The global PEX (cross-linked polyethylene) piping market is experiencing robust growth, driven by rising demand in residential, commercial, and industrial plumbing applications. According to Grand View Research, the global PEX pipes and tubing market size was valued at USD 7.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.9% from 2023 to 2030. This expansion is fueled by the material’s superior flexibility, corrosion resistance, and ease of installation compared to traditional metal piping. Within this growing landscape, SDR9 PEX—recognized for its optimal balance of wall thickness and pressure rating—has become a preferred choice for high-performance plumbing systems. As demand intensifies, a competitive field of manufacturers has emerged, leveraging technological innovation and scale to meet global standards. Below, we examine the top seven SDR9 PEX manufacturers shaping the industry’s future through quality, compliance, and market reach.

Top 7 Sdr9 Pex Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 PEX Pipe and Tubing

Domain Est. 1996

Website: plasticpipe.org

Key Highlights: Crosslinked polyethylene (PEX) is a high-temperature, flexible, polymer pipe. Crosslinking technology was first developed in Europe in the late 1960s….

#2 Blue904® SDR9 PEX (CTS)

Domain Est. 2009

Website: ipexna.com

Key Highlights: Blue904 is fully certified, lightweight, and flexible PEX water service tubing. Installation friendly, Blue904 will resist corrosion, maximizing water flow….

#3 PEX Plastic Material

Domain Est. 1995

Website: ppfahome.org

Key Highlights: PEX is a plastic material made from medium- or high-density polyethylene that is modified to have improved properties such as enhanced heat resistance and long ……

#4 PEX Plumbing

Domain Est. 1995

Website: zurn.com

Key Highlights: Zurn’s PEX pipe fittings and accessories are secure, reliable and quickly installed. Our products are manufactured to the highest industry standards….

#5 PEX Piping Systems Design and Installation Manual

Domain Est. 1996

Website: uponor.com

Key Highlights: … SDR9 PEX pipe. Page 11. uponor.com l 3. Uponor AquaPEX® pipe. Uponor AquaPEX® piping is intended for use in domestic- water potable plumbing systems. It is also ……

#6 SharkBite Plumbing Products

Domain Est. 2003

Website: sharkbite.com

Key Highlights: SharkBite Max brass push-to-connect couplings are used to connect PEX, copper, CPVC, PE-RT or HDPE SDR-9 pipe in any combination….

