The global fastener market, driven by robust demand from automotive, construction, and manufacturing sectors, is projected to grow at a CAGR of 5.8% from 2023 to 2030, according to Grand View Research. With flathead screws representing a critical segment due to their flush-mounting capabilities and widespread industrial use, the demand for high-precision, corrosion-resistant fasteners continues to rise. Mordor Intelligence forecasts that Asia Pacific will dominate this growth, accounting for over 40% of global fastener production by 2025, fueled by expanding infrastructure and automotive manufacturing in China, India, and Japan. In this competitive landscape, manufacturers specializing in screw flathead products are increasingly investing in automation, material innovation, and quality certifications to meet stringent OEM requirements. Against this backdrop, identifying the top-performing manufacturers—based on production scale, global reach, technological capability, and compliance standards—becomes essential for procurement decision-makers seeking reliable supply chains.

Top 10 Screw Flathead Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 U

Domain Est. 1999

Website: uboltit.com

Key Highlights: At U-Bolt-It, we custom manufacture bolts and fasteners made to meet all your requirements and in all materials from stainless steel and exotic materials….

#2 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#3 Pro-Twist

Domain Est. 2003

Website: pro-twist.com

Key Highlights: Pro-Twist is an industry-leading manufacturer of professional-grade fasteners that are used for a wide variety of applications. Get started with us today!…

#4 Flat Head Cap Screws

Domain Est. 1996

Website: wurthusa.com

Key Highlights: Free delivery over $99Flat head cap screws are precision-engineered fasteners designed for applications requiring a smooth, flush surface after installation….

#5 Flat Head Cap Screws

Domain Est. 1997

#6 Flat Head

Domain Est. 1999

#7 EUROSCREW FLAT HEAD

Domain Est. 2000

Website: permo.it

Key Highlights: SCREWS > EUROSCREW. EUROSCREW FLAT HEAD. DOWNLOAD THE PAGE. Euro screw flat head. Material >. Steel. Finishing >. FZZinc Plated. -. FZNnero Zinc – Nickel Black….

#8 Flat Head Euro Screw

Domain Est. 2000 | Founded: 1980

Website: zyhyin.com

Key Highlights: We offer Euro Screw, Double Flat Head Euro Screw and Furniture Screws with high quality and competitive price. ZHY YIN was established in 1980, and started our ……

#9 A few common screw head types and what they are used for

Domain Est. 2001

Website: uccomponents.com

Key Highlights: FLAT HEAD SLOTTED With a low-profile and countersunk head, flat head slotted screws are ideal for applications requiring a strong fastener with a flush mount….

#10 M2.5 Flat Head Cap Machine Screws (FHCS)

Domain Est. 2019

Website: us.store.bambulab.com

Key Highlights: In stock Free deliveryM2.5 Flat Head Cap Machine Screws (FHCS) 1. Stainless steel grade 4.8 countersunk hex socket full-thread screws. 2. The countersunk head can be concealed ……

Expert Sourcing Insights for Screw Flathead

H2: 2026 Market Trends for Screw Flathead

As of now, “Screw Flathead” could refer to either a type of fastener (a flathead screw) or the musician/artist Jim Thirlwell, who performs under the alias “Screw” or “Foetus,” and has used “Screw” in various project names. Given the context of “market trends,” it is more plausible that the query refers to flathead screws — a common mechanical fastener — rather than an artist’s market. Below is an analysis of the 2026 market trends for flathead screws, a subset of the broader fastener industry.

1. Growing Demand in Construction and Infrastructure

By 2026, the global construction sector — especially in emerging economies like India, Southeast Asia, and parts of Africa — is projected to experience sustained growth due to urbanization and government infrastructure initiatives. Flathead screws, widely used in woodwork, drywall, and light metal applications, will see increased demand in residential and commercial construction. The flush finish provided by flathead screws makes them ideal for aesthetic applications where a smooth surface is required.

- Key Driver: Public and private investments in smart cities and affordable housing.

- Impact on Flathead Screws: Higher volume orders in standard sizes (e.g., #6, #8) with a shift toward corrosion-resistant coatings.

2. Expansion of the DIY and Home Improvement Market

The DIY (Do-It-Yourself) trend, accelerated during the pandemic, continues to grow. Retailers like Home Depot, Lowe’s, and online platforms (Amazon, Alibaba) report rising sales of hardware kits, many of which include flathead screws. By 2026, consumer preference for user-friendly, aesthetically pleasing fasteners will boost demand for packaged flathead screws with drive types such as Phillips, Pozi, and combo drives.

