The global textile printing machinery market is experiencing robust growth, driven by increasing demand for customized apparel and advancements in digital printing technologies. According to Mordor Intelligence, the shirt printing press market is projected to grow at a CAGR of approximately 5.8% from 2023 to 2028, fueled by rising consumer preference for personalized fashion and sustainable production methods. Complementing this, Grand View Research reported that the global digital textile printing market size was valued at USD 3.7 billion in 2022 and is expected to expand at a CAGR of 12.5% from 2023 to 2030. This surge is largely attributed to the textile industry’s shift toward automation, eco-friendly inks, and on-demand manufacturing. As brands seek faster turnaround times and greater design flexibility, leading shirt printing press manufacturers are innovating with high-speed, precision-driven solutions to meet evolving market demands. In this competitive landscape, a select group of manufacturers have emerged as frontrunners, combining technological excellence with scalable production capabilities.

Top 10 Shirt Printing Press Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

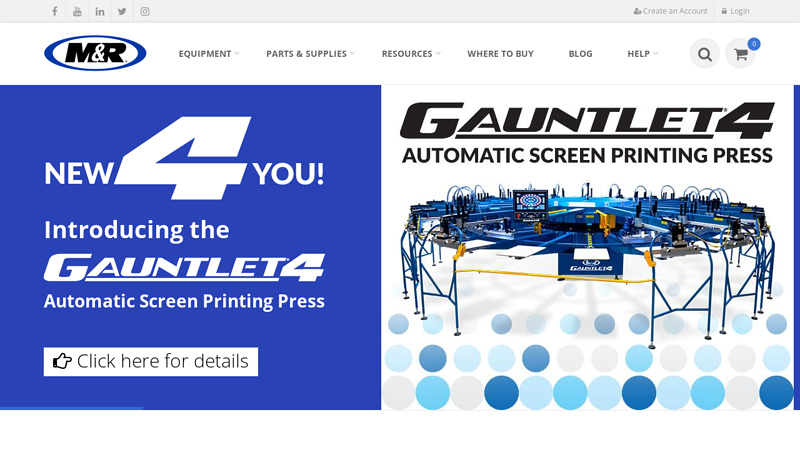

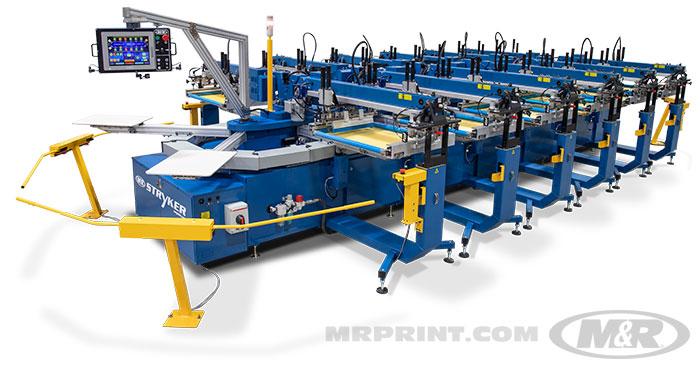

#1 M&R Printing Equipment Inc. :: DTF

Domain Est. 1996

Website: mrprint.com

Key Highlights: M&R makes a wide range of textile printing equipment, including Direct to Film (DTF), Direct to Garment, (DTG), Hybrid Digital Printing, manual & automatic ……

#2 ColDesi, Inc. Make Your Own Customized Products

Domain Est. 2010

Website: coldesi.com

Key Highlights: Leading provider of customized products equipment. Including: commercial embroidery machines, direct-to-garment printers, and more….

