The global industrial fasteners market, driven by rising demand from construction, automotive, and manufacturing sectors, is projected to grow at a CAGR of 5.2% from 2023 to 2028, according to Mordor Intelligence. Within this expanding landscape, shank in bolts—valued for their enhanced load distribution and structural integrity—have become critical components in heavy-duty applications. With infrastructure investments accelerating worldwide and stringent safety standards elevating product expectations, the need for high-performance shank in bolt manufacturers has intensified. This growing demand has fostered innovation and competition among leading producers, positioning a select group of companies at the forefront of quality, precision, and scalability. Based on production capacity, global reach, product specifications, and compliance with international standards, the following eight manufacturers stand out as key players driving the shank in bolt segment forward.

Top 8 Shank In Bolt Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Threaded Fasteners, Inc.

Domain Est. 2003

Website: threadedfasteners.com

Key Highlights: Threaded Fastener Manufacturer and Distributor of pole line hardware, anchor cages, anchor bolts, A325 Structural Bolts, nuts, bolts, washers….

#2 American Bolt

Domain Est. 2003

Website: americanboltcorp.com

Key Highlights: American Bolt Corp is a high quality industrial fastener supplier for a variety of different industries. We provide top fastener solutions to meet any need!…

#3 High Tensile Bolts

Domain Est. 2010

Website: bigboltnut.com

Key Highlights: We specialise is manufacturing and exporting High tensile bolts & fasteners in 8.8, 10.9 and 12.9 grade and Stainless steel bolt in SS A4, A4-50, A4-70, SS 304, ……

#4 Oval Shank

Domain Est. 1995

Website: hubbell.com

Key Highlights: 30-day returnsDiscover our selection of Oval Shank products. Our product experts are here to assist you. Get in touch with our team now….

#5 Fastener Finder

Domain Est. 1995

Website: strongtie.com

Key Highlights: Quickly search our wide array of fasteners to find exactly what you need. Search by multiple criteria, such as application, type and model number….

#6

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: We then power extrude the front end to achieve the reduction and hardness in the shank resulting in a bolt with even strength and hardness from end to end….

#7 Bolt Industry Archives

Domain Est. 1998

Website: portlandbolt.com

Key Highlights: Unthreaded Shank. What do you call the unthreaded shank of a bolt? The unthreaded portion of a headed bolt is called the grip. The length of all headed bolts ……

#8 Custom Manufactured Bolts

Domain Est. 2001

Website: masterbolt.com

Key Highlights: We specialize in manufacturing custom bolts, especially in regard to length. Most other bolt manufactures cannot produce custom products….

Expert Sourcing Insights for Shank In Bolt

H2: 2026 Market Trends Outlook for Shank in Bolt Industry

The global shank in bolt market is poised for steady growth and transformation by 2026, driven by advancements in manufacturing technologies, rising infrastructure investment, and increasing demand from key end-use sectors such as construction, automotive, and renewable energy. A comprehensive analysis of market dynamics reveals several defining trends expected to shape the industry landscape over the next few years.

-

Rising Demand from Construction and Infrastructure

With governments worldwide prioritizing infrastructure development—especially in emerging economies—the demand for high-strength, durable fasteners like shank-in bolts is increasing. Projects related to bridges, highways, and commercial buildings require reliable anchoring solutions, positioning shank-in bolts as essential components. The trend toward sustainable and resilient infrastructure will further boost demand for corrosion-resistant and high-performance bolt variants. -

Growth in Renewable Energy Projects

The expansion of wind and solar energy installations is a critical driver for the shank-in bolt market. Wind turbine towers, in particular, utilize large-diameter shank-in bolts for structural stability and safety. As countries accelerate their transition to clean energy, the need for specialized bolts capable of withstanding dynamic loads and harsh environmental conditions is expected to surge by 2026. -

Advancements in Material Science and Coatings

Manufacturers are increasingly investing in advanced materials such as high-tensile steel, alloy steel, and stainless steel, along with innovative anti-corrosion coatings. These improvements enhance bolt durability and performance, especially in challenging environments like offshore platforms or coastal construction sites. The integration of smart coatings and surface treatments is anticipated to become a competitive differentiator in the market. -

Automation and Precision Manufacturing

The adoption of automated production lines and digital quality control systems is improving consistency and efficiency in shank-in bolt manufacturing. CNC machining, robotic assembly, and real-time monitoring allow for tighter tolerances and customized bolt designs. This shift supports industries requiring precision-engineered fasteners, such as aerospace and high-end automotive manufacturing. -

Regional Market Shifts

Asia-Pacific, led by China, India, and Southeast Asia, is expected to remain the largest market for shank-in bolts due to rapid urbanization and industrial growth. Meanwhile, North America and Europe will see steady demand driven by infrastructure modernization and strict regulatory standards for structural safety. Emerging markets in Latin America and Africa are also projected to contribute to growth, albeit at a slower pace. -

Sustainability and Regulatory Compliance

Environmental regulations and sustainability goals are influencing material sourcing and production processes. Manufacturers are focusing on reducing carbon footprints through energy-efficient manufacturing and recyclable materials. Compliance with international standards (e.g., ISO, ASTM, DIN) is becoming mandatory, especially for export-oriented producers. -

Supply Chain Resilience

Post-pandemic supply chain challenges have prompted companies to reevaluate sourcing strategies. Regionalization of supply chains and inventory diversification are becoming common practices to mitigate disruptions. This trend is likely to encourage localized production hubs, enhancing responsiveness and reducing lead times.

In conclusion, the 2026 outlook for the shank-in bolt market reflects a convergence of technological innovation, sector-specific demand, and global sustainability initiatives. Companies that invest in R&D, adopt smart manufacturing, and align with regulatory and environmental standards are expected to gain a competitive edge in this evolving market.

Common Pitfalls When Sourcing Shank in Bolt (Quality and Intellectual Property)

Sourcing Shank in Bolts—particularly high-precision or engineered fasteners used in critical applications—exposes buyers to several quality and intellectual property (IP) risks. Overlooking these pitfalls can lead to compromised structural integrity, project delays, legal liabilities, and reputational damage. Below are key concerns to watch for:

Quality-Related Pitfalls

Inconsistent Material Composition

Suppliers may use substandard or non-compliant materials to cut costs, leading to bolts that fail under stress or in corrosive environments. Without proper material certifications (e.g., mill test reports, MTRs), verifying compliance with required standards (such as ASTM, ISO, or DIN) becomes challenging.

Poor Dimensional Accuracy and Tolerances

Shank in Bolts often require tight tolerances for fit and performance. Inconsistent machining, especially from low-cost manufacturers, can result in bolts that do not meet blueprint specifications, causing assembly issues or premature fatigue failure.

Inadequate Heat Treatment and Hardness

Improper or undocumented heat treatment affects strength and durability. Bolts may appear visually sound but fail under load due to insufficient hardness or incorrect tempering processes.

Lack of Traceability and Certification

Reputable suppliers provide full traceability (e.g., heat number tracking, batch records). Sourcing from vendors without proper documentation raises red flags about quality control and makes it difficult to conduct root-cause analysis in the event of a failure.

Insufficient Testing and Inspection

Some suppliers skip essential mechanical and non-destructive testing (e.g., tensile strength, hardness checks, ultrasonic testing). Relying on visual inspections alone is inadequate for critical applications.

Intellectual Property (IP) Pitfalls

Unauthorized Manufacturing or Counterfeiting

Some suppliers may produce bolts that replicate patented designs, trademarks, or proprietary geometries without licensing. Purchasing such items—even unknowingly—can expose the buyer to legal risks, including contributory infringement claims.

Misrepresentation of Brand or Certification

Suppliers may falsely claim compliance with industry standards or falsely represent their products as OEM equivalents. This mislabeling can violate trademark laws and undermine quality assurance.

Lack of IP Due Diligence from Suppliers

Many low-cost manufacturers do not conduct IP audits or respect design patents. If the Shank in Bolt design includes protected features (e.g., thread profile, underhead geometry), sourcing from such suppliers increases the risk of IP violations.

Grey Market and Diversion Risks

Purchasing from unauthorized distributors or third-party marketplaces increases the chance of acquiring counterfeit or diverted goods. These products may not adhere to the original IP holder’s quality standards or licensing agreements.

Mitigation Strategies

- Require full documentation: Insist on material certifications, test reports, and traceability records.

- Audit suppliers: Conduct on-site quality audits or use third-party inspection services.

- Verify IP compliance: Work with legal counsel to confirm that sourced parts do not infringe on patents or trademarks.

- Source from authorized channels: Prefer direct suppliers or authorized distributors, especially for branded or patented fasteners.

- Use clear specifications: Define exact requirements, including standards, materials, and tolerances, in procurement contracts.

By proactively addressing these pitfalls, organizations can ensure both the mechanical reliability and legal safety of the Shank in Bolts they source.

Logistics & Compliance Guide for Shank In Bolt

This guide outlines the essential logistics and compliance considerations for the procurement, handling, transportation, and use of Shank In Bolts (also known as Shoulder Bolts or Shoulder Screws). Proper management ensures safety, regulatory adherence, and operational efficiency across supply chains.

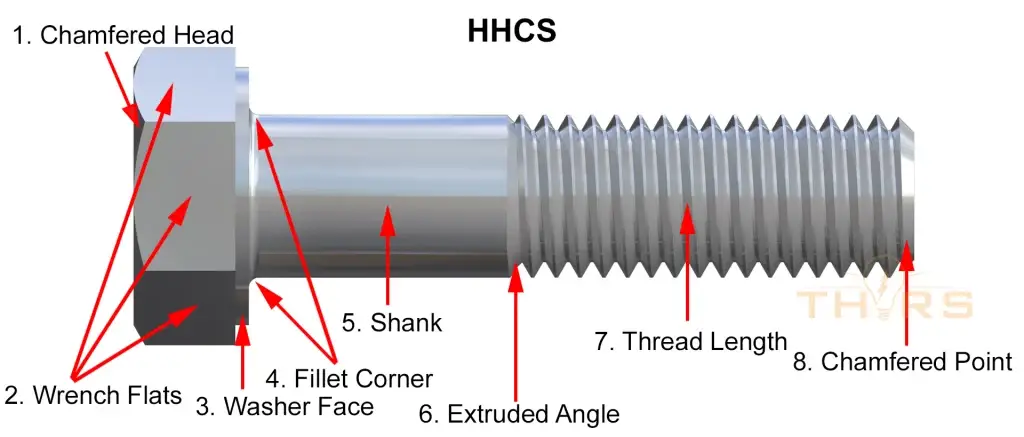

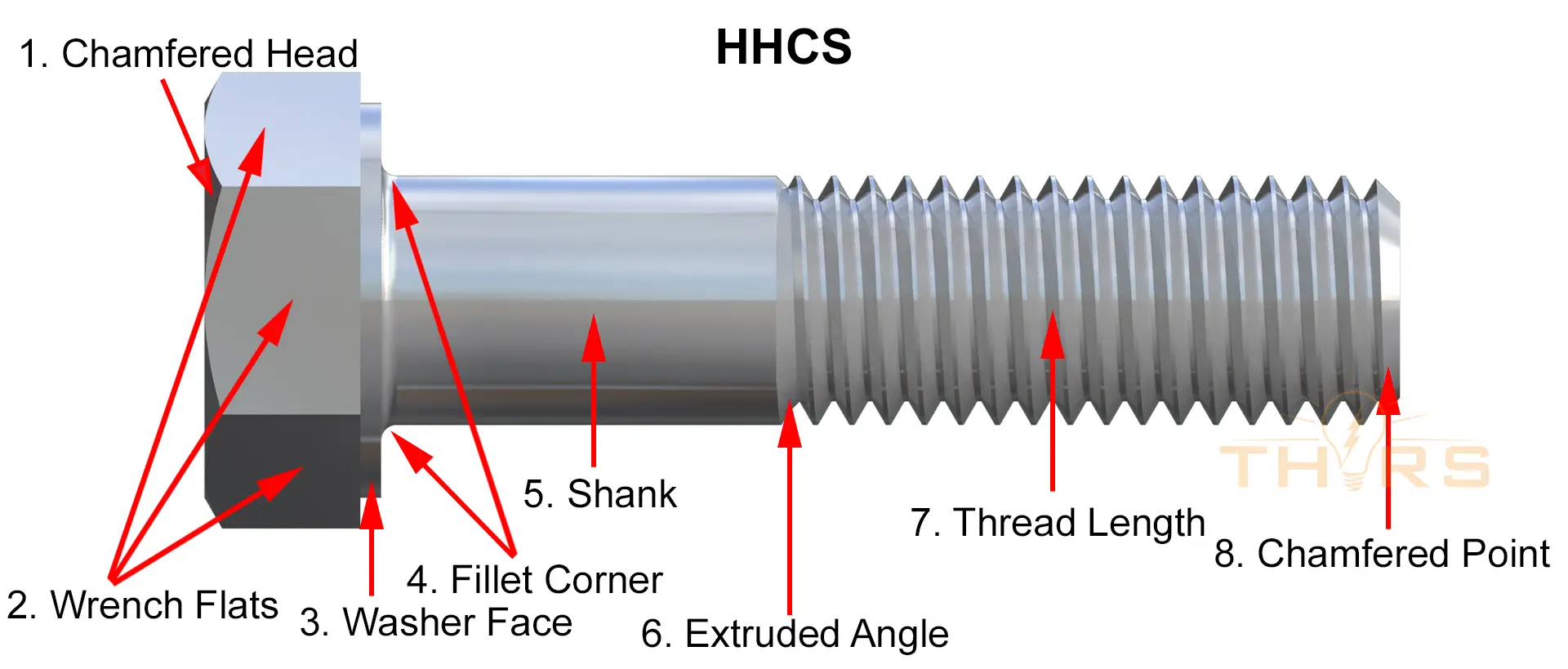

Product Overview and Specifications

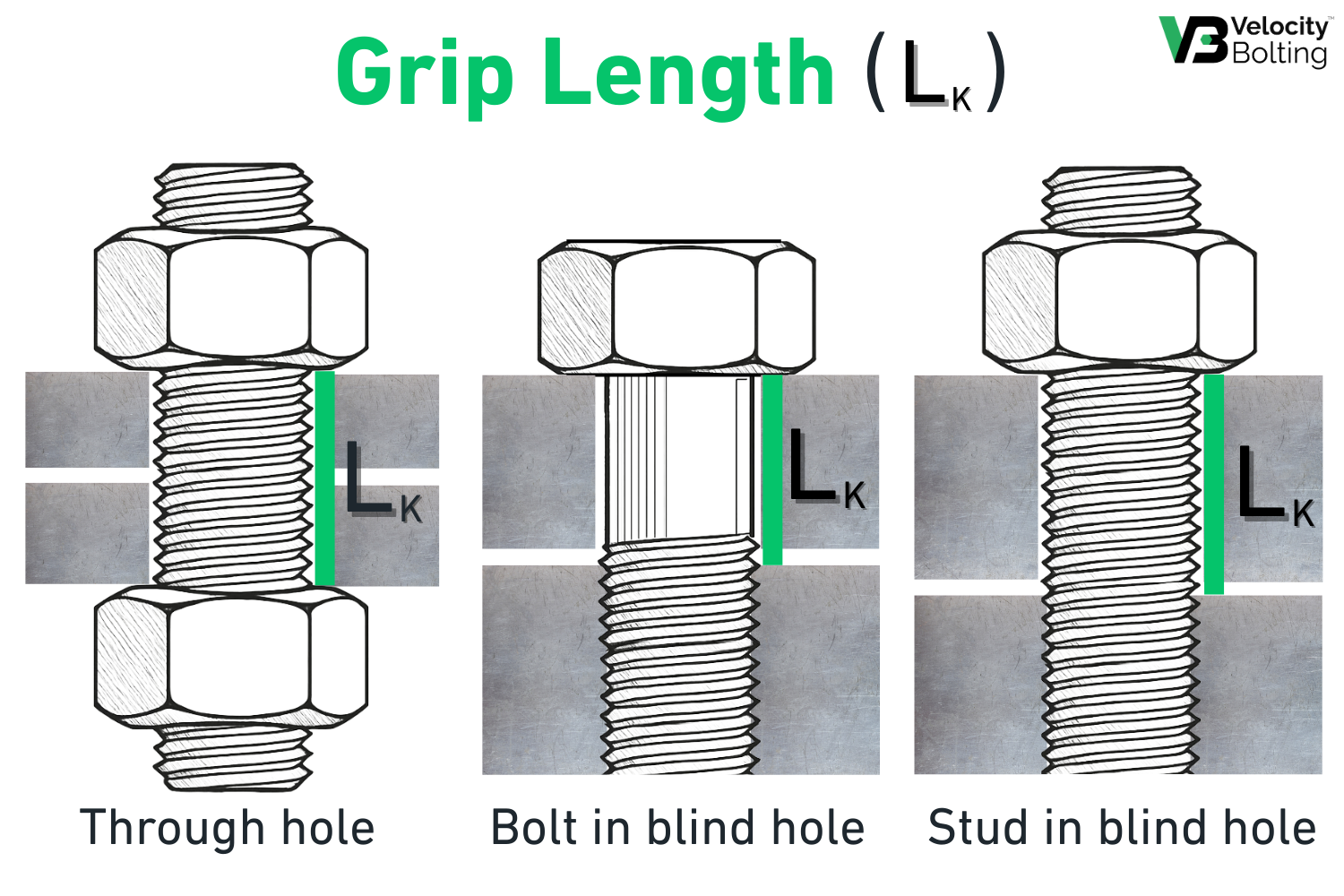

Shank In Bolts are fasteners featuring a smooth, cylindrical shank (shoulder) beneath the head, followed by a threaded end. They are commonly used in precision machinery, pivots, control linkages, and applications requiring precise alignment or low-friction rotation. Key specifications include:

– Shank diameter and length

– Thread size and length

– Overall length

– Material (e.g., alloy steel, stainless steel, brass)

– Finish or coating (e.g., zinc plating, black oxide)

– Compliance with standards such as ASME B18.8.2, ISO 7379, or DIN 1494

Ensure all supplied bolts meet project-specific engineering drawings and material certifications.

Regulatory and Safety Compliance

Shank In Bolts must comply with relevant international, national, and industry-specific regulations:

– Material Restrictions: Adhere to RoHS (Restriction of Hazardous Substances), REACH, and conflict minerals regulations, especially for exports to the EU or use in electronics.

– Quality Standards: Confirm alignment with ISO 9001 (quality management) and ISO 14001 (environmental management) where applicable.

– Safety Standards: Ensure fasteners meet mechanical performance standards (e.g., tensile strength, hardness) per ASTM or ISO specifications.

– Certifications: Request mill test reports (MTRs), Certificates of Conformance (CoC), and traceability documentation from suppliers.

Non-compliant fasteners may lead to structural failure, legal liability, or import/export denials.

Packaging and Labeling Requirements

Proper packaging protects Shank In Bolts during transit and ensures traceability:

– Use moisture-resistant, anti-corrosive packaging (e.g., VCI paper, sealed plastic bags) for metal bolts.

– Label each package with:

– Part number and description

– Quantity

– Batch/lot number

– Material and finish

– Manufacturer or supplier name

– Date of manufacture

– Compliance markings (e.g., CE, RoHS)

– Include packing lists and commercial invoices for international shipments.

Storage and Handling Guidelines

To preserve performance and prevent damage:

– Store in a dry, temperature-controlled environment to avoid corrosion.

– Keep away from direct sunlight, chemicals, and moisture.

– Use original packaging until ready for use.

– Handle with clean tools; avoid scratching or deforming the shank, which is critical for fit and function.

– Implement FIFO (First In, First Out) inventory rotation.

Transportation and Shipping Protocols

Ensure safe and compliant transit:

– Use secure, non-shifting packaging within shipping containers or pallets.

– Label shipments with handling instructions (e.g., “Fragile,” “Do Not Stack”).

– For international shipments, comply with:

– Incoterms (e.g., FOB, EXW, DDP)

– Customs documentation (commercial invoice, packing list, CoO)

– Import/export controls (e.g., ECCN classification if applicable)

– Monitor for customs delays due to material or origin concerns.

Supplier and Quality Assurance

Select suppliers with:

– Proven quality control systems and audit trails.

– Capability to provide full documentation (CoC, MTRs, test reports).

– Compliance with industry standards and ethical sourcing practices.

– Regular third-party audits (e.g., ISO certification).

Perform incoming inspections to verify dimensions, material, and finish against purchase specifications.

Environmental and Disposal Compliance

Address end-of-life considerations:

– Recycle metal bolts through certified scrap metal processors.

– Follow local regulations for disposal of coated or treated fasteners that may contain restricted substances.

– Maintain records of waste disposal to support environmental compliance reporting.

Documentation and Recordkeeping

Maintain detailed records for traceability and audits:

– Purchase orders and contracts

– Inspection reports

– Certificates of Conformance and Material Test Reports

– Shipping and customs documents

– Storage logs and inventory records

Retain documentation for a minimum of 7–10 years, depending on industry requirements (e.g., aerospace, automotive).

Conclusion

Adhering to this Logistics & Compliance Guide for Shank In Bolts ensures product integrity, regulatory compliance, and supply chain efficiency. Partner with qualified suppliers, implement rigorous quality checks, and maintain thorough documentation to mitigate risks and support long-term operational success.

Conclusion on Sourcing Shank in Bolts:

The sourcing of shank in bolts is a critical aspect of fastener selection and manufacturing, directly impacting the performance, reliability, and safety of mechanical and structural assemblies. The shank—the unthreaded portion of the bolt—plays a vital role in determining load distribution, shear strength, and alignment accuracy. When sourcing bolts with specific shank requirements, factors such as material grade, diameter, length, surface finish, and compliance with international standards (e.g., ISO, ASTM, DIN) must be carefully evaluated.

Proper sourcing ensures that the bolt’s shank can effectively withstand applied stresses, minimize stress concentrations, and maintain structural integrity under dynamic or cyclic loading. Additionally, choosing reputable suppliers and verifying quality certifications are essential to avoid defects and ensure consistency in high-performance applications.

In conclusion, sourcing bolts with the appropriate shank characteristics is not merely a procurement decision but a key engineering consideration. Attention to shank specifications enhances joint durability, safety, and overall system efficiency, making it a crucial step in the design and maintenance of reliable mechanical connections.