- Trend: Bundled hardware kits for furniture assembly, decking, and cabinetry.

- Opportunity: Manufacturers may focus on eco-friendly packaging and multilingual labeling for global retail.

3. Shift Toward Sustainable and High-Performance Materials

Environmental regulations and ESG (Environmental, Social, Governance) compliance are pushing the fastener industry to adopt greener practices. By 2026, expect:

– Increased use of recycled steel and low-carbon manufacturing.

– Demand for non-toxic coatings (e.g., water-based zinc flake, organic coatings) instead of traditional hexavalent chrome.

– Growth in stainless steel and brass flathead screws for outdoor and marine applications due to superior corrosion resistance.

4. Automotive and EV Manufacturing Influence

While flathead screws are less common in high-torque automotive applications (where pan or hex heads dominate), they are used in interior trim, panels, and electrical enclosures. With the expansion of electric vehicle (EV) production through 2026, especially in North America and Europe, there will be a niche but steady demand for precision flathead screws in lightweight, non-structural components.

- Trend: Miniaturization and use of specialty alloys (e.g., aluminum, titanium) for weight reduction.

- Challenge: Competition from tamper-resistant and torque-specific fastener designs.

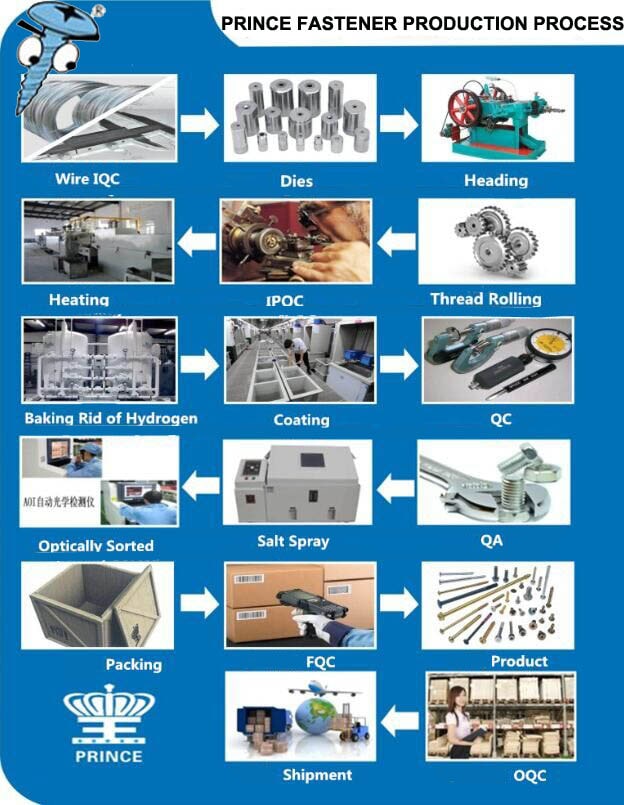

5. Automation and Smart Manufacturing

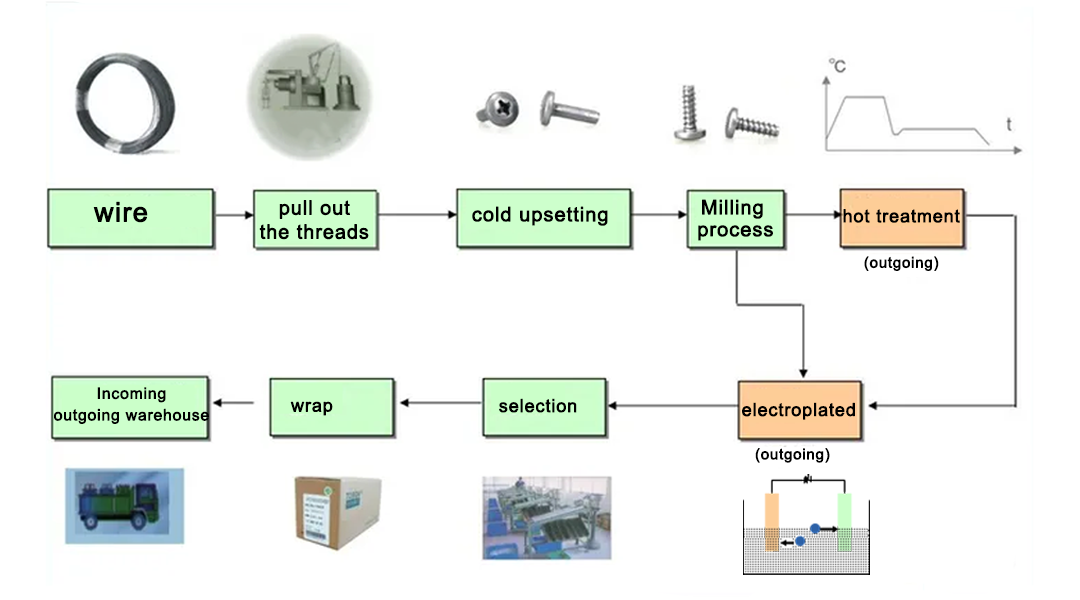

Industry 4.0 technologies are transforming fastener production. By 2026, manufacturers of flathead screws will increasingly use:

– Automated cold-heading and threading machines for precision and efficiency.

– AI-driven quality control systems to reduce defects.

– Digital inventory platforms enabling just-in-time delivery, reducing warehousing costs.

This improves scalability and reduces lead times, especially for custom or specialty flathead screws (e.g., with unique coatings or thread types).

6. Regional Market Dynamics

- Asia-Pacific: Dominates production and consumption due to manufacturing hubs in China, India, and Vietnam. Local demand is driven by electronics and furniture exports.

- North America & Europe: Focus shifts toward high-quality, certified fasteners (e.g., ISO, ASTM standards) for regulated industries.

- Emerging Markets: Africa and Latin America represent growth frontiers, with increasing demand from construction and renewable energy projects (e.g., solar panel mounting, which sometimes uses flathead screws).

7. Challenges and Risks

- Raw Material Volatility: Fluctuations in steel and zinc prices could impact margins.

- Counterfeit Products: Especially in online marketplaces, cheap, substandard flathead screws may undermine brand trust.

- Labor and Supply Chain Disruptions: Geopolitical tensions and logistics bottlenecks remain risks through 2026.