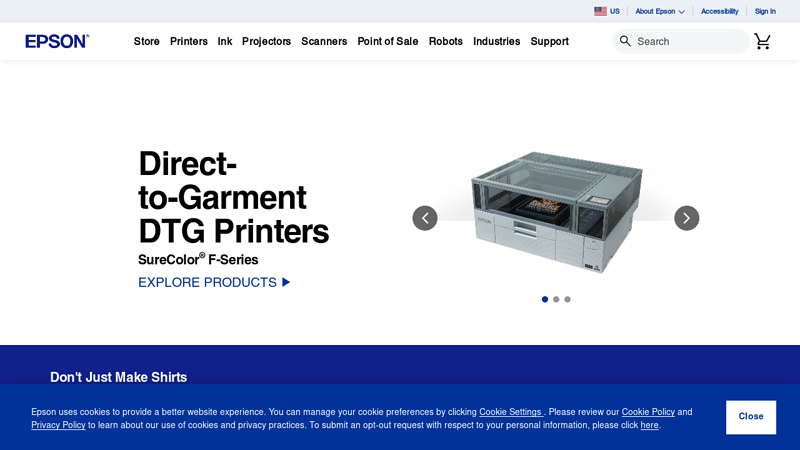

#3 Hybrid DTG/DTFilm Printers

Domain Est. 1991

Website: epson.com

Key Highlights: Epson’s powerhouse hybrid DTG/DTFilm printers: engineered for high quality, hybrid print capabilities, and on-demand printing….

#4 Queensboro

Domain Est. 1996

Website: queensboro.com

Key Highlights: Queensboro.com specializes in custom shirts, polos, hats & promotional products with no minimums, free logo setup, and fast turn-around….

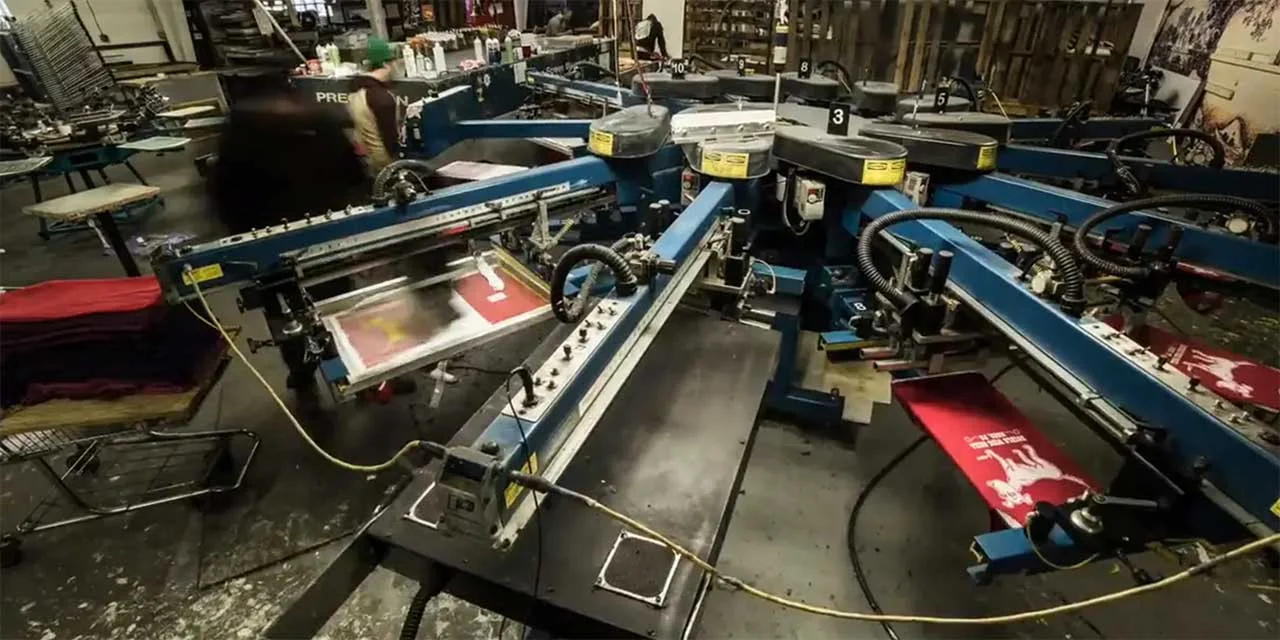

#5 Anatol Equipment

Domain Est. 1998

Website: anatol.com

Key Highlights: Anatol Equipment offers high-quality automatic screen printing presses for textile businesses worldwide. Discover our innovative solutions today….

