The global sewing machine market is undergoing a steady resurgence, driven by rising demand in both industrial textile manufacturing and the growing DIY home sewing segment. According to a report by Mordor Intelligence, the global sewing machine market was valued at approximately USD 28.5 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. A critical yet often overlooked component within this ecosystem is the sewing machine light bulb—a small but essential element that ensures precision, reduces eye strain, and enhances productivity, especially in low-light conditions. As demand for high-performance sewing equipment increases, so does the need for reliable, long-lasting, and energy-efficient lighting solutions. This has led to a surge in innovation and specialization among manufacturers of sewing machine light bulbs. Based on market presence, product quality, technological advancement, and distribution strength, here are the top nine sewing machine light bulb manufacturers shaping the industry today.

Top 9 Sewing Machine Light Bulb Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 SEWING MACHINE LIGHT MANUFACTURER

Domain Est. 2015

Website: sewinglight.net

Key Highlights: As the sewing machine light manufacturer,Dermay Technology Co Ltd supply good quality products and good service worldwidly….

#2 Sewing Machine Light Bulbs

Domain Est. 1999

Website: kenssewingcenter.com

Key Highlights: Free delivery over $50We service everything we sell, backed up by technicians that are trained by the factory on all the latest sewing machines and sergers on the market today….

#3 light bulb

Domain Est. 1995

#4 Domestic appliances

Domain Est. 1996

Website: signify.com

Key Highlights: Explore all types of light bulbs for appliances with recommended wattage and proper shape and size. 5 items. Sort by. Default….

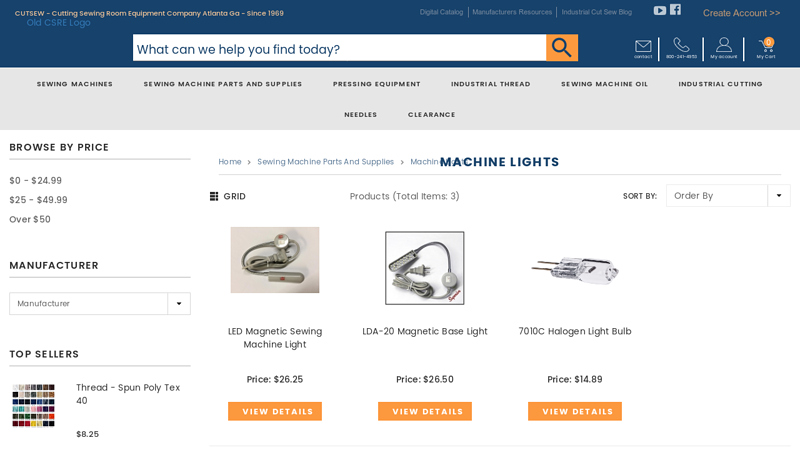

#5 Sewing Machine LED Lights

Domain Est. 1996

Website: cutsew.com

Key Highlights: 60-day returnsLED Magnetic Sewing Machine Light. Price: $26.25 ; LDA-20 Magnetic Base Light · Price: $26.50 ; 7010C Halogen Light Bulb. Price: $14.89….

#6 SEWING MACHINE LIGHT BULBS

Domain Est. 1998

#7 Sewing Machine Light Bulbs

Domain Est. 2001

#8 Sewing Machine Lights & Bulbs

Domain Est. 2002

#9 Sewing Machine Bulbs

Domain Est. 2022

Website: sewingmachineforum.com

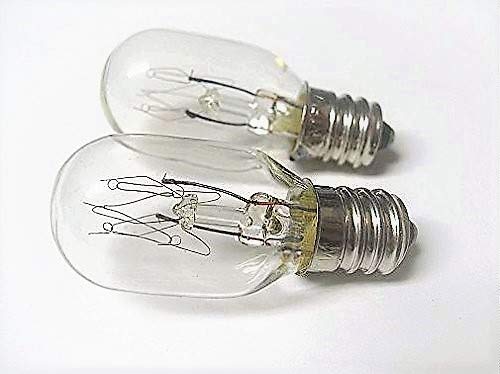

Key Highlights: Sewing machine bulbs, also known as sewing machine light bulbs, are small light sources designed to illuminate the work area on a sewing ……

Expert Sourcing Insights for Sewing Machine Light Bulb

2026 Market Trends for Sewing Machine Light Bulbs

The market for sewing machine light bulbs in 2026 is poised for transformation, driven by technological advancements, sustainability imperatives, and evolving consumer preferences. While a niche segment within the broader lighting and sewing accessories industry, several key trends are expected to shape its trajectory.

