The global screw fastener market is experiencing robust growth, driven by increasing demand across industries such as automotive, construction, aerospace, and electronics. According to a report by Mordor Intelligence, the market was valued at USD 98.5 billion in 2023 and is projected to grow at a CAGR of over 5.2% from 2024 to 2029. This expansion is attributed to rising infrastructure development, advancements in manufacturing technologies, and the growing need for high-performance, precision-engineered fastening solutions. Regional industrialization, particularly in Asia-Pacific, continues to serve as a key growth catalyst, with countries like China and India emerging as major production and consumption hubs. In this evolving landscape, leading screw fastener manufacturers are investing heavily in R&D, automation, and sustainable production practices to maintain competitive advantage. Based on market presence, innovation, production capacity, and global reach, the following list highlights the top 10 screw fastener manufacturers shaping the industry’s future.

Top 10 Screw Fastener Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 AMPG

Domain Est. 1997

Website: ampg.com

Key Highlights: AMPG is a trusted USA manufacturer of high-quality fasteners. We provide precision-engineered sex bolts, shoulder screws, washer, shims and other industrial ……

#2 Valley Forge & Bolt

Domain Est. 1997

Website: vfbolts.com

Key Highlights: We are an internationally renowned manufacturer of hot forged industrial fasteners. Our patented bolting products are trusted for their quality, performance ……

#3 The Phillips Screw Company

Domain Est. 1998

Website: phillips-screw.com

Key Highlights: Phillips Screw Company is a leader in the design and engineering of proprietary fastener technology, including high-performance drive systems….

#4 Custom Fasteners Manufacturer

Domain Est. 1999

Website: nationalbolt.com

Key Highlights: National Bolt and Nut Corporation is a ISO Certified Nationwide custom fasteners manufacturer of nuts, washers, bolts and fasteners. Contact us today!…

#5 Star Drive Wood Screws – Screw Products, Inc.

Domain Est. 1999

Website: screw-products.com

Key Highlights: Screw Products Inc. specializes in star drive stainless steel and heat treated wood screws for decks, log homes, remodeling, kitchen cabinets, docks, ……

#6 Midwest Fastener

Domain Est. 2000

Website: fastenerconnection.com

Key Highlights: Midwest Fastener is a fastener supplier and fastener manufacturer offering construction fasteners, drywall screws, and much, much more….

#7 PEM – PennEngineering

Domain Est. 1996

Website: pemnet.com

Key Highlights: PEM offers innovative fastening solutions for a variety of applications across industries like Automotive Electronics, Consumer Electronics, Datacom and more….

#8

Domain Est. 1997

Website: arp-bolts.com

Key Highlights: ARP was the first company to design and engineer fasteners specifically for racing. We developed many patented process for manufacturing high strength ……