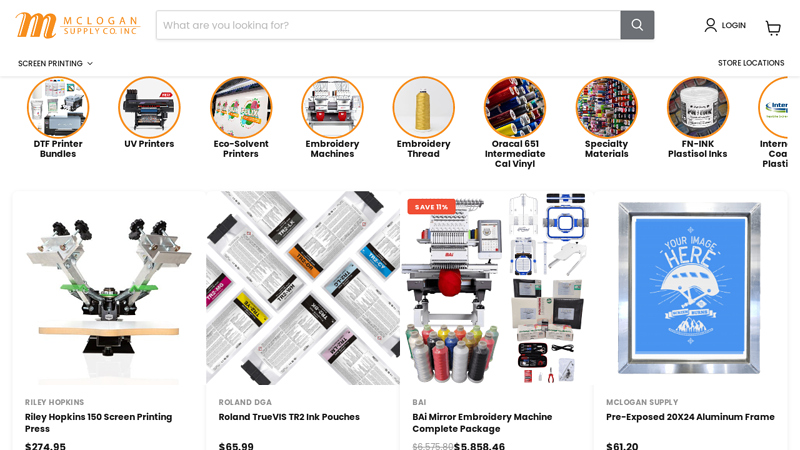

#6 Screen Printing, Heat Transfer, and DTG Supplies & Equipment

Domain Est. 1998

Website: mclogan.com

Key Highlights: Free delivery over $250 20-day returnsOct 8, 2025 · McLogan Supply is the leading supplier of low-cost, high-quality screen printing, heat transfer & signage supplies & equipment, …

#7 Screen Printing Presses

Domain Est. 1999

Website: rileyhopkins.com

Key Highlights: 30-day returnsThe Riley Hopkins press line offers four kinds of presses with different color and station configurations. Let’s take a look at each press, check out its uses ……

#8 COMMONWEALTH PRESS

Domain Est. 2007

Website: cwpress.com

Key Highlights: pittsburgh based screen printing commonwealth press offers quality printing, design, and retail for whatever you need….

#9 T-Shirt Printing & Fulfillment

Domain Est. 2014

Website: scalablepress.com

Key Highlights: PRINT-ON-DEMAND FULFILLMENT. Scalable Press lets you order 1000s of print-on-demand products from different suppliers through a single-invoice ordering platform….

#10 Geo Knight Co Heat Presses Made in USA

Domain Est. 1997

Website: heatpress.com

Key Highlights: Manufacturer of industrial grade heat press machines for t shirts, mugs, caps, tiles, plates, and more. The best heat presses, including manual heat presses ……

Expert Sourcing Insights for Shirt Printing Press

2026 Market Trends for Shirt Printing Press

Rising Demand for Customization and Personalization

By 2026, consumer preference for unique, personalized apparel is expected to drive significant growth in the shirt printing press market. Advances in digital printing technologies enable cost-effective small-batch and on-demand production, allowing businesses and individuals to create highly customized designs. E-commerce platforms and print-on-demand services will further fuel this trend, making it easier for entrepreneurs and artists to launch custom apparel brands without large inventories.

Growth of Direct-to-Garment (DTG) and Digital Printing Technologies

DTG printing is projected to dominate the shirt printing press landscape by 2026 due to its ability to produce high-resolution, full-color images on cotton and cotton-blend fabrics with minimal setup time. Continuous improvements in ink formulations, print speed, and machine durability will make DTG more accessible to small and medium-sized enterprises. Additionally, hybrid systems combining DTG with direct-to-film (DTF) technology are gaining traction for their versatility across various fabric types.

Sustainability and Eco-Friendly Practices

Environmental concerns will play a major role in shaping the 2026 market. Printers and manufacturers will increasingly adopt water-based, non-toxic inks and energy-efficient machines to reduce environmental impact. Demand for sustainable garment options—such as organic cotton and recycled fabrics—will push printing press operators to align with eco-conscious supply chains. Certifications like OEKO-TEX and GOTS will become key differentiators in the competitive market.