LED Dominance and Performance Enhancements

By 2026, Light Emitting Diode (LED) technology will solidify its position as the standard for sewing machine lighting, replacing older incandescent and halogen bulbs almost entirely. Consumers and manufacturers alike prioritize energy efficiency, longevity, and cooler operation—key advantages of LEDs. Innovations will focus on improving color rendering index (CRI), with bulbs achieving 90+ CRI to provide truer, more natural light that reduces eye strain and enhances precision during detailed sewing. Miniaturized, high-lumen LED modules designed for compact sewing machine housings will become more prevalent, offering brighter illumination without compromising machine design.

Integration and Smart Features

As sewing machines evolve into smart, connected devices, their lighting systems are following suit. In 2026, expect increased integration of light bulbs with machine sensors and user interfaces. Features such as automatic brightness adjustment based on ambient light, programmable color temperatures (e.g., warm for comfort, cool for detail work), and synchronization with stitch selection may emerge in premium models. While standalone replacement bulbs will remain common, OEMs will increasingly offer proprietary, embedded LED systems that are not user-replaceable, shifting the market toward integrated solutions.

Sustainability and Regulatory Compliance

Environmental regulations and consumer demand for sustainability will influence product development. Bulbs will be designed for longer lifespans (up to 50,000 hours) to minimize waste, and manufacturers will emphasize recyclable materials and reduced packaging. Compliance with RoHS and energy efficiency standards will be universal. Additionally, the shift to LEDs supports broader carbon reduction goals, aligning with corporate ESG initiatives among sewing machine brands.

Aftermarket and Compatibility Challenges

The growing diversity of sewing machine models—especially from Asian manufacturers—will create complexity in the replacement bulb market. By 2026, third-party suppliers will expand their product lines to cover a wider array of base types, voltages, and form factors. Online marketplaces will play a crucial role in distribution, with detailed compatibility guides and customer reviews helping users identify correct replacements. However, the trend toward non-replaceable LED units may gradually shrink the aftermarket, pushing consumers toward service centers or full machine upgrades.

Niche Demand and Customization

A growing maker and quilting community will sustain demand for specialized lighting solutions. Enthusiasts may seek customizable LED strips or external task lighting that complements built-in machine bulbs. Brands catering to this segment will offer modular or upgradeable lighting kits, often marketed alongside ergonomic accessories. This demand will support a niche but resilient segment focused on enhancing the sewing workspace beyond factory specifications.

In conclusion, the 2026 sewing machine light bulb market will be characterized by technological maturity in LED lighting, increased integration with smart machines, and a focus on sustainability and user experience. While replacement bulbs will remain relevant, the long-term trend points toward embedded, high-performance lighting as a core feature of modern sewing equipment.

Common Pitfalls When Sourcing Sewing Machine Light Bulbs (Quality and Intellectual Property)

Sourcing sewing machine light bulbs may seem straightforward, but several critical pitfalls related to quality and intellectual property (IP) can lead to performance issues, safety hazards, legal risks, and reputational damage. Being aware of these challenges is essential for ensuring reliable and compliant procurement.

Poor Quality Components and Materials

One of the most frequent issues is receiving bulbs made from substandard materials. Low-cost suppliers may use inferior filaments, weak glass envelopes, or poor base soldering, leading to short lifespans, frequent burnouts, or even bulb shattering during operation—posing safety risks to end users.

Inconsistent Electrical Specifications

Many generic bulbs fail to meet the precise voltage, wattage, or current requirements of specific sewing machine models. Using an incompatible bulb can cause overheating, damage to the machine’s electrical system, or inadequate lighting, reducing usability and potentially voiding equipment warranties.

Lack of Compliance with Safety Standards

Reputable sewing machine bulbs must comply with electrical safety standards such as UL (USA), CE (Europe), or RoHS (hazardous substance restrictions). Sourcing from non-compliant suppliers increases the risk of fire, electric shock, or regulatory rejection, particularly in regulated markets.

Misrepresentation of Bulb Type and Fit

Suppliers may incorrectly label bulbs as compatible with certain brands (e.g., “Singer,” “Brother”) without proper validation. Mismatches in base type (e.g., E10, BA9s), size, or shape can prevent installation or lead to loose connections, creating arcing or intermittent lighting.

Counterfeit or IP-Infringing Products

A significant IP risk involves sourcing bulbs that counterfeit original equipment manufacturer (OEM) designs or packaging. Some suppliers replicate branded bulbs without authorization, violating trademarks and design patents. Distributing such products can expose buyers to legal action, customs seizures, and loss of business credibility.

