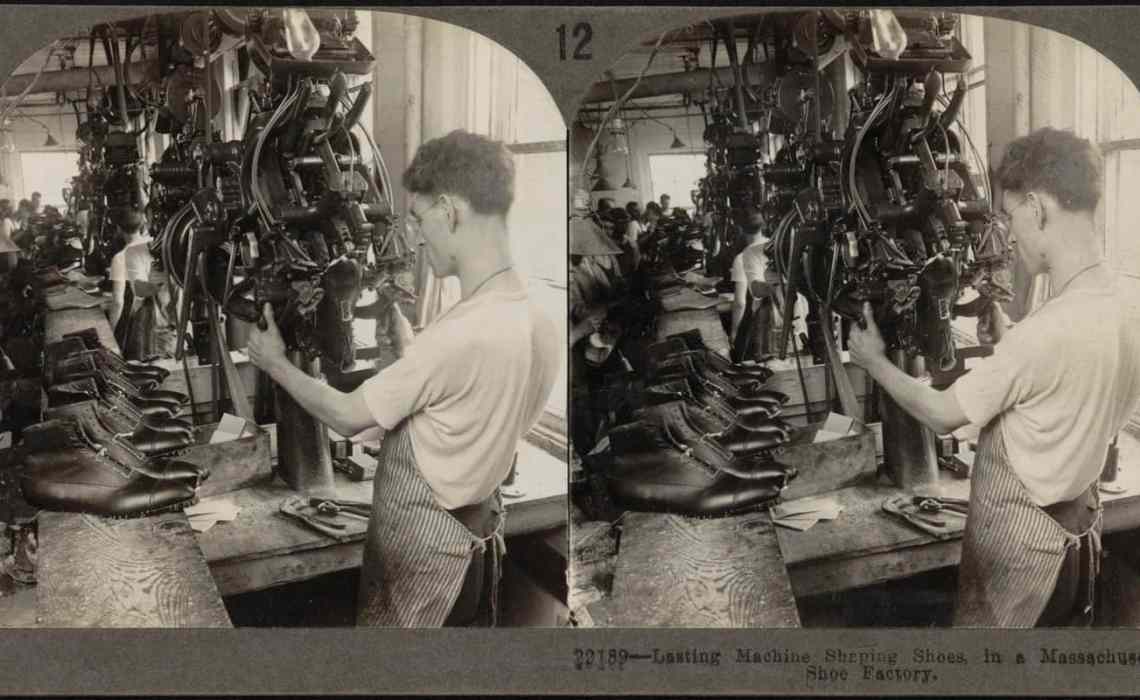

The global footwear manufacturing equipment market is experiencing steady growth, driven by rising demand for automated production solutions and the expansion of the global footwear industry. According to Mordor Intelligence, the footwear market is projected to grow at a CAGR of over 5.5% between 2023 and 2028, bolstering the need for advanced machinery such as shoe lasting machines that enhance precision, efficiency, and production speed. As labor costs rise and manufacturers seek to reduce cycle times, automation in processes like lasting — where the upper is stretched and secured over the last — has become critical. Grand View Research notes that the increasing adoption of automated systems in footwear manufacturing, particularly across Asia-Pacific’s leading production hubs, is accelerating investment in high-performance lasting equipment. In this competitive landscape, a select group of manufacturers has emerged as leaders, offering innovative, durable, and technologically advanced shoe lasting solutions that cater to both mass production and niche markets.

Top 10 Shoe Lasting Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ESM Shoe Machinery

Domain Est. 2018

Website: esmshoemachinery.com

Key Highlights: ESM Shoe Machinery, Iridium Works, 65-66 Carrington Street, Kettering Northamptonshire, NN16 0BY, UK, [email protected], +44 (0)1536 483 583…

#2 Shoes Making Machine Manufacturer Factory,Toe Lasting Machine …

Domain Est. 2022

Website: shoes-machine.com

Key Highlights: DaFeng Shoes Making Machine Factory Is One Of Top Ten Shoes Making Machine Manufacturer And Supplier In China,Start With Toe Lasting Machine,Help You Build ……

#3 Tecnica Group

Domain Est. 2003

Website: tecnicagroup.com

Key Highlights: Tecnica Group is a leading sport equipment manufacturer in the market of footwear and winter sports equipment….

#4 Elitech Shoe Making Machines

Domain Est. 2014 | Founded: 2005

Website: shoemachinery.com.tw

Key Highlights: We offer the Complete Set Shoe Machines from Taiwan since 2005, Free Consultant of shoe factory set up, Shoe Factory Planning and Layout, Shoe Machines ……

#5 Tenghong Lasting Machines for Footwear Manufacturing

Domain Est. 2022

Website: tenghongmachinery.com

Key Highlights: Tenghong’s lasting machines are engineered for precision, durability, and high efficiency, making them ideal for both small and large manufacturers….

#6 Kouyi Shoe Manufacturing Machine: Shoe Machines

Domain Est. 1997 | Founded: 1959

Website: kouyi.com.tw

Key Highlights: Kou Yi has manufactured all kinds of shoe machine, shoes making machine since 1959. In 1962, due to the increasing demands of shoe-manufacturing sector….

#7 Shoe Making Machinery Supplier

Domain Est. 1998

Website: chenfeng.com.tw

Key Highlights: We have a professional R&D team with electromechanical integration design, automation and system design, and focus on product development, manufacturing, sales ……

#8 NEWLAST

Domain Est. 1999

Website: newlast.com

Key Highlights: In addition to the most advanced systems for shoe lasts modification, design and production, we develop CAD/CAM platforms and foot scanners….

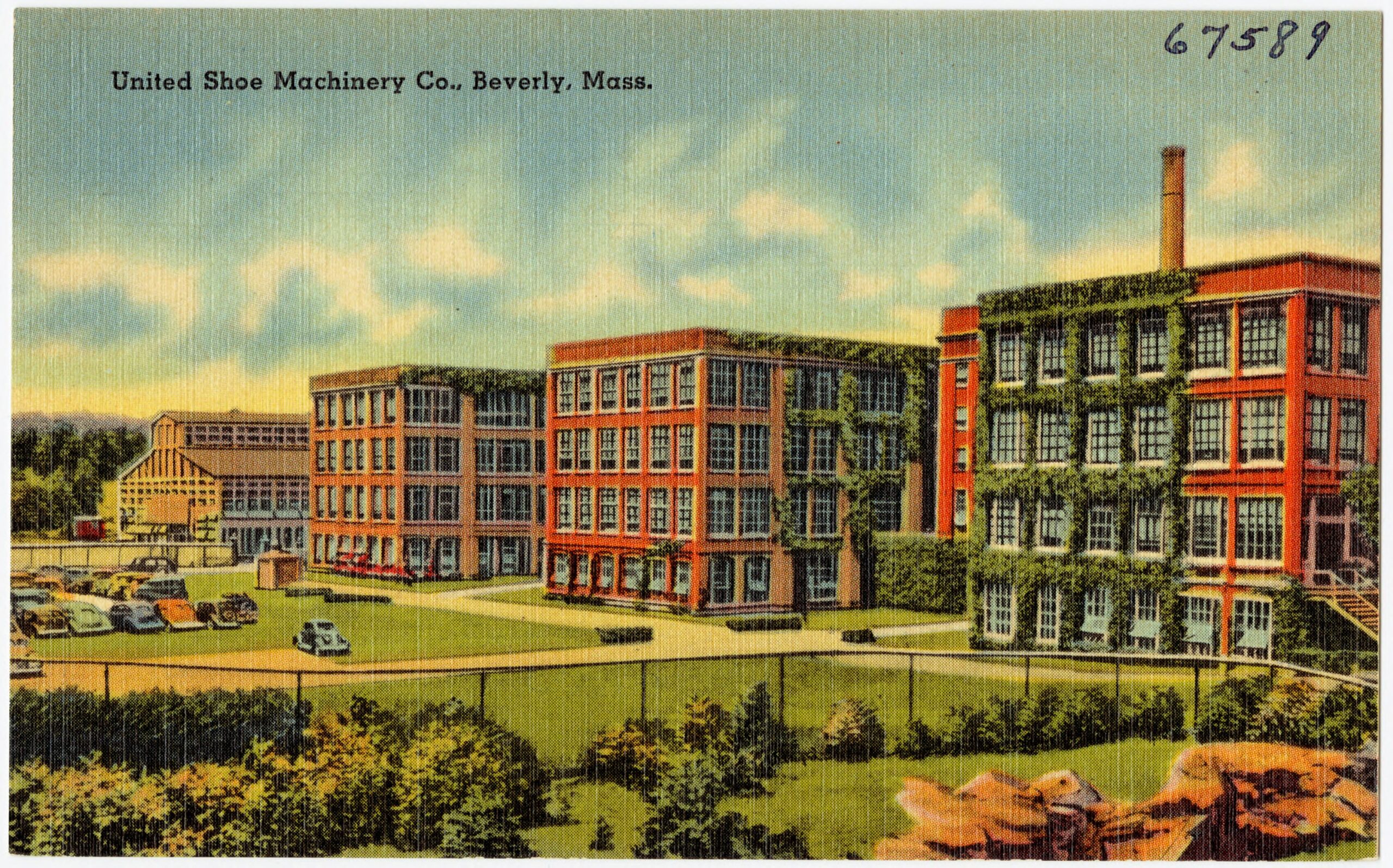

#9 American Shoe Machinery Company

Domain Est. 2022

Website: asmc-us.com

Key Highlights: ASMC offers design, manufacture and a wide variety of shoe making machinery to assist in the shoe making process as well as die cutting machinery for various ……

#10 Shoe Upper Lasting Machines

Domain Est. 2022

Website: dgsf-machinery.com

Key Highlights: Shoe Upper Lasting Machines ; Hydraulic Automatic Heel Seat Lasting Machine TH-727A · $4450 ; Computer Memory control Automatic Cementing Toe Lasting ……

Expert Sourcing Insights for Shoe Lasting Machine

H2: Projected Market Trends for Shoe Lasting Machines in 2026

The global shoe lasting machine market is poised for significant evolution by 2026, driven by technological innovation, shifting consumer demands, and the expansion of automated manufacturing in the footwear industry. As the footwear sector increasingly prioritizes efficiency, customization, and sustainability, the demand for advanced shoe lasting machines is expected to grow steadily. Below are the key market trends anticipated to shape the industry in 2026:

-

Increased Automation and Smart Manufacturing Integration

By 2026, automation will be a dominant force in footwear production. Shoe lasting machines are expected to incorporate more advanced robotics, AI-driven controls, and IoT connectivity to enable real-time monitoring and predictive maintenance. These smart systems will enhance precision, reduce labor costs, and improve production throughput, making them especially attractive to mid- and large-scale manufacturers. -

Growing Demand for Customization and On-Demand Production

With the rise of direct-to-consumer (DTC) brands and personalized footwear, shoe manufacturers are investing in versatile lasting machines capable of handling small batch and custom production. Machines with programmable settings and modular designs will be in higher demand to support flexible manufacturing lines that can quickly switch between styles and sizes. -

Expansion in Emerging Markets

Asia-Pacific, particularly countries like India, Vietnam, and Indonesia, will continue to be key growth regions due to their expanding footwear manufacturing bases and lower labor costs. Increased foreign investments and government support for industrial modernization are expected to drive the adoption of automated shoe lasting equipment in these regions. -

Focus on Sustainability and Energy Efficiency

As environmental regulations tighten, manufacturers will seek shoe lasting machines that are energy-efficient and use eco-friendly materials and processes. Equipment designed to minimize waste, reduce noise, and lower power consumption will gain preference, aligning with broader corporate sustainability goals. -

Technological Advancements in Machine Design

Innovations such as servo-driven actuators, laser-guided alignment, and digital twin integration will enhance the accuracy and repeatability of lasting operations. These advancements will not only improve product quality but also reduce setup times and operator dependency. -

Consolidation and Competitive Landscape Shifts

The market is likely to see increased consolidation among equipment manufacturers as companies aim to offer comprehensive, end-to-end footwear production solutions. Strategic partnerships between machine makers and footwear brands will also rise, fostering co-development of tailored machinery. -

Impact of Reshoring and Nearshoring Trends

In North America and Europe, the trend toward reshoring production to reduce supply chain risks may boost demand for high-performance, compact lasting machines suitable for smaller, agile factories. This shift will encourage innovation in space-saving and user-friendly machine designs.

In conclusion, the 2026 shoe lasting machine market will be characterized by a strong push toward intelligent, flexible, and sustainable automation. Manufacturers who adapt to these trends by investing in next-generation technology and aligning with evolving production models will be best positioned to capture market share in a competitive and dynamic global landscape.

Common Pitfalls When Sourcing Shoe Lasting Machines (Quality and Intellectual Property)

Sourcing a shoe lasting machine is a significant investment for any footwear manufacturer. While cost and delivery are important, overlooking critical aspects related to quality and intellectual property (IP) can lead to costly setbacks, production delays, and legal risks. Here are key pitfalls to avoid:

Overlooking Build Quality and Material Standards

Many buyers focus on price and specifications without verifying the actual build quality. Machines constructed with substandard materials (e.g., low-grade steel, poor welds, or weak components) lead to frequent breakdowns, inconsistent stitching, and reduced machine lifespan. Always request detailed information on materials used and inspect sample machines in person or via video audit.

Ignoring Precision and Consistency in Operation

A lasting machine’s core function relies on precision. Poorly manufactured machines may have misaligned components, inconsistent pressure application, or unstable clamping mechanisms, resulting in defective lasts, uneven stitching, and high rejection rates. Ensure the supplier provides performance data and test results demonstrating repeatability and accuracy under production conditions.

Falling for Copycat Designs with Hidden Flaws

Some manufacturers produce machines that closely mimic reputable brands but lack engineering integrity. These clones may look similar but often use inferior mechanisms, leading to reliability issues. Be wary of unusually low prices or vague technical descriptions—these can be red flags for imitation models with compromised performance.

Neglecting Intellectual Property Verification

Purchasing a machine that infringes on existing patents or designs can expose your business to legal action. Before finalizing a purchase, especially from lesser-known suppliers, conduct due diligence on the machine’s IP status. Ask the supplier directly about patents, design rights, or licensing agreements. Avoid vendors who are evasive or cannot provide documentation.

Assuming All Certifications Are Genuine

Suppliers may claim compliance with international standards (e.g., CE, ISO) without valid certification. Fake or self-issued certificates are common. Request copies of authentic, third-party certification reports and verify them when possible. Non-compliant machines may fail safety inspections or be restricted from use in certain markets.

Underestimating After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance and repairs. Sourcing from suppliers with weak support networks or limited spare parts inventory leads to prolonged downtime. Confirm the availability of technical support, training, and genuine replacement parts before purchasing—especially if sourcing internationally.

Failing to Conduct On-Site or Live Performance Testing

Relying solely on brochures or supplier demonstrations can be misleading. Whenever possible, insist on witnessing the machine in operation—ideally running your specific shoe styles and materials. This reveals real-world performance and helps identify potential quality or compatibility issues early.

By proactively addressing these pitfalls related to quality and intellectual property, manufacturers can make informed decisions, reduce risk, and ensure long-term productivity from their shoe lasting machine investment.

Logistics & Compliance Guide for Shoe Lasting Machine

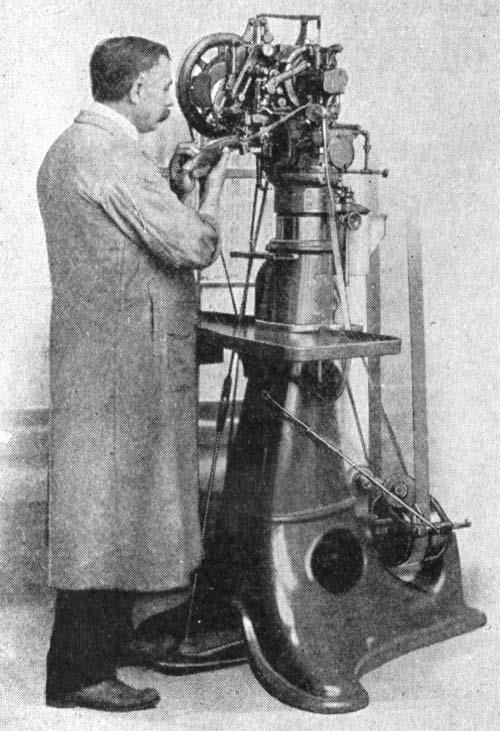

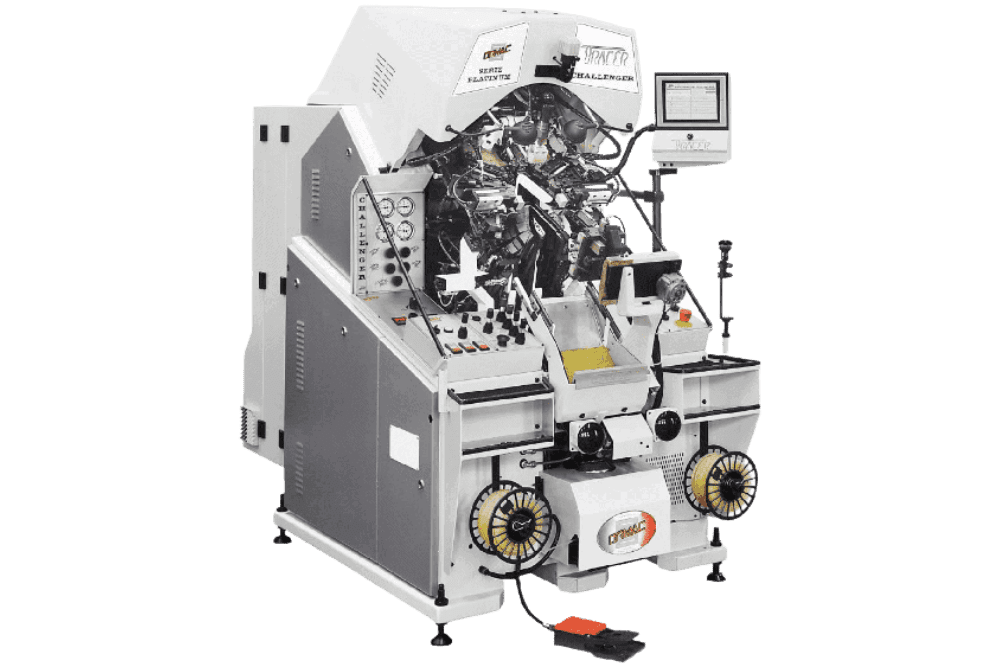

Overview of the Shoe Lasting Machine

A shoe lasting machine is a specialized industrial equipment used in footwear manufacturing to shape and secure the upper part of a shoe over a mold (last). Due to its size, weight, and mechanical complexity, shipping and regulatory compliance require careful planning.

International Shipping Considerations

- Weight and Dimensions: Shoe lasting machines are typically heavy (500–2,000 kg) and bulky. Accurate measurement is essential for freight classification and container loading.

- Packaging Requirements: Machines must be crated with wooden skids, waterproof wrapping, and internal bracing to prevent damage during transit. Use export-standard packaging compliant with ISPM-15 for wooden materials.

- Transport Mode: Typically shipped via sea freight (FCL or LCL) due to size and cost. Air freight may be used for urgent, smaller components but is cost-prohibitive for full units.

- Incoterms Selection: Define responsibilities clearly using agreed Incoterms (e.g., FOB, CIF, or DDP) to allocate costs and risks between buyer and seller.

Export Documentation

Ensure the following documents are prepared accurately:

– Commercial Invoice (with machine value, weight, and technical specifications)

– Packing List (itemized contents, dimensions, and gross/net weights)

– Bill of Lading or Air Waybill

– Certificate of Origin (required by many customs authorities)

– Export License (if applicable based on country and technology controls)

– Equipment Declaration (for customs clearance)

Regulatory Compliance

- CE Marking (EU): Required for machinery sold in the European Economic Area. Must comply with the Machinery Directive (2006/42/EC), including safety, electrical, and noise standards.

- UL/CSA Certification (North America): U.S. and Canada require electrical safety certification. UL (Underwriters Laboratories) or CSA (Canadian Standards Association) marks are often mandatory.

- RoHS Compliance: Restriction of Hazardous Substances directive applies to electrical components in the EU and other regions.

- EPA & OSHA (U.S.): Machines may need to meet noise emission standards and workplace safety requirements under EPA and OSHA regulations.

Import Regulations by Region

- European Union: CE certification and Declaration of Conformity are mandatory. VAT and customs duties apply based on HS Code 8455.21 or similar.

- United States: No federal import license required, but FDA does not regulate industrial machinery. However, CBP (Customs and Border Protection) assesses duties using HTS Code 8455.21.

- China: Requires CCC certification if electrical components are involved. Import duties vary; prior registration with customs may be needed.

- Other Countries: Check local industrial equipment regulations. Some countries (e.g., India, Brazil) may require BIS or INMETRO certification.

Environmental & Safety Standards

- Noise Emissions: Machines must meet local noise level standards (e.g., EU limits under 85 dB(A)). Include noise test reports in compliance dossiers.

- Waste Electrical and Electronic Equipment (WEEE): In the EU, producers may be responsible for end-of-life take-back. Provide WEEE registration if applicable.

- Hazardous Materials: Ensure no restricted substances (e.g., lead, cadmium) exceed permitted levels in components.

Installation & After-Sales Support Logistics

- Spare Parts Shipment: Plan for logistics of spare parts and tooling kits; use consolidated shipments to reduce cost.

- Technical Documentation: Provide multilingual manuals (installation, operation, maintenance) to comply with local requirements.

- On-Site Support: Coordinate technician travel, visas, and tools if installation or training is required.

Risk Management & Insurance

- Marine Cargo Insurance: Cover all shipments against damage, loss, or delay. Specify coverage for heavy machinery.

- Force Majeure Clauses: Include in contracts to address delays due to port congestion, strikes, or natural disasters.

- Compliance Audits: Conduct regular reviews of export controls and certifications to avoid penalties.

Summary

Shipping and complying with regulations for shoe lasting machines involves detailed logistics planning and adherence to international standards. Proper documentation, certification, packaging, and risk management are essential to ensure smooth global delivery and legal operation in target markets.

Conclusion for Sourcing a Shoe Lasting Machine

Sourcing a shoe lasting machine is a critical investment for any footwear manufacturing operation aiming to enhance production efficiency, ensure consistent product quality, and remain competitive in the global market. After thorough evaluation of available options, it is evident that selecting the right machine involves balancing factors such as automation level, precision, durability, cost, after-sales support, and compatibility with existing production processes.

Both domestic and international suppliers offer a range of machines—from semi-automatic to fully automated systems—each suited to different production scales and budgetary considerations. While machines from established manufacturers in countries like China, Italy, and Germany often provide advanced technology and reliability, careful due diligence is required to assess supplier credibility, service network, and long-term maintenance costs.

Ultimately, the decision should align with the company’s production volume, quality standards, and strategic growth objectives. Investing in a high-quality shoe lasting machine not only improves operational efficiency but also contributes to better shoe fit, reduced material waste, and enhanced brand reputation. Therefore, a well-informed sourcing strategy, supported by technical assessments and supplier evaluations, is essential to achieving sustainable success in footwear manufacturing.