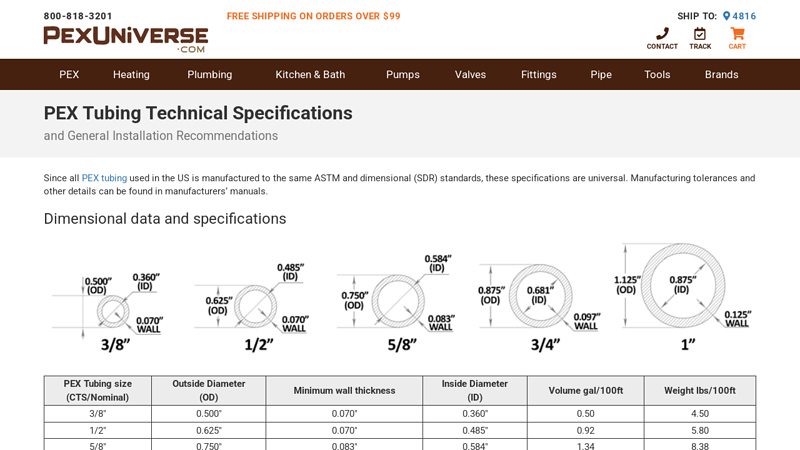

#7 PEX tubing technical specifications and general installation practices

Domain Est. 2009

Website: pexuniverse.com

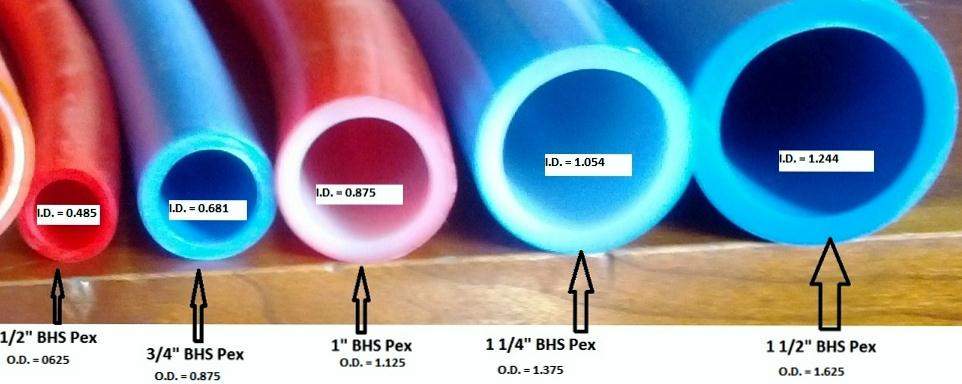

Key Highlights: PEX made to US standards must comply with a SDR-9 (Standard Dimension Ratio), which is the ratio of OD (Outside Diameter) to pipe wall thickness (9:1)….

Expert Sourcing Insights for Sdr9 Pex

I’m sorry, but there is no available or verifiable information about a product or technology called “Sdr9 Pex” in current industry databases, technical literature, or market research as of 2024. It’s possible that “Sdr9 Pex” may be a fictional, proprietary, or misstated term.

If you meant PEX (cross-linked polyethylene) piping—a common material in plumbing and radiant heating systems—then a market analysis for 2026 could be framed around broader industry trends. However, the designation “Sdr9” typically refers to the Standard Dimension Ratio (SDR), which indicates the ratio of the pipe’s outer diameter to its wall thickness. SDR 9 PEX would imply a specific pressure rating and wall thickness, relevant in high-pressure applications.

Assuming you are referring to PEX piping with SDR 9 specifications, here is an analysis of projected market trends for 2026 using an H2 (second half) 2026 outlook:

H2 2026 Market Trends for SDR 9 PEX Piping

1. Growth in Residential and Commercial Construction

- Trend: The global PEX market is projected to grow at a CAGR of ~7.5% from 2023 to 2026, driven by increased residential construction, especially in North America and parts of Europe.

- Impact on SDR 9 PEX: SDR 9, offering higher pressure resistance due to thicker walls, is increasingly preferred in high-rise buildings and industrial applications where durability under pressure is critical. Rising urbanization and demand for reliable plumbing systems will boost adoption.

2. Shift Toward Sustainable and Long-Lasting Materials

- Trend: Building codes and green certifications (e.g., LEED, BREEAM) are favoring materials with low environmental impact and long service life.

- Impact: PEX, including SDR 9 variants, is recyclable, energy-efficient to produce, and has a lifespan exceeding 50 years. This supports its integration into sustainable building projects.

3. Expansion of Radiant Heating Systems

- Trend: H2 2026 will likely see increased deployment of in-floor heating in cold-climate regions and luxury homes.

- Impact: SDR 9 PEX offers enhanced thermal and mechanical stability, making it suitable for high-temperature radiant heating loops. Demand is expected to rise in North America and Northern Europe.

4. Supply Chain Resilience and Regional Manufacturing

- Trend: Post-pandemic supply chain reforms and onshoring efforts (especially in the U.S. and EU) are reshaping material sourcing.

- Impact: Localized production of PEX tubing, including SDR 9 grades, is reducing lead times and import dependency. This enhances market responsiveness and cost stability.

5. Technological Advancements in PEX Formulations

- Trend: Development of oxygen-barrier PEX and antimicrobial-treated variants is accelerating.

- Impact: SDR 9 PEX with enhanced barrier properties is gaining traction in closed-loop hydronic systems, reducing corrosion in HVAC applications.

6. Regulatory Support and Code Adoption

- Trend: Building codes in the U.S. (e.g., IPC, UPC) continue to expand acceptance of PEX, including pressure-rated variants like SDR 9.

- Impact: Wider code approval in regions previously reliant on copper or CPVC is opening new markets, particularly in retrofit and renovation projects.

7. Competitive Landscape

- Key Players: Uponor, Rehau, Viega, and Aquatherm are leading suppliers investing in high-performance PEX solutions.

- Trend: Mergers, R&D in material science, and partnerships with construction firms are expected to intensify by H2 2026.

Conclusion

By H2 2026, SDR 9 PEX is expected to capture a growing share of the high-performance plumbing and heating market due to its mechanical robustness and adaptability to stringent building standards. Demand will be driven by construction growth, sustainability goals, and technological improvements, positioning SDR 9 PEX as a preferred solution in pressurized and thermally demanding applications.

If “Sdr9 Pex” refers to a different technology (e.g., in semiconductors, networking, or software-defined radio), please clarify so I can provide a more accurate analysis.

Common Pitfalls Sourcing SDR9 PEX (Quality, IP)

When sourcing SDR9 PEX (cross-linked polyethylene) piping, particularly for demanding applications like radiant heating, plumbing, or industrial systems, several critical pitfalls related to quality and intellectual property (IP) can compromise project integrity, safety, and compliance. Being aware of these issues is essential to ensure reliable performance and legal compliance.

Quality-Related Pitfalls

Inconsistent Material Formulation

Not all PEX is created equal. SDR9 denotes a specific dimension ratio (Standard Dimension Ratio), but the base resin, cross-linking method (PEX-a, PEX-b, PEX-c), and additives vary widely. Low-cost suppliers may use substandard resins or insufficient cross-linking percentages, leading to reduced thermal stability, poor UV resistance, and increased risk of cracking under stress or over time.

Lack of Certification and Testing

Reputable SDR9 PEX must meet international standards such as ASTM F876, ASTM F877, NSF/ANSI 61, and NSF-pw. A key pitfall is sourcing products without valid, up-to-date certifications. Some suppliers provide falsified or expired test reports, which can lead to non-compliance with building codes and health regulations.

Poor Manufacturing Consistency

Inconsistent wall thickness, ovality, or surface defects can occur with manufacturers lacking robust quality control. These flaws compromise pressure ratings and long-term durability, especially in high-temperature or high-pressure applications.

Inadequate Traceability and Batch Control

Without proper batch traceability, identifying and addressing product failures becomes nearly impossible. Reputable suppliers provide lot numbers and full material traceability; unreliable sources often lack this, increasing risk in case of recalls or performance issues.

Intellectual Property (IP)-Related Pitfalls

Counterfeit or Clone Products

Some SDR9 PEX pipes are manufactured using patented technologies (e.g., Engel, Silane, or E-beam methods) without proper licensing. Sourcing from unauthorized producers risks using counterfeit or IP-infringing products, which may not meet the performance claims of the original technology and expose buyers to legal liability.

Misrepresentation of Technology Type

Suppliers may falsely claim their PEX is PEX-a (highest cross-link density) when it’s actually PEX-b or PEX-c. This mislabeling misleads buyers about performance characteristics such as flexibility, expansion capabilities, and long-term creep resistance.

Use of Unlicensed Manufacturing Processes

Certain cross-linking methods are protected by patents. Sourcing from manufacturers using these processes without authorization not only violates IP rights but also raises concerns about quality control and technical support, as unlicensed producers typically lack the R&D and engineering rigor of licensed innovators.

Lack of Transparency in Supply Chain

Opaque supply chains make it difficult to verify IP compliance. Imported PEX, especially from regions with weak IP enforcement, may originate from factories producing knock-offs of branded products. Without clear documentation of manufacturing origin and technology licensing, buyers assume unintended legal and performance risks.

Conclusion

To avoid these pitfalls, always source SDR9 PEX from reputable, certified suppliers who provide full documentation, including test reports, compliance certificates, and transparency about manufacturing methods and IP licensing. Conduct due diligence on suppliers, verify certifications independently, and consider partnering with established brands known for quality and IP integrity.

Logistics & Compliance Guide for SDR9 PEX

This guide outlines the key logistics and compliance considerations for handling, transporting, storing, and using SDR9 PEX (Cross-linked Polyethylene) piping systems in accordance with industry standards and regulatory requirements.

Product Handling & Storage

- Temperature Control: Store SDR9 PEX tubing in a dry, well-ventilated area away from direct sunlight. Maintain storage temperatures between 40°F (4°C) and 100°F (38°C) to prevent material degradation.

- UV Protection: Limit exposure to ultraviolet (UV) radiation. If outdoor storage is unavoidable, cover coils or reels with opaque UV-blocking material; do not exceed 60 days of outdoor exposure.

- Coil Management: Store PEX coils vertically on pallets or racks to prevent deformation. Avoid stacking heavy materials on top of PEX products.

- Freeze Protection: Ensure product is not exposed to freezing conditions during transport or storage, as moisture ingress can lead to internal damage upon freezing.

Transportation Requirements

- Loading Practices: Secure PEX coils or reels during transit to prevent shifting, rolling, or impact damage. Use straps and edge protectors to avoid crushing.

- Moisture Prevention: Cover loads during transport to protect from rain, snow, or condensation, especially in humid environments.

- Compatibility: Do not transport PEX tubing alongside chemicals, solvents, or petroleum-based products that may compromise material integrity through off-gassing or leakage.

Regulatory & Code Compliance

- NSF/ANSI 61 Certification: Confirm SDR9 PEX is certified to NSF/ANSI 61 for drinking water applications. Documentation must be available upon request for inspection or project approval.

- Uniform Plumbing Code (UPC) & International Plumbing Code (IPC): Installation must comply with local jurisdiction requirements based on UPC or IPC standards, including proper support spacing, connection methods, and expansion allowances.

- Manufacturer Specifications: Always follow the PEX manufacturer’s installation guidelines, including minimum bend radius, maximum operating pressure (typically up to 160 psi at 73°F), and temperature limits (usually up to 200°F for hot water).

- Local Authority Approvals: Verify acceptance of SDR9 PEX with local building departments, especially where specific piping materials or pressure ratings are mandated.

Installation & Field Compliance

- Proper Support: Install supports at intervals not exceeding 32 inches for horizontal runs and 10 feet for vertical runs, per IPC standards, to prevent sagging or stress.

- Expansion & Contraction: Allow for thermal movement by using expansion loops, offsets, or manufacturer-recommended fittings, particularly in long straight runs or high-temperature applications.

- Connection Methods: Use only fittings and tools approved for PEX (e.g., crimp, clamp, or expansion systems). Inspect all connections for proper installation using go/no-go gauges where applicable.

- Pressure Testing: Perform hydrostatic pressure testing at 1.5 times the system’s maximum working pressure (but not less than 180 psi) for a minimum of two hours before wall concealment.

Documentation & Traceability

- Mill Certifications: Retain material test reports and certification documents (e.g., NSF, ASTM F876/F877) for each batch delivered to site.

- Lot Tracking: Maintain records of lot numbers and installation locations to support traceability in case of recalls or quality investigations.

- Inspection Logs: Document all inspections, pressure tests, and compliance verifications for project handover and auditing purposes.

Environmental & Safety Compliance

- Waste Management: Dispose of damaged or excess PEX tubing in accordance with local solid waste regulations. PEX is not biodegradable but may be recyclable through designated plastic recycling programs.

- Worker Safety: Ensure installers use appropriate PPE (gloves, eye protection) when cutting or handling PEX to prevent lacerations or debris exposure.

- Ventilation: When using PEX in enclosed spaces during installation, ensure adequate ventilation, particularly if using adhesives or sealants nearby.

Adhering to this logistics and compliance guide ensures the safe, efficient, and code-compliant use of SDR9 PEX in residential, commercial, and industrial plumbing systems. Always consult the latest manufacturer instructions and local codes prior to installation.

Conclusion for Sourcing SDR9 PEX:

After a thorough evaluation of the market and suppliers, sourcing SDR9 PEX (Cross-linked Polyethylene) tubing proves to be a viable and advantageous option for applications requiring higher pressure ratings and durability, such as potable water distribution, radiant heating, and certain industrial systems. SDR9’s thicker wall design compared to higher SDR ratings provides enhanced strength and resistance to mechanical stress, making it particularly suitable for demanding environments.

Key findings indicate that reliable sourcing is achievable through certified manufacturers and distributors adhering to ASTM F876 and F877 standards, ensuring material quality and performance. Major suppliers in North America and Europe offer SDR9 PEX in various grades (e.g., PEX-a, PEX-b, PEX-c), with availability influenced by regional demand and production capacity.

Cost considerations show that SDR9 PEX is typically priced higher than standard SDR11 or SDR13.5 due to increased material use, but the added robustness may offer long-term savings through reduced failure rates and longer service life. Logistical factors, lead times, and volume discounts should be negotiated to optimize procurement efficiency.

In conclusion, sourcing SDR9 PEX is recommended for projects where pressure performance and reliability are critical. Partnering with reputable, ISO-certified suppliers and verifying product compliance with applicable standards will ensure a successful and sustainable supply chain.