The global market for drywall and sheetrock tools has experienced steady expansion, driven by growth in residential and commercial construction activities. According to Grand View Research, the global power tools market was valued at USD 36.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030—with tools for drywall installation representing a significant segment. Mordor Intelligence further highlights that rising demand for energy-efficient buildings and interior renovations is accelerating the adoption of specialized fastening and drilling solutions, including sheetrock-specific drill attachments.

As contractors and DIY professionals prioritize efficiency and precision, the need for high-performance attachments designed to streamline sheetrock installation has grown. These tools reduce labor time, minimize material damage, and improve consistency across installations. With both professional and consumer demand on the rise, manufacturers are investing in innovative designs and durable materials to gain a competitive edge. In this competitive landscape, seven key manufacturers have emerged as leaders in producing reliable, high-quality sheetrock drill attachments—combining engineering excellence with real-world performance.

Top 7 Sheetrock Drill Attachment Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

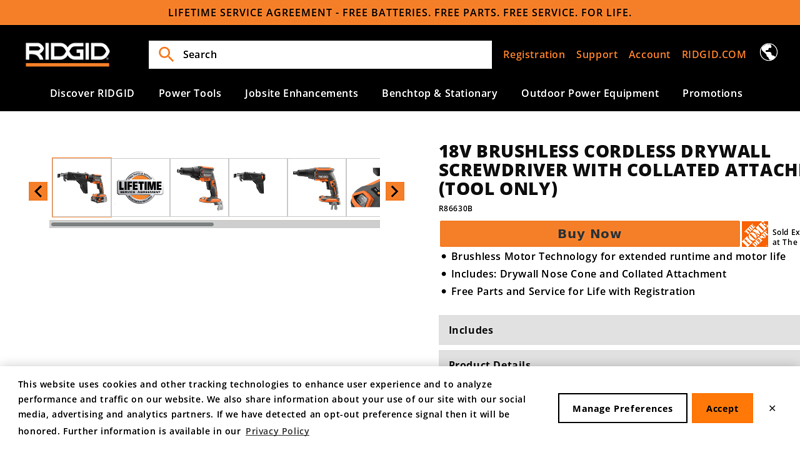

#1 18V Brushless Cordless Drywall Screwdriver with Collated …

Domain Est. 1995

Website: powertools.ridgid.com

Key Highlights: RIDGID introduces the 18V Brushless Cordless Drywall Screwdriver with Collated Attachment (Tool Only). This tool offers 2-in-1 functionality, both drywall …Missing: sheetrock ma…

#2 Drywall Screw Guns

Domain Est. 1998

Website: craftsman.com

Key Highlights: CRAFTSMAN® Drywall Screw Guns deliver efficiency and precision for drywall installation. Featuring high-torque motors, adjustable depth settings, …Missing: sheetrock manufacture…

#3 Screw Systems

Domain Est. 1993

Website: senco.com

Key Highlights: 30-day returnsScrew Systems ; By Job. Decking; Drywall ; POWER TYPE. Cordless; Corded ; MAX FASTENER LENGTH. 2″; 3″….

#4 Quik Drive® Systems and Attachments

Domain Est. 1995

Website: strongtie.com

Key Highlights: The Quik Drive Project Pro screw driving tool makes it easy to drive screws up to four times faster using almost any cordless drill or driver motor. Quik Drive® ……

#5 Accessories for drill drivers and screwdrivers

Domain Est. 1995

Website: hilti.com

Key Highlights: $31 delivery 28-day returnsFind chucks, belt hooks, gauge checks, and other accessories for your drill drivers and screwdrivers….

#6 Malco Tools

Domain Est. 1996

Website: malcotools.com

Key Highlights: The TSPC1 is your go-to drill attachment for fast, precise cuts on ribbed metal and vinyl panels. Built for pros who demand clean results and rugged ……

#7 Festool Cordless construction screwdriver DWC 18

Domain Est. 1999

Website: festool.com

Key Highlights: Specialised in drywall construction in every detail. The compact design and the balanced centre of gravity ensure optimum weight distribution – even ……

Expert Sourcing Insights for Sheetrock Drill Attachment

H2: Projected 2026 Market Trends for Sheetrock Drill Attachments

The market for sheetrock drill attachments is expected to experience steady growth and notable innovation by 2026, driven by advancements in power tool technology, rising demand in residential and commercial construction, and increasing emphasis on labor efficiency. As a niche but essential component within the broader power tool accessories market, sheetrock drill attachments—designed to simplify drywall installation by pre-drilling pilot holes for screws—are seeing increased adoption among professional contractors and DIY enthusiasts alike.

