The global semi-trailer market is experiencing robust growth, fueled by rising demand for efficient freight transport and expanding logistics networks. According to a report by Mordor Intelligence, the semi-trailer market was valued at USD 58.7 billion in 2023 and is projected to grow at a CAGR of 5.2% through 2029. A critical yet often overlooked component of these trailers—the doors—plays a pivotal role in cargo security, accessibility, and operational efficiency. As demand for specialized trailers increases across refrigerated transport, dry vans, and intermodal applications, so does the need for high-performance, durable trailer doors. This surge has elevated the prominence of leading manufacturers that combine engineering precision with innovative materials and smart design. Based on market presence, product innovation, global reach, and customer reviews, we’ve compiled a data-driven overview of the top 10 semi-trailer door manufacturers shaping the industry’s future.

Top 10 Semi Trailer Doors Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 High quality truck trailers

Domain Est. 1998

Website: fontainetrailer.com

Key Highlights: Fontaine is the #1 flatbed trailer manufacturer in North America. Whether you’re a dealer, fleet manager or independent owner, we have trailers to fit your ……

#2 Stoughton Trailers: Semi

Domain Est. 2000

Website: stoughtontrailers.com

Key Highlights: Tailored solutions for your business with Stoughton Trailer, leading semi-trailer manufacturers. Quality-driven, customer-focused excellence!…

#3 Strick Trailers

Domain Est. 2006

Website: stricktrailers.com

Key Highlights: When a one-size-fits-all trailer just won’t cut it, a custom semi trailer from Strick gives you everything you need. Learn more!…

#4 Great Dane

Domain Est. 1996

Website: greatdane.com

Key Highlights: With an extensive network of authorized Great Dane trailer and truck body dealers, service centers, and parts distributors, we keep your fleet covered wherever ……

#5 Utility Trailer

Domain Est. 1996

Website: utilitytrailer.com

Key Highlights: The proven Utility 3000R and 3000R Multi-Temp refrigerated trailers are the industry’s strong light weight high payload performers. The Utility 3000R can also ……

#6 Jim Hawk Truck Trailers

Domain Est. 1997

Website: jhtt.com

Key Highlights: YOUR powerhouse Semi-Trailer and Spotter Truck dealership. We Proudly Offer: Over-the-Road, Construction, and Ag Trailers; Spotter Trucks; Parts; Service ……

#7 Dexter Group

Domain Est. 2002

Website: dextergroup.com

Key Highlights: Dexter is the premier supplier of axles, doors, venting products, and related components in the utility trailer, RV, heavy duty, recreational boating, and ……

#8 Semi-Trailer Doors

Domain Est. 2002

Website: ustrailerparts.com

Key Highlights: We stock a variety of semi-trailer doors for sale. Check out our huge inventory by visiting us today!…

#9 Vanguard National Trailer Corp.

Domain Est. 2003

Website: vanguardtrailer.com

Key Highlights: Vanguard National Trailer Corp. manufactures dry freight and refrigerated, semi-trailer vans for the North American transportation industry….

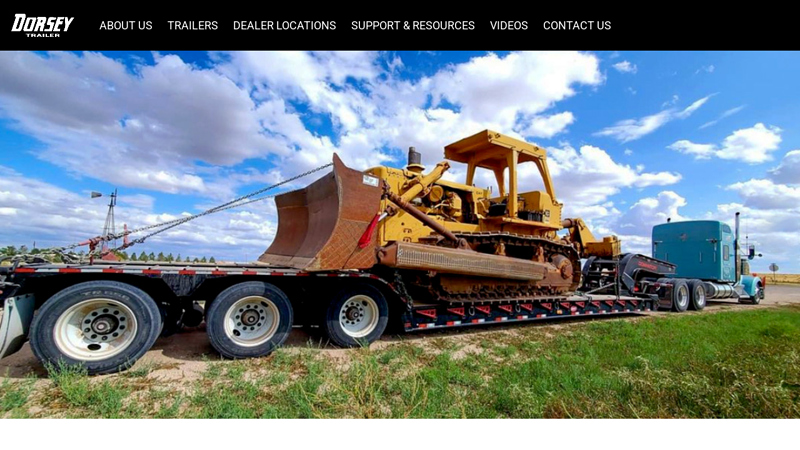

#10 Dorsey Trailer

Domain Est. 2007

Website: dorseytrailer.net

Key Highlights: For over 100 years, Dorsey has been committed to building the most durable trailers on the road. That commitment combined with a dedicated dealer network….

