The global screw rod market is experiencing steady expansion, driven by rising demand across construction, automotive, and industrial manufacturing sectors. According to a 2023 report by Mordor Intelligence, the global threaded rod market was valued at USD 6.8 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.2% from 2023 to 2028. This growth is fueled by infrastructure development in emerging economies, increased adoption in seismic retrofitting, and stricter building codes requiring high-tensile fastening solutions. Additionally, Grand View Research highlights the expanding use of corrosion-resistant and high-strength alloy screw rods in industrial applications as a key market driver. With these dynamics shaping the industry landscape, identifying leading manufacturers becomes critical for procurement teams and project planners seeking reliable, high-performance fastening solutions.

Top 10 Screw Rod Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Threaded Rod

Domain Est. 1997

Website: vulc.com

Key Highlights: Vulcan Steel Products is the nation’s largest domestic manufacturer and supplier of threaded products. Vulcan’s success is not just coincidence….

#2 Dependable Acme Threaded Products

Domain Est. 2000

Website: dependableacme.com

Key Highlights: We are the manufacturers of ACME threaded screws, ACME rods and nuts. We have been manufacturing these items for over 65 years….

#3 Threaded Rod Manufacturer

Domain Est. 2000

Website: baystandard.com

Key Highlights: We are the largest manufacturer of threaded rod in the Western United States producing more than 2 million pounds of finished product a month….

#4 Rod Manufacturer

Domain Est. 2021

Website: gobigbolt.com

Key Highlights: Big Bolt manufactures low-carbon stainless steel and B7 rods. We offer right-hand threaded and left-hand threaded ACME rods. We can manufacture in custom ……

#5 Leading Threaded Rod Manufacturers

Website: screwmachinecompanies.com

Key Highlights: Locate the leading threaded rod manufacturers and suppliers in the USA whose companies are ISO certified, and have many years of experience….

#6 Keystone Threaded Products

Domain Est. 1997

Website: keystonethreaded.com

Key Highlights: We have unparalleled roll threading capabilities and can create a wide variety of threading products, from Acme threaded bars to specialty forms….

#7 Coach Screw Rod

Domain Est. 1998

Website: phd-mfg.com

Key Highlights: Designed for use as a vertical hanger attachment to wood structures. Material: Carbon steel Finish: Plain or electro-galvanized…

#8 Threaded Rod

Domain Est. 2002

Website: allfasteners.com

Key Highlights: 4-day delivery 30-day returnsFrom pre galvanized to stainless steel, Allfasteners has the range of threaded rod you need to complete your next project. Check out our line of zinc, …

#9 All Thread Rod

Domain Est. 2013

Website: allthreadrod.com

Key Highlights: Cut thread all thread rod is manufactured for special grades of steel that are not mass produced. These rods are cut slightly longer than the finished length, ……

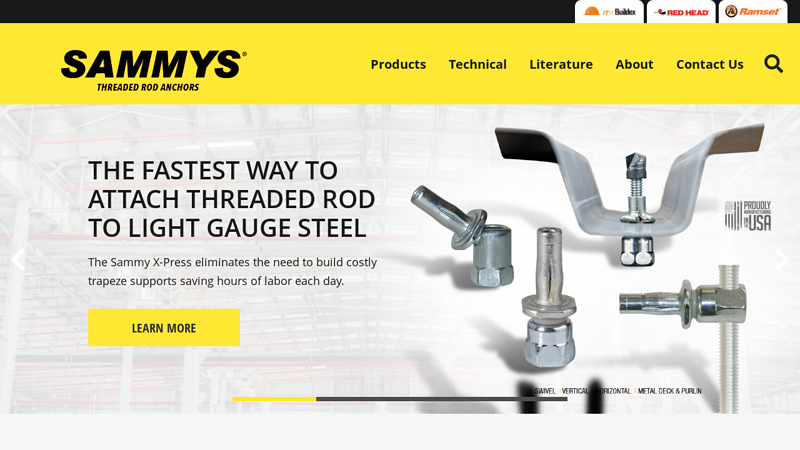

#10 Sammys Anchors

Domain Est. 2018

Website: sammysanchors.com

Key Highlights: Sammys has revolutionized threaded rod hanging on jobsites across America saving countless hours in labor on Fire Sprinkler, Electrical, and HVAC projects….