Absence of Genuine OEM Licensing

Even if a bulb is functionally accurate, using OEM logos, part numbers, or packaging without a licensing agreement constitutes IP infringement. Buyers should verify whether the supplier is an authorized licensee or produces bulbs under a legitimate private-label agreement.

Inadequate Testing and Quality Control

Many low-cost suppliers lack rigorous testing protocols. Bulbs may not undergo proper life cycle testing, thermal stress evaluation, or vibration resistance checks—critical for sewing machines that generate heat and movement. This results in higher failure rates post-purchase.

Supply Chain Transparency Issues

Without clear visibility into the manufacturing origin and supply chain, buyers risk encountering unethical labor practices, unverified component sources, or exposure to sanctioned regions. This undermines corporate social responsibility goals and increases supply chain vulnerability.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting compliance documentation, verifying IP rights, and conducting sample testing before scaling procurement.

Logistics & Compliance Guide for Sewing Machine Light Bulbs

Product Classification & HS Code

Sewing machine light bulbs are typically classified under the Harmonized System (HS) code 8539.90 (“Electric filament or discharge lamps, including sealed beam lamp units and ultraviolet or infrared lamps; arc-lamps: Other”). Final classification may vary by country and specific bulb characteristics (e.g., LED vs. incandescent), so consult local customs authorities for precise determination.

Packaging & Labeling Requirements

Ensure bulbs are securely packaged to prevent breakage during transit, using padded inner packaging and sturdy outer cartons. Label packaging with: product name, voltage/wattage (e.g., 12V 25W), bulb type (e.g., E10 base), compliance marks (e.g., CE, UKCA), manufacturer details, and handling symbols (e.g., “Fragile,” “This Way Up”). Include multilingual labels if shipping internationally.

Regulatory Compliance – Key Regions

- European Union (EU): Must comply with CE marking requirements, including the Low Voltage Directive (LVD 2014/35/EU) and RoHS (2011/65/EU) for restriction of hazardous substances. Energy-related products may also require Ecodesign and Energy Labeling compliance if applicable.

- United Kingdom (UK): Requires UKCA marking for bulbs placed on the market in Great Britain. Northern Ireland follows EU rules (CE marking). RoHS and LVD regulations apply under UK law.

- United States (US): No general certification body for light bulbs, but must comply with safety standards such as UL 1993 (fluorescent lamps) or ANSI C78 series. If LED-based, comply with ENERGY STAR or FTC Lighting Facts labeling if marketed for energy efficiency.

- Canada: Requires CSA certification or equivalent to meet Canadian Electrical Code standards. Must also comply with RoHS-like regulations under the Canadian Environmental Protection Act (CEPA).

Shipping & Transportation

Classify bulbs appropriately under the International Air Transport Association (IATA) or International Maritime Dangerous Goods (IMDG) Code. Standard incandescent or LED bulbs are generally non-hazardous but may be subject to special handling due to fragility. Avoid extreme temperatures and moisture during storage and transit. Use carriers experienced in handling small electrical components.

Import Duties & Documentation

Prepare commercial invoice, packing list, bill of lading/airway bill, and certificate of origin. Some countries may require a conformity assessment certificate (e.g., SONCAP for Nigeria, BIS for India). Import duties vary by destination; verify rates using the local tariff schedule. Keep records for at least five years for audit purposes.

Environmental & Disposal Compliance

Adhere to WEEE (Waste Electrical and Electronic Equipment) directives in the EU and similar e-waste regulations elsewhere. Provide information on proper disposal and, where required, participate in take-back programs. Avoid using mercury or restricted substances in bulb production to meet global environmental standards.

Recordkeeping & Audit Preparedness

Maintain detailed records of compliance testing, certifications, supplier declarations of conformity, and shipping documentation. Conduct periodic audits to ensure ongoing compliance with changing regulations in target markets. Assign a compliance officer or team to monitor regulatory updates.

In conclusion, sourcing the appropriate light bulb for a sewing machine requires careful consideration of specifications such as voltage, wattage, base type, and bulb shape to ensure compatibility and optimal visibility during sewing tasks. After evaluating various options, including incandescent, LED, and halogen bulbs, LED bulbs emerge as the most efficient and long-lasting choice, offering energy savings, cooler operation, and brighter light output. Reliable sourcing can be achieved through reputable suppliers, sewing machine manufacturers, or trusted online marketplaces, ensuring genuine and high-quality replacements. Ultimately, selecting the correct and durable light bulb enhances sewing precision, extends machine usability, and improves the overall sewing experience.