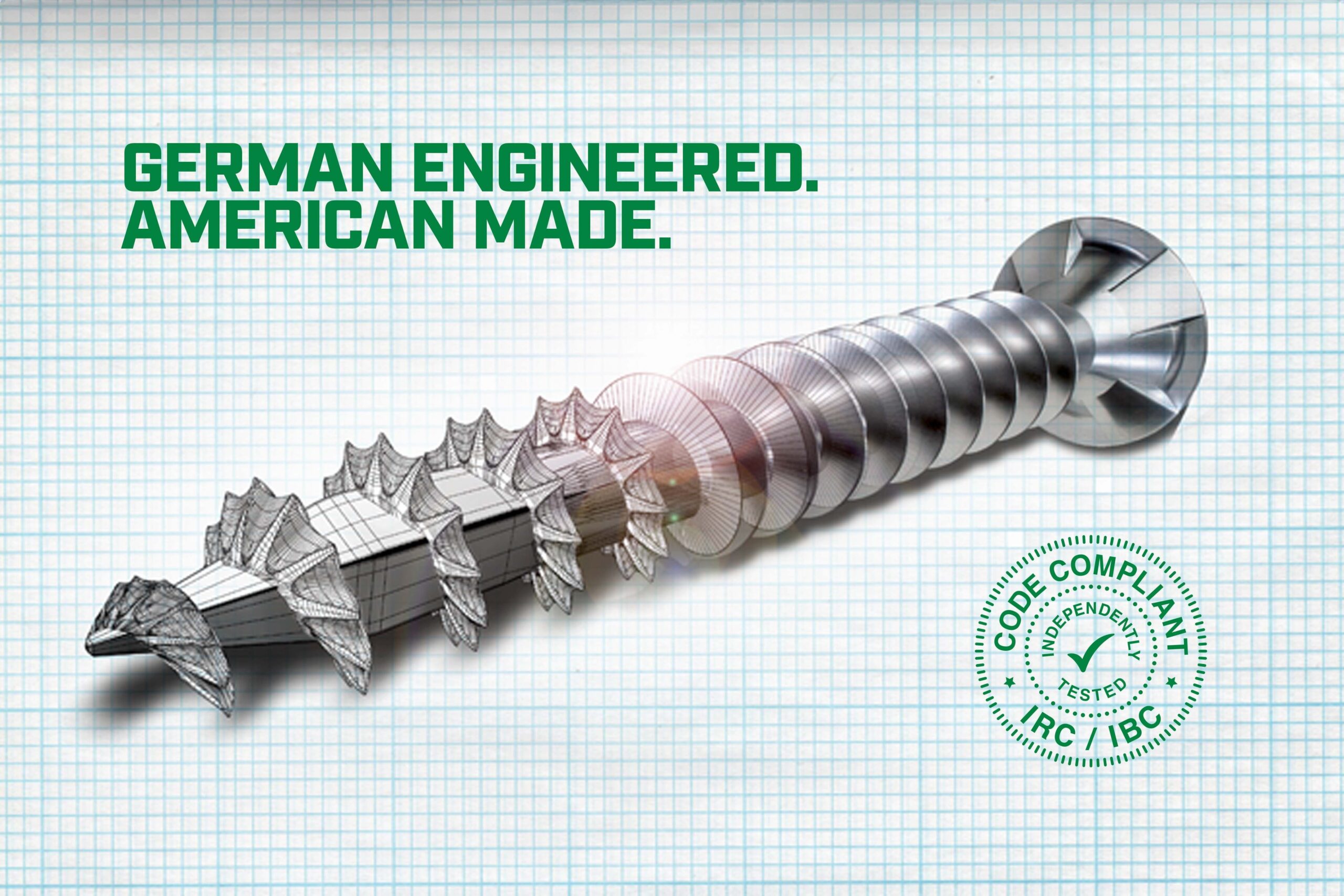

#9 SPAX US

Domain Est. 2004

Website: spax.us

Key Highlights: Our Engineered Screws & Fasteners are manufactured and rigorously tested right here in the heart of America. Rely on us to help you drive the highest quality….

#10 Global Fastener Platform

Domain Est. 2010

Website: globalfastener.com

Key Highlights: Products & Standards · Hex Bolts & Screws · Flanged / Collared Hex Bolts · Hex Structural Bolts · Square Head Bolts · Round Head Bolts · Countersunk Head Bolts · Eye ……

Expert Sourcing Insights for Screw Fastener

H2: 2026 Market Trends for Screw Fasteners

The global screw fastener market in 2026 is poised for steady growth, driven by sustained demand across key industries and evolving technological and regulatory landscapes. Key trends shaping the market include:

-

Resilient Demand from Core Industries: The automotive and construction sectors remain the primary drivers. The continued shift towards electric vehicles (EVs) necessitates specialized lightweight, high-strength fasteners, while infrastructure development in emerging economies fuels demand for standard and corrosion-resistant screws in construction.