One significant trend shaping the 2026 outlook is the integration of smart technology and ergonomic design. Manufacturers are focusing on lightweight, battery-compatible attachments that seamlessly interface with cordless drills, enhancing portability and reducing user fatigue. These improvements align with the broader industry shift toward cordless, energy-efficient tools, particularly as lithium-ion battery technology continues to improve in power and longevity.

Another key driver is the expansion of the global construction sector, especially in North America and parts of Asia-Pacific. With housing starts and renovation projects on the rise post-pandemic, demand for time-saving tools like sheetrock drill attachments is expected to grow. Contractors are increasingly prioritizing tools that reduce on-site labor time and minimize material waste, both of which this attachment facilitates.

Additionally, sustainability and material innovation are emerging trends. By 2026, manufacturers may introduce eco-friendly materials in attachment housings and explore recyclable components as part of broader corporate sustainability initiatives. The push for greener construction practices is likely to influence product development across the tool accessory sector.

Finally, e-commerce growth and direct-to-consumer marketing strategies will play a crucial role in market penetration. Online platforms enable easier access to specialized tools, allowing smaller brands to compete with industry giants and reach a wider audience of tradespeople and homeowners.

In summary, the 2026 market for sheetrock drill attachments will be characterized by technological integration, efficiency-focused design, construction industry growth, and digital market expansion—making it a promising segment within the power tool ecosystem.

Common Pitfalls When Sourcing a Sheetrock Drill Attachment (Quality and Intellectual Property)

Logistics & Compliance Guide for Sheetrock Drill Attachment

This guide outlines essential logistics and compliance considerations for the distribution, handling, and use of the Sheetrock Drill Attachment. Adherence ensures safety, regulatory compliance, and efficient supply chain operations.

Product Classification & Documentation

Ensure accurate product classification for shipping and customs:

– HS Code (Harmonized System): 8207.50 (Interchangeable tools for hand tools, of which the working part is of steel; drilling, milling, threading or tapping tools). Verify with local customs authorities as classifications may vary.

– Product Specifications: Maintain up-to-date technical data sheets including dimensions, weight, materials (e.g., hardened steel, coated tips), and compatibility (e.g., fits standard ⅜” or ½” chucks).

– User Manual & Safety Instructions: Include multilingual user guides with assembly, operation, maintenance, and safety warnings in all target markets.

Packaging & Labeling Requirements

Proper packaging protects the product and ensures regulatory compliance:

– Primary Packaging: Use durable blister packs or clamshells with tamper-evident seals. Include UPC/EAN barcodes for retail scanning.

– Secondary Packaging: Ship in corrugated master cartons with internal dividers to prevent movement. Label cartons with:

– Product name and model number

– Quantity per box

– Net weight and gross weight

– Handling symbols (e.g., “Fragile,” “Do Not Stack,” “Keep Dry”)

– Manufacturer and distributor information

– Compliance Labels: Clearly display required regional markings:

– CE Marking (European Economic Area): Indicates conformity with health, safety, and environmental protection standards.

– UKCA Marking (United Kingdom): Required for products placed on the UK market.

– FCC/IC ID (if applicable): Not typically required for passive attachments, but confirm if integrated electronics are present.

– RoHS Compliance: Confirm absence of restricted substances (lead, cadmium, mercury, etc.) for EU and other regulated markets.

Shipping & Transportation

Optimize logistics for cost efficiency and product integrity:

– Weight & Dimensions: Record exact unit and master carton measurements for freight classification (e.g., LTL, parcel). Example: 0.3 lbs per unit, 12 units per carton, carton size: 10” x 8” x 3”.

– Carrier Requirements: Comply with carrier-specific packaging guidelines (e.g., UPS, FedEx, DHL). Use UN-certified packaging if shipping hazardous materials (not applicable unless lubricants or coatings are regulated).

– Storage Conditions: Store in dry, temperature-controlled environments (10°C to 30°C). Avoid exposure to moisture to prevent corrosion.

– Shelf Life: No expiration, but inspect for rust or damage after long storage.

Regulatory & Safety Compliance

Ensure the product meets all applicable safety and environmental regulations:

– OSHA/ANSI (USA): While the attachment itself is not power-driven, ensure compatibility with OSHA-compliant power tools. Provide safety warnings for end-users (e.g., wear eye protection, secure workpiece).

– REACH (EU): Confirm no Substances of Very High Concern (SVHC) above threshold in materials.

– Proposition 65 (California): Assess if any components (e.g., metal alloys, coatings) contain listed chemicals. If so, include appropriate warning labels.

– WEEE Compliance (EU): Although not electronic, classify correctly under WEEE categories. Provide take-back information if required by distributor agreements.

Import/Export Considerations

Facilitate cross-border trade with proper documentation:

– Commercial Invoice & Packing List: Required for all international shipments. Include detailed product description, value, origin (country of manufacture), and Incoterms (e.g., FOB, DDP).

– Certificate of Origin: May be required for preferential tariff treatment under trade agreements.

– Import Duties & Taxes: Calculate based on HS code and destination country. Use duty calculators or customs brokers for accuracy.

– Restricted Markets: Verify no import bans or special permits needed (e.g., Russia, certain Middle Eastern countries may have tool restrictions).

End-of-Life & Sustainability

Promote responsible disposal and environmental stewardship:

– Recyclability: Constructed primarily of steel; label as recyclable where possible.

– Disposal Instructions: Advise users to dispose of at end of life via metal recycling programs.

– Sustainable Sourcing: Use materials from audited suppliers with environmental and labor compliance (e.g., ISO 14001).

Compliance Monitoring & Audits

Maintain ongoing compliance through:

– Supplier Audits: Regularly assess manufacturing partners for quality and regulatory adherence.

– Documentation Archive: Retain test reports, certifications, and compliance records for minimum of 10 years.

– Regulatory Updates: Monitor changes in product safety laws (e.g., EU Machinery Regulation, U.S. CPSC guidelines) and update documentation accordingly.

By following this guide, stakeholders ensure safe, legal, and efficient handling of the Sheetrock Drill Attachment across the global supply chain.

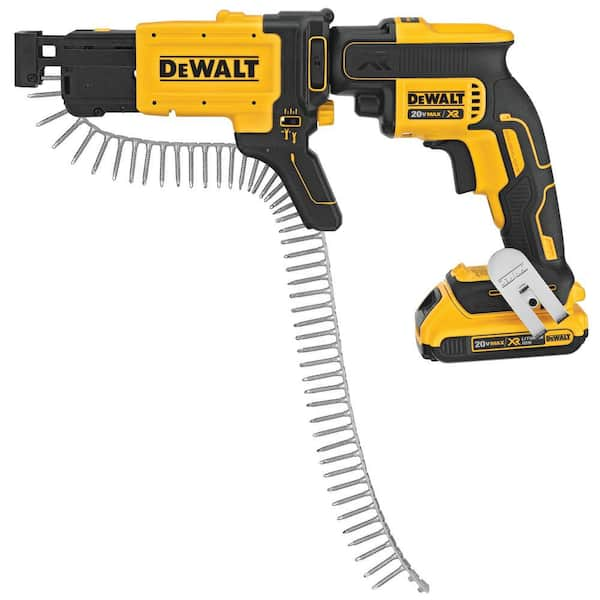

After evaluating various options for sourcing a sheetrock drill attachment, it is clear that selecting the right supplier involves balancing cost, quality, availability, and compatibility with existing tools. Key factors such as durability, ease of use, and customer reviews indicate that reputable brands like Milwaukee, DeWalt, and Bosch offer reliable and efficient attachments designed specifically for precision work in drywall applications. Sourcing from authorized distributors or trusted online retailers ensures authenticity and access to warranties or customer support. In conclusion, investing in a high-quality sheetrock drill attachment from a reputable supplier not only enhances productivity and accuracy but also reduces long-term maintenance and replacement costs, making it a worthwhile addition for professionals and DIY enthusiasts alike.