Expert Sourcing Insights for Semi Trailer Doors

2026 Market Trends for Semi Trailer Doors

The semi trailer door market is poised for significant evolution by 2026, driven by advancements in materials, automation, sustainability demands, and shifting logistics needs. As global supply chains adapt to e-commerce growth, regulatory changes, and technological innovation, trailer door systems are becoming more than just access points—they are integral components of efficiency, security, and operational safety. This analysis explores the key trends expected to shape the semi trailer door industry in 2026.

Rising Demand for Lightweight and Durable Materials

A dominant trend in 2026 will be the increased adoption of lightweight composite and aluminum materials in semi trailer door construction. Manufacturers are prioritizing weight reduction to improve fuel efficiency and payload capacity. Aluminum doors, in particular, offer corrosion resistance and durability without adding excess weight. Additionally, advanced composite materials—such as fiberglass-reinforced polymers—are gaining traction due to their strength-to-weight ratio and resistance to dents and wear.

Automation and Smart Door Technologies

By 2026, smart and automated door systems are expected to become mainstream in the commercial transport sector. Features such as motorized roll-up doors, remote-controlled access via mobile apps, and integration with fleet management systems enhance operational efficiency. Sensors and IoT-enabled diagnostics will allow real-time monitoring of door status (open/closed, locked/unlocked), improving security and reducing cargo theft. These systems also support predictive maintenance by detecting mechanical stress or wear in hinges and tracks.

Focus on Security and Anti-Theft Mechanisms

With cargo theft remaining a critical issue, especially in high-value freight transportation, semi trailer doors in 2026 will feature enhanced security mechanisms. This includes tamper-proof locking systems, biometric access, and integration with GPS tracking. Some manufacturers are developing doors with embedded alarms and reinforced locking bars that resist forced entry. Regulatory pressures and insurance requirements are expected to accelerate the adoption of such security features.

Expansion of Electric and Refrigerated Trailer Fleets

The growth of the electric vehicle (EV) market and cold-chain logistics will influence door design. Refrigerated trailers will require doors with superior insulation and tighter seals to maintain temperature integrity. In electric semi-trailers, door systems may be designed to integrate with low-power automated systems to conserve battery life. This dual focus on energy efficiency and thermal performance will drive innovation in sealing technologies and door frame construction.

Sustainability and Recyclability

Environmental regulations and corporate sustainability goals are pushing manufacturers toward eco-friendly production methods. In 2026, expect to see more semi trailer doors made from recyclable materials and produced using energy-efficient processes. Life-cycle assessments will become standard, influencing purchasing decisions among environmentally conscious fleets. Additionally, modular designs that allow for easy repair or replacement of components will reduce waste and extend product lifespans.

Regional Market Dynamics

North America and Europe will lead in adopting advanced door technologies due to stringent safety and emissions standards. Meanwhile, emerging markets in Asia-Pacific and Latin America will experience rising demand driven by expanding logistics infrastructure and e-commerce. Localized manufacturing and customization—especially for doors suited to regional climates and road conditions—will become increasingly important.

Conclusion

By 2026, the semi trailer door market will be shaped by technological innovation, environmental responsibility, and the need for smarter, more secure logistics solutions. Stakeholders—from manufacturers to fleet operators—must adapt to these evolving demands by investing in intelligent systems, sustainable materials, and integrated security features. As trailers become smarter and more connected, the humble door will play a pivotal role in defining the future of freight transportation.

Common Pitfalls When Sourcing Semi Trailer Doors (Quality & Intellectual Property)

Sourcing semi trailer doors involves more than just finding the lowest price. Overlooking critical quality and intellectual property (IP) considerations can lead to costly consequences, including safety risks, downtime, legal disputes, and reputational damage. Here are key pitfalls to avoid:

Poor Material and Construction Quality

Low-cost doors often use substandard steel, inadequate coatings, or weak welds, leading to premature rust, warping, and structural failure. This compromises cargo security and trailer longevity, increasing maintenance costs and safety hazards.