-

Material Innovation & Lightweighting: Pressure to reduce weight (especially in automotive and aerospace) and improve performance will accelerate the adoption of advanced materials. Expect increased use of high-strength steel alloys, aluminum, titanium, and specialty polymers, moving beyond traditional carbon steel.

-

Sustainability as a Core Imperative: Environmental regulations and corporate ESG goals will intensify focus on:

- Recyclability: Design for disassembly and use of easily recyclable materials.

- Reduced Carbon Footprint: Adoption of energy-efficient manufacturing processes (e.g., cold forging optimization) and sourcing of low-carbon materials.

- Circular Economy: Exploration of closed-loop recycling models for metal scrap within the supply chain.

-

Digitalization & Smart Manufacturing: Integration of Industry 4.0 technologies will enhance efficiency and quality:

- Automation & Robotics: Wider use in production and assembly lines for precision and consistency.

- IoT & Data Analytics: Real-time monitoring of production parameters and predictive maintenance for machinery.

- Digital Twins: Simulation for optimizing fastener design and manufacturing processes.

-

Supply Chain Resilience & Regionalization: Ongoing geopolitical tensions and lessons from recent disruptions will push manufacturers towards:

- Nearshoring/Reshoring: Increased regional production to reduce dependency on single geographies (e.g., moving some capacity from Asia to North America/Europe).

- Diversification: Broader supplier networks and strategic inventory management to mitigate risks.

- Supply Chain Transparency: Enhanced tracking and verification of material origins and ethical practices.

-

Rise of Customization & Value-Added Services: Beyond standard screws, demand will grow for engineered fastening solutions:

- Application-Specific Designs: Fasteners tailored for unique challenges in EVs, renewable energy (wind turbines, solar), and advanced electronics.

- Integrated Services: Vendors offering design support, kitting, inventory management (VMI), and technical consultancy become more crucial.

-

Price Pressures & Cost Optimization: Despite material cost volatility, intense competition will keep pricing pressure high. Manufacturers will need to focus on operational efficiency, automation, and lean manufacturing to maintain margins.

In conclusion, the 2026 screw fastener market will be characterized by a balance between steady volume growth from core sectors and significant transformation driven by innovation, sustainability demands, digitalization, and the need for resilient, flexible supply chains. Success will favor companies that can adapt quickly, offer value beyond the basic component, and meet the evolving technical and environmental requirements of their customers.

Common Pitfalls When Sourcing Screw Fasteners (Quality, IP)

Sourcing screw fasteners may seem straightforward, but overlooking key quality and industrial property (IP) considerations can lead to significant issues, including product failure, safety hazards, and legal complications. Below are common pitfalls to avoid:

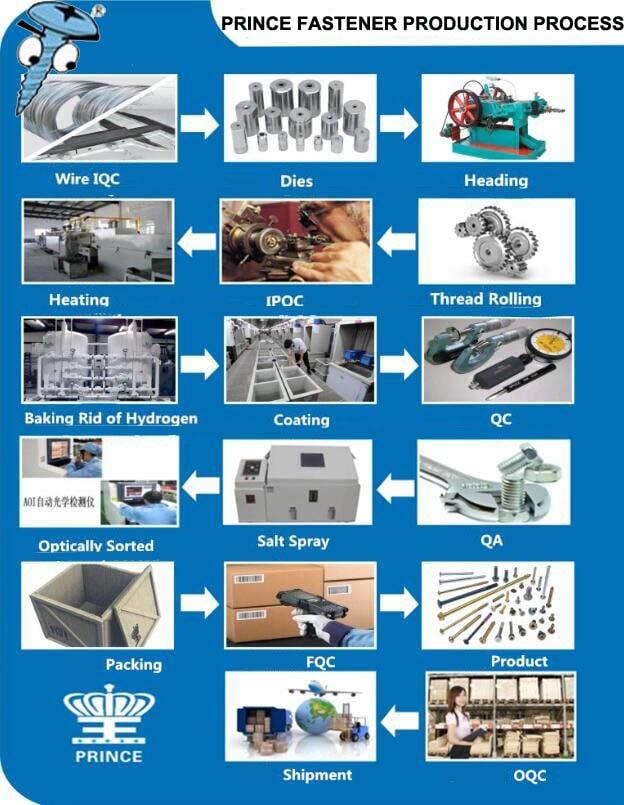

Poor Quality Control and Inconsistent Manufacturing

One of the most frequent issues is sourcing from suppliers with inadequate quality control processes. This can result in dimensional inaccuracies, inconsistent thread quality, incorrect material composition, or poor surface finishes. Fasteners that fail to meet required tolerances may not fit properly, leading to assembly difficulties or premature failure under stress.

Misrepresentation of Material and Grade Specifications

Suppliers—especially in unregulated markets—may falsely claim that fasteners meet certain standards (e.g., ASTM, ISO, DIN) or are made from specific materials (e.g., A2/A4 stainless steel, Grade 8.8). Without proper certification or third-party testing, these claims can be misleading, resulting in fasteners that corrode easily or lack necessary strength.

Lack of Traceability and Certifications

Reputable screw fasteners should come with traceable certifications such as material test reports (MTRs), ISO certifications, or RoHS compliance. Failing to verify these documents increases the risk of receiving substandard or non-compliant components, particularly in regulated industries like aerospace, automotive, or medical devices.

Counterfeit or IP-Infringing Fasteners

Some suppliers sell fasteners that infringe on patented designs or trademarks (e.g., imitation Torx, Allen, or proprietary drive systems). Using such components exposes your business to legal liability, potential product recalls, and damage to brand reputation. Always verify that the supplier has rights to produce and sell the fastener design.

Inadequate Corrosion Resistance for Application

Choosing fasteners without proper consideration of environmental exposure—such as humidity, salt spray, or chemical contact—leads to premature rusting or degradation. Assuming all “stainless steel” fasteners are equal is a common mistake; for example, A2 (304) stainless is not suitable for marine environments, where A4 (316) is required.

Ignoring IP and Licensing Requirements

Certain fastener designs (e.g., patented drive systems like Torx, Robertson, or specialized thread profiles) are protected by intellectual property rights. Sourcing unlicensed versions may violate these rights, even if the functional performance appears adequate. Always confirm that the supplier is authorized to manufacture and distribute IP-protected fasteners.

Overlooking Packaging and Labeling Standards

Poor packaging can lead to contamination, corrosion, or mix-ups during storage and assembly. Additionally, incorrect labeling—such as missing grade markings, material codes, or manufacturer IDs—compromises traceability and makes quality audits difficult.

Relying Solely on Price as a Decision Factor

While cost is important, selecting the cheapest option often leads to compromised quality, reliability, and compliance. The total cost of ownership—including failure rates, maintenance, and potential liability—can far exceed initial savings from low-cost, substandard fasteners.

Avoiding these pitfalls requires due diligence: vetting suppliers, requesting documentation, conducting sample testing, and understanding both technical specifications and IP implications.

Logistics & Compliance Guide for Screw Fasteners

This guide outlines key logistics and compliance considerations for the international shipment, handling, and regulatory adherence of screw fasteners. Proper planning ensures timely delivery, avoids penalties, and maintains product quality.

Product Classification and HS Code

Screw fasteners are typically classified under Harmonized System (HS) codes related to iron, steel, or other metals. The most common HS code for steel screw fasteners is 7318.15 (Screws, bolts, and bolts with their nuts or washers, of iron or steel). However, classification may vary by material (e.g., stainless steel, brass), thread type, head style, and coating. Accurate classification is essential for determining import duties, taxes, and trade regulations in the destination country.

