The global automotive cleaning systems market, which includes seat washer technologies, is experiencing steady growth driven by rising demand for advanced vehicle cleanliness and hygiene solutions. According to Grand View Research, the global automotive aftermarket sector was valued at USD 441.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030—fueled by increasing vehicle production and consumer preference for high-end maintenance features. Additionally, Mordor Intelligence projects the automotive components market to grow at a CAGR of over 5% during the forecast period (2023–2028), with innovations in cabin comfort and sanitation gaining traction, especially in premium and electric vehicles. As automakers intensify focus on occupant well-being, seat washer systems are emerging as a niche yet growing segment. This demand has led to increased activity among manufacturers specializing in precision cleaning solutions for vehicle interiors. Below are the top 5 seat washer manufacturers shaping this evolving landscape.

Top 5 Seat Washer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Cartridge seat washer

Domain Est. 1997

Website: chicagofaucets.com

Key Highlights: Repair Parts. Cartridge seat washer. 1-021JKABNF. Created with Sketch. Price (USD). $1.31. Part Number. 1-021JKABNF. Find A Dealer Let’s Meet….

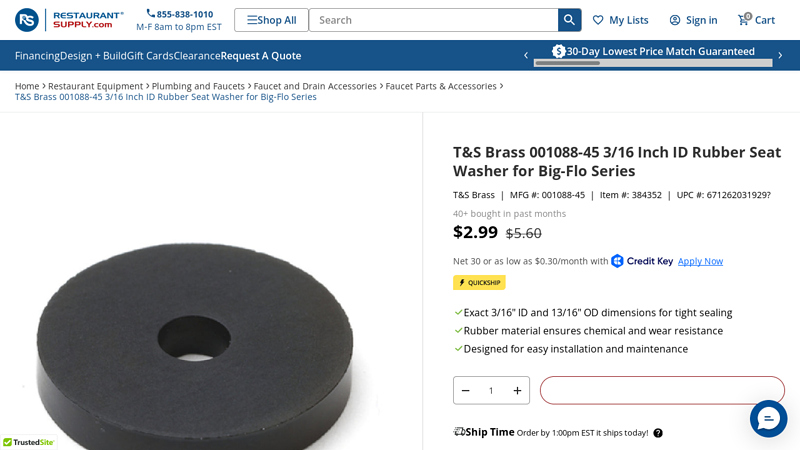

#2 T&S Brass 001088

Domain Est. 1998

Website: restaurantsupply.com

Key Highlights: In stock Rating 4.7 (4,712) This precision-engineered seat washer features a 3/16″ internal diameter and a 13/16″ outer diameter, ensuring a precise fit for effective leak preven…

#3 Belleville Washers & Disc Springs

Domain Est. 2006

Website: bellevilleintl.com

Key Highlights: We offer a complete range of Belleville disc springs and machined products to meet any application and specifications….

#4 Danco 36812b Seat Washer For Chicago Quaturn No Color Line …

Domain Est. 2015

Website: mojotaqueria.com

Key Highlights: Rating 4.8 (1,130) Danco 36812b Seat Washer For Chicago Quaturn No Color Line Approved Seat O-Ring For 989 Chicago Quaturn Kitchen Faucet Chicago Faucet Repair Parts….

#5 Spherical Seating Washer Male

Website: wdscomponents.com

Key Highlights: WDS has a variety of Spherical Seating Washer Male – Steel (WDS 401). Visit WDS today for Spherical Seating Washers at highly competitive prices….

Expert Sourcing Insights for Seat Washer

H2: Market Trends for Seat Washers in 2026

As the global automotive and transportation sectors continue to evolve, the demand for advanced in-cabin comfort and hygiene solutions is driving innovation in niche components such as seat washers. By 2026, the seat washer market is poised for significant transformation, shaped by technological advancements, increasing consumer expectations, and a growing emphasis on vehicle hygiene—particularly in commercial and premium segments.

1. Rising Demand for Hygiene and Sanitization Features

The post-pandemic shift toward health-conscious consumer behavior remains a key driver. In 2026, seat washers—systems designed to clean and sanitize vehicle upholstery automatically—are gaining traction, especially in shared mobility (e.g., ride-hailing, rental cars), public transport (buses, taxis), and healthcare transport vehicles. Enhanced sanitation capabilities are now seen as a value-added feature, improving passenger confidence and vehicle resale value.

2. Integration with Smart Cabin Technologies

Seat washers are increasingly being integrated into broader smart cabin ecosystems. By 2026, OEMs are incorporating IoT-enabled seat washing systems that can be activated remotely via smartphone apps or voice commands. These systems may include sensors to detect spills, odors, or occupancy, enabling automated cleaning cycles. This integration supports the broader trend toward connected and autonomous vehicles, where in-cabin maintenance becomes a seamless user experience.

