The global foam materials market is experiencing robust growth, driven by rising demand across industries such as furniture, automotive, packaging, and healthcare. According to Grand View Research, the global flexible foam market size was valued at USD 55.6 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2030. This growth is fueled by increasing urbanization, evolving consumer preferences for comfort-oriented products, and advancements in material science. Scrim foam—reinforced foam with a layer of fabric or mesh for enhanced durability and tear resistance—has emerged as a critical material in applications requiring structural integrity and longevity. As demand for high-performance foam solutions intensifies, manufacturers are scaling production capabilities, investing in R&D, and expanding geographically to capture growing market opportunities. In this competitive landscape, the following eight companies have distinguished themselves as leading scrim foam manufacturers based on innovation, product breadth, global reach, and manufacturing excellence.

Top 8 Scrim Foam Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Scrim

Domain Est. 1996

#2 Scrim and Roll Foam

Domain Est. 1997

Website: keystonbros.com

Key Highlights: Scrim and Roll Foam ; SCRIM FOAM 1/8″ ANTI-MICROBIAL. Compare. FOM18AM. Sew Foam – Anti-Microbial – 1/8″ x 56″ x 50 yd Rolls. In Stock – Nationwide*. UOM : YD….

#3 Carolina Gym Supply Scrim Back Foam

Domain Est. 1997

Website: carolinagym.com

Key Highlights: Use the Carolina Gym Supply Scrim Back Foam to prevent foam from splitting over the fiberglass rods of your rod floor. Order Today From Carolina Gym Supply….

#4 F.P. Woll & Company of Philadelphia, PA

Domain Est. 2000

Website: fpwoll.com

Key Highlights: F. P. Woll & Company has been providing custom packaging and cushioning solutions for almost 100 years….

#5 Scrim Foam

Domain Est. 2002

#6 Foam Scrim Roll

Domain Est. 2003

Website: a1foamandfabrics.com

Key Highlights: In stock $22.46 deliveryScrim backed foam is primarily used for Automotive Interior seating & general upholstery.It is available in 56″ width and comes 1/4″ & 1/2″ by the yard or ….

#7 1/4 inch Sew Foam High Grade

Domain Est. 2009

Website: dltcorporation.com

Key Highlights: In stock Free delivery over $150Foam with scrim backing to be used for sewing channels in auto seats, boat seats. Our Pink colored scrimback foam is a perfect 1/4” high-grade sew …