Packaging and Labeling Requirements

Screw fasteners should be packaged to prevent damage during transit and to meet international shipping standards:

- Use moisture-resistant packaging (e.g., sealed plastic liners inside cardboard boxes or steel drums) to prevent corrosion.

- Label each package with essential information: part number, quantity, material grade, finish/coating, net weight, country of origin, and handling instructions (e.g., “Fragile,” “Keep Dry”).

- Include compliance labels such as RoHS, REACH, or other certifications if applicable.

- Ensure labeling complies with destination country language requirements (e.g., bilingual labels in Canada or French-speaking countries).

Transportation and Handling

- Mode of Transport: Screw fasteners are commonly shipped via ocean freight (FCL/LCL), air freight (for urgent or high-value orders), or ground transport (for regional distribution).

- Palletization: Securely stack packages on standard pallets (e.g., EUR/EPAL or ISO) and wrap with stretch film. Weight distribution should be even to prevent shifting.

- Container Load Plans: Optimize container space using load planning software. Prevent moisture ingress by using desiccants and vapor barriers, especially in sea freight.

- Handling: Use appropriate forklifts and lifting equipment. Avoid dropping or impact that could deform fasteners or compromise packaging.

Regulatory Compliance

Ensure screw fasteners meet all relevant regulatory standards in both origin and destination markets:

- RoHS (EU): Restricts hazardous substances (e.g., lead, cadmium) in electrical and electronic equipment. Applies if fasteners are used in such products.

- REACH (EU): Requires registration, evaluation, and authorization of chemicals. Declare Substances of Very High Concern (SVHC) if present above thresholds.

- ASTM/ISO Standards: Fasteners must conform to recognized standards (e.g., ISO 898 for mechanical properties, ASTM A574 for alloy steel socket screws) as specified by customers or market requirements.

- Customs Documentation: Provide commercial invoice, packing list, bill of lading/air waybill, and certificates of origin/compliance. Include technical specifications and test reports if requested.

Trade Restrictions and Sanctions

- Verify that the destination country is not under trade sanctions or embargoes (e.g., by OFAC, EU, or UN).

- Check for export control regulations (e.g., EAR in the U.S.) that may apply if fasteners are used in defense, aerospace, or strategic industries.

- Obtain export licenses if required based on product specifications or end-use.

Quality Assurance and Traceability

- Maintain traceability from raw material to finished product using batch/lot numbering.

- Conduct quality inspections (e.g., dimensional checks, tensile testing, salt spray testing for coatings) per customer or industry standards.

- Provide mill test certificates (MTCs) or material certifications upon request.

Environmental and Safety Considerations

- Comply with environmental regulations for surface treatments (e.g., zinc plating, passivation) under local laws (e.g., EPA in the U.S.).

- Classify packaging waste appropriately under Extended Producer Responsibility (EPR) schemes in the EU or other regions.

- Ensure worker safety during manufacturing and handling per OSHA or equivalent standards.

Returns and Reverse Logistics

- Establish a clear policy for handling non-conforming shipments, including return authorization (RMA) procedures.

- Use reusable or recyclable packaging where possible to support sustainability goals.

- Track returned items for root cause analysis and process improvement.

By adhering to this logistics and compliance framework, businesses can ensure reliable delivery of screw fasteners while meeting global regulatory requirements and maintaining customer trust.

Conclusion for Sourcing Screw Fasteners

Sourcing screw fasteners requires a strategic approach that balances quality, cost, availability, and compliance. It is essential to partner with reliable suppliers who adhere to industry standards and provide consistent product quality to ensure the integrity and safety of the final assembly. Factors such as material type, corrosion resistance, drive type, thread specifications, and environmental conditions must be carefully evaluated to select the most suitable fastener for the application.

Moreover, establishing strong supplier relationships, conducting regular quality audits, and maintaining inventory efficiency through just-in-time or bulk purchasing strategies can significantly improve supply chain performance. With the global nature of manufacturing, considering total landed costs—including shipping, tariffