The global shipping container repurposing market has gained significant momentum in recent years, driven by rising demand for sustainable, modular, and cost-effective construction solutions. According to a 2023 report by Mordor Intelligence, the global container recycling market is projected to grow at a CAGR of over 5.8% from 2023 to 2028, fueled by increased adoption in commercial, residential, and industrial applications. Similarly, Grand View Research estimates that the modular construction market—where shipping container structures play a key role—will expand at a CAGR of 7.2% from 2024 to 2030, with sustainability and rapid deployment as key growth drivers. As demand for eco-friendly and prefabricated buildings rises, shipping container shed manufacturers are emerging as innovative players in the alternative construction space. From backyard storage solutions to commercial workspaces, these manufacturers leverage the durability and modularity of steel containers to deliver turnkey sheds that are both functional and environmentally responsible. Below, we spotlight the top 10 shipping container shed manufacturers leading this transformation with scalable, customizable, and high-quality offerings.

Top 10 Shipping Containers Shed Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1

Domain Est. 2017

Website: nexgencontainer.com

Key Highlights: NexGen is one of the leading American manufacturers of shipping containers. Key Facts.. ISO 9001 Certified….

#2

Domain Est. 2022

Website: flatpackcontainer.co

Key Highlights: Flat Pack Container is a wholesale distributor of Flat Pack Container storage units. We work with our manufacturers to provide wholesale pricing and ……

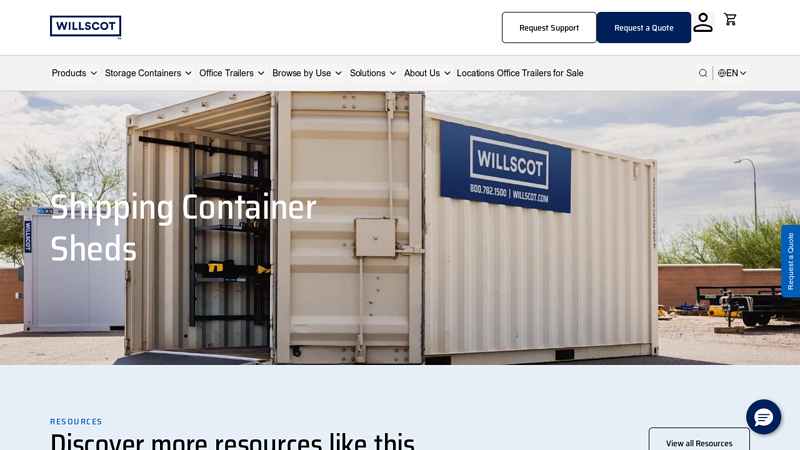

#3 Shipping Container Storage Sheds

Domain Est. 1995

Website: willscot.com

Key Highlights: We source shipping container sheds that are versatile and flexible enough to tackle any and all of your commercial storage needs….

#4 SEA BOX

Domain Est. 1996

Website: seabox.com

Key Highlights: Custom Container Solutions. SEA BOX can design and manufacture customized containers to suit virtually any purpose. Learn More….

#5 Custom Modular Storage Containers

Domain Est. 1996

Website: wilmotmodular.com

Key Highlights: Secure and Convenient Modular Storage Containers · Sizes include: 8′ x 10′, 8′ x 20′, 8′ x 40′, or customize your own length · 8′ height · Secure storage space….

#6 Big Blue Boxes

Domain Est. 2007

Website: bigblueboxes.com

Key Highlights: Big Blue Boxes has spent the past 25 years supporting people and companies on the move in Minnesota, Wisconsin, Illinois and throughout the Upper Midwest….

#7 Shipping Container Sheds

Domain Est. 2017

Website: pelicancontainers.com

Key Highlights: Discover how shipping container sheds upgrade storage and workspaces ⏩ Versatile, durable, and cost-effective — even for 40ft business use….

#8 to Top Gun Storage Solutions

Domain Est. 2018

Website: topgunstoragesolutions.com

Key Highlights: We are a Disabled Veteran Owned and Operated business created in the United States of America. Our goal is to not only satisfy those storage needs but ……

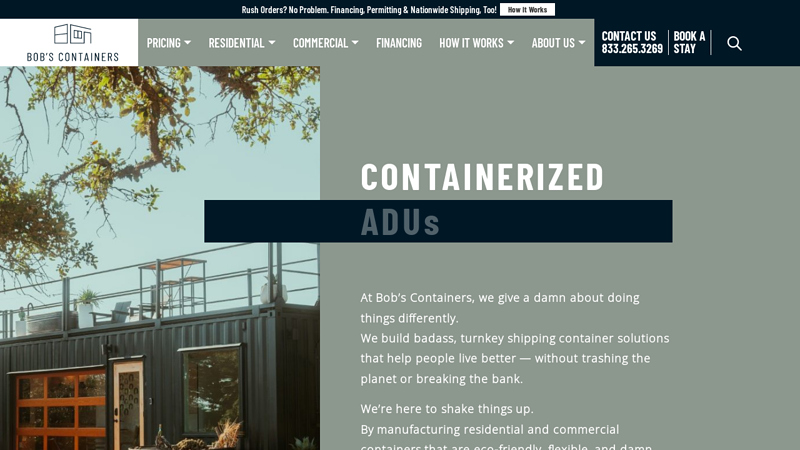

#9 Bob’s Containers

Domain Est. 2019

Website: bobscontainers.com

Key Highlights: By manufacturing residential and commercial containers that are eco-friendly, flexible, and damn good-looking, we’re cutting the crap out of traditional ……

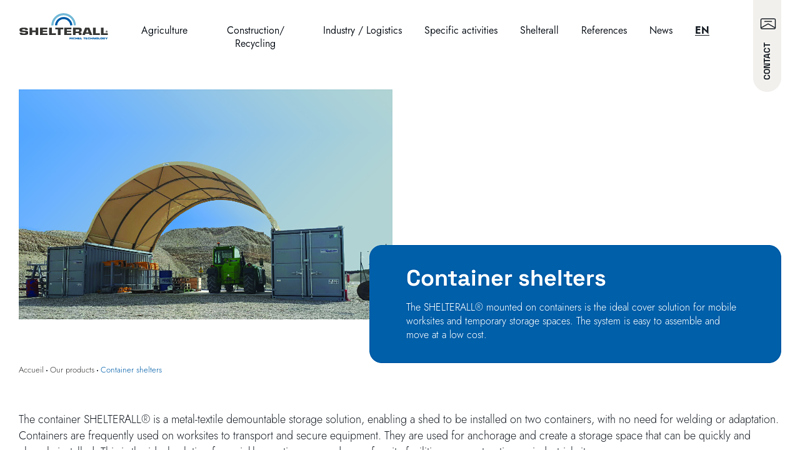

#10 Container shelter & shed

Website: shelterall.eu

Key Highlights: The container SHELTERALL® is a metal-textile demountable storage solution, enabling a shed to be installed on two containers, with no need for welding or ……

Expert Sourcing Insights for Shipping Containers Shed

2026 Market Trends for Shipping Container Sheds

The global market for shipping container sheds is poised for significant transformation by 2026, driven by sustainability demands, urbanization, modular construction growth, and economic shifts. These repurposed containers, once limited to maritime logistics, are now being widely adopted as cost-effective, durable, and eco-friendly structures across residential, commercial, and industrial sectors. Below is an analysis of key trends shaping the shipping container shed market through 2026.

Rising Demand for Sustainable and Modular Construction

One of the most influential trends driving the shipping container shed market is the global shift toward sustainable building practices. With growing awareness of environmental impact, architects, developers, and homeowners are increasingly opting for recycled and low-carbon construction materials. Shipping container sheds align perfectly with this demand, as they repurpose steel containers that would otherwise contribute to landfill waste.

Modular construction, which emphasizes prefabrication and rapid assembly, is also on the rise. Container sheds offer built-in modularity, allowing for scalable designs and reduced construction timelines. According to industry forecasts, the modular construction market is expected to grow at a CAGR of over 7% through 2026, directly benefiting the demand for container-based structures.

Urbanization and Space Optimization

Rapid urbanization, particularly in emerging economies, continues to strain housing and infrastructure resources. Shipping container sheds provide an innovative solution for space-constrained environments. Due to their compact footprint and vertical build potential, they are being deployed as affordable housing units, pop-up retail stores, urban gardening hubs, and temporary office spaces.

Cities in Asia-Pacific and Africa are increasingly adopting container sheds as transitional housing or emergency shelters, further boosting market growth. Governments and NGOs are investing in container-based projects to address housing shortages, contributing to market expansion.

Technological Advancements and Smart Integration

By 2026, technological integration is expected to enhance the functionality and appeal of shipping container sheds. Innovations such as solar panel integration, smart insulation systems, IoT-enabled climate control, and prefabricated smart home features are becoming standard in premium models. These upgrades improve energy efficiency and comfort, making container sheds viable for long-term residential and commercial use.

Additionally, advancements in corrosion-resistant coatings and structural reinforcement techniques are extending the lifespan of container sheds, even in harsh climates. These improvements are easing concerns about durability and safety, helping to normalize container architecture.

Cost-Effectiveness and Rapid Deployment

Cost remains a major driver for the adoption of shipping container sheds. Compared to traditional construction, container sheds offer lower material and labor costs, especially when used for temporary or semi-permanent structures. The ability to deploy these units quickly—often within days—makes them ideal for disaster relief, construction site offices, and seasonal retail spaces.

The DIY (do-it-yourself) market is also expanding, with more consumers purchasing pre-cut or partially assembled container kits. This trend is supported by online platforms offering design templates, regulatory guidance, and supply chains for modifications.

Regulatory and Standardization Challenges

Despite growth, the market faces challenges related to building codes and zoning regulations. Many regions lack standardized policies for container-based structures, leading to permitting delays and inconsistent enforcement. However, by 2026, increased adoption is expected to spur regulatory harmonization, with governments developing specific guidelines for container construction safety, insulation, and livability.

Industry stakeholders are also pushing for certification standards to ensure structural integrity and fire safety, which will help legitimize container sheds as mainstream construction options.

Regional Market Dynamics

The North American and European markets are witnessing strong demand for container sheds in the residential and commercial sectors, driven by eco-conscious consumers and green building incentives. In contrast, the Asia-Pacific region leads in volume due to urbanization, population density, and government-backed affordable housing initiatives.

Latin America and the Middle East are emerging markets, with growing investments in infrastructure and logistics hubs that utilize container sheds for site offices and storage.

Conclusion

By 2026, the shipping container shed market is projected to expand significantly, fueled by sustainability trends, modular construction, urban space constraints, and technological innovation. While regulatory hurdles remain, increasing standardization and consumer acceptance are paving the way for broader adoption. Businesses and consumers alike are recognizing the value of container sheds not just as temporary solutions, but as long-term, adaptable, and eco-conscious alternatives to traditional buildings.

Common Pitfalls When Sourcing Shipping Container Sheds (Quality & Intellectual Property)

Sourcing shipping container sheds can offer fast, cost-effective construction solutions, but buyers often encounter significant challenges related to quality control and intellectual property (IP) risks. Being aware of these pitfalls is essential to avoid costly setbacks and legal complications.

Poor Material Quality and Structural Integrity

One of the most frequent issues when sourcing shipping containers for sheds is inconsistent material quality. Many suppliers use retired maritime containers that may have unseen corrosion, dents, or structural fatigue. Containers previously used for transporting hazardous or corrosive cargo may have compromised steel integrity. Buyers might receive units that look adequate externally but fail to meet safety standards or require extensive, unplanned refurbishment.

Inadequate Modifications and Workmanship

The conversion process—adding doors, windows, insulation, and electrical systems—can introduce new risks if not done professionally. Poor welding, improper sealing, or substandard insulation can lead to leaks, condensation, mold, or energy inefficiency. Sourcing from vendors without proper certifications or experience often results in shoddy craftsmanship that compromises both functionality and longevity.

Misrepresentation of Container Condition

Suppliers may mislabel containers as “one-trip” or “as-new” when they are actually heavily used or damaged. Without independent inspection or verifiable documentation, buyers risk paying premium prices for subpar units. This misrepresentation directly affects the shed’s durability and resale value.

Lack of Compliance with Building Codes

Container sheds must meet local building, safety, and insulation codes. Some suppliers provide designs or modifications that do not comply with regional regulations, especially when sourcing internationally. This can result in failed inspections, fines, or costly retrofits to bring the structure up to code.

Intellectual Property Infringement Risks

Using patented or trademarked container shed designs—even unintentionally—can lead to IP disputes. Some vendors sell “off-the-shelf” designs that may be protected by intellectual property rights. If a buyer replicates or modifies such a design without authorization, they could face litigation or be forced to remove or alter the structure.

Use of Counterfeit or Unlicensed Components

Lower-cost suppliers may incorporate counterfeit or unlicensed components (e.g., roofing materials, windows, HVAC systems) to cut costs. These parts often fail prematurely and may void warranties. In some cases, using such components can also expose the buyer to liability, especially if they contribute to safety hazards.

Inadequate Documentation and Traceability

Shipping containers should come with a Certificate of Conformity, CSC (Convention for Safe Containers) plate, and modification records. A lack of proper documentation makes it difficult to verify origin, safety history, or compliance—raising red flags during inspections or resale.

