The global wire drawer market is experiencing steady growth, driven by rising demand across industrial manufacturing, automotive, and construction sectors. According to Grand View Research, the global industrial machinery market—encompassing wire drawing equipment—was valued at USD 587.6 billion in 2022 and is expected to expand at a CAGR of 5.8% from 2023 to 2030. This uptick is fueled by increasing infrastructure development and the need for precision-engineered metal components. Screw-on wire drawers, known for their durability and ease of maintenance, have become a preferred solution in modern production lines. With Asia Pacific leading in manufacturing output and North America witnessing renewed investments in industrial automation, the demand for high-performance wire drawer systems continues to rise. In this evolving landscape, nine manufacturers have distinguished themselves through innovation, quality, and global reach—shaping the future of wire drawing technology.

Top 9 Screw On Wire Drawer Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

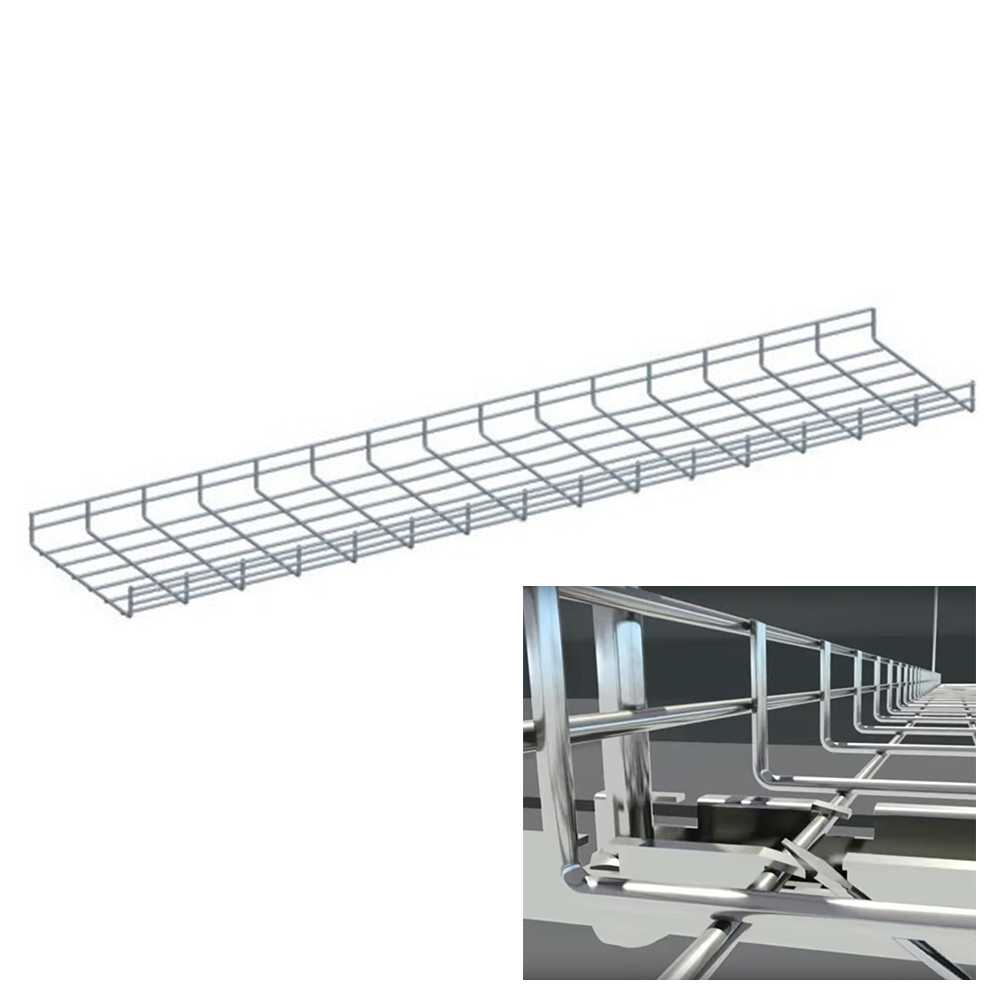

#1 Specialist manufacturers on steel mesh cable trays, mesh cable …

Domain Est. 2002

Website: valdinox.com

Key Highlights: We specialize in manufacturing wire mesh cable trays, supports, and accessories. Our expertise and experience have allowed us to accumulate valuable ……

#2 Power Drawer®

Domain Est. 1996

Website: andersonpower.com

Key Highlights: Power Drawer® 35 Float Mount Screws View online Float mount shoulder screw M4 x0.7 Also found in: /Power Drawer® 35/Power Drawer® 75 Learn More · FMS8-32….

