The global electric sentry market is experiencing robust growth, driven by rising demand for automated security solutions across military, defense, and critical infrastructure sectors. According to a 2023 report by Mordor Intelligence, the global military robotics market—encompassing electric sentry systems—is projected to grow at a CAGR of over 12.5% from 2023 to 2028. Similarly, Grand View Research estimates that the global security robot market will expand at a CAGR of 10.8% during the same period, reaching a value of USD 12.5 billion by 2028. This surge is fueled by advancements in AI, machine learning, and battery technology, enabling longer operational endurance and smarter threat detection. As organizations seek scalable, around-the-clock surveillance, electric sentry systems have emerged as a strategic asset. Below are the top 5 electric sentry manufacturers leading innovation and market penetration in this rapidly evolving landscape.

Top 5 Sentry Electric Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sentry Electrical Group

Domain Est. 2014

Website: sentryelec.com

Key Highlights: Sentry Electrical Group is a leading electrical contractor for renewable energy, utility, and industrial construction services….

#2 Contact Sentry Electric

Domain Est. 1998

Website: sentryelectric.com

Key Highlights: 3400 Gladstone St. Lincoln, NE 68504 Our Hours Mon-Fri: 7:30 am – 5:00 pm Sat & Sun: Closed Call Us (402) 467-5550…

#3 Sentry is Partnering with Potter

Domain Est. 1999

Website: sentryalarm.com

Key Highlights: Sentry Alarm Systems is proud to announce that we’ll be teaming up with Potter Electric Signal Company as a Certified Fire Alarm Systems Dealer….

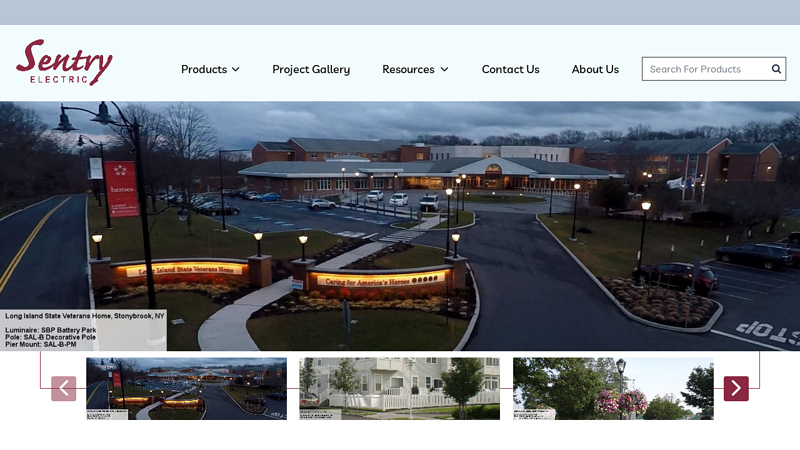

#4 Sentry Lighting

Domain Est. 2001

Website: sentrylighting.com

Key Highlights: Email: [email protected] · Phone: 516-379-4660 · Fax: 516-378-0624 · 185 Buffalo Avenue, Freeport, NY 11520. Connect with us. © Sentry Electric LLC 2026….

#5 Electrical

Domain Est. 2014

Website: sentryusa.com

Key Highlights: Our electrician team provides expert electrical services to Watertown, SD, and surrounding areas from residential to commercial projects….

Expert Sourcing Insights for Sentry Electric

H2: Market Trends for Sentry Electric in 2026

As the global energy landscape evolves rapidly, Sentry Electric is poised to navigate a dynamic set of market trends in 2026. These trends are shaped by technological advancements, regulatory shifts, sustainability imperatives, and changing consumer behaviors. Below is an analysis of the key market trends expected to influence Sentry Electric’s operations, strategy, and growth prospects in 2026.

1. Accelerated Adoption of Renewable Energy Integration

By 2026, renewable energy sources—particularly solar and wind—are projected to account for over 35% of global electricity generation (IEA, 2025). Sentry Electric is well-positioned to benefit from increased demand for grid modernization and smart infrastructure that supports bidirectional energy flows. The company’s investment in advanced metering infrastructure (AMI) and grid-edge technologies will be critical in enabling seamless integration of distributed energy resources (DERs).

2. Growth in Electrification of Transportation and Buildings

The electric vehicle (EV) market is expected to surpass 40 million annual sales globally by 2026 (BloombergNEF, 2025), driving significant demand for EV charging infrastructure. Sentry Electric’s expansion into smart charging solutions and partnerships with municipal and private fleet operators will be key growth drivers. Similarly, building electrification—driven by stricter carbon regulations—will increase demand for efficient electrical distribution systems in residential and commercial properties.

3. Smart Grid and Digitalization Expansion

Utility digital transformation will accelerate in 2026, with AI-driven analytics, IoT sensors, and digital twins becoming standard across power networks. Sentry Electric’s portfolio of intelligent switchgear, remote monitoring systems, and predictive maintenance platforms aligns with this trend. The company can leverage data analytics to offer value-added services, improving grid reliability and reducing outage times.

4. Regulatory and Policy Tailwinds

Government policies, including the U.S. Inflation Reduction Act (IRA) and EU Green Deal, continue to provide funding and incentives for grid resilience, clean energy, and domestic manufacturing. Sentry Electric is likely to benefit from federal and state-level grants targeting grid modernization and cybersecurity enhancements. Regulatory pressure to reduce outage duration and improve storm resilience will also boost demand for Sentry’s hardened electrical components.

5. Supply Chain Resilience and Onshoring

Geopolitical instability and trade tensions have prompted a shift toward regionalized supply chains. By 2026, Sentry Electric’s strategic investments in North American manufacturing and nearshoring of critical components will enhance supply chain resilience and reduce lead times—key competitive advantages in a market increasingly prioritizing speed and reliability.

6. Cybersecurity as a Core Utility Concern

As grid systems become more connected, cybersecurity risks intensify. In 2026, utilities will prioritize vendors that offer secure-by-design electrical equipment. Sentry Electric’s integration of cybersecurity protocols into its smart devices—aligned with NERC CIP and ISO 27001 standards—will be a differentiator in winning contracts with public and private sector clients.

7. Customer-Centric Energy Management Solutions

End-users—from industrial plants to homeowners—are demanding greater control over energy usage. Sentry Electric can capitalize on this trend by expanding its offerings in energy management systems (EMS), real-time load monitoring, and demand response integration. These solutions enhance customer engagement and support utility programs aimed at peak load reduction.

Conclusion

In 2026, Sentry Electric operates in a high-growth, innovation-driven market shaped by decarbonization, digitalization, and decentralization. By focusing on smart infrastructure, renewable integration, and resilient supply chains, the company is well-positioned to capture emerging opportunities. Strategic alignment with regulatory trends and customer needs will be essential for sustained leadership in the evolving electric ecosystem.

Common Pitfalls Sourcing Sentry Electric (Quality, IP)

Sourcing products or services from Sentry Electric—or any third-party manufacturer—can present several challenges, particularly concerning quality control and intellectual property (IP) protection. Being aware of these pitfalls is essential for minimizing risk and ensuring a successful partnership.

Quality Inconsistencies

One of the most frequent issues when sourcing from manufacturers like Sentry Electric is inconsistent product quality. Even with established standards, variations in materials, workmanship, or assembly processes can lead to defective units or performance issues. Without rigorous quality assurance protocols and on-site audits, companies may receive batches that fail to meet specifications, leading to increased returns, customer dissatisfaction, and reputational damage.

Lack of Transparent Manufacturing Processes

Sentry Electric may outsource certain components or sub-assemblies to secondary suppliers, making it difficult to trace the full supply chain. This lack of transparency can obscure the true origin of materials and manufacturing practices, increasing the risk of substandard components entering the final product. Without clear visibility, enforcing quality standards becomes significantly harder.

Inadequate Quality Control Documentation

Suppliers may provide incomplete or falsified quality control reports, such as missing test results, certificates of conformance, or material traceability data. Relying solely on documentation without independent verification can leave buyers exposed to undetected defects or non-compliance with safety and regulatory standards.

Intellectual Property Exposure

Sharing proprietary designs, schematics, or technical specifications with Sentry Electric poses a significant IP risk. Without strong legal protections—such as comprehensive non-disclosure agreements (NDAs) and IP ownership clauses—there’s a danger that your designs could be replicated, shared with competitors, or used in unauthorized products. This is especially concerning in regions with weaker IP enforcement.

Reverse Engineering and Unauthorized Production

Once a design is shared for manufacturing, there’s a risk that Sentry Electric or its subcontractors could reverse engineer the product and produce it independently for other buyers or under their own brand. This not only erodes market exclusivity but can also lead to counterfeit goods competing with your own.

Weak Contractual Safeguards

Many sourcing agreements lack specific clauses around IP ownership, usage rights, and post-termination obligations. Vague contracts can create legal grey areas, making it difficult to take action if IP is misused. Ensuring that contracts clearly define IP rights and include audit rights and penalties for violations is critical.

Supply Chain Complexity and Component Substitution

Sentry Electric may substitute components without prior approval to cut costs or address supply shortages. These substitutions can impact performance, reliability, and compliance, especially if alternative parts are not rigorously tested. Without strict change control processes, such swaps can go unnoticed until field failures occur.

Limited Recourse in Case of Disputes

If quality issues or IP violations arise, legal and logistical challenges—especially when sourcing internationally—can make enforcement difficult and costly. Jurisdictional differences, language barriers, and lengthy legal processes may limit your ability to seek remedies effectively.