Automation and Smart Manufacturing Integration

The integration of automation, AI-driven design tools, and IoT-enabled printing equipment will streamline production processes by 2026. Automated color mixing, predictive maintenance, and real-time monitoring will improve efficiency, reduce waste, and lower operational costs. Cloud-based workflow management systems will allow for remote operation and seamless integration between design, printing, and fulfillment stages.

Expansion of E-Commerce and On-Demand Models

The proliferation of online marketplaces and social media-driven branding will continue to boost demand for agile shirt printing solutions. Print-on-demand (POD) models will eliminate overproduction and inventory risks, making them ideal for startups and influencers. By 2026, shirt printing presses capable of rapid turnaround and integration with major e-commerce platforms (e.g., Shopify, Etsy, Amazon) will be highly sought after.

Regional Market Growth and Emerging Opportunities

While North America and Europe remain key markets, rapid growth is anticipated in Asia-Pacific, Latin America, and Africa due to increasing internet penetration, rising disposable incomes, and the popularity of localized apparel designs. Localized production hubs using compact, high-efficiency printing presses will emerge to serve regional markets and reduce shipping times and costs.

Conclusion

By 2026, the shirt printing press industry will be shaped by technological innovation, sustainability imperatives, and evolving consumer behavior. Businesses that embrace digital transformation, eco-friendly practices, and flexible production models will be best positioned to capitalize on these dynamic market trends.

Common Pitfalls When Sourcing a Shirt Printing Press (Quality and Intellectual Property)

Sourcing a shirt printing press—whether for starting a new business or expanding operations—can significantly impact your product quality, production efficiency, and legal compliance. While cost and capacity are often prioritized, overlooking quality control and intellectual property (IP) considerations can lead to costly setbacks. Below are key pitfalls to avoid.

Overlooking Build Quality and Material Durability

Many buyers focus on upfront price without evaluating the construction quality of the printing press. Low-cost machines may use substandard metals, weak electrical components, or poorly engineered mechanisms. This can result in frequent breakdowns, inconsistent print registration, and higher long-term maintenance costs. Always verify the materials and components used—such as aluminum frames, durable heating elements, and precision alignment systems—before purchasing.

Ignoring Print Registration and Consistency

A major quality issue arises when presses lack accurate registration systems. Misaligned prints can ruin entire batches of garments, especially during multi-color designs. Some budget presses do not offer micro-adjustments or durable calibration settings, leading to operator fatigue and inconsistent results. Ensure the machine provides reliable registration tools and consistent pressure distribution across the platens.

Skipping Vendor Due Diligence on IP Compliance

One of the most serious but often overlooked risks is intellectual property infringement. Some suppliers, especially in unregulated markets, may replicate patented press designs or use counterfeit control systems (e.g., copied software or unauthorized touchscreen interfaces). Purchasing such equipment can expose your business to legal action, customs seizures, or forced equipment removal. Always source from reputable manufacturers who can provide proof of IP ownership or licensing.

Assuming All Software and Controls Are Legal

Digital presses often come with integrated software for temperature control, timing, and automation. However, pirated or reverse-engineered firmware may be installed to cut costs. This not only raises IP concerns but can also lead to safety hazards, unreliable performance, and lack of updates or support. Request documentation on software licensing and verify compatibility with legitimate operating systems.

Failing to Verify Safety and Certification Standards

Cheaply sourced presses may not comply with international safety standards (e.g., CE, UL, or RoHS). This can pose fire risks, electrical hazards, or unsafe operation conditions. Moreover, non-compliant equipment may be barred from use in commercial facilities or during inspections. Confirm that the press has proper certifications and safety cutoffs before deployment.

Neglecting After-Sales Support and Spare Parts Availability

Even high-quality presses require maintenance. Sourcing from vendors without reliable customer support or accessible spare parts can lead to extended downtime. Some suppliers disappear after the sale or charge exorbitant fees for replacements. Choose a supplier with a track record of responsive support and an established parts supply chain.

Underestimating Training and Operator Skill Requirements

Advanced printing presses may require specific training to operate effectively. Assuming that any team member can use the machine without proper instruction often results in poor print quality and equipment damage. Confirm whether the supplier offers training programs or detailed operational manuals—especially for automated or multi-station models.

By being aware of these common pitfalls in quality and intellectual property, businesses can make informed decisions when sourcing a shirt printing press, ensuring long-term reliability, legal safety, and production excellence.

Logistics & Compliance Guide for Shirt Printing Press

Order Management & Processing

Establish a clear workflow for receiving, tracking, and fulfilling customer orders. Use order management software to monitor each stage—from design approval to shipping. Confirm order details such as shirt size, color, quantity, ink type, and delivery deadlines. Set realistic production timelines and communicate delays promptly.

Inventory Management

Maintain accurate records of blank garment stock, ink, transfer paper, packaging materials, and other consumables. Implement a first-in, first-out (FIFO) system to reduce waste from expired materials. Conduct regular inventory audits to prevent overstocking or stockouts that could delay production.

Printing & Production Workflow

Standardize operating procedures for screen printing, direct-to-garment (DTG), heat transfer, or sublimation methods. Calibrate equipment regularly and train staff on safety and quality control. Schedule preventive maintenance to minimize downtime and ensure consistent print quality.

Quality Control Procedures

Inspect finished garments for print alignment, color accuracy, ink adhesion, and fabric defects. Implement a spot-check system per batch and document any issues. Address inconsistencies immediately and adjust production settings as needed to maintain brand standards.

Packaging & Shipping

Package shirts to prevent damage during transit—use polybags, tissue paper, or branded mailers as appropriate. Include order documentation such as invoices or packing slips. Partner with reliable carriers and offer tracking for all shipments. Optimize packaging size and weight to reduce shipping costs.

Labeling & Product Compliance

Ensure all printed shirts comply with country-specific labeling laws (e.g., FTC regulations in the U.S.). Labels must include fiber content, country of origin, care instructions, and manufacturer/importer information. Verify that custom designs do not infringe on trademarks or copyrighted material.

Health & Safety Regulations

Follow OSHA (or local equivalent) guidelines for workplace safety. Store inks, solvents, and adhesives in approved containers with proper ventilation. Provide employees with personal protective equipment (PPE) such as gloves and masks. Maintain fire extinguishers and post emergency procedures.

Environmental Compliance

Dispose of printing waste—including screens, rags, and chemical residues—according to local environmental regulations. Recycle materials whenever possible. Use water-based or eco-friendly inks to reduce volatile organic compound (VOC) emissions and comply with air quality standards.

Data Privacy & Customer Information

Safeguard customer data collected during the ordering process. Comply with data protection laws such as GDPR or CCPA by securing databases, using encrypted connections, and obtaining consent for data usage. Limit access to sensitive information within your team.

Business Licensing & Tax Requirements

Obtain necessary local, state, and federal business licenses. Register for sales tax and collect it appropriately on customer orders. Keep detailed financial records and file taxes on time. If selling across state lines or internationally, understand nexus rules and import/export requirements.

Intellectual Property & Design Rights

Require customers to confirm they have rights to any artwork they submit. Avoid printing logos, characters, or branded content without proper licensing. Maintain records of design approvals and disclaimers to protect against infringement claims.

Returns, Refunds & Customer Service

Publish a clear returns and exchange policy on your website. Inspect returned items for print defects or customer errors. Process refunds or replacements promptly and document all customer interactions to maintain compliance with consumer protection laws.

In conclusion, sourcing a shirt printing press requires careful consideration of several key factors, including print quality, production capacity, budget, maintenance requirements, and long-term scalability. Whether opting for screen printing, direct-to-garment (DTG), heat press, or roll-to-roll systems, it is essential to align the chosen technology with your specific business needs and target market. Evaluating suppliers based on reliability, after-sales support, and equipment durability ensures a wise investment that enhances efficiency and product consistency. Additionally, considering future growth and potential technological advancements will help maintain competitiveness in the evolving apparel printing industry. Ultimately, a well-researched and strategic approach to sourcing a shirt printing press lays the foundation for a successful and sustainable printing operation.