Inadequate Weather Sealing and Water Ingress

Poorly designed or manufactured seals fail to prevent water, dust, and debris from entering the trailer. This can damage cargo, promote corrosion, and violate transportation regulations—especially for temperature-controlled or sensitive goods.

Non-Compliance with Safety and Industry Standards

Many suppliers overlook critical standards such as DOT, CVSA, or regional safety regulations. Doors with weak hinges, faulty latches, or improper locking mechanisms can fail during transit, posing serious safety risks and potential liability.

Lack of Durability in High-Use Environments

Doors not engineered for frequent opening/closing or harsh conditions (e.g., cold storage, off-road) suffer from hinge wear, latch failure, or frame deformation. This leads to increased downtime and replacement costs.

Counterfeit or Unlicensed Products

Some suppliers sell doors that mimic patented designs from major OEMs (e.g., Wabash, Utility, Manac). These counterfeit products infringe on intellectual property rights and may not meet OEM performance or safety specifications.

Weak or Missing IP Documentation

OEMs and distributors may fail to provide proof of licensing or design ownership. Purchasing doors with unclear IP status exposes buyers to legal risk, including cease-and-desist orders or seizure of goods.

Inconsistent Fit and Interchangeability

Doors sourced from non-OEM or unqualified manufacturers may not align properly with existing trailer frames or hardware. This results in installation challenges, poor operation, and compromised door integrity.

Limited Warranty and After-Sales Support

Low-quality suppliers often offer minimal or voidable warranties. Without reliable technical support or replacement parts, resolving defects becomes difficult and expensive.

Supply Chain and Traceability Gaps

Opaque sourcing makes it hard to verify material origins or manufacturing processes. This increases exposure to regulatory risks (e.g., forced labor, environmental violations) and complicates quality audits.

Overlooking Total Cost of Ownership

Focusing solely on upfront price ignores long-term costs related to maintenance, repairs, cargo damage, and downtime. High-quality, IP-compliant doors often offer better value over the trailer’s lifecycle.

To mitigate these risks, conduct thorough due diligence: verify certifications, request material test reports, confirm IP legitimacy, and prioritize suppliers with proven track records and strong warranties.

Logistics & Compliance Guide for Semi Trailer Doors

Semi trailer doors are a critical component in the safe, secure, and compliant transportation of goods. Proper operation, maintenance, and adherence to regulations are essential for efficient logistics and to prevent cargo loss, damage, or regulatory violations. This guide outlines key considerations for managing semi trailer doors across logistics and compliance domains.

Door Types and Configurations

Understanding the various types of trailer doors is fundamental to proper logistics planning and compliance:

- Swing Doors (Bi-Fold or Double-Swing): Most common; open outward and are secured with cam-style locks. Require clearance for opening and are susceptible to wind damage if not properly secured.

- Roll-Up Doors: Slide vertically into a housing above the door opening. Require less clearance than swing doors and are often used in cold storage or high-volume loading docks.

- Sliding (Slam) Doors: Move laterally along tracks on the side of the trailer. Ideal for tight loading dock spaces.

- Hydraulic or Power-Operated Doors: Used in specialized trailers, such as refrigerated units or curtain-sided trailers, allowing easier opening/closing but requiring maintenance and power checks.

Choose the appropriate door type based on cargo, loading environment, security needs, and regulatory requirements.

Safety Protocols and Operational Best Practices

Ensuring the safety of personnel and cargo begins with proper door handling:

- Pre-Trip Inspection: Inspect doors for damage, corrosion, or misalignment before each use. Check hinges, latches, locks, and seals.

- Secure Closure: Confirm doors are fully closed and locked before departure. Use cam-lock mechanisms properly—ensure handles are rotated to the fully locked position.

- Clearance Awareness: Ensure adequate space for door operation, especially swing doors. Warn nearby personnel before opening.

- Wind Precautions: Avoid opening swing doors in high winds. If necessary, secure doors with straps or braces during loading/unloading.

- Use of Door Retainers: Employ door holders or restraints to keep doors open safely during loading to prevent accidental closure.