Mitigation Strategies

To avoid these pitfalls, buyers should:

– Conduct thorough due diligence and factory audits.

– Implement clear quality control checkpoints and third-party inspections.

– Use robust contracts with explicit IP protections and audit rights.

– Limit access to sensitive design information on a need-to-know basis.

– Consider working with legal counsel experienced in international manufacturing law.

Proactive planning and vigilance are key to navigating the risks associated with sourcing from Sentry Electric or similar suppliers.

Logistics & Compliance Guide for Sentry Electric

This guide outlines the essential logistics and compliance procedures to ensure efficient operations and regulatory adherence across all Sentry Electric activities. Adherence to these standards is mandatory for all team members involved in shipping, receiving, warehousing, and regulatory reporting.

Supply Chain & Transportation Logistics

All inbound and outbound shipments must follow standardized routing procedures approved by the Logistics Manager. Freight carriers must be pre-qualified based on safety records, delivery reliability, and compliance with environmental regulations. Use designated freight management software to track shipments in real time and update stakeholders proactively. All shipments must include accurate packing lists, bills of lading, and material safety data sheets (MSDS) where applicable. Temperature-sensitive or hazardous electrical components require specialized handling and monitored transport solutions.

Inventory Management & Warehousing

Maintain inventory accuracy through regular cycle counts and annual physical audits. All products must be stored according to environmental specifications—particularly for sensitive electrical components requiring dry, temperature-controlled environments. Use barcoding or RFID systems to track stock levels and locations. Implement a first-expired, first-out (FEFO) or first-in, first-out (FIFO) rotation system as appropriate. Document all inventory movements and retain records for a minimum of seven years.

Domestic & International Shipping Compliance

Ensure all domestic shipments comply with U.S. Department of Transportation (DOT) regulations, including proper labeling and documentation for hazardous materials when applicable. For international shipments, verify compliance with International Maritime Dangerous Goods (IMDG) Code, International Air Transport Association (IATA) regulations, and destination country import requirements. Accurate Harmonized System (HS) codes, commercial invoices, and export declarations must be prepared for every cross-border shipment. Utilize the Automated Export System (AES) filing where required under the Foreign Trade Regulations (FTR).

Regulatory & Safety Compliance

All electrical products must meet applicable safety standards, including UL, CSA, and CE certifications, as required by market. Maintain up-to-date product compliance documentation and make available upon request. Employees handling hazardous materials must complete OSHA-mandated training, including HAZWOPER and GHS communication standards. Conduct annual compliance audits and address findings promptly. Report any compliance incidents or near-misses through the internal incident reporting system.

Environmental, Social, and Governance (ESG) Commitments

Sentry Electric is committed to reducing its carbon footprint across the logistics chain. Optimize transportation routes to minimize fuel consumption and prioritize carriers with verified sustainability practices. Recycle packaging materials and reduce single-use plastics in shipping. Ensure all subcontracted logistics partners adhere to Sentry Electric’s Supplier Code of Conduct, which includes labor rights, environmental stewardship, and anti-corruption policies.

Documentation & Record Retention

All logistics and compliance documents—including shipping manifests, customs filings, safety certifications, audit reports, and training records—must be securely stored in the centralized document management system. Retain records per regulatory requirements: minimum of five years for shipping and customs documents, seven years for safety training and compliance audits. Access to sensitive files is restricted to authorized personnel only.

Training & Accountability

All employees in logistics and compliance roles must complete onboarding training and annual refreshers covering key regulations, internal procedures, and emergency response protocols. Managers are accountable for ensuring team compliance and must report any regulatory changes or operational risks to the Compliance Officer immediately. Non-compliance may result in corrective action, up to and including disciplinary measures.

For questions or updates to this guide, contact the Compliance Department at [email protected].

Conclusion for Sourcing Sentry Electric Equipment

In conclusion, sourcing Sentry Electric products presents a strategic opportunity to enhance the reliability, safety, and efficiency of electrical systems. Sentry Electric is recognized for its high-quality electrical components, including transfer switches, load banks, and power monitoring systems, which are engineered to meet rigorous industry standards. Their reputation for durability, innovative design, and compliance with NEC, UL, and CSA requirements makes them a trusted brand in both commercial and industrial applications.

Sourcing from Sentry Electric offers several advantages, including long-term cost savings through reduced maintenance and downtime, improved system uptime, and strong technical support. Additionally, their products integrate seamlessly with existing power management systems, providing scalability and adaptability for future upgrades.

However, considerations such as lead times, availability through authorized distributors, and total cost of ownership should be evaluated during procurement planning. Partnering with certified suppliers and ensuring alignment with project specifications will help mitigate risks and ensure compliance.

Overall, sourcing Sentry Electric equipment supports robust infrastructure development, promotes operational continuity, and aligns with best practices in electrical safety and performance. For critical power applications, Sentry Electric stands as a reliable and reputable choice.