The global shipping container conversion and modular construction market is experiencing robust growth, driven by rising demand for sustainable, cost-effective, and rapidly deployable structures across residential, commercial, and industrial sectors. According to Mordor Intelligence, the global shipping container market was valued at USD 7.67 billion in 2023 and is projected to reach USD 10.79 billion by 2029, growing at a CAGR of 5.8% during the forecast period. This expansion is fueled by increasing urbanization, logistical needs, and innovative reuse of containers in architecture and mobile units—all of which require reliable mobility solutions. A critical enabler of this versatility is the adoption of high-quality shipping container wheels kits, which transform static units into portable assets. As demand surges, manufacturers specializing in durable, load-rated, and corrosion-resistant wheel systems are playing an increasingly vital role in the ecosystem. The following list highlights the top 10 manufacturers leading innovation and quality in shipping container wheels kits, selected based on product performance, market presence, certifications, and customer reviews.

Top 10 Shipping Container Wheels Kit Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 ISO Shipping Container Castors & Wheels

Domain Est. 2003

Website: industrialwheels.com

Key Highlights: 7-day returnsExplore a large collection of shipping and freight container wheels and castors, specifically designed for heavy industrial use! ✓ 70+ years of experience!…

#2 ISO Shipping Container Casters

Domain Est. 2003

Website: accesscasters.com

Key Highlights: 5–9 day delivery 30-day returnsMake ISO shipping containers mobile and available for towing with our ISO 1161 sets. Our sets of 4 include 2 swivel and 2 rigid casters….

#3 Shipping Container Wheels & Tow Bar Kit

Domain Est. 2004

#4 Shipping Container Wheels & Castors

Domain Est. 2016

Website: containersalesgroup.com

Key Highlights: Add mobility to your shipping container with heavy-duty wheels and castors. Ideal for portable storage, workshops, and temporary container setups….

#5 Shipping Container End Wheels

Domain Est. 2018

Website: containgo.com

Key Highlights: Our patented shipping container end wheels make moving containers quick, simple, and safe. They install in seconds, by hand, no tools needed….

#6 TriWich

Domain Est. 2019

Website: triwich.com

Key Highlights: Discover TriWich’s modular mobility solutions, shipping container dolly, wheel dollies & container jacks, built for businesses, EV dealerships & military use….

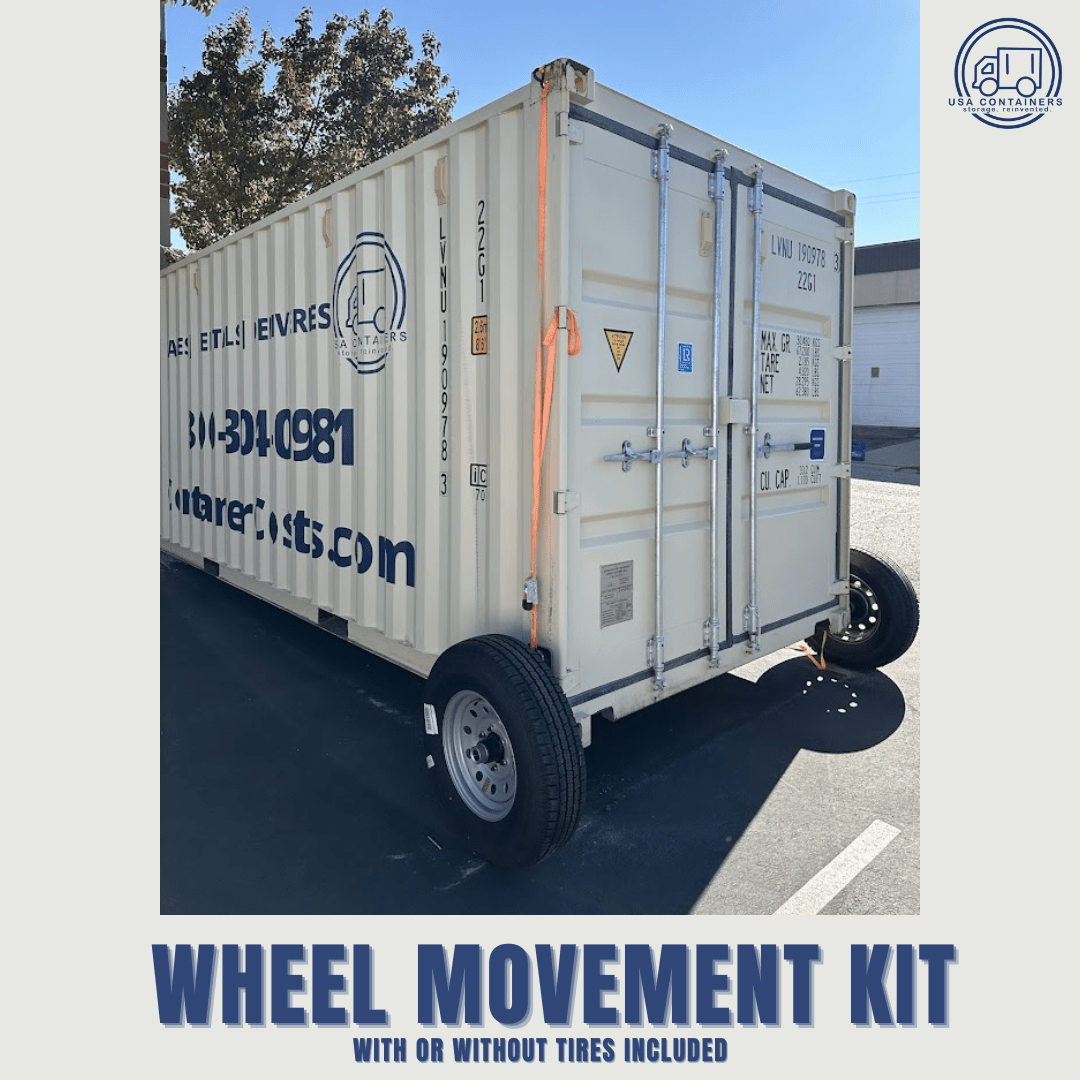

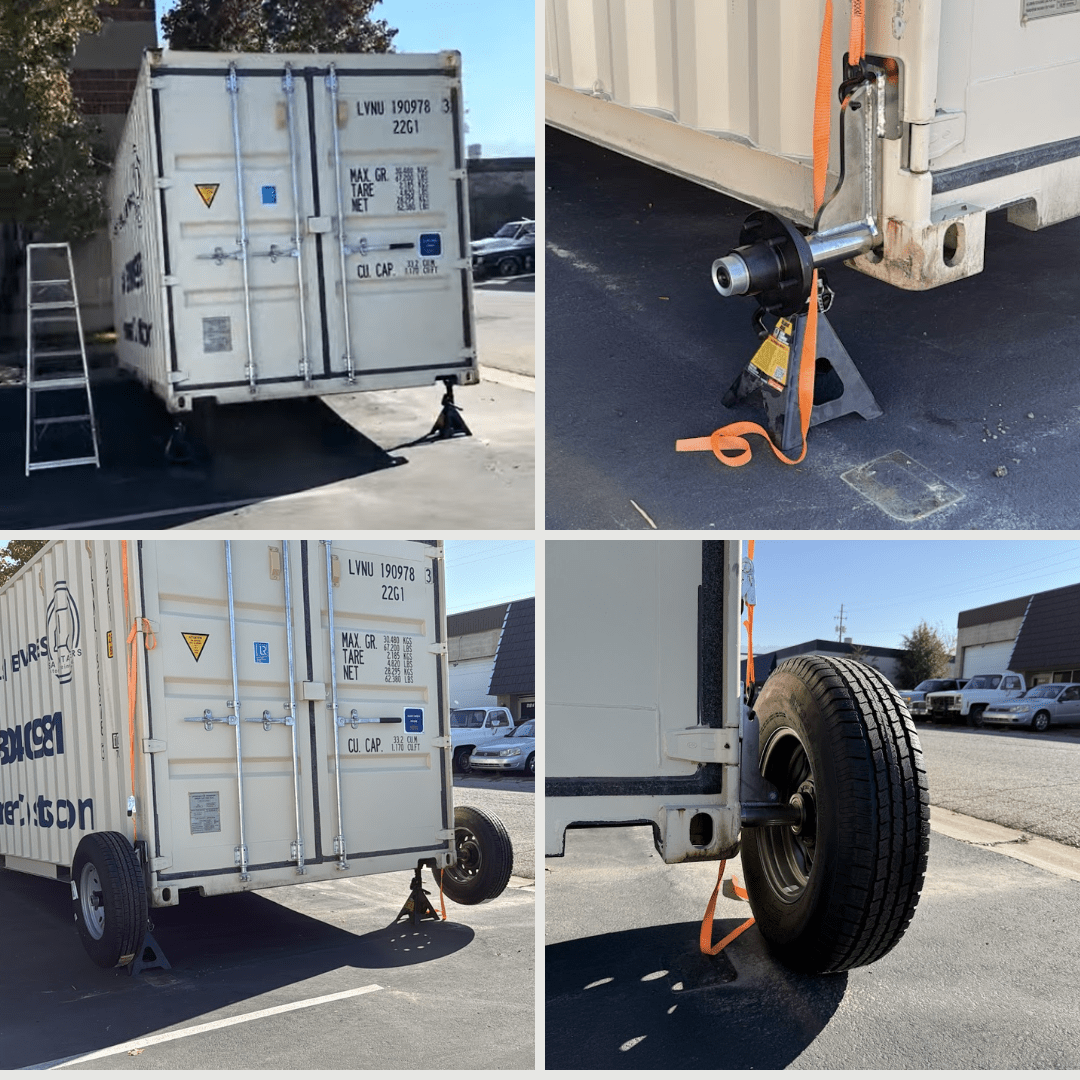

#7 Container Movement Kit

Domain Est. 2019

Website: usacontainers.co

Key Highlights: Designed for simple setup and smooth transport, our solutions make repositioning your shipping container fast, safe, and hassle-free….

#8 Shipping Container Wheels

Domain Est. 2022

Website: shippingcontainerwheels.com

Key Highlights: Our shipping container end wheels and tow bar make relocating or moving a shipping container fast, simple, and safe….

#9 Move & Level Shipping Containers with EZY Wheels + EZY Lift

Domain Est. 2023

#10 Twistlock Dynamics

Domain Est. 2024

Website: twistlockdynamics.com

Key Highlights: Set of 4 shipping container wheels, 250 mm in diameter and 73 mm wide, featuring a side-lock mechanism, directional lock and brakes….

Expert Sourcing Insights for Shipping Container Wheels Kit

2026 Market Trends for Shipping Container Wheels Kit

The global market for shipping container wheels kits is poised for significant transformation by 2026, driven by increasing demand for modular, mobile, and rapidly deployable infrastructure solutions. These kits—enabling standard shipping containers to be converted into movable units—are gaining traction across industries such as construction, logistics, disaster relief, and mobile retail. Below is an analysis of key trends expected to shape the market in 2026.

Rising Demand for Mobile and Modular Solutions

One of the primary drivers of the shipping container wheels kit market is the growing interest in modular and mobile infrastructure. As urbanization accelerates and space becomes a premium, businesses and governments are turning to repurposed shipping containers for temporary housing, pop-up stores, field hospitals, and mobile offices. The integration of wheels kits enhances mobility, allowing containers to be easily transported without crane or forklift assistance. By 2026, this trend is expected to expand further, especially in emerging economies where rapid deployment and cost-effective solutions are critical.

Growth in Construction and Remote Site Applications

The construction industry is increasingly adopting container-based site offices, storage units, and worker accommodations. Shipping container wheels kits facilitate the repositioning of these units across large project sites, improving operational efficiency. With infrastructure development projects on the rise globally—particularly in Asia-Pacific, Africa, and Latin America—the demand for mobile container solutions is projected to grow steadily. By 2026, integration with smart site management systems may further boost adoption, as companies seek agile and relocatable site assets.

Innovation in Wheel Kit Design and Durability

Technological advancements are expected to redefine shipping container wheels kits by 2026. Manufacturers are focusing on lightweight yet robust materials such as high-grade steel alloys and composites to improve load capacity and reduce wear. Features like airless tires, all-terrain capability, and integrated braking systems are becoming standard. Additionally, modular and bolt-on designs that require no welding are gaining popularity due to ease of installation and compliance with freight standards. These innovations will likely increase product lifespan and usability across diverse environments.

Sustainability and Circular Economy Influence

Sustainability trends are significantly impacting the container repurposing market. As companies aim to reduce carbon footprints and embrace circular economy principles, reusing shipping containers aligns with environmental goals. Wheels kits contribute to this sustainability by extending the functional life of containers beyond traditional shipping use. By 2026, eco-conscious procurement policies and green building certifications (e.g., LEED) may drive demand, particularly in government and corporate projects emphasizing sustainable practices.

Expansion of E-Commerce and Last-Mile Logistics

The boom in e-commerce continues to fuel demand for flexible logistics solutions. Shipping containers equipped with wheels are being used as mobile fulfillment centers, pop-up distribution hubs, and last-mile delivery stations in urban areas. This trend is expected to accelerate by 2026, especially in congested cities where space constraints limit traditional warehouse development. Wheels kits enable rapid relocation of these mobile units based on demand fluctuations, offering logistical agility.

Regulatory and Standardization Developments

As the use of mobile container units grows, regulatory bodies are likely to introduce clearer standards for safety, roadworthiness, and transport compliance by 2026. This includes load limits, axle configurations, and braking requirements for wheeled containers used on public roads. Manufacturers of wheels kits may need to align with regional transportation regulations (e.g., DOT in the U.S., ECE in Europe), potentially leading to more certified and standardized product offerings.

Regional Market Dynamics

The Asia-Pacific region is expected to lead market growth due to rapid urbanization, infrastructure investments, and a thriving shipping industry. China, India, and Southeast Asian nations are key adopters. North America and Europe will follow, driven by demand in disaster response, military applications, and commercial pop-up ventures. Meanwhile, the Middle East and Africa are emerging as high-potential markets, particularly for humanitarian and remote construction applications.

Conclusion

By 2026, the shipping container wheels kit market will be shaped by innovation, sustainability, and the increasing need for mobile infrastructure. As industries continue to value flexibility and cost-efficiency, the integration of advanced wheels kits will play a pivotal role in transforming static containers into dynamic, multi-functional assets. Strategic investments in R&D, compliance, and distribution will determine market leadership in this evolving sector.

Common Pitfalls When Sourcing Shipping Container Wheels Kit (Quality and Intellectual Property)

Sourcing shipping container wheels kits can present several challenges, particularly concerning product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable performance and legal compliance.

Poor Material Quality and Durability

One of the most frequent issues is receiving wheels kits made from substandard materials. Low-grade steel or inadequate axle treatments can lead to premature wear, cracking, or failure under load. This compromises safety and increases long-term maintenance costs, especially in harsh environments or heavy-duty applications.

Inconsistent Load Ratings and Performance

Some suppliers misrepresent or exaggerate load capacities. Kits may not meet international standards (e.g., ISO or ASTM), leading to structural failure when used beyond their actual capacity. Always verify third-party certifications and conduct load testing when possible.

Lack of Weather and Corrosion Resistance

Shipping containers operate in diverse climates. Kits without proper rust protection—such as galvanization or powder coating—deteriorate quickly. Overlooking corrosion resistance results in reduced lifespan and potential safety hazards.

Non-Compliance with Industry Standards

Many low-cost kits fail to meet dimensional, safety, or compatibility standards for ISO shipping containers. This can prevent secure attachment or interfere with container handling equipment, creating operational inefficiencies.

Intellectual Property (IP) Infringement Risks

Sourcing from manufacturers that copy patented designs—such as unique suspension systems or wheel mounting mechanisms—exposes buyers to legal liability. Counterfeit or cloned kits may violate IP rights, leading to shipment seizures, fines, or litigation, especially in regulated markets.

Inadequate Documentation and Traceability

Reputable suppliers provide clear technical specifications, material certifications, and traceable manufacturing details. Opaque supply chains often hide poor practices and increase the risk of receiving non-compliant or unsafe products.

Hidden Costs from Frequent Replacements

Initially low-priced kits often lead to higher total costs due to frequent breakdowns and replacements. Prioritizing lowest cost over quality results in downtime and increased logistical expenses.

Limited After-Sales Support and Warranties

Many budget suppliers offer little to no warranty or technical support. Without reliable after-sales service, resolving issues becomes difficult, especially when operating in remote locations.

To mitigate these risks, conduct thorough due diligence: verify supplier credentials, request product certifications, perform site audits if possible, and ensure IP compliance through legal review when sourcing proprietary designs.

Logistics & Compliance Guide for Shipping Container Wheels Kit

Product Classification and HS Code

Identify the correct Harmonized System (HS) code for the wheels kit to ensure proper customs clearance. A typical classification might fall under HS 8708.29 (Parts and accessories of vehicles for the transport of goods), but verify with local customs authorities based on exact composition (e.g., steel wheels, axles, mounting hardware). Accurate classification affects tariffs, import duties, and compliance with trade regulations.

Packaging and Securement for Transport

Package the wheels kit in durable, weather-resistant materials such as wooden crates or heavy-duty pallets wrapped in stretch film. Ensure components are secured to prevent movement during transit. Include protective coating or VCI (Vapor Corrosion Inhibitor) paper if metal parts are susceptible to rust. Label each package clearly with handling instructions (e.g., “Fragile,” “This Side Up”).

Shipping Documentation Requirements

Prepare essential shipping documents including Commercial Invoice, Packing List, Bill of Lading (or Air Waybill), and Certificate of Origin. The Commercial Invoice must detail product description, value, weight, and HS code. For shipments to certain regions, a Material Safety Data Sheet (MSDS) or Declaration of Conformity may be required, even if the kit contains no hazardous materials.

Import/Export Regulations and Permits

Check destination country regulations for imported vehicle parts. Some countries require certification (e.g., DOT in the U.S., ECE in Europe) for wheel and axle components, especially if intended for road use. Confirm whether the wheels kit is classified as a complete axle system or replacement parts, as this may trigger different compliance standards.

Dimensional and Weight Restrictions

Adhere to international shipping standards for containerized freight. Ensure the packaged kit complies with standard container dimensions (20’ or 40’) and weight limits. Exceeding payload restrictions may incur additional fees or require special handling. Optimize packaging size to reduce freight classification (e.g., avoiding DIM weight surcharges in air freight).

Customs Duties and Taxation

Research applicable import duties, VAT, or GST based on the destination country. Use the correct HS code to determine duty rates. Consider leveraging preferential trade agreements (e.g., USMCA, ASEAN) if manufacturing and sourcing meet rules of origin requirements to reduce or eliminate tariffs.

Labeling and Marking Compliance

Mark each package with the shipper’s and consignee’s full address, country of origin, net/gross weight, and handling symbols per ISO 780 standards. Include any required regulatory labels such as CE marking (if compliant with EU directives) or country-specific warnings. Barcodes or RFID tags may be added for inventory tracking.

Restricted and Prohibited Items Considerations

Verify that no components (e.g., lubricants, adhesives) in the kit are classified as hazardous materials under IATA, IMDG, or ADR regulations. Even small quantities may require special documentation or packaging if they contain controlled substances. Most container wheels kits are non-hazardous, but confirmation is essential.

Environmental and RoHS Compliance

Ensure electrical or coated components (if any) comply with environmental directives such as the EU’s RoHS (Restriction of Hazardous Substances). While mechanical wheel kits typically fall outside RoHS scope, confirm material composition—especially if fasteners or housings contain restricted metals like lead or hexavalent chromium.

Returns and Reverse Logistics Procedure

Establish a clear process for handling defective or incorrect shipments. Include return authorization (RMA) protocols, repackaging standards, and responsibility for return freight costs in sales agreements. Maintain records of returned items for compliance audits and warranty tracking.

Carrier and Freight Forwarder Coordination

Partner with experienced freight forwarders familiar with automotive parts shipments. Confirm carrier acceptance of the packaged wheels kit and verify insurance coverage for damage or loss. Choose Incoterms (e.g., FOB, CIF, DDP) that clearly define liability and delivery obligations.

Country-Specific Compliance Examples

- United States: No DOT certification required if not for road-traveling containers, but customs may inspect under CBP guidelines.

- European Union: May require CE marking if the kit alters structural or safety features of the container.

- Australia: Check with the Department of Infrastructure for any import restrictions on vehicle components.

Always consult with local legal and customs experts to ensure ongoing compliance with evolving international trade laws.

Conclusion: Sourcing Shipping Container Wheels Kit

Sourcing a shipping container wheels kit requires careful consideration of several key factors, including load capacity, wheel material, axle strength, compatibility with container dimensions, and intended use (e.g., permanent installation, temporary mobility, or off-road applications). After evaluating various suppliers, product specifications, and customer reviews, it is evident that high-quality kits made from durable materials such as galvanized steel or reinforced rubber are essential for ensuring longevity and safe transportation.

Opting for kits with easy installation features and compliance with industry standards enhances both usability and safety. Additionally, purchasing from reputable suppliers that offer warranties and responsive customer support provides long-term value and peace of mind.

In conclusion, selecting the right shipping container wheels kit involves balancing cost, quality, and suitability for the specific application. With proper research and due diligence, businesses and individuals can successfully source reliable wheel kits that transform static containers into mobile, versatile assets for construction, storage, retail, or emergency response purposes.