The global oil and gas drilling equipment market is experiencing steady growth, driven by rising energy demand and increased exploration activities, particularly in emerging economies. According to Mordor Intelligence, the global mud motor market was valued at approximately USD 1.2 billion in 2023 and is projected to grow at a CAGR of over 5.8% from 2024 to 2029. This growth is fueled by the expanding adoption of directional drilling techniques, where short tail mud motor kits play a critical role in enhancing drilling efficiency and precision. As operators seek reliable, high-performance tools to reduce non-productive time and improve wellbore placement, the demand for advanced mud motor solutions continues to rise. In this competitive landscape, a select group of manufacturers has emerged as leaders, combining innovation, durability, and technical expertise to serve upstream operations worldwide. Based on market presence, product performance, and technological advancement, the following nine companies represent the top short tail mud motor kit manufacturers shaping the future of directional drilling.

Top 9 Short Tail Mud Motor Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

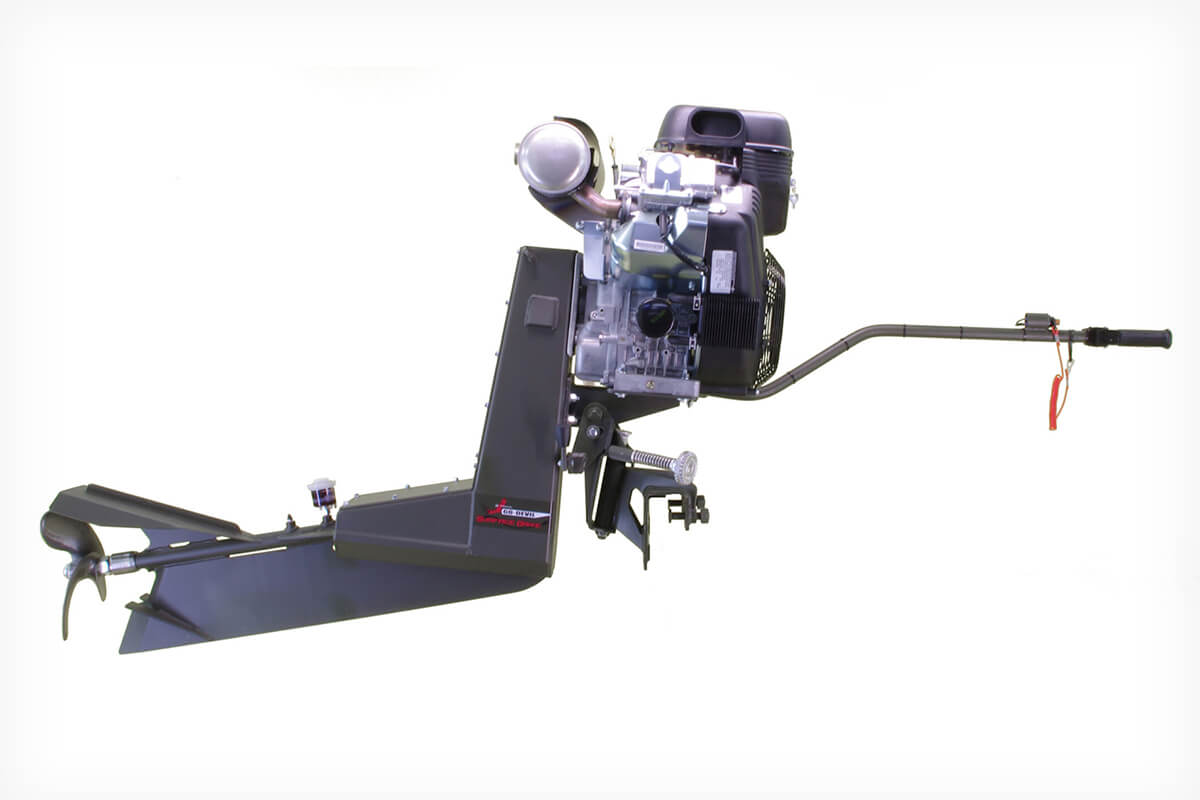

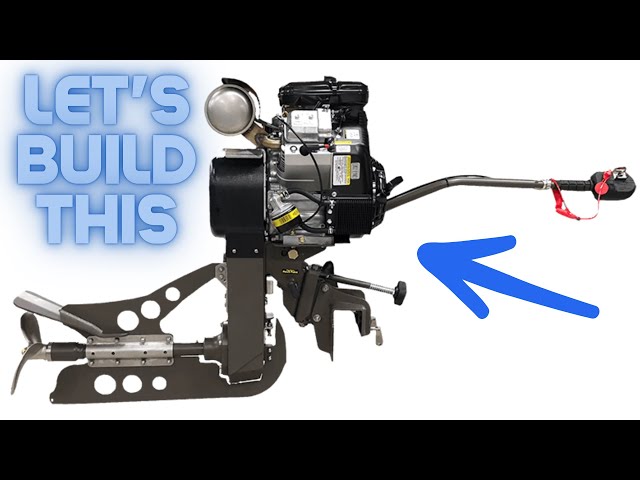

#1 Surface Drives

Domain Est. 1997

Website: godevil.com

Key Highlights: The GO-DEVIL® Surface Drive Engine is packed with features that are engineered to provide our customers the maximum performance and durability….

#2 Motors

Domain Est. 2010

Website: backwaterinc.com

Key Highlights: We have made a giant leap forward with the introduction of our SWOMP series of mud motors. If you have any questions, call 320-420-8202 to speak with an expert ……

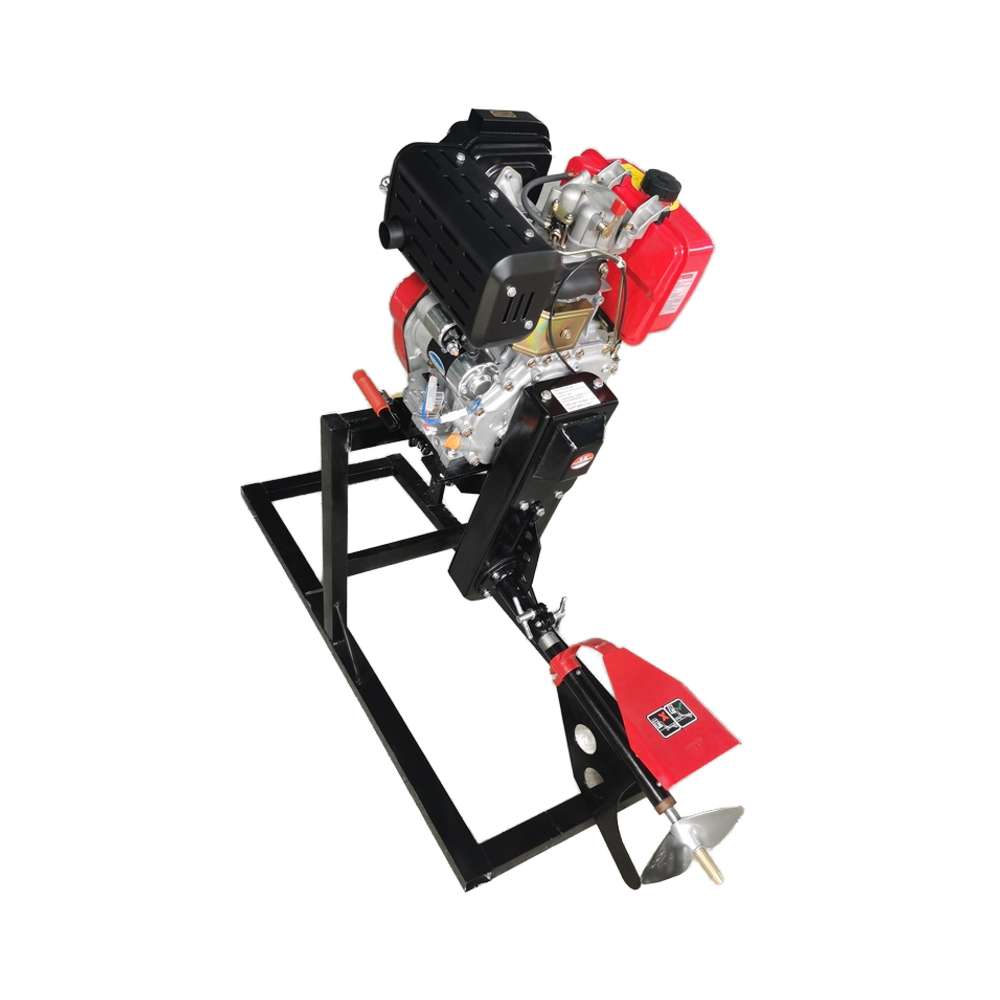

#3 PFF Mud Motors

Domain Est. 2013

#4 which mud motor is right for you?

Domain Est. 1999

Website: mudbuddy.com

Key Highlights: As the world’s largest mud motor company, Mud Buddy Motors has a broader range of Longtail and Short Tail Surface Drive Mud Motors than all other mud motor ……

#5 GatorTail Outboards

Domain Est. 2003

Website: gator-tail.com

Key Highlights: Gator Tail Outboards are the toughest mud motors and surface drive boats on the planet. Gator Tail can take you places you never thought possible….

#6 TWISTER SHORT LONG TAIL 18

Domain Est. 2013

Website: mud-skipper.com

Key Highlights: In stock Rating 5.0 (3) Twister 4. Suitable for 18-23hp engines with 1″ Horizontal Keyed Output Shafts. We’ve beefed up our Twister XL and installed a redesigned flex shaft capab…

#7 BEAVER DAM MUD RUNNERS~A World To See Get Where You …

Domain Est. 2013

Website: beaverdammudrunners.com

Key Highlights: Beavertail Longtail Mud Motor Kits for Jon Boats & More. Explore the World of Long Tail Mud Motor Kits with Beaver Dam Mud RunnersWelcome to… Read more….

#8 Backwater Performance Store

Domain Est. 2015

Website: backwaterperformance.com

Key Highlights: 6–9 day delivery · 30-day returns…

#9 CKS INTER CO.,LTD

Domain Est. 2022

Website: en.ckspro.com

Key Highlights: Short tail SC300 V.2 for 9-13 hp engine (mud motor)(mud motor)(excluding engine). 13,500.00 THB. Short tail SC390 V.2 for 9-13 hp engine (mud ……

Expert Sourcing Insights for Short Tail Mud Motor Kit

H2: 2026 Market Trends for Short Tail Mud Motor Kits

The Short Tail Mud Motor Kit market is projected to experience significant evolution by 2026, driven by technological advancements, shifting drilling demands, and regional energy dynamics. Below is an analysis of the key trends expected to shape this specialized oilfield equipment segment.

H2: Increasing Demand for Directional Drilling Efficiency

Short tail mud motor kits are poised to gain traction due to their inherent advantage in enabling high-precision directional drilling with reduced equipment footprint. As operators focus on maximizing hydrocarbon recovery from complex reservoirs—particularly in shale plays and offshore fields—there is a growing preference for compact, agile motor systems. The short tail design allows for tighter build rates and improved steerability in confined spaces, making it ideal for slimhole and multilateral drilling applications. By 2026, rising activity in unconventional formations across North America, the Middle East, and parts of Latin America is expected to boost demand for these efficient motor kits.

H2: Technological Innovation and Material Advancements

Advancements in materials science and motor design are expected to enhance the durability and performance of short tail mud motor kits. Innovations such as high-torque rotor-stator configurations, improved elastomer formulations resistant to high temperatures and abrasive drilling fluids, and integrated measurement-while-drilling (MWD) compatibility will define next-generation kits. By 2026, manufacturers are likely to offer smart motor kits with embedded sensors for real-time downhole diagnostics, enabling predictive maintenance and reducing non-productive time. This trend toward digitalization and reliability will appeal to operators seeking to optimize drilling performance and lower operational costs.

H2: Regional Market Diversification and Growth

While North America—particularly the U.S. shale basins—will remain a dominant market, emerging regions are expected to contribute significantly to growth by 2026. Expansion in deepwater projects in Brazil, enhanced oil recovery initiatives in the Middle East, and onshore developments in Africa and Southeast Asia will drive demand for versatile drilling tools like short tail mud motor kits. Moreover, national oil companies are increasingly investing in advanced drilling technologies, creating new opportunities for equipment suppliers. Localization strategies and regional service hubs are expected to emerge as competitive advantages.

H2: Competitive Landscape and Supply Chain Optimization

The market will likely see intensified competition among key players such as Schlumberger (SLB), Halliburton, Baker Hughes, and specialized OEMs. Differentiation will stem from technological superiority, service support, and cost-efficiency. By 2026, strategic partnerships between motor kit manufacturers and drilling contractors could become more common to co-develop customized solutions. Additionally, supply chain resilience—especially post-pandemic and amid geopolitical volatility—will be critical. Companies investing in modular designs and localized manufacturing may achieve faster delivery times and reduced lead times, enhancing market responsiveness.

H2: Sustainability and Operational Cost Pressures

Environmental, social, and governance (ESG) considerations are influencing drilling operations, prompting demand for more energy-efficient and lower-emission technologies. While mud motors are inherently mechanical, improvements in efficiency reduce fuel consumption and associated emissions per foot drilled. Furthermore, the longer lifespan and reduced failure rates of advanced short tail kits contribute to lower waste and fewer tripping operations. Operators seeking to meet sustainability goals while maintaining economic viability will increasingly favor high-performance, durable motor kits, accelerating adoption by 2026.

In summary, the 2026 outlook for short tail mud motor kits is positive, characterized by technological innovation, expanding applications, and growing demand across diverse geographies. Success will depend on adaptability, performance reliability, and alignment with broader industry trends toward efficiency and sustainability.

Common Pitfalls When Sourcing Short Tail Mud Motor Kits: Quality and Intellectual Property Risks

Sourcing Short Tail Mud Motor Kits, especially from non-OEM or offshore suppliers, presents several critical challenges related to product quality and intellectual property (IP) protection. Being aware of these pitfalls is essential for maintaining operational reliability and avoiding legal exposure.

Quality Inconsistencies and Substandard Components

One of the most prevalent issues is inconsistent quality. Non-certified or unauthorized manufacturers may use inferior materials—such as low-grade steels or subpar elastomers—that fail prematurely under downhole conditions. This can lead to catastrophic motor failures, unplanned downtime, and costly fishing operations. Additionally, dimensional inaccuracies or poor machining tolerances can prevent proper assembly or cause premature wear. Without adherence to API specifications or ISO quality standards, there is no guarantee of performance, durability, or interchangeability with OEM equipment.

Lack of Traceability and Certification

Many low-cost suppliers cannot provide proper documentation, such as material test reports (MTRs), quality control certifications, or compliance with API 6A/13A standards. This lack of traceability makes it difficult to verify the origin of components or validate performance claims. In regulated environments or high-risk drilling operations, using uncertified equipment can violate safety protocols and expose operators to liability in the event of failure.

Intellectual Property Infringement

Short Tail Mud Motor designs are often protected by patents and technical copyrights held by original equipment manufacturers (OEMs). Sourcing replicas or “compatible” kits from third parties may involve the unauthorized use of proprietary designs, leading to IP infringement. Buyers risk legal action, seizure of equipment by customs, or reputational damage. Even if the supplier claims the product is “reverse-engineered,” it may still violate design or utility patents, especially in jurisdictions with strong IP enforcement.

Voided Warranties and Limited Support

Using non-OEM kits typically voids the warranty on the entire motor assembly or associated tools. Moreover, technical support and troubleshooting assistance are often unavailable from OEMs when third-party components are involved. This lack of support increases operational risk, especially in complex or deep drilling scenarios where motor performance is critical.

Supply Chain and Counterfeit Risks

Global supply chains can introduce counterfeit or misrepresented products. Some suppliers may rebrand used or refurbished parts as new, or falsely claim OEM affiliation. Without rigorous vetting and on-site audits, buyers may inadvertently purchase unreliable or unsafe equipment, undermining drilling efficiency and safety.

To mitigate these risks, buyers should prioritize suppliers with proven quality management systems, request full technical documentation, verify IP compliance, and consider the long-term cost of failure—not just the initial purchase price.

Logistics & Compliance Guide for Short Tail Mud Motor Kit

This guide outlines the essential logistics and compliance considerations for the international shipment, handling, and use of the Short Tail Mud Motor Kit. Adherence to these guidelines ensures safe, efficient, and legally compliant operations across the supply chain.

Regulatory Classification & Documentation

Proper classification of the Short Tail Mud Motor Kit is critical for customs clearance and regulatory compliance. The kit typically consists of downhole drilling tools made from high-strength steel, elastomers, and specialized alloys.

- HS Code (Harmonized System Code): 8431.39.00 – Parts suitable for use solely or principally with drilling or boring machinery. Note: Confirm with local customs authority, as sub-categorization may vary by country.

- Export Control Classification Number (ECCN): Likely EAR99 under the U.S. Export Administration Regulations (EAR), indicating low-level dual-use controls. Confirm if any components (e.g., specialized sensors) require stricter controls.

- Required Documentation:

- Commercial Invoice (with full product description, value, and country of origin)

- Packing List (detailing weight, dimensions, and contents per package)

- Bill of Lading or Air Waybill

- Certificate of Origin (if required by destination country)

- Export Declaration (as required by exporting country)

Packaging & Handling Standards

Robust packaging is essential to protect the mud motor kit during transit and prevent damage that could compromise operational safety.

- Packaging Requirements:

- Use heavy-duty wooden crates or steel-reinforced containers compliant with ISPM 15 for international shipments.

- Apply internal padding and bracing to prevent movement; use corrosion-inhibiting VCI (Vapor Corrosion Inhibitor) paper or grease on metal surfaces.

- Clearly label packages with “Fragile,” “This Side Up,” and “Do Not Stack” indicators.

- Handling Instructions:

- Use certified lifting equipment with soft slings to avoid damaging threads or housings.

- Avoid dropping or impacting motor components.

- Store in a dry, temperature-controlled environment when not in transit.

Transportation & Shipping

The transportation method must account for the weight, dimensions, and sensitivity of the mud motor components.

- Mode of Transport:

- Air Freight: Suitable for urgent shipments; confirm weight and dimensional restrictions with carrier.

- Sea Freight: Most cost-effective for large kits; use 20’ or 40’ dry containers; ensure proper lashing and moisture control.

- Ground Transport: Use flatbed or step-deck trailers with secure tie-downs for regional movement.

- Special Considerations:

- Avoid exposure to extreme temperatures or prolonged humidity.

- Monitor for customs delays; pre-clear documentation where possible.

Import & Customs Clearance

Timely customs clearance requires accurate compliance with the destination country’s import regulations.

- Duties & Taxes: Calculate applicable import duties, VAT, or GST based on declared value and HS code. Use Incoterms (e.g., DDP, DAP, FOB) to clarify responsibility.

- Compliance Requirements:

- Provide technical specifications if requested by customs.

- Some countries may require product certification (e.g., CE, GOST, SONCAP) – verify in advance.

- Register with local customs brokers familiar with oilfield equipment imports.

Environmental & Safety Compliance

Ensure the mud motor kit meets environmental and occupational health and safety standards.

- Hazardous Materials: Confirm kit contains no hazardous substances (e.g., restricted chemicals in elastomers). Provide SDS (Safety Data Sheet) if applicable.

- RoHS & REACH: Comply with EU directives on restricted substances if shipping to Europe.

- End-of-Life Disposal: Follow local regulations for disposal of worn or damaged components; recycle metals where possible.

Operational Compliance

The end-user must ensure the mud motor is operated in accordance with industry standards and regulatory frameworks.

- API Standards: Equipment should meet relevant API specifications (e.g., API 7-1 for drilling equipment).

- Wellbore Regulations: Operators must comply with drilling permits, environmental impact assessments, and safety protocols (e.g., OSHA, HSE).

- Training & Certification: Personnel using the kit should be trained in proper handling, inspection, and operational procedures.

Recordkeeping & Traceability

Maintain comprehensive records for audit, warranty, and regulatory purposes.

- Documentation to Retain:

- Batch/serial numbers of components

- Shipping and customs documents

- Inspection and test reports

- Maintenance logs (post-deployment)

- Retention Period: Minimum of 5 years, or as required by jurisdiction or client contracts.

Adhering to this logistics and compliance framework ensures the safe, legal, and efficient deployment of the Short Tail Mud Motor Kit across global operations. Always consult local regulations and involve compliance experts when entering new markets.

Conclusion:

After a comprehensive evaluation of potential suppliers and market options for the short tail mud motor kit, it is evident that sourcing from specialized oilfield equipment manufacturers with proven track records in mud motor production offers the most reliable and cost-effective solution. Suppliers from regions such as China, North America, and the Middle East provide competitive pricing, technical expertise, and after-sales support. However, priority should be given to vendors who comply with industry standards (e.g., API and ISO certifications), offer strong warranty terms, and demonstrate consistent product quality.

Direct engagement with manufacturers—supported by rigorous technical assessments, sample testing, and supply chain due diligence—will mitigate risks related to performance, delivery timelines, and long-term maintenance. Additionally, establishing long-term partnerships with one or two key suppliers can enhance supply chain resilience and potentially secure favorable pricing and service agreements.

In conclusion, the optimal sourcing strategy for the short tail mud motor kit combines quality assurance, regulatory compliance, technical support, and strategic supplier relationships to ensure operational efficiency and reliability in drilling applications.