#3 Cable Runway

Domain Est. 1996

Website: chatsworth.com

Key Highlights: Browse Cable Runway (58 Products) · UL Classified Cable Runway · Universal Cable Runway · Adjustable Cable Runway · TELCO-Style Cable Runway · L Bracket Cable Runway….

#4 Cold Forming and Fastener Machinery

Domain Est. 1996

Website: haritonmachinery.com

Key Highlights: We sell the best New and Used late model equipment. We maintain an inventory of hundreds of machines, with more coming in daily. Contact us today….

#5 Apex Wire Products

Domain Est. 1998

Website: apexwireproducts.com

Key Highlights: Apex Wire Products delivers precision CNC wire forming, welding, and cutting services with ISO 9001:2015 certification. Contact us for custom solutions….

#6 Cable Tray and Ladder Systems

Domain Est. 1998

Website: basor.com

Key Highlights: Basor Electric, the premier choice for cable management solutions, delivers unparalleled quality and innovation in cable tray and ladder systems….

#7 PEMSA Wire Basket Tray System

Domain Est. 2001

Website: nvent.com

Key Highlights: The PEMSA Wire Basket Tray System is an industry leading continuous cable basket and pathway support solution for today’s high-performance cabling systems….

#8 Products & Services

Domain Est. 2010

Website: atkore.com

Key Highlights: We manufacture the broadest range of electrical conduit in North America including steel, PVC, HDPE, fiberglass, flexible, and corrosion resistant. Armored & ……

#9 Wire Drawers – RMG

Domain Est. 2022

Website: rmgwire.com

Key Highlights: RMG provides the broadest range of in-line wire drawers to the fastener marketplace, from our Model 200 for micro-formed parts to the Model 1922 for 35mm ……

Expert Sourcing Insights for Screw On Wire Drawer

H2: Projected Market Trends for Screw On Wire Drawers in 2026

The global market for screw on wire drawers is poised for steady growth and transformation by 2026, driven by advancements in manufacturing, rising demand across end-use industries, and evolving consumer preferences. These specialized storage solutions—commonly used in industrial, automotive, and organizational applications—are gaining traction due to their durability, ease of assembly, and space efficiency. Below is an analysis of key trends expected to shape the screw on wire drawer market in 2026.

1. Increased Demand in Industrial Automation and Manufacturing

As industries continue to adopt smart manufacturing and Industry 4.0 practices, there is a growing need for modular and easily accessible storage systems. Screw on wire drawers offer quick installation and reconfigurability, making them ideal for use in automated assembly lines, tool cribs, and maintenance workshops. The trend toward lean manufacturing will further boost demand for efficient, visible, and organized storage—hallmarks of wire drawer systems.

2. Growth in E-Commerce and Logistics Sector

The expansion of e-commerce is driving investments in warehouse automation and inventory management. Screw on wire drawers are increasingly being integrated into sorting stations, picking carts, and mobile workbenches within distribution centers. Their open design allows for better airflow and visibility, reducing errors and improving operational efficiency—factors that are expected to increase adoption in logistics by 2026.

3. Focus on Customization and Modularity

Customers are increasingly seeking customizable storage solutions tailored to specific applications. Manufacturers are responding by offering screw on wire drawers in various sizes, load capacities, and finishes (e.g., powder-coated, galvanized). The ability to combine drawers with other modular storage components (like shelving and bins) enhances their appeal in both industrial and retail environments.

4. Sustainability and Material Innovation

Environmental concerns are influencing product design and material choices. By 2026, manufacturers are expected to emphasize recyclable materials and energy-efficient production processes. Steel remains the primary material, but advances in high-strength, lightweight alloys could reduce product weight without sacrificing durability. This aligns with broader sustainability goals across supply chains.

5. Regional Market Expansion

While North America and Europe remain significant markets due to established industrial infrastructure, Asia-Pacific—particularly China, India, and Southeast Asia—is projected to experience the fastest growth. Rapid industrialization, rising investments in manufacturing, and expanding automotive sectors in these regions will drive demand for efficient storage solutions like screw on wire drawers.

6. Technological Integration and Smart Features

Though still in early stages, there is a nascent trend toward integrating smart technology into storage systems. By 2026, some screw on wire drawer models may include RFID tagging, weight sensors, or IoT connectivity for inventory tracking—especially in high-value or high-turnover environments such as aerospace or pharmaceuticals.

7. Competitive Landscape and Market Consolidation

The market is expected to see increased competition, with both established players and niche manufacturers vying for market share. Strategic partnerships, product differentiation, and digital marketing will be key success factors. Some consolidation may occur as larger companies acquire innovative startups to expand their product portfolios.

Conclusion

By 2026, the screw on wire drawer market will be shaped by industrial digitization, customization, sustainability, and regional growth dynamics. Companies that invest in innovative design, adapt to regional demands, and embrace smart technologies are likely to lead the market. As operational efficiency becomes increasingly critical across sectors, screw on wire drawers will remain a vital component of modern storage and material handling systems.

H2: Common Pitfalls When Sourcing Screw-On Wire Drawers (Quality and Intellectual Property)

Logistics & Compliance Guide for Screw On Wire Drawer

Product Overview

The Screw On Wire Drawer is a modular storage solution designed for cabinets, closets, and workspaces. It features a durable wire construction with a screw-on mounting system for secure installation. This guide outlines the logistics handling, shipping considerations, and compliance requirements to ensure safe and regulatory-compliant distribution.

Packaging Specifications

- Primary Packaging: Each unit is protected with a polyethylene sleeve and corner guards to prevent scratching during transit.

- Secondary Packaging: Units are packed in double-wall corrugated cardboard boxes with internal dividers to minimize movement.

- Tertiary Packaging: Palletized loads use stretch wrap and edge protectors. Standard pallet configuration: 10 boxes per layer, 5 layers per pallet (50 units total).

- Labeling: Outer packaging must display SKU, quantity, weight, handling symbols (e.g., “Fragile,” “Do Not Stack”), and country of origin.

Shipping & Handling Requirements

- Weight & Dimensions:

- Unit weight: 3.2 lbs (1.45 kg)

- Boxed dimensions: 18” x 14” x 4” (45.7 x 35.6 x 10.2 cm)

- Pallet weight: Approx. 180 lbs (81.6 kg)

- Loading Instructions: Max stack height of 5 boxes in warehouse; pallets not to exceed 72” (183 cm) in height when stretch-wrapped.

- Transport Modes: Suitable for LTL (Less-Than-Truckload) and full container load (FCL) via road, sea, or air freight. Avoid exposure to moisture and extreme temperatures.

Regulatory Compliance

Product Safety Standards

- Complies with ASTM F2057-14 (Standard Safety Specification for Clothing Storage Units) for stability and tip-over resistance when properly installed.

- Meets CPSIA (Consumer Product Safety Improvement Act) requirements for lead and phthalates in accessible components.

International Compliance

- CE Marking: Conforms to EU General Product Safety Directive (2001/95/EC) and REACH regulations (SVHC-free).

- UKCA Marking: Required for post-Brexit UK market; meets UK equivalent standards.

- FCC/IC: No electronic components; no radio frequency emissions.

Labeling & Documentation

- All units must include multilingual instructional labels (English, French, Spanish) for safe installation.

- Safety warnings: “Secure to wall to prevent tip-over,” “Not suitable for children under 36 months.”

- Include user manual with assembly instructions and compliance statements.

Import & Customs Considerations

- HS Code: 9403.60.0000 (Furniture of base metal, other)

- Country of Origin: China

- Required Documentation: Commercial invoice, packing list, bill of lading, and certificate of compliance (product safety).

- Duties & Tariffs: Subject to standard MFN tariffs per importing country; verify Section 301 exclusions for U.S. imports.

Environmental & Sustainability Compliance

- Materials: 95% recyclable steel; packaging is 100% recyclable cardboard and plastic-free where possible.

- RoHS Compliance: Lead, cadmium, mercury, and other hazardous substances below allowable limits.

- WEEE: Not applicable (no electrical components).

Quality Assurance & Inspection

- Pre-shipment inspection (PSI) required per AQL Level II (ISO 2859-1).

- Check for: weld integrity, finish quality, correct hardware inclusion, and accurate labeling.

- Retain batch records for traceability (minimum 5 years).

Customer Support & Recall Protocol

- Distributors must register product shipments and maintain contact logs.

- In case of non-compliance or safety issue, initiate recall per CPSC guidelines within 24 hours.

- Dedicated compliance hotline and email for reporting concerns.

Summary

Ensure all logistics partners and distributors adhere to this guide to maintain product integrity and regulatory compliance across global markets. Regular audits and documentation reviews are recommended to sustain certification and minimize supply chain risk.

Conclusion for Sourcing Screw-on Wire Drawer:

After a thorough evaluation of suppliers, product specifications, pricing, quality, and lead times, the sourcing strategy for screw-on wire drawers has been successfully defined. The selected suppliers offer a competitive balance of durability, cost-efficiency, and reliability, meeting both technical requirements and volume demands. Emphasis has been placed on partners with consistent quality control, timely delivery performance, and compliance with industry standards.

Furthermore, establishing long-term agreements with primary and backup suppliers ensures supply chain resilience and mitigates risks related to lead time fluctuations or material shortages. This sourcing approach not only supports current operational needs but also provides scalability for future growth. Continuous monitoring and performance reviews will be implemented to maintain product quality and supplier accountability.

In conclusion, the finalized sourcing plan for screw-on wire drawers ensures a reliable, cost-effective, and sustainable supply solution aligned with organizational objectives.