Hidden Costs from Poor Sourcing Decisions

Initial cost savings from choosing low-quality suppliers can quickly disappear due to hidden expenses: structural repairs, mold remediation, code compliance upgrades, or legal fees from IP claims. Investing upfront in vetted suppliers with transparent practices helps mitigate these long-term risks.

By carefully evaluating supplier credentials, inspecting containers prior to purchase, verifying compliance, and ensuring IP rights are respected, buyers can avoid these common pitfalls and achieve a durable, legal, and high-quality shipping container shed.

Logistics & Compliance Guide for Shipping Containers Shed

Understanding Shipping Container Specifications

Shipping containers used for sheds must meet standard ISO dimensions and structural requirements. Common sizes include 20-foot and 40-foot lengths. Ensure containers are CSC (Convention for Safe Containers) certified, indicating they meet international safety standards. Verify the condition of the container (e.g., one-trip or used) for structural integrity, corrosion, and watertight seals.

Site Preparation and Delivery Logistics

Prepare a level, stable foundation—typically concrete pads, gravel, or piers—capable of supporting the container’s weight (up to 30,000 kg when fully loaded). Coordinate with delivery services to confirm access: ensure roads and entry points accommodate the delivery truck and crane or forklift. Schedule delivery during weekdays and allow buffer time for delays due to traffic or weather.

Transport and Handling Requirements

Use licensed transporters experienced in container delivery. Most containers are delivered via tilt-bed trucks or flatbeds and require side-lift, crane, or forklift unloading. Confirm ground clearance, overhead power lines, and turning radius at the delivery site. Never attempt manual handling—improper lifting can damage the structure and pose safety hazards.

Permits and Zoning Compliance

Check local zoning laws and building codes before installation. Many jurisdictions require permits for container structures, even as sheds. Verify setback requirements, height restrictions, and land use regulations. Submit site plans showing container placement, access routes, and drainage. Some areas classify container sheds as temporary structures, which may have different rules.

Building Code and Safety Standards

Adhere to local building codes for wind, snow, and seismic loads. Reinforce foundations and anchoring systems as needed. If modifying the container (e.g., cutting doors or windows), ensure structural integrity is maintained. Install proper ventilation, lighting, and fire safety measures. In some regions, electrical or plumbing modifications require inspections and licensed contractors.

Environmental and Waste Compliance

Dispose of hazardous materials (e.g., old paint, insulation) according to local environmental regulations. Many used containers have CCA-treated wood floors—check disposal guidelines. Use eco-friendly paints and sealants to prevent soil and water contamination. Manage rainwater runoff with proper grading or gutters to avoid erosion or pooling.

Customs and Import Regulations (if applicable)

For imported containers, ensure compliance with customs documentation, tariffs, and biosecurity inspections (e.g., ISPM 15 for wooden components). Provide proof of origin and container history. Domestic use may still require compliance with national transport and safety standards even if not crossing borders.

Insurance and Liability Considerations

Obtain appropriate property and liability insurance for the container shed. Inform your insurer of the structure’s purpose and modifications. Document the container’s condition upon delivery to avoid disputes. Anchor the shed securely to mitigate wind damage and potential liability from structural failure.

Maintenance and Ongoing Compliance

Inspect annually for rust, seal degradation, and foundation shifts. Repaint with weather-resistant coatings as needed. Keep records of permits, inspections, and maintenance. Notify local authorities of any major modifications to ensure continued compliance with zoning and safety codes.

Conclusion: Sourcing Shipping Container Sheds

Sourcing shipping container sheds offers a cost-effective, sustainable, and versatile solution for a wide range of storage, workspace, and shelter needs. By repurposing durable steel containers, individuals and businesses can benefit from strong, weather-resistant structures that are easily customizable and quickly deployable. With options to purchase new or used containers and the availability of modified or turnkey units, sourcing container sheds provides flexibility in budget, design, and timeline.

Key considerations—such as container condition, modifications required (e.g., doors, windows, insulation), delivery logistics, and compliance with local regulations—should be carefully evaluated to ensure the right fit for the intended use. Additionally, choosing reputable suppliers and understanding long-term maintenance needs contribute to a successful investment.

In conclusion, shipping container sheds represent a smart, innovative alternative to traditional construction, combining affordability, durability, and sustainability. With proper planning and sourcing, they can serve as practical and long-lasting solutions across residential, commercial, and industrial applications.