Expert Sourcing Insights for Screw Rod

2026 Market Trends for Screw Rod (H2 Analysis)

Based on current industry trajectories and forward-looking indicators, the global Screw Rod market in the second half of 2026 (H2 2026) is projected to experience sustained growth, driven by technological innovation, evolving industrial demands, and strategic regional developments. Key trends shaping the market include:

1. Accelerated Adoption of High-Performance Materials & Coatings: H2 2026 will see a significant shift towards advanced materials. Demand for screw rods made from corrosion-resistant alloys (e.g., duplex stainless steels), wear-resistant coatings (like DLC – Diamond-Like Carbon), and high-tensile strength steels will surge. This is primarily driven by industries requiring longer service life, reduced maintenance (especially in automation and robotics), and operation in harsh environments (offshore, chemical processing). Titanium and composite screw rods, while niche, will gain traction in aerospace and high-end medical applications.

2. Dominance of Precision and Miniaturization in Automation & Electronics: The relentless push towards Industry 4.0 and advanced manufacturing will intensify demand for ultra-precision ball screw rods and lead screw rods with micron-level accuracy and repeatability. Miniaturization trends in electronics assembly, semiconductor manufacturing, and medical devices will drive the market for compact, high-efficiency screw rod systems with improved load capacity in smaller form factors. Integration with smart sensors for real-time monitoring (position, temperature, wear) will become a key differentiator.

3. Strategic Regional Manufacturing Shifts & Supply Chain Resilience: Geopolitical factors and the push for supply chain security will solidify manufacturing hubs. North America (particularly the US) will see growth in high-precision screw rod production for defense, aerospace, and reshored manufacturing. Southeast Asia (Vietnam, Thailand) will emerge as a key production and consumption center, fueled by electronics and automotive assembly. China will maintain dominance in volume production but increasingly focus on high-value, technologically advanced screw rods to move up the value chain. Nearshoring and dual-sourcing strategies will be prevalent among major industrial consumers.

4. Sustainability and Energy Efficiency as Competitive Imperatives: Environmental regulations and corporate ESG goals will influence screw rod design and manufacturing. Demand will grow for screw rods with lower friction coefficients (reducing energy consumption in linear motion systems) and manufactured using sustainable processes (renewable energy, reduced waste, recyclable materials). Lifecycle analysis (LCA) will become a crucial factor in procurement decisions for large industrial clients.

5. Digitalization and Integration with Smart Systems: Screw rod suppliers will increasingly offer integrated digital solutions. This includes digital twins for predictive maintenance, IoT-enabled screw rod assemblies providing real-time performance data, and compatibility with industrial IoT platforms. This trend will blur the lines between component supplier and system integrator, creating new revenue streams through data-driven services.

Conclusion: H2 2026 will mark a period of maturation and specialization for the screw rod market. Success will hinge on innovation in materials and precision, strategic geographical positioning, a strong focus on sustainability and energy efficiency, and the ability to leverage digital technologies. While traditional industrial sectors remain core, growth will be disproportionately driven by high-tech applications in automation, electronics, and advanced manufacturing. Suppliers failing to adapt to these trends risk commoditization, while those embracing them will capture significant value.

Common Pitfalls When Sourcing Screw Rods: Quality and Intellectual Property Concerns

Sourcing screw rods, especially for precision applications in industries like automation, aerospace, or machinery, involves navigating several potential pitfalls. Two critical areas where buyers often encounter challenges are product quality and intellectual property (IP) risks. Understanding these pitfalls can help procurement teams and engineers make informed decisions and avoid costly mistakes.

