The global drywall and finishing products market has experienced steady expansion, driven by rising construction activities and demand for energy-efficient, cost-effective interior solutions. According to Mordor Intelligence, the global drywall market was valued at USD 40.8 billion in 2023 and is projected to grow at a CAGR of 5.2% through 2029. A critical yet often overlooked component within this ecosystem is J bead—primarily used to provide clean, durable edges for sheetrock installations in both residential and commercial builds. As architectural standards and finish quality expectations rise, so does the demand for high-performance, dimensionally stable J bead products. This growth trajectory underscores the importance of reliable manufacturing partners who can deliver consistent quality and innovation. Based on market presence, product performance, and industry reputation, the following four manufacturers have emerged as leaders in the sheetrock J bead segment.

Top 4 Sheetrock J Bead Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Trim

Domain Est. 1996

Website: trim-tex.com

Key Highlights: Trim-Tex is the premier manufacturer of drywall beads & accessories. We coined the term “Drywall Art” and serve as a Design & Training Center….

#2 USG Middle East Drywall J Trims

Domain Est. 2003

#3 Builders Suppliers

Domain Est. 2008

Website: myfbm.com

Key Highlights: Looking for a specialist in building and construction materials? With FBM, find industry-leading tools, accessories and PPE for your next project. Shop now….

#4 J

Domain Est. 2011

Website: clarkdietrich.com

Key Highlights: J-Bead is designed to cover raw edges of drywall under all window and door casing. Found in: Interior Finishing > Commercial Beads….

Expert Sourcing Insights for Sheetrock J Bead

H2: Projected 2026 Market Trends for Sheetrock J Bead

The Sheetrock J Bead market is poised for notable growth and transformation by 2026, driven by evolving construction practices, material innovations, and regional development dynamics. As a key component in drywall finishing—especially for creating clean, durable edges along drywall panels—J Bead is witnessing increased demand across residential, commercial, and industrial construction sectors.

One of the primary drivers shaping the 2026 outlook is the global rise in construction activities, particularly in emerging economies. Countries in Asia-Pacific, the Middle East, and parts of Africa are experiencing rapid urbanization and infrastructure investments, fueling demand for efficient and cost-effective drywall solutions. The Sheetrock J Bead, known for its ease of installation and ability to reinforce corners and perimeters, is becoming a preferred choice in both new builds and renovation projects.

Another significant trend is the growing emphasis on energy efficiency and sustainable building materials. Manufacturers are responding by developing J Beads with improved durability, moisture resistance, and recyclable components. These eco-friendly variants are gaining traction among green-certified building projects, aligning with LEED and other sustainability standards. By 2026, products with low volatile organic compound (VOC) emissions and recycled content are expected to command a larger market share.

Technological advancements are also influencing the market. Pre-taped and self-adhesive J Bead systems are gaining popularity due to their time-saving benefits and reduced labor costs. These innovations are particularly appealing in high-volume construction settings, where speed and consistency are critical. Additionally, the integration of digital measurement tools and building information modeling (BIM) is streamlining the installation process, further boosting demand for precision-engineered J Beads.

Regionally, North America is expected to maintain a strong market position due to robust residential remodeling and commercial construction. Europe follows closely, with stringent building regulations promoting the use of high-performance drywall accessories. Meanwhile, the Asia-Pacific region is projected to record the highest compound annual growth rate (CAGR), supported by expanding urban housing projects and rising disposable incomes.

In conclusion, the 2026 Sheetrock J Bead market will be shaped by sustainability, innovation, and global construction growth. Stakeholders who adapt to these trends—by investing in advanced materials, automation, and regional market insights—are likely to gain a competitive edge in this evolving landscape.

Common Pitfalls Sourcing Sheetrock J Bead (Quality, IP)

When sourcing Sheetrock® J Bead, particularly from international suppliers or third-party vendors, several key pitfalls related to quality and intellectual property (IP) can arise. Being aware of these issues helps ensure you receive a reliable, code-compliant product that protects your project and avoids legal complications.

1. Inferior Material Quality and Gauge Thickness

One of the most frequent issues is receiving J Bead made from substandard materials. Authentic Sheetrock® J Bead is manufactured to precise ASTM standards with consistent galvanized steel thickness (typically 25–28 gauge). Counterfeit or low-cost alternatives may use thinner, weaker steel (e.g., 30+ gauge), which bends easily during installation and fails to provide proper edge support. This can lead to cracking at corners and poor long-term durability.

2. Inaccurate Dimensions and Profile Tolerances

Non-genuine J Beads often deviate from standard dimensions—flange width, leg length, or channel depth may be inconsistent. These variances make it difficult to achieve clean, flush finishes when taping and mudding. Poorly formed profiles can cause gaps or uneven surfaces, compromising both aesthetics and performance.

3. Inadequate Corrosion Resistance

Genuine Sheetrock® J Bead features high-quality galvanization for rust resistance, especially important in humid environments. Imitation products may use inferior coatings or less zinc content, increasing the risk of oxidation over time. This can lead to staining, deterioration, and reduced lifespan, particularly in bathrooms or exterior applications.

4. Misuse of Trademarks and Branding (IP Violations)

Many suppliers falsely label generic metal corner beads as “Sheetrock® J Bead” to imply authenticity. This constitutes trademark infringement and misrepresentation. Purchasing such products may expose contractors or builders to legal risk, especially if project specifications require genuine USG-branded materials. Always verify product packaging, labeling, and supplier authorization.

5. Lack of Compliance and Testing Documentation

Authentic Sheetrock® products come with technical data sheets, fire ratings, and compliance certifications (e.g., ICC-ES, ASTM C840). Knockoff J Beads often lack proper documentation, making it difficult to validate performance standards or meet building code requirements during inspections.

6. Inconsistent Availability and Supply Chain Reliability

Generic or off-brand J Beads may appear cost-effective but can suffer from inconsistent stock levels or discontinued product lines. Relying on such sources risks project delays if the same product isn’t available for later phases or repairs.

7. Poor Packaging and Handling Damage

Counterfeit or low-tier products are often poorly packaged, increasing the likelihood of bent or damaged beads during shipping. This leads to waste, reordering, and increased labor costs on-site.

Best Practices to Avoid Pitfalls

- Purchase directly from authorized USG distributors or verify supplier credentials.

- Inspect samples for gauge, finish, and dimensional accuracy before bulk ordering.

- Request product data sheets and certification documents.

- Avoid unusually low prices—these often indicate subpar quality or IP violations.

- Clearly specify “USG Sheetrock® Brand J Bead” in contracts and submittals when required.

By prioritizing authenticity and verifying product specifications, you ensure both structural integrity and compliance, avoiding costly rework and legal exposure.

Logistics & Compliance Guide for Sheetrock J Bead

Product Overview

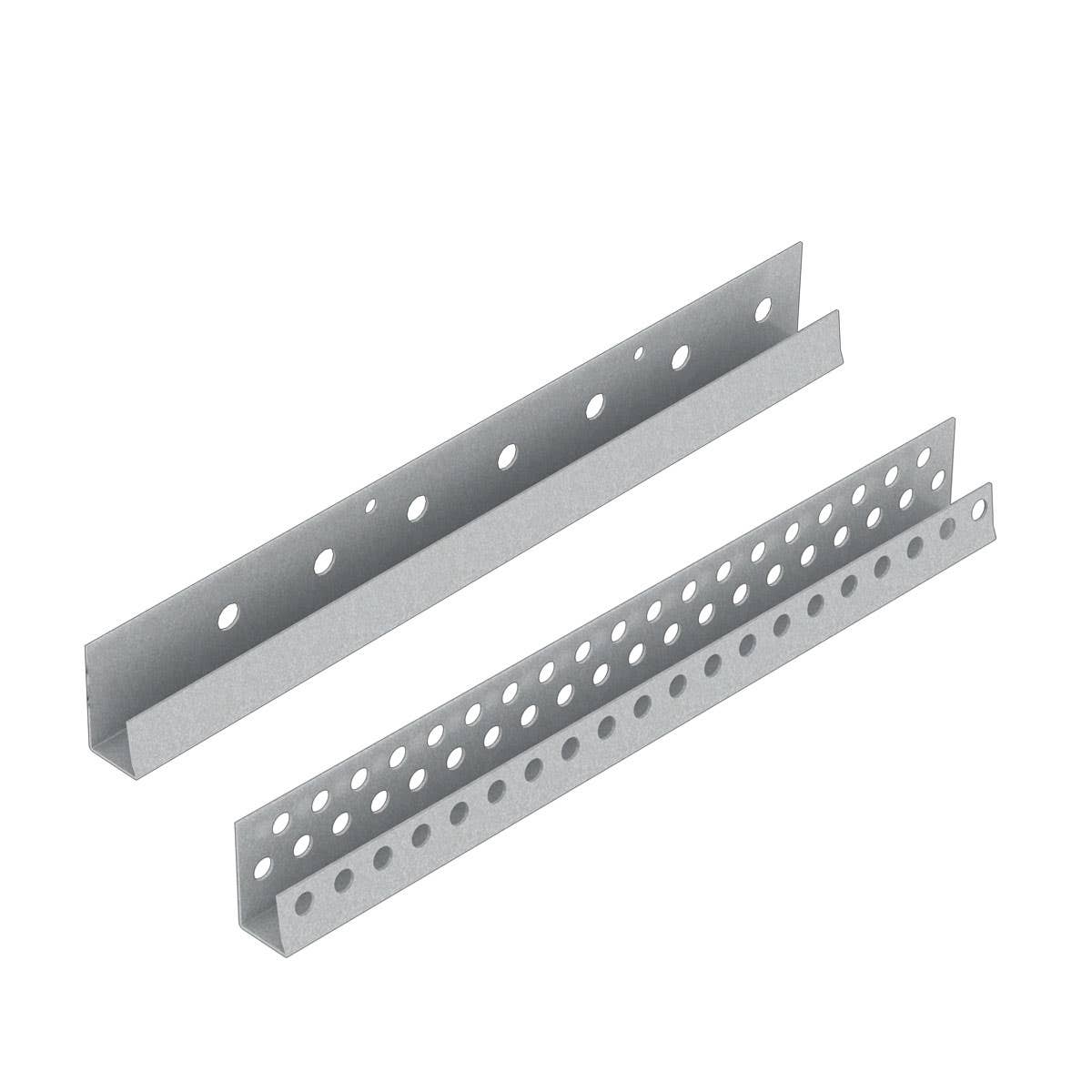

Sheetrock J Bead is a pre-finished, lightweight edge treatment used in drywall applications to provide clean, durable corners and edges around windows, doors, and other wall openings. It is typically made from galvanized steel or rigid vinyl and designed for ease of installation and long-term performance. This guide outlines key logistics and compliance considerations for handling, transporting, storing, and using Sheetrock J Bead in construction projects.

Packaging & Handling

Sheetrock J Bead is commonly packaged in bundled strips or boxed units to prevent deformation and damage during transit.

– Handle bundles with care to avoid bending or crushing.

– Use appropriate lifting equipment (e.g., forklifts or dollies) when moving large quantities.

– Avoid dragging packages across surfaces to prevent abrasion or coating damage.

– Keep material off the ground during handling and storage to prevent moisture absorption and contamination.

Transportation Requirements

Ensure proper transportation to maintain product integrity:

– Secure loads on trucks using straps or bracing to prevent shifting.

– Protect from exposure to rain, snow, or excessive humidity during transit.

– Store in closed, weatherproof vehicles whenever possible.

– Avoid extreme temperatures that may affect material properties (particularly for vinyl variants).

Storage Conditions

Proper storage is critical to maintain compliance and performance:

– Store in a dry, well-ventilated indoor area away from direct moisture.

– Keep packaging intact until ready for use to prevent rust (for metal beads) or warping.

– Stack bundles flat and avoid excessive height to prevent crushing.

– Maintain storage temperature between 40°F and 100°F (4°C to 38°C) for optimal condition.

Regulatory Compliance

Sheetrock J Bead products are subject to industry and regional standards:

– Complies with ASTM C840 – Standard Specification for Application and Finishing of Gypsum Board.

– Meets ASTM A653/A653M for galvanized steel components (if applicable).

– Conforms to ICC-ES evaluation reports (e.g., ESR numbers) for code compliance in U.S. building projects.

– Follow local building codes regarding fire resistance, moisture barriers, and installation practices.

Environmental & Safety Considerations

- Metal J Beads may produce sharp edges; wear cut-resistant gloves during handling.

- Follow OSHA guidelines for safe material handling and fall protection during installation.

- Recyclable materials (e.g., galvanized steel) should be disposed of or recycled per local regulations.

- Product contains no asbestos or hazardous air pollutants (HAPs) in compliance with EPA standards.

Installation & Job Site Compliance

- Install per manufacturer’s instructions and framing specifications.

- Ensure proper fastening with approved drywall screws or nails at recommended intervals.

- Coordinate with other trades to avoid damage during subsequent construction phases.

- Inspect installed J Bead for alignment and damage prior to taping and finishing.

Documentation & Traceability

Maintain the following for audit and compliance purposes:

– Retain product data sheets (PDS), safety data sheets (SDS), and ICC-ES reports.

– Record batch/lot numbers for traceability in case of quality issues.

– Provide compliance documentation to general contractors or building inspectors upon request.

Conclusion

Proper logistics and compliance practices ensure that Sheetrock J Bead performs as intended and meets all structural, safety, and regulatory requirements. Adhering to these guidelines supports efficient installation, reduces waste, and contributes to overall project success. Always consult the latest manufacturer specifications and local codes before use.

In conclusion, sourcing sheetrock J-bead requires careful consideration of material quality, supplier reliability, cost-effectiveness, and project-specific requirements. Whether purchasing locally or online, it is essential to ensure compatibility with your drywall system and environmental conditions—especially in areas prone to moisture. Comparing options from reputable suppliers, verifying product specifications, and reading customer reviews can help ensure you obtain durable, code-compliant J-bead for clean, professional edge finishes. By prioritizing availability, consistency, and value, you can efficiently source the right J-bead to support a high-quality drywall installation.