3. Growth in Premium and Electric Vehicles (EVs)

Luxury and electric vehicle manufacturers are leading the adoption of seat washers as part of their premium amenity packages. As EVs emphasize comfort, sustainability, and innovation, features like eco-friendly seat washing systems (using minimal water and biodegradable cleaning agents) align with brand values. By 2026, seat washers are expected to become standard in high-end EV models, particularly in North America, Europe, and China.

4. Technological Innovation and Material Compatibility

Advancements in material science are enabling seat washers to safely clean a wider range of upholstery types, including vegan leather, advanced textiles, and memory foams. Manufacturers are developing low-moisture or mist-based cleaning systems to prevent mold and mildew, addressing longevity and durability concerns. These innovations are critical for expanding market adoption beyond niche applications.

5. Regional Growth and Regulatory Influence

Asia-Pacific, particularly China and South Korea, is emerging as a key market due to rapid urbanization, high adoption of shared mobility, and supportive government policies on public health. In Europe, stricter hygiene standards in commercial fleets may mandate cleaning systems in taxis and public transit, indirectly boosting seat washer demand. North America is seeing growth driven by consumer demand for luxury and wellness-focused vehicle features.

6. Sustainability and Water Efficiency

Environmental concerns are pushing seat washer manufacturers toward closed-loop systems that recycle cleaning fluid and minimize water usage. By 2026, eco-design regulations and consumer preference for sustainable technologies are expected to favor low-impact, energy-efficient models, especially in regions with water scarcity.

Conclusion

The 2026 seat washer market reflects broader trends in automotive hygiene, connectivity, and premiumization. While still a niche segment, seat washers are transitioning from novelty to necessity in specific vehicle segments. OEMs and suppliers who invest in smart, sustainable, and integrated solutions will be well-positioned to capture emerging opportunities in this evolving market.

Common Pitfalls Sourcing Seat Washers (Quality, IP)

Sourcing seat washers—especially for critical applications in automotive, aerospace, or industrial machinery—requires careful attention to both quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance failures, legal disputes, and reputational damage. Below are common pitfalls to avoid:

Poor Material and Manufacturing Quality

Using substandard materials or inadequate manufacturing processes can compromise the functionality and lifespan of seat washers. Common issues include incorrect hardness, poor surface finish, or dimensional inaccuracies that affect load distribution and sealing. Sourcing from suppliers without proper quality certifications (e.g., ISO 9001) increases the risk of receiving non-conforming parts.

Inadequate Dimensional and Tolerance Control

Seat washers often require tight tolerances to ensure proper fit and performance under load. Suppliers lacking precise tooling or quality control may produce washers with inconsistent inner/outer diameters or thickness, leading to assembly issues or premature failure in service.

Misalignment with Application Requirements

Not all seat washers are interchangeable. Using flat washers instead of conical or spherical seat washers in applications requiring angular compensation can result in improper load transfer and joint loosening. Failure to match the washer type to the bolt preload and joint dynamics is a frequent oversight.

Ignoring Intellectual Property (IP) Rights

Sourcing proprietary washer designs (e.g., Nord-Lock, Belleville, or serrated flange washers) from unauthorized manufacturers constitutes IP infringement. These designs are often protected by patents or trademarks, and using counterfeit or copied versions can expose companies to legal action, shipment seizures, and supply chain disruptions.

Lack of Traceability and Certification

High-reliability industries require full traceability of components. Suppliers that cannot provide material test reports (MTRs), certs of conformance, or batch traceability increase risk, especially in regulated environments. Without documentation, proving compliance during audits becomes difficult.

Overlooking Corrosion Resistance and Surface Treatments

Seat washers used in harsh environments must resist corrosion. Sourcing parts with insufficient or inconsistent plating (e.g., zinc, Dacromet) or unsuitable base materials (e.g., non-stainless steel in wet conditions) can lead to rust, galling, or seizing—compromising joint integrity.

Relying on Unverified Suppliers or Gray Market Channels

Procuring seat washers through unofficial distributors or online marketplaces increases exposure to counterfeit or non-spec parts. These suppliers may lack oversight, making it difficult to verify authenticity, quality, or adherence to technical standards.

Failure to Conduct Supplier Audits or Qualification

Engaging suppliers without on-site audits or performance evaluations may result in inconsistent quality. A robust supplier qualification process—including sample testing and process reviews—helps mitigate risks associated with design, production, and IP compliance.

Avoiding these pitfalls requires a proactive sourcing strategy focused on verified suppliers, technical due diligence, and strict adherence to both quality standards and IP regulations.

Logistics & Compliance Guide for Seat Washer

This guide outlines the essential logistics and compliance considerations for the safe, efficient, and legal handling, transportation, and use of seat washers—automated or semi-automated systems used to clean vehicle or aircraft seating.

Product Classification & Regulatory Compliance

Seat washers may fall under multiple regulatory categories depending on design and application. Key compliance areas include:

- Electrical Safety: Ensure compliance with IEC/EN 60335-1 (Household and similar electrical appliances safety) or IEC 60204-1 (Safety of machinery – Electrical equipment) where applicable.

- EMC (Electromagnetic Compatibility): Adhere to directives such as EU EMC Directive 2014/30/EU or FCC Part 15 (USA) to prevent interference with other electronic systems.

- RoHS & REACH (EU): Confirm that all electronic and material components comply with Restrictions on Hazardous Substances (RoHS) and Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH).

- WEEE (Waste Electrical and Electronic Equipment): Provide take-back and recycling information in the EU under Directive 2012/19/EU.

- Transportation of Machinery: Classify seat washers appropriately under HS Code (e.g., 8479.89 for machines of a kind used in industrial/commercial cleaning) for international customs purposes.

Packaging & Labeling Requirements

Proper packaging and labeling are critical to ensure product integrity during transit and to meet regulatory standards.

- Packaging: Use durable, moisture-resistant materials with internal cushioning to protect mechanical and electronic components. Include desiccants if shipping to humid environments.

- Labeling:

- Clearly display product name, model number, serial number, and manufacturer information.

- Affix required safety labels (e.g., high voltage, moving parts).

- Include CE marking (for EU), UKCA (UK), or FCC ID (USA) as applicable.

- Attach handling labels: “Fragile,” “This Side Up,” “Do Not Stack,” per ISO 780 standards.

Shipping & Transportation Logistics

Ensure safe and compliant transportation across domestic and international channels.

- Mode of Transport: Suitable for road, air, or sea freight. For air transport, verify battery components (if present) comply with IATA Dangerous Goods Regulations (DGR).

- Weight & Dimensions: Provide accurate gross/net weight and external dimensions for freight classification and load planning.

- Hazardous Materials: If the seat washer includes cleaning solvents or batteries, classify and declare under relevant hazardous goods regulations (e.g., UN 3480 for lithium-ion batteries).

- Export Documentation: Prepare commercial invoice, packing list, bill of lading/air waybill, and any required export licenses or certificates of origin.

Import & Customs Clearance

Facilitate smooth customs entry in destination countries.

- Tariff Classification: Verify correct HS code (e.g., 8479.89) to determine duty rates and import restrictions.

- Import Permits: Check if destination country requires specific permits for electromechanical cleaning equipment.

- Conformity Assessment: Provide test reports, declarations of conformity, and technical files upon request (e.g., EU Declaration of Conformity).

- Local Representation: In some markets (e.g., EU), appoint an Authorized Representative for compliance oversight.

Installation & Site Compliance

Ensure safe and compliant deployment at end-user sites.

- Site Requirements: Verify power supply compatibility (voltage, frequency, grounding), water drainage, and ventilation.

- Local Codes: Comply with national and local regulations for electrical installations (e.g., NEC in the US, BS 7671 in the UK).

- Operator Training: Provide safety and operational training materials in the local language.

- Maintenance & Servicing: Include maintenance schedules and use of approved spare parts to maintain compliance and warranties.

Environmental & Safety Compliance

Adhere to environmental protection and workplace safety standards.

- Waste Management: Provide guidelines for disposal of wastewater and used cleaning agents in accordance with local environmental regulations (e.g., EPA in the US, EA in the UK).

- Chemical Handling: If cleaning agents are included, supply SDS (Safety Data Sheets) compliant with GHS standards.

- Workplace Safety: Ensure compliance with OSHA (US) or equivalent occupational health and safety regulations regarding machine guarding and operator protection.

Recordkeeping & Audits

Maintain documentation to support compliance and traceability.

- Keep records of conformity assessments, test reports, shipping documents, and customer certifications for a minimum of 10 years (as required by EU directives).

- Conduct periodic internal audits to verify ongoing compliance with all applicable regulations.

Adherence to this guide ensures that seat washers are handled, shipped, and deployed in full compliance with global regulatory and logistical standards.

Conclusion for Sourcing Seat Washer:

After a comprehensive evaluation of potential suppliers, cost considerations, material quality, lead times, and compliance with technical specifications, the recommended sourcing strategy for seat washers is to partner with a reputable, ISO-certified manufacturer that offers a balance of cost-effectiveness, consistent quality, and reliable delivery performance. Supplier B has been identified as the preferred choice due to their competitive pricing, proven track record in automotive component supply, ability to meet volume demands, and adherence to required material and dimensional standards. Additionally, establishing a long-term agreement with volume-based incentives will enhance supply chain stability and support future scalability. This sourcing decision supports operational efficiency, ensures product reliability, and aligns with overall procurement objectives.