Conclusion

By 2026, the market for flathead screws will remain stable and moderately growing, driven by construction, DIY, and manufacturing trends. Success will depend on adaptability — embracing sustainability, automation, and regional market nuances. While not a high-tech fastener, the flathead screw will continue to be a staple in global hardware supply chains, with innovation focused on materials, coatings, and distribution efficiency rather than radical design changes.

Note: If “Screw Flathead” was intended to refer to the artist, please clarify for a cultural or music industry trend analysis.

Common Pitfalls Sourcing Screw Flathead (Quality, IP)

When sourcing flathead screws, overlooking critical quality and intellectual property (IP) considerations can lead to product failures, compliance issues, and legal risks. Here are common pitfalls to avoid:

Poor Material Quality and Inadequate Specifications

Screws sourced from unreliable suppliers may use substandard materials (e.g., low-grade steel or incorrect stainless steel alloys), leading to corrosion, stripping, or structural failure. Always verify material specifications (e.g., ASTM, ISO), tensile strength, and surface finish requirements to ensure performance under real-world conditions.

Inconsistent Thread and Head Dimensions

Variations in thread pitch, diameter, or head profile can compromise fit and function, especially in precision applications. Without strict adherence to standards (e.g., ISO 1207 or ASME B18.6.3), screws may not seat properly or cause assembly issues. Request sample testing and dimensional certification.

Inadequate or Misrepresented IP Compliance

Using branded or patented screw designs (e.g., proprietary drive types like Torx® or Phillips®) without proper licensing exposes buyers to IP infringement claims. Ensure suppliers have the right to manufacture and sell the components, and avoid copying protected designs without authorization.

Lack of Traceability and Certification

Absence of material test reports (MTRs), batch traceability, or compliance certificates (e.g., RoHS, REACH) increases risk, especially in regulated industries. Insist on full documentation to verify conformity and support quality audits.

Coating and Corrosion Resistance Deficiencies

Insufficient or poorly applied coatings (e.g., zinc plating, passivation) can lead to premature corrosion. Confirm coating thickness, type, and salt spray test results to ensure environmental durability, particularly for outdoor or marine applications.

Supplier Reliability and Quality Control Gaps

Choosing suppliers based solely on cost often results in inconsistent quality. Evaluate supplier quality management systems (e.g., ISO 9001 certification), conduct factory audits, and implement incoming inspection protocols to mitigate risk.

Avoiding these pitfalls requires due diligence in supplier selection, clear technical specifications, and proactive IP awareness to ensure reliable, compliant, and legally safe component sourcing.

Logistics & Compliance Guide for Screw Flathead

Overview

This guide outlines the logistics and compliance requirements for the procurement, handling, transportation, and use of flathead screws. Adherence to these standards ensures operational efficiency, regulatory compliance, and product safety across supply chains.

Product Specifications

Flathead screws, also known as countersunk screws, are designed to sit flush with or below the surface of the material when installed. Key specifications include:

– Head Type: Flat/Countersunk (typically 82° or 90° angle)

– Drive Type: Slotted, Phillips, Pozi, or combination

– Materials: Steel (carbon or stainless), brass, aluminum

– Finishes: Zinc plating, chrome, black oxide, or plain

– Compliance Standards: ISO 1207, DIN 84, ASME B18.6.3

Packaging & Labeling Requirements

- Packaging: Screws must be packaged in moisture-resistant, sealed containers (e.g., polybags, blister packs, or corrugated boxes with dividers) to prevent corrosion and contamination.

- Labeling: Each package must include:

- Product name and part number

- Material and finish

- Quantity and size (e.g., M4 x 20mm)

- Manufacturer name and lot number

- Compliance markings (e.g., RoHS, REACH, CE if applicable)

- Unit Load: Pallets must be secured with stretch wrap and labeled with handling instructions (e.g., “Fragile,” “Do Not Stack”).

Transportation & Handling

- Modes of Transport: Suitable for road, sea, and air freight. Avoid exposure to extreme temperatures and humidity.

- Storage Conditions: Store in a dry, climate-controlled environment (10°C to 30°C, relative humidity <60%). Keep away from corrosive chemicals.

- Handling: Use appropriate PPE (gloves, safety glasses). Avoid dropping or dragging containers to prevent damage and spillage.

Regulatory Compliance

- RoHS (EU): Ensure screws are free from restricted substances (e.g., lead, cadmium, hexavalent chromium).

- REACH (EU): Confirm no SVHCs (Substances of Very High Concern) above threshold levels.

- Conflict Minerals (US Dodd-Frank Act): Suppliers must certify that materials (e.g., tantalum, tin) are sourced responsibly.

- Customs Documentation: Provide accurate HS codes (e.g., 7318.15 for threaded screws), commercial invoices, and certificates of origin for international shipments.

Quality Assurance & Traceability

- Inspection: Incoming shipments must undergo visual and dimensional checks per ISO 2859-1 sampling standards.

- Documentation: Maintain batch records, material test reports (MTRs), and compliance certificates for a minimum of 5 years.

- Traceability: Implement a lot-tracking system to enable rapid recall if non-conformities arise.

Environmental & Safety Considerations

- Waste Disposal: Metal scrap and packaging must be disposed of in accordance with local environmental regulations (e.g., recycling metal waste).

- Safety Data Sheets (SDS): Available upon request for plated or chemically treated screws.

- Workplace Safety: Train personnel on safe handling to prevent injuries from sharp edges or spills.

Supplier & Vendor Requirements

- All suppliers must be ISO 9001 certified.

- Conduct annual audits to verify compliance with quality and ethical sourcing standards.

- Require written compliance declarations for environmental and safety regulations.

Conclusion

Proper logistics and compliance management for flathead screws ensures product integrity, legal adherence, and supply chain reliability. Regular reviews of this guide are recommended to incorporate regulatory updates and industry best practices.

Conclusion for Sourcing Screw Flathead:

After evaluating various suppliers, material options, cost considerations, and quality standards, it is evident that sourcing flathead screws requires a balanced approach focusing on quality, reliability, and cost-efficiency. Selecting a supplier that adheres to international standards (such as ISO or ASTM), ensures consistent material composition (e.g., stainless steel, zinc-plated steel, or alloy types), and offers competitive pricing with reliable lead times is crucial. Additionally, considering factors such as thread precision, drive type (e.g., Phillips, slotted), corrosion resistance, and application-specific requirements will ensure optimal performance and durability. Establishing long-term partnerships with vetted suppliers, conducting periodic quality audits, and maintaining clear communication will help mitigate risks and support sustainable procurement. In conclusion, a strategic and thorough sourcing process will ensure the consistent supply of high-quality flathead screws that meet technical and operational demands.