Compliance with Regulatory Standards

Adherence to transportation regulations is mandatory and affects both domestic and international operations:

- FMCSA (Federal Motor Carrier Safety Administration) – USA: Requires that cargo be adequately secured. Doors must be closed and latched during transit; failure can result in citations under 49 CFR §393.102.

- Transport Canada – CVSA Standards: Enforces similar cargo securement rules; open or improperly secured doors can lead to out-of-service orders.

- ADR (European Agreement concerning the International Carriage of Dangerous Goods by Road): For hazardous materials, doors must be leak-proof, securely closed, and labeled accordingly. Additional sealing and inspection requirements apply.

- Customs & Border Security (e.g., C-TPAT, AEO): Tamper-evident seals are required on doors for international shipments. These seals must be applied after loading and verified before and after transit. Record seal numbers in shipping documentation.

- ISPM 15 (Wood Packaging): While not directly about doors, wooden door components (e.g., frames) must comply if made from raw wood—proper heat treatment and stamping required.

Maintenance and Inspection Requirements

Regular maintenance prevents failures and ensures compliance:

- Daily/Pre-Trip Checks: Inspect door seals, latches, hinges, and locking mechanisms for wear or damage.

- Scheduled Maintenance: Lubricate hinges and locks regularly. Replace worn gaskets to maintain weatherproofing and insulation (critical for refrigerated units).

- Post-Incident Inspection: After any impact or accident, inspect door alignment and structural integrity.

- Documentation: Maintain logs of inspections, repairs, and seal usage for audit and compliance purposes.

Sealing and Security Best Practices

Door security is critical for loss prevention and regulatory compliance:

- Use of Tamper-Evident Seals: Apply numbered security seals approved by customs authorities (e.g., ISO 17712 compliant). Seals should be applied at the point of loading and broken only at final destination.

- Seal Verification: Record seal numbers on bills of lading, manifests, and customs forms. Verify seal integrity at checkpoints.

- Door Alarms and Sensors (Optional): Some fleets use electronic monitoring systems to detect unauthorized door openings during transit.

- Chain of Custody: Maintain strict control over who has access to keys or codes for door opening, especially in multi-party logistics.

Environmental and Load-Specific Considerations

Door performance can vary based on cargo and environmental factors:

- Refrigerated Trailers (Reefers): Door seals must be intact to maintain temperature. Minimize open time during loading to prevent thermal loss.

- Dry Vans and General Freight: Ensure doors are weather-sealed to protect cargo from moisture.

- Curtain-Sided Trailers: Fabric curtains require different handling—ensure tensioning systems and protective flaps are properly secured.

- Hazardous Materials: Doors must be compatible with containment requirements. No leaks or gaps permitted.

Training and Accountability

Proper training ensures all stakeholders follow protocols:

- Driver Training: Include door operation, inspection, sealing, and compliance procedures in onboarding and ongoing training.

- Loader/Unloader Guidelines: Provide clear instructions to warehouse and dock personnel on proper door handling and safety.

- Compliance Audits: Conduct regular audits to verify adherence to door-related procedures and regulations.

By following this guide, logistics operators can ensure semi trailer doors contribute to safe, efficient, and compliant transportation operations. Regular attention to door condition, proper use, and regulatory alignment reduces risk, enhances cargo security, and supports supply chain integrity.

Conclusion on Sourcing Semi-Trailer Doors

Sourcing semi-trailer doors requires a strategic approach that balances quality, durability, cost-efficiency, and compliance with industry standards. Reliable suppliers must be carefully evaluated based on their manufacturing capabilities, material quality, and adherence to safety and regulatory requirements. Whether opting for standard or custom door configurations—such as swing, roll-up, or barn-style doors—it is essential to align specifications with operational needs, including cargo type, loading processes, and regional climate conditions.

Establishing long-term partnerships with reputable manufacturers or distributors can lead to better pricing, consistent quality, and faster delivery times. Additionally, considering factors like corrosion resistance, ease of maintenance, and compatibility with existing trailer fleets ensures long-term performance and minimizes downtime.

In summary, effective sourcing of semi-trailer doors involves thorough research, clear specifications, and due diligence in supplier selection to ensure reliable, safe, and cost-effective solutions that support efficient logistics and transportation operations.