Quality-Related Pitfalls

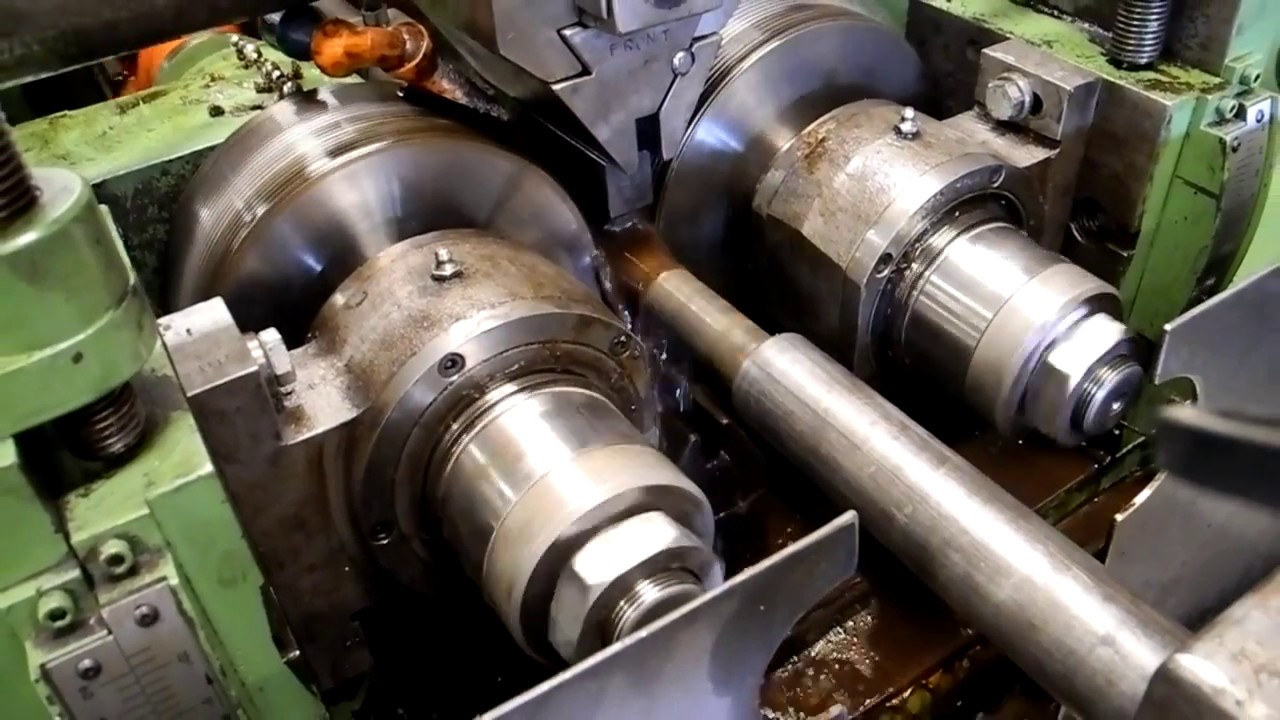

One of the most prevalent issues when sourcing screw rods—particularly from low-cost manufacturers or unfamiliar suppliers—is inconsistent or substandard quality. Screw rods require high precision in thread geometry, material composition, hardness, and surface finish to perform reliably under load and over time.

- Inadequate Material Specifications: Some suppliers may use inferior-grade steel or fail to meet required hardness standards (e.g., HRC ratings), leading to premature wear, deformation, or failure.

- Poor Thread Accuracy: Inaccurate pitch, lead error, or non-compliance with international standards (e.g., ISO, DIN, or ANSI) can result in poor fit, increased friction, and reduced efficiency in motion systems.

- Lack of Heat Treatment Documentation: Proper heat treatment is essential for durability. Suppliers may skip or inadequately perform this step, and without proper certification, it’s difficult to verify.

- Insufficient Surface Finish and Corrosion Protection: Poor plating or coating can lead to rust or galling, especially in humid or corrosive environments.

- Inconsistent Tolerances: Variability from batch to batch affects interchangeability and system performance, particularly in CNC or linear motion applications.

To mitigate these risks, buyers should demand material certs, conduct third-party inspections, and consider working with suppliers who adhere to ISO 9001 or other quality management systems.

Intellectual Property (IP) Risks

Another significant, often overlooked pitfall in sourcing screw rods—especially ball screw assemblies or precision lead screws—is the risk of infringing on intellectual property rights.

- Counterfeit or Reverse-Engineered Products: Some suppliers, particularly in regions with weak IP enforcement, may produce copies of patented screw rod designs (e.g., proprietary ball recirculation systems or thread profiles) without authorization.

- Use of Branded Components Without Licensing: A supplier might incorporate OEM-designed components (e.g., rebranded ball nuts from well-known brands like THK, HIWIN, or NSK) into their assemblies, misleading buyers about origin and authenticity.

- Lack of IP Warranty: Many low-cost suppliers do not provide legal guarantees that their products don’t infringe on existing patents, leaving the buyer exposed to litigation if used in commercial products.

To protect against IP violations, buyers should:

– Conduct due diligence on supplier legitimacy.

– Request IP indemnification clauses in contracts.

– Avoid suppliers offering “compatible” or “equivalent” versions of patented designs at suspiciously low prices.

– Work with reputable manufacturers who design and patent their own technology.

In conclusion, while cost savings are important, compromising on quality or overlooking IP risks when sourcing screw rods can lead to long-term reliability issues, legal liabilities, and reputational damage. A strategic sourcing approach that emphasizes verification, certification, and supplier transparency is essential.