#8 Galaxy Foam Rolls with Scrim

Domain Est. 2020

Expert Sourcing Insights for Scrim Foam

H2: 2026 Market Trends for Scrim Foam

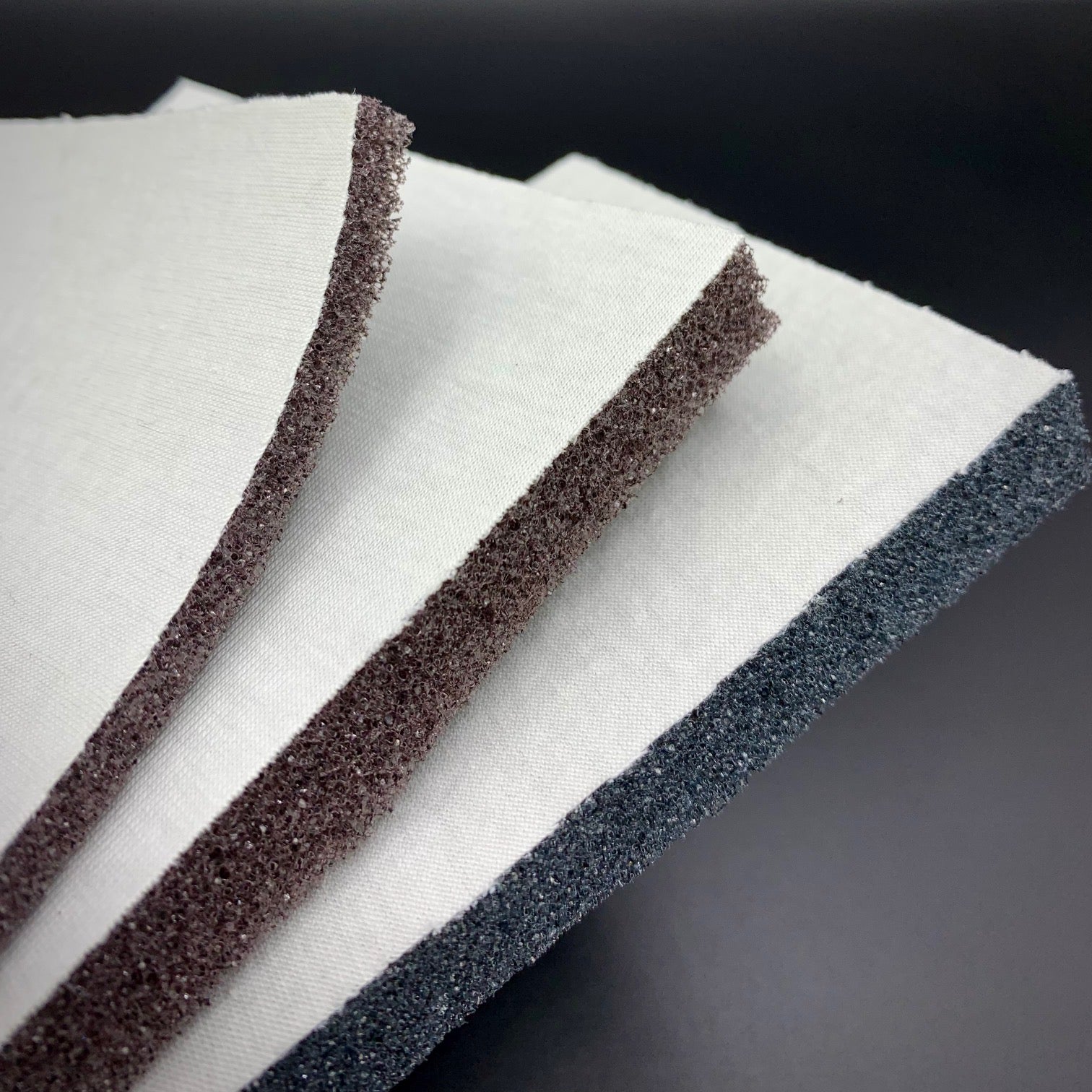

The global scrim foam market is poised for notable transformation by 2026, driven by evolving industrial demands, sustainability initiatives, and technological advancements in material science. Scrim foam—a composite material consisting of a foam layer bonded with a reinforcing scrim (typically polyester or fiberglass for added strength and dimensional stability)—is widely used in applications such as upholstery, automotive interiors, packaging, insulation, and medical equipment. The following analysis outlines key market trends expected to shape the scrim foam industry through 2026.

-

Rising Demand in the Automotive Sector

The automotive industry is projected to be a major growth driver for scrim foam. With the increasing production of electric vehicles (EVs), manufacturers are prioritizing lightweight, durable, and acoustically efficient materials. Scrim foam offers enhanced structural integrity and sound dampening properties, making it ideal for EV seating, headliners, and door panels. By 2026, demand from automotive OEMs is expected to surge, particularly in North America, Europe, and emerging markets in Southeast Asia. -

Expansion in Furniture and Bedding Industries

The global furniture and bedding markets are experiencing a revival post-pandemic, with increased consumer spending on home comfort and ergonomic design. Scrim-reinforced foam is widely used in premium mattresses and upholstered furniture due to its durability and resistance to sagging. As consumers shift toward long-lasting, high-performance products, scrim foam adoption is anticipated to grow, especially in the e-commerce-driven DTC (direct-to-consumer) mattress segment. -

Emphasis on Sustainability and Recyclability

Environmental regulations and consumer preferences are pushing manufacturers to develop eco-friendly scrim foam solutions. By 2026, there will be a notable shift toward bio-based foams and recyclable scrims. Companies are investing in closed-loop production systems and exploring water-based adhesives to reduce volatile organic compound (VOC) emissions. Certifications such as Greenguard and OEKO-TEX are becoming critical for market entry, particularly in Europe and North America. -

Technological Innovation in Material Engineering

Advancements in foam lamination techniques and scrim integration are enhancing product performance. Innovations such as 3D-knitted scrims, antimicrobial coatings, and phase-change materials (PCMs) embedded in foam are expected to gain traction. These developments cater to specialized applications in healthcare (e.g., pressure-relief mats) and high-performance sports equipment, expanding the addressable market for scrim foam. -

Regional Market Dynamics

Asia-Pacific is anticipated to dominate the scrim foam market by 2026, fueled by rapid industrialization, urbanization, and a growing middle class in countries like China, India, and Vietnam. The region is also becoming a manufacturing hub for automotive and furniture exports, further boosting local demand. Meanwhile, North America and Europe will focus on high-value, specialty scrim foam products, with strong regulatory support for sustainable materials. -

Supply Chain and Raw Material Challenges

Volatility in petrochemical prices—key for polyurethane foam production—and supply chain disruptions could impact profitability. However, by 2026, increased regionalization of supply chains and investments in alternative feedstocks (e.g., soy-based polyols) are expected to mitigate these risks. Strategic partnerships between scrim producers and foam manufacturers will become more common to ensure consistent quality and supply.

Conclusion

By 2026, the scrim foam market will be shaped by innovation, sustainability, and expanding end-use applications. Companies that invest in R&D, adopt circular economy principles, and align with regional regulatory frameworks will be best positioned to capture growth. As industries from automotive to healthcare increasingly recognize the value of reinforced foam solutions, scrim foam is expected to transition from a niche material to a cornerstone of modern material design.

Common Pitfalls When Sourcing Scrim Foam: Quality and Intellectual Property Concerns

Sourcing scrim foam—commonly used in upholstery, bedding, packaging, and automotive applications—can present several challenges, particularly regarding material quality consistency and intellectual property (IP) risks. Being aware of these pitfalls helps ensure reliable supply and protects your business from legal and reputational damage.

Inconsistent Material Quality

One of the most frequent issues when sourcing scrim foam is variability in product quality. Scrim foam consists of polyurethane or polyethylene foam laminated with a reinforcing scrim layer (typically polyester or fiberglass), and inconsistencies can arise at multiple levels:

- Foam Density and Compression Resistance: Suppliers may use substandard foam with lower density than specified, leading to poor durability and reduced load-bearing capacity.

- Scrim Adhesion: Poor lamination techniques can result in delamination under stress or over time, especially in high-humidity or high-temperature environments.

- Thickness Tolerances: Off-spec thickness affects fit and performance, particularly in precision applications like automotive seating or medical devices.

- Raw Material Substitution: Some manufacturers may substitute cheaper raw materials (e.g., recycled content without disclosure), affecting flame resistance, odor, or long-term resilience.

To mitigate this, require material certifications (e.g., ASTM, ISO), conduct batch testing, and perform on-site audits of supplier facilities.

Intellectual Property (IP) Infringement Risks

Scrim foam technology often involves proprietary formulations, lamination processes, or performance characteristics protected by patents or trade secrets. Sourcing from unethical or uninformed suppliers can expose your company to IP violations:

- Patented Foam Formulations: Some high-performance scrim foams use patented chemical blends or blowing agents. Sourcing knock-offs may infringe on existing patents, especially from major chemical companies like BASF or Dow.

- Proprietary Lamination Techniques: Unique methods of bonding scrim to foam can be patented. Using a supplier that replicates these processes without licensing can lead to legal action.

- Counterfeit or Gray Market Materials: Some suppliers may offer branded scrim foam (e.g., Evazote®, Volara®) at suspiciously low prices, which could be counterfeit or diverted from authorized channels, increasing IP and liability risks.

- Lack of IP Warranty: Many suppliers, especially offshore ones, do not provide IP indemnification, leaving the buyer liable in case of infringement claims.

To avoid IP issues, vet suppliers thoroughly, request proof of licensing for branded materials, include IP warranties in contracts, and consider working with legal counsel to perform freedom-to-operate analyses when developing new products.

By addressing both quality control and intellectual property due diligence, companies can reduce risk and ensure a reliable, compliant supply of scrim foam.

Logistics & Compliance Guide for Scrim Foam

Scrim foam is a versatile material commonly used in packaging, construction, furniture, and automotive industries. Due to its physical properties and potential regulatory considerations, proper logistics and compliance handling are essential for safe transportation, storage, and legal conformity. This guide outlines key procedures and requirements.

Product Overview

Scrim foam consists of a foam core (typically polyethylene or polyurethane) laminated with a reinforcing scrim fabric (often polyester or fiberglass). This combination enhances tear resistance and durability. Variants may include flame-retardant (FR), anti-static, or low-emission formulations, each with specific handling and compliance needs.

Storage Requirements

Store scrim foam in a clean, dry, and well-ventilated area away from direct sunlight and extreme temperatures. Ideal storage conditions are between 10°C and 30°C (50°F–86°F) with relative humidity under 60%. Rolls or sheets should be stored vertically on pallets or racks to prevent deformation. Avoid stacking heavy materials on top of foam products to maintain shape and integrity.

Handling & Packaging

Use appropriate lifting equipment (e.g., forklifts with drum clamps or roll handlers) when moving large rolls to prevent physical damage. Protect edges and ends with corner boards or edge protectors. Wrap material in polyethylene or kraft paper to shield against dust, moisture, and UV degradation. Clearly label packages with product details, batch numbers, and handling instructions (e.g., “This Side Up,” “Do Not Stack”).

Transportation Guidelines

Secure scrim foam loads to prevent shifting during transit. Use straps, shrink wrap, or load locks to stabilize pallets. Avoid exposure to rain, snow, or high humidity during loading/unloading and transport. If shipping internationally, ensure packaging meets ISPM 15 standards if using wooden pallets. Consider temperature-controlled transport for sensitive or flame-retardant grades.

Regulatory Compliance

Compliance depends on the foam type and region. Key considerations include:

- Flame Retardancy: If the scrim foam is FR-treated, it must comply with relevant fire safety standards such as:

- USA: CAL 117, NFPA 701, or ASTM E84

- EU: EN 13501-1 (Euroclass B-s1, d0 for example)

-

Provide test reports and labeling as required.

-

REACH & RoHS (EU): Ensure compliance with REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) and RoHS (Restriction of Hazardous Substances) if applicable, especially for electronic or indoor applications.

-

VOC Emissions: For indoor use, confirm low VOC emissions per standards like:

- GREENGUARD Gold or CertiPUR-US®

-

EU Ecolabel or AgBB Scheme (Germany)

-

REACH SVHC: Declare any Substances of Very High Concern above 0.1% w/w in the final product.

Safety Data Sheet (SDS)

Maintain an up-to-date Safety Data Sheet (SDS) compliant with GHS (Globally Harmonized System). The SDS should include handling precautions, first aid measures, fire-fighting instructions, and disposal recommendations. Provide SDS to customers and logistics partners upon request.

Import/Export Documentation

For international shipments, ensure the following documents are prepared:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Test Reports (e.g., fire, flammability, RoHS)

- SDS (if required by destination country)

Verify tariff classifications (HS Code) — commonly 3921.13 or 5903.20 depending on composition — and confirm any import restrictions or duties.

Environmental & Disposal Compliance

Scrim foam is generally non-hazardous but not always recyclable due to composite structure. Dispose of waste in accordance with local regulations. Incineration should only occur in approved facilities with proper emission controls. Encourage customers to explore recycling programs for foam materials where available.

Quality Assurance & Traceability

Implement batch tracking to ensure full traceability. Record lot numbers, production dates, and test results. Conduct periodic audits of storage and handling practices to maintain product integrity and compliance.

Training & Documentation

Train warehouse and logistics staff on proper handling, storage, and emergency procedures. Maintain records of training, inspections, and compliance certifications for audit purposes.

By following this guide, businesses can ensure the safe, legal, and efficient logistics of scrim foam products across the supply chain.

Conclusion for Sourcing Scrim Foam:

After a thorough evaluation of suppliers, material quality, cost, and availability, it is evident that sourcing scrim foam requires a balanced approach that considers both performance requirements and budget constraints. High-quality scrim-reinforced polyurethane foam offers superior durability, tear resistance, and longevity, making it ideal for applications in upholstery, bedding, packaging, and automotive interiors.

Key factors in successful sourcing include verifying foam density, thickness consistency, scrim adhesion strength, and fire retardancy compliance with industry standards. Establishing relationships with reputable suppliers—whether domestic or international—ensures reliable lead times, consistent quality control, and scalability.

Moreover, sustainable sourcing practices, such as opting for recycled or low-VOC materials, can align with environmental goals and enhance brand reputation.

In conclusion, an effective scrim foam sourcing strategy combines due diligence in supplier selection, clear specification of technical requirements, and a focus on long-term value over initial cost. This approach ensures optimal product performance, customer satisfaction, and operational efficiency.