight, mold-resistant, and durable bathroom environment. Key considerations such as material compatibility, water resistance, ease of application, mold and mildew resistance, and longevity should guide the selection process. After evaluating various options—including silicone-based, acrylic, and specialty sealants—the most effective choice tends to be a high-quality, mildew-resistant silicone sealant due to its durability, flexibility, and superior adhesion to glass and framing materials.

When sourcing, it’s important to prioritize reputable suppliers or brands known for consistent performance and compliance with indoor air quality standards (e.g., low VOC emissions). Whether purchasing from local hardware stores, online retailers, or professional-grade suppliers, comparing product specifications, customer reviews, and warranty offerings ensures a reliable and cost-effective decision.

Ultimately, investing time in selecting and correctly applying the proper sealant not only enhances the functionality and aesthetics of the shower enclosure but also reduces long-term maintenance and repair costs, contributing to a healthier and more sustainable bathroom environment.