Logistics & Compliance Guide for Screw Rod

Overview

Screw rods, also known as threaded rods or all-thread rods, are widely used in construction, manufacturing, and mechanical applications for fastening and structural support. Proper logistics handling and compliance with international and local regulations are essential to ensure safe, timely, and legal transportation and use.

Packaging & Handling

- Protective Packaging: Screw rods should be bundled and wrapped in plastic or protective coating to prevent corrosion and surface damage. Use end caps on threaded ends to avoid deformation.

- Bundling: Typically bundled in standard lengths (e.g., 1m, 2m, 3m) with steel or plastic strapping. Bundles must be secured to prevent shifting during transit.

- Labeling: Clearly label each bundle with product specifications (diameter, length, material grade, thread type), batch number, and handling instructions (e.g., “Do Not Stack,” “Keep Dry”).

- Storage: Store in dry, ventilated areas off the ground. Avoid exposure to moisture and corrosive environments to prevent rusting.

Transportation Requirements

- Domestic Transport: Secure loads on pallets or in crates to prevent movement. Comply with local road or rail safety regulations regarding load dimensions and securing methods.

- International Shipping:

- Use seaworthy packaging for ocean freight.

- Declare accurate weight, volume, and packaging type for container loading (FCL or LCL).

- Ensure compliance with IMDG Code if transporting hazardous-coated rods (e.g., oil-based anti-rust treatment).

- Air Freight: Not typically used due to weight and cost, but if required, comply with IATA dangerous goods regulations if applicable.

Regulatory Compliance

- Material Standards: Screw rods must meet recognized standards such as:

- ASTM A307 (General Purpose Carbon Steel Threaded Rod)

- ASTM A193 (Alloy Steel and Stainless Steel Bolting for High-Temperature Service)

- ISO 898-1 (Mechanical properties of fasteners)

- DIN 975 (Metric Threaded Rod)

- Certifications: Provide Mill Test Certificates (MTC) or Certificate of Conformance (CoC) upon request.

- REACH & RoHS: Ensure compliance with EU regulations regarding restricted substances, especially for rods exported to Europe.

- Customs Documentation:

- Commercial Invoice

- Packing List

- Bill of Lading or Air Waybill

- Certificate of Origin

- Product-specific certifications (if required by destination country)

Import/Export Controls

- HS Code Classification: Use appropriate Harmonized System (HS) code for screw rods (e.g., 7318.15 for threaded steel rods). Accurate classification affects tariffs and import duties.

- Export Licensing: Generally not required for standard screw rods, but verify if rods are made from restricted materials or intended for sanctioned regions.

- Country-Specific Regulations: Some countries may require additional testing or certification (e.g., Saudi Arabia SASO, India BIS).

Quality & Safety Compliance

- Inspection: Conduct pre-shipment inspection for thread integrity, dimensional accuracy, and surface quality.

- Traceability: Maintain lot traceability through batch coding and documentation.

- Handling Safety: Provide safety data sheets (SDS) if rods are coated with chemicals. Train personnel on safe handling to prevent cuts from sharp threads.

Environmental & Sustainability Considerations

- Recyclability: Steel screw rods are 100% recyclable. Promote recycling of packaging materials.

- Eco-Friendly Coatings: Use water-based or non-toxic anti-corrosion coatings where possible to meet environmental standards.

Conclusion

Effective logistics and compliance for screw rods require attention to packaging, international standards, documentation, and regulatory requirements. Adhering to this guide ensures product integrity, legal compliance, and customer satisfaction across global supply chains.

Conclusion for Sourcing Screw Rods:

In conclusion, sourcing screw rods requires a strategic approach that balances quality, cost, material specifications, and supplier reliability. Critical factors such as thread accuracy, tensile strength, corrosion resistance, dimensional tolerance, and compliance with international standards (e.g., ISO, DIN, ASTM) must be carefully evaluated to ensure the screw rods meet the intended application’s performance requirements.

Establishing partnerships with reputable suppliers—either local or global—with proven track records in delivering consistent quality and on-time delivery is essential. Additionally, considering total cost of ownership, including shipping, lead times, and potential risks such as supply chain disruptions, can significantly impact long-term success.

By conducting thorough supplier assessments, leveraging competitive quotations, and implementing rigorous quality control processes, organizations can secure reliable screw rod supply chains that support operational efficiency and product integrity. Ultimately, effective sourcing not only reduces costs but also enhances the overall reliability and performance of mechanical systems in which screw rods are utilized.