The global drywall tools and accessories market, driven by rising residential and non-residential construction activity, is projected to grow at a CAGR of 5.8% from 2023 to 2028, according to Mordor Intelligence. As demand for efficient, precision-based installation solutions increases, the need for high-performance sheet rock cutters has become critical for contractors and DIY professionals alike. With accuracy, durability, and ease of use ranking among the top purchasing criteria, manufacturers are innovating rapidly to capture market share. In this competitive landscape, nine standout companies have emerged as leaders in sheet rock cutter design, manufacturing, and distribution—combining engineering excellence with field-tested reliability. Drawing on market analysis and product performance data, here are the top nine sheet rock cutter manufacturers shaping the future of drywall installation.

Top 9 Sheet Rock Cutter Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Warner Tool

Domain Est. 1996

Website: warnertool.com

Key Highlights: America’s leading brand of Paint and Drywall Tools for the Professional … Warner Manufacturing Company 13435 Industrial Park Blvd. Plymouth, MN 55441….

#2 Hyde Tools

Domain Est. 1996

Website: hydetools.com

Key Highlights: Free delivery over $50For a Better Finish, Start with Hyde. ; Free Shipping. When you spend $50+ ; Give Us A Call. +1 (800) 872-4933. 8am-4pm ET. Monday-Friday ; Chat With Us. 8am-…

#3 Drywall Solutions

Domain Est. 1996

Website: boschtools.com

Key Highlights: Ergonomic 18V screwgun design – gets drywall jobs done comfortably and fast, while cutting the cord · Well-balanced grip – ideal for comfortably holding the tool ……

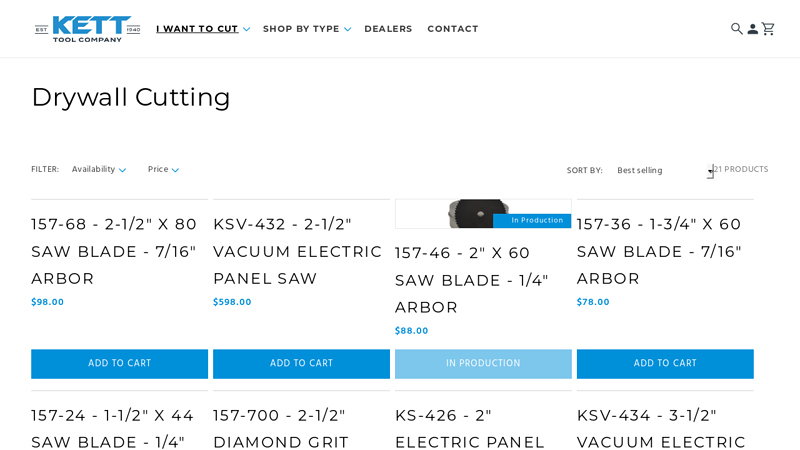

#4 Drywall Cutting

Domain Est. 1998

Website: kett-tool.com

Key Highlights: 12-day delivery 60-day returnsCollection: Drywall Cutting. 157-68 – 2-1/2″ x 80 Saw Blade – 7/16″ Arbor. 157-68 – 2-1/2″ x 80 Saw Blade – 7/16″…

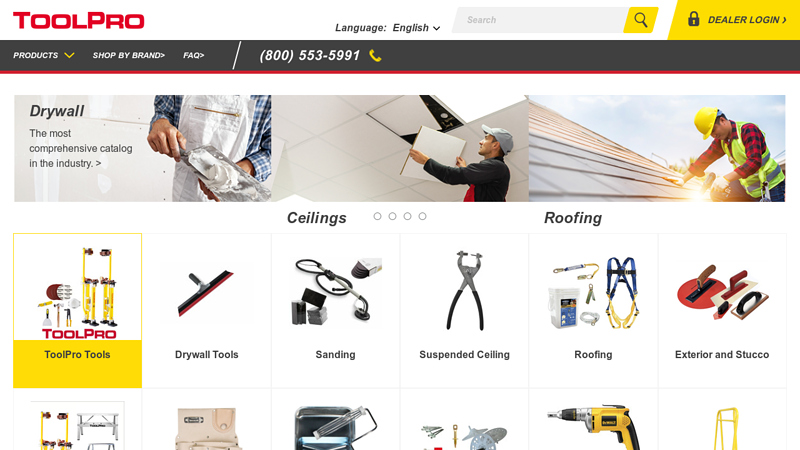

#5 ToolPro

Domain Est. 1998

Website: toolpro.com

Key Highlights: High Quality Tools for Drywall, EIFS/Stucco, Auto Taping, Acoustical, and Jobsite Including Stilts, Power Tools & More! Competitively Priced and Built to ……

#6 Tools for Paint and Drywall

Domain Est. 2004

Website: festoolusa.com

Key Highlights: Festool provides the right tools and high-quality abrasives for efficient surface preparation. Pair them with dust extractors to minimize cleanup….

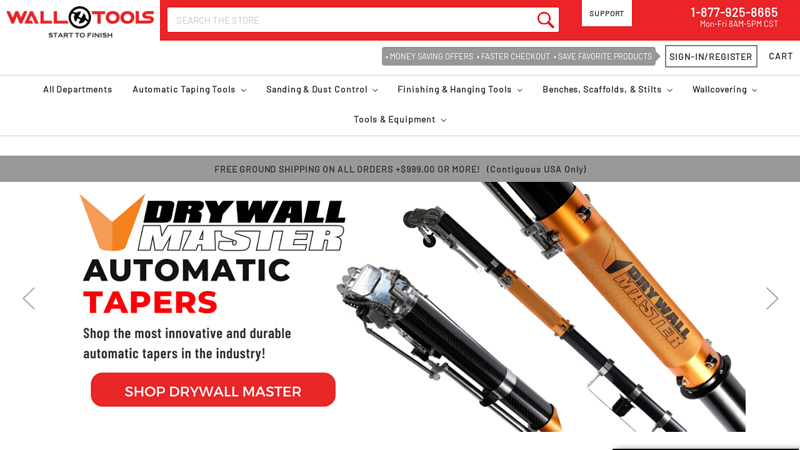

#7 Drywall Tools Store

Domain Est. 2009

#8 Adjustable Can Light Hole Saw 13 Sizes

Domain Est. 2012

Website: idealind.com

Key Highlights: 30-day returnsThe IDEAL® Adjustable Can Light Hole Saw is a versatile tool designed for cutting precise holes in drywall and ceiling tiles for can lights….

#9 Drywall Saws & Cutting Tools

Domain Est. 1996

Website: doitbest.com

Key Highlights: 2-day deliveryExplore a wide selection of premium Drywall Saws & Cutting Tools at Do it Best, including Drywall Jab Saw, Drywall Circle Cutter, Drywall Saw….

Expert Sourcing Insights for Sheet Rock Cutter

2026 Market Trends for Sheet Rock Cutter: Industry Outlook and Growth Drivers

The sheet rock cutter market is poised for significant transformation by 2026, shaped by evolving construction practices, technological innovation, and growing emphasis on efficiency and sustainability. As demand for drywall installation continues to rise globally—fueled by residential, commercial, and renovation projects—tools like sheet rock cutters are becoming increasingly critical to productivity on job sites. This analysis explores the key trends expected to define the sheet rock cutter landscape in 2026.

Rising Demand in Construction and Renovation Sectors

A primary driver for the sheet rock cutter market is the sustained growth in global construction activities. Urbanization, population growth, and housing shortages—particularly in emerging economies—are accelerating new building projects. Simultaneously, aging infrastructure in developed regions is spurring renovation and retrofitting work. Both sectors require efficient drywall installation, increasing reliance on precision cutting tools. By 2026, the demand for faster, cleaner, and more accurate cutting solutions will push contractors toward advanced sheet rock cutters that reduce labor time and material waste.

Technological Advancements and Smart Tool Integration

By 2026, the integration of smart technology into hand and power tools is expected to reshape the sheet rock cutter market. Manufacturers are increasingly incorporating features such as laser-guided alignment, digital depth adjustment, and ergonomic designs with vibration reduction. Battery-powered and cordless cutters are gaining traction due to improved lithium-ion battery life and portability, allowing for greater mobility on job sites. Additionally, IoT-enabled tools that track usage, maintenance needs, and performance analytics may begin to enter the professional market, offering contractors data-driven insights to optimize workflow.

Shift Toward Ergonomic and Labor-Saving Designs

Labor shortages in the construction industry are driving demand for tools that enhance worker efficiency and reduce physical strain. In 2026, sheet rock cutters with improved ergonomics—such as lightweight materials, balanced weight distribution, and one-handed operation—will be highly valued. Tools designed to minimize repetitive motion injuries and fatigue will gain preference among contractors focused on worker safety and long-term productivity. This trend supports the adoption of motorized cutters over traditional manual knives, especially for large-scale projects.

Sustainability and Waste Reduction Initiatives

Environmental concerns and green building standards are influencing tool selection. Precision cutters that minimize drywall waste align with sustainability goals and cost-efficiency objectives. In 2026, manufacturers are expected to emphasize tools that enable accurate first-time cuts, reducing material overuse and disposal. Additionally, recyclable or long-lasting cutter blades and components will appeal to eco-conscious contractors and firms adhering to LEED or other green certifications.

Expansion of E-Commerce and Direct-to-Professional Sales

The distribution model for sheet rock cutters is evolving rapidly. Online platforms and e-commerce marketplaces are becoming dominant channels for purchasing construction tools, especially among younger, tech-savvy contractors. By 2026, brands that invest in digital marketing, virtual product demonstrations, and direct sales through online platforms will likely capture greater market share. Subscription services for tool maintenance or blade replacement could also emerge as a competitive advantage.

Regional Market Dynamics

North America and Europe will remain key markets due to high construction activity and early adoption of advanced tools. However, the Asia-Pacific region—especially countries like India, China, and Southeast Asian nations—is expected to witness the highest growth rate. Rapid urban development, government housing programs, and expanding middle-class demand are creating new opportunities for sheet rock cutter manufacturers. Localization of product design and pricing will be critical to success in these diverse markets.

In conclusion, the 2026 sheet rock cutter market will be defined by innovation, efficiency, and adaptability. As construction demands grow and labor resources tighten, tools that deliver speed, precision, and user comfort will dominate. Companies that anticipate these trends—investing in R&D, sustainability, and digital engagement—will be best positioned to lead in the evolving global marketplace.

Common Pitfalls When Sourcing a Sheet Rock Cutter (Quality, IP)

Sourcing a sheet rock cutter—especially one involving proprietary technology or intellectual property (IP)—can present several challenges. Overlooking these pitfalls can lead to subpar product quality, legal risks, or supply chain disruptions. Below are key issues to watch for:

Poor Manufacturing Quality

One of the most frequent issues is receiving sheet rock cutters that fail to meet performance or durability standards. Low-quality materials, imprecise machining, or inadequate assembly can result in tools that jam, wear out quickly, or deliver inconsistent cuts. This is especially common when sourcing from suppliers with lax quality control processes or limited experience in tool manufacturing.

Lack of Intellectual Property Protection

When sourcing a specialized or innovative cutter design, there’s a significant risk of IP infringement or misappropriation. Suppliers may copy or reverse-engineer designs, especially in regions with weak IP enforcement. Failure to secure patents, trademarks, or design rights—and to include strong IP clauses in supplier contracts—can leave your company vulnerable to counterfeit products or legal disputes.

Inadequate Supplier Vetting

Choosing a supplier based solely on cost or lead time without verifying their certifications, production capacity, or track record can lead to problems. Unqualified suppliers might lack the technical expertise to produce precision cutters or the infrastructure to scale production reliably. Conducting thorough due diligence, including on-site audits and sample testing, is critical.

Inconsistent Product Specifications

Even with detailed technical drawings, discrepancies can arise between the prototype and mass-produced units. Variations in blade hardness, cutting depth, or ergonomic design can affect usability and safety. Without clear specifications and robust quality assurance protocols, such inconsistencies undermine product reliability.

Hidden Costs and Lack of Transparency

Initial quotes may not include tooling fees, minimum order quantities (MOQs), or shipping costs, leading to unexpected expenses. Additionally, some suppliers may use lower-grade materials than agreed upon to cut costs, compromising quality without notice. Transparent contracts and regular communication are essential to avoid these issues.

Supply Chain and Lead Time Risks

Reliance on a single supplier, particularly in distant regions, introduces risks related to logistics delays, customs issues, or geopolitical instability. Unpredictable lead times can disrupt product launches or inventory planning. Diversifying suppliers and maintaining buffer stock can mitigate these risks.

Non-Compliance with Safety and Regulatory Standards

Sheet rock cutters must meet relevant safety standards (e.g., CE, UL, or ANSI). Sourcing from suppliers unfamiliar with these regulations can result in non-compliant products that cannot be sold in target markets. Ensuring compliance during the design and manufacturing phases is crucial.

By addressing these pitfalls proactively—through rigorous supplier evaluation, strong IP protections, and clear quality agreements—companies can source reliable, legally sound sheet rock cutters that meet market demands.

Logistics & Compliance Guide for Sheet Rock Cutter

Product Classification and Regulations

Sheet rock cutters, whether manual or powered, are typically classified under industrial tools or construction equipment. Depending on the model, they may fall under machinery directives (e.g., EU Machinery Directive 2006/42/EC) or general product safety regulations. Ensure compliance with relevant standards such as EN 62841 for powered hand tools or ANSI B11.19 in North America for safety of machinery.

Packaging and Handling

Use robust, corrugated packaging with internal foam or molded inserts to prevent movement during transit. Clearly label packages with “Fragile,” “This Side Up,” and “Protect from Moisture” indicators. For powered models, remove batteries or secure them per IATA/IMDG regulations if shipping internationally. Sharp blades must be securely sheathed or encapsulated to prevent injury during handling.

Transportation Requirements

Ground and air shipments must comply with carrier-specific policies for tools containing motors, batteries, or sharp components. Lithium-ion batteries (if applicable) must meet UN38.3 testing requirements and be shipped at ≤30% charge. Declare the product accurately on shipping manifests using proper Harmonized System (HS) codes—typically 8205.40 for hand tools or 8467.21 for power tools.

Import and Export Compliance

Verify country-specific import regulations. In the U.S., comply with OSHA and CPSC standards; in the EU, ensure CE marking with Declaration of Conformity. Non-EU countries may require certificates of conformity (e.g., SONCAP for Nigeria, PVoC for Kenya). Include safety data sheets (SDS) if components contain regulated substances (e.g., lubricants).

Customs Documentation

Prepare complete documentation, including commercial invoice, packing list, bill of lading/air waybill, and certificates of origin. For regulated markets, include test reports, conformity certificates, and user manuals in the local language. Accurate HS code classification (e.g., 8205.40.30 for manual drywall cutters) ensures correct duty assessment and avoids delays.

Safety and Labeling

Products must display required safety markings—CE, UKCA, or FCC for electronic components. User manuals must include multilingual safety instructions, proper usage guidelines, and maintenance procedures. Comply with REACH (EU) and RoHS directives regarding restricted substances in materials.

Storage and Warehouse Management

Store in a dry, temperature-controlled environment to prevent corrosion or damage to electrical components. Maintain separation between sharp tools and other inventory to reduce risk. Implement FIFO (First In, First Out) stock rotation, especially for models with replaceable blades or consumables.

End-of-Life and Environmental Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) directives in applicable regions for powered models. Provide take-back or recycling options where required. For manual tools, ensure packaging is recyclable and minimize single-use plastics.

Audit and Record-Keeping

Maintain records of compliance testing, certifications, shipping documentation, and customer safety communications for a minimum of five years. Conduct periodic internal audits to verify adherence to logistics and regulatory standards across the supply chain.

Conclusion for Sourcing a Sheet Rock Cutter

After evaluating various suppliers, models, and pricing options, sourcing a sheet rock cutter requires a balanced consideration of cost, durability, precision, and ease of use. Manual cutters offer affordability and portability for light to moderate tasks, while powered or automatic cutters provide increased efficiency and accuracy for large-scale or commercial projects. Key factors such as blade quality, adjustable depth settings, build material, and user ergonomics significantly impact performance and long-term value.

Based on the assessment, it is recommended to source sheet rock cutters from reputable manufacturers or suppliers that offer warranties, reliable customer support, and positive user reviews. Prioritizing tools with proven track records in similar applications will ensure consistent results, reduce material waste, and enhance overall job site productivity. Additionally, bulk purchasing or establishing long-term supplier relationships may yield cost savings without compromising quality.

In conclusion, the ideal sheet rock cutter for your needs depends on project scope and frequency of use, but investing in a high-quality, well-reviewed tool from a trusted source will deliver optimal performance, safety, and return on investment.