The global drywall and interior finishing market has experienced steady expansion, driven by rising construction activities and increasing demand for cost-effective, aesthetically pleasing wall finishes. According to a report by Mordor Intelligence, the global gypsum boards market—integral to sheetrock and drywall applications—was valued at USD 35.6 billion in 2023 and is projected to grow at a CAGR of 5.2% through 2029. This growth directly influences the demand for specialized application equipment, including sheetrock texture machines. As contractors and renovation professionals seek efficiency and consistency in texturing finishes, the role of high-performance machinery has become increasingly critical. This has led to technological advancements and competitive innovation among manufacturers. Below is a data-driven overview of the top eight sheetrock texture machine manufacturers shaping the industry with reliable, high-output solutions tailored to modern construction demands.

Top 8 Sheetrock Texture Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Interior Texture Sprayers

Domain Est. 1994

Website: graco.com

Key Highlights: Interior Texture Sprayers. High-quality and reliable Graco interior texture sprayers have set the standard for professional contractors for 25 years….

#2 Drywall Finishing Tools, Drywall Tools, Drywall Pumps, Drywall …

Domain Est. 1998

Website: apla-tech.com

Key Highlights: We make quality drywall tools, including: drywall finishing tools, drywall pumps, drywall texturing tools, and drywall texture sprayer that are available…

#3 Texture Machines

Domain Est. 1998

#4 Drywall Texture Sprayer

Domain Est. 1999

#5 Wall Products

Domain Est. 2000 | Founded: 1971

Website: murcowall.com

Key Highlights: We have been the preferred supplier of drywall materials, paint products, tools and supplies, to dealers and contractors across the United States since 1971….

#6 Drywall Spray Equipment

Domain Est. 2001

Website: descospray.com

Key Highlights: Tank sizes range from 60 to 500 gallons, with options for single-tank systems (one pump, one texture at a time) or split-tank models (two pumps, two textures ……

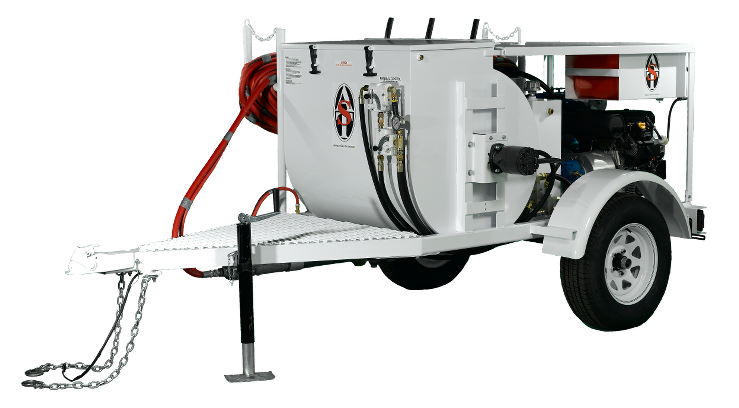

#7 American Spray Technologies

Domain Est. 2002

Website: sprayrig.com

Key Highlights: Find top-quality texture spray machines at American Spray Technologies. Trusted by drywall contractors for exceptional performance and customer service….

#8 Products Textures ProForm® Perfect Spray® EM

Domain Est. 2020

Website: proformfinishing.com

Key Highlights: Provides an innovative time and money-saving option to ordinary painting. Decorative texturing product for fast spray applications to interior surfaces….

Expert Sourcing Insights for Sheetrock Texture Machine

H2: 2026 Market Trends for Sheetrock Texture Machine

The global market for sheetrock texture machines is poised for notable transformation by 2026, driven by advancements in construction technology, shifts in building practices, and increasing demand for energy-efficient and aesthetically refined interior finishes. As the construction industry embraces automation, sustainability, and labor efficiency, the sheetrock texture machine segment is expected to reflect these broader trends.

-

Increased Adoption of Automated and Smart Texture Machines

By 2026, automation will play a central role in the evolution of sheetrock texture equipment. Manufacturers are integrating IoT-enabled sensors, adjustable spray nozzles, and programmable settings into texture machines, allowing contractors to achieve consistent finishes with minimal manual intervention. These smart machines will offer preset texture profiles (e.g., orange peel, knockdown, or skip trowel), reducing skill dependency and improving project turnaround. -

Growing Demand in Residential Renovation and Multifamily Construction

The residential sector—particularly home renovation and multifamily housing—will remain a key growth driver. As urban populations expand and housing shortages persist in regions like North America and parts of Asia-Pacific, demand for fast, cost-effective interior finishing solutions will rise. Sheetrock texture machines enable faster wall finishing compared to traditional hand-texturing methods, making them ideal for high-volume projects. -

Sustainability and Low-VOC Material Compatibility

Environmental regulations and green building standards (such as LEED and BREEAM) are pushing contractors to use low-VOC (volatile organic compound) joint compounds and eco-friendly materials. By 2026, sheetrock texture machines will increasingly be designed to handle these sustainable compounds without clogging or performance degradation. Equipment manufacturers will emphasize energy-efficient motors and reduced material waste as selling points. -

Rise of Rental and Shared Equipment Models

To lower entry barriers for small contractors and DIY users, equipment rental platforms and construction tool-sharing services are expected to expand. This trend will boost accessibility to high-end sheetrock texture machines without requiring large capital investments. Companies like Sunbelt Rentals and United Rentals are likely to expand their inventory of texture-spraying systems by 2026. -

Regional Market Expansion in Emerging Economies

While North America and Europe will continue to dominate due to established construction ecosystems, emerging markets in Southeast Asia, the Middle East, and Latin America will see accelerated growth. Infrastructure development and rising disposable incomes will fuel demand for modern interior finishes, increasing the need for efficient texture application tools. -

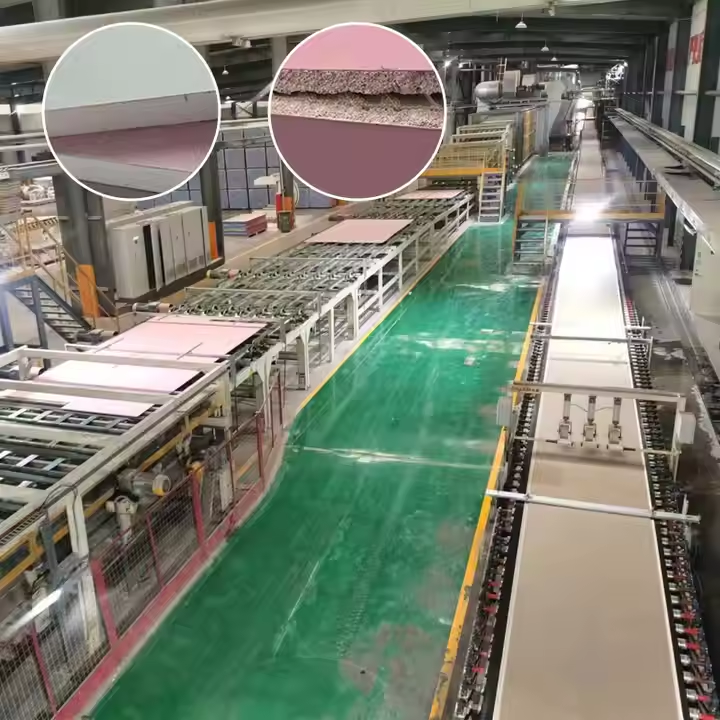

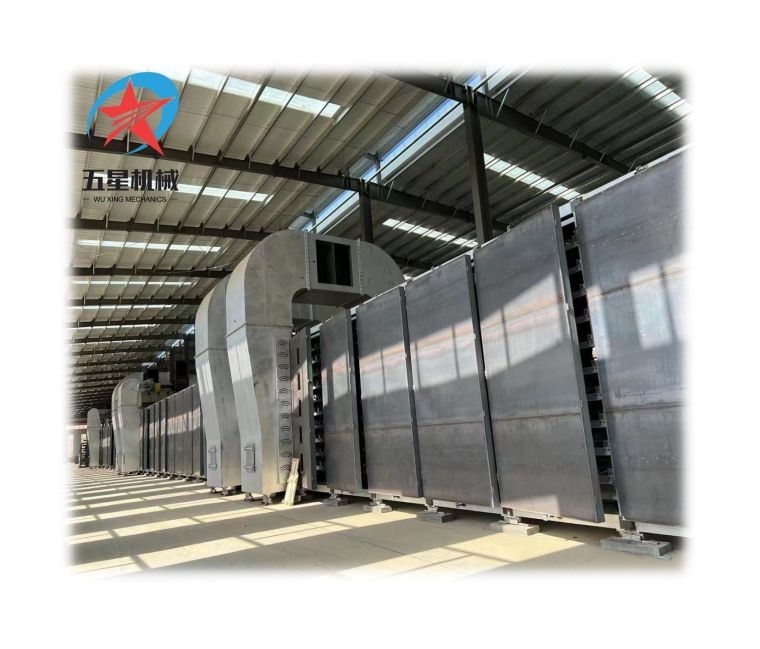

Integration with Prefabrication and Modular Construction

The rise of off-site construction and modular building techniques will influence texture machine design. By 2026, compact, portable, and modular-compatible texture sprayers will gain traction, enabling pre-finishing of wall panels in factory settings. This shift supports faster on-site assembly and improved quality control. -

Focus on Ergonomics and Operator Safety

With labor shortages and increasing emphasis on worker well-being, manufacturers will prioritize lightweight, ergonomically designed machines with reduced vibration and noise levels. Features like adjustable handles, improved airflow systems, and easy maintenance will become standard to enhance user comfort and reduce fatigue.

In summary, the 2026 market for sheetrock texture machines will be characterized by innovation in automation, alignment with sustainable construction, and expansion into new geographic and application segments. Companies that invest in smart, adaptable, and eco-conscious equipment are likely to lead the market, meeting the evolving needs of professional contractors and modern building projects.

Common Pitfalls When Sourcing a Sheetrock Texture Machine (Quality, IP)

Sourcing a Sheetrock texture machine—especially from international suppliers—can present several challenges related to product quality and intellectual property (IP). Being aware of these pitfalls helps ensure you invest in reliable equipment while protecting your business from legal and operational risks.

Poor Build Quality and Material Standards

One of the most frequent issues is receiving machines constructed with substandard materials or poor manufacturing practices. Low-cost suppliers may use inferior metals, weak motors, or non-durable components that lead to frequent breakdowns, inconsistent texture application, and increased maintenance costs. Always verify material specifications, request third-party inspection reports, and consider factory audits before placing large orders.

Inconsistent Texture Output and Performance

A poorly designed or manufactured texture machine may fail to deliver uniform spray patterns or consistent texture finishes. This can result in rework, wasted materials, and project delays. Look for machines tested under real-world conditions and ask for performance data or video demonstrations to verify consistency across different joint compound viscosities and application speeds.

Lack of Safety and Compliance Certifications

Many budget machines, especially from unverified manufacturers, lack essential safety certifications (e.g., CE, UL, or CSA). This not only poses a risk to operators but can also prevent the machine from being used on job sites governed by strict safety regulations. Confirm that the machine meets relevant electrical, mechanical, and emissions standards in your target market.

Inadequate After-Sales Support and Spare Parts Availability

Even high-quality machines require maintenance and occasional repairs. Sourcing from suppliers with limited customer support or no spare parts distribution network can lead to long downtimes. Ensure the supplier offers a warranty, technical support, and a clear plan for spare parts delivery—especially if sourcing from overseas.

Intellectual Property Infringement Risks

Some manufacturers produce texture machines that closely mimic patented designs or incorporate proprietary technologies without authorization. Purchasing such equipment can expose your business to indirect IP liability, particularly if the machine is used commercially in regions with strong IP enforcement (e.g., the U.S. or EU). Always vet suppliers for original designs or proper licensing, and avoid models that appear to copy well-known brands.

Misrepresentation of Technical Specifications

Suppliers may exaggerate performance metrics such as spray capacity, motor power, or compatibility with various textures (e.g., knockdown, orange peel). Misleading specs can result in choosing a machine unsuitable for your workflow. Request independent test results, user reviews, or third-party verification to confirm stated capabilities.

No Clear Ownership of Design or Innovation

When customizing or private-labeling a texture machine, ensure that IP rights—such as design patents, software, or branding—are explicitly transferred to your company. Failure to secure IP ownership in contracts can limit your ability to modify, resell, or protect the product in the future.

By addressing these common pitfalls proactively, businesses can source Sheetrock texture machines that deliver reliable performance, meet regulatory standards, and avoid costly legal complications.

Logistics & Compliance Guide for Sheetrock Texture Machine

This guide outlines the essential logistics and compliance considerations for transporting, handling, installing, and operating a Sheetrock® Texture Machine. Adherence to these guidelines ensures safe operations, regulatory compliance, and product longevity.

Transportation & Handling

Ensure the texture machine is securely packaged if shipped. Use proper lifting techniques or mechanical aids (e.g., pallet jack, forklift) when moving the unit. Always transport the machine upright to prevent damage to internal components or fluid leaks. Protect the machine from moisture, extreme temperatures, and physical impact during transit.

Storage Requirements

Store the machine in a clean, dry, and temperature-controlled environment. Avoid exposure to freezing conditions or excessive heat (above 100°F/38°C). Keep the machine covered when not in use to prevent dust accumulation. Ensure adequate ventilation if stored near solvents or flammable materials.

Import/Export Compliance

Verify all import/export documentation, including commercial invoices, packing lists, and certificates of origin. Comply with destination country regulations regarding electrical equipment and motorized tools. Confirm adherence to U.S. Export Administration Regulations (EAR) if shipping internationally. Machines with electric motors may require specific customs classifications (e.g., HS Code 8424.89).

Electrical Safety & Standards

The machine must be used with a properly grounded electrical outlet that matches its voltage and amperage requirements (typically 120V, 60Hz in North America). Ensure compliance with National Electrical Code (NEC) standards and local electrical regulations. Use a GFCI (Ground Fault Circuit Interrupter) outlet when operating in damp or outdoor conditions.

Emissions & Environmental Regulations

Comply with EPA regulations regarding volatile organic compounds (VOCs) when using texture materials. Use low-VOC or zero-VOC approved compounds where required by local air quality management districts (e.g., SCAQMD, Bay Area AQMD). Dispose of cleaning solvents and waste materials according to RCRA (Resource Conservation and Recovery Act) guidelines.

Workplace Safety (OSHA Compliance)

Operators must follow OSHA 29 CFR 1926 standards for construction safety. Use appropriate personal protective equipment (PPE), including safety glasses, gloves, hearing protection, and respiratory protection when spraying. Ensure proper ventilation in confined spaces. Train personnel on machine operation, emergency shutdown procedures, and hazard communication (HazCom) for materials used.

Manufacturer Certification & Documentation

Ensure the machine carries relevant safety certifications such as ETL or UL listing for electrical components. Retain the owner’s manual, warranty documentation, and product specifications. Follow all manufacturer-recommended maintenance schedules to remain compliant with operational warranties and safety standards.

Disposal & End-of-Life

Dispose of the machine in accordance with local electronic waste (e-waste) regulations. Contact certified e-waste recyclers for proper decommissioning. Do not landfill motorized components or electrical parts. Recycle metal housings and plastic components where facilities exist.

Adhering to this guide ensures safe, legal, and efficient use of your Sheetrock® Texture Machine throughout its lifecycle.

Conclusion: Sourcing a Sheetrock Texture Machine

After evaluating various options for sourcing a sheetrock texture machine, it is clear that selecting the right equipment is crucial for achieving consistent, high-quality finishes in drywall applications. Whether for small-scale residential projects or large commercial operations, the ideal machine should balance performance, durability, ease of use, and cost-effectiveness.

Key factors to consider include the type of texture required (e.g., knockdown, orange peel, popcorn), production volume, portability, and compatibility with existing tools and materials. Renting may be cost-efficient for one-time or infrequent jobs, while purchasing offers long-term value for contractors with ongoing projects. Additionally, sourcing from reputable suppliers or manufacturers ensures access to reliable customer support, warranties, and replacement parts.

In conclusion, a well-informed decision—based on project needs, budget, and long-term goals—will enhance productivity and finish quality. Investing time in researching and testing available sheetrock texture machines will ultimately lead to better results, greater client satisfaction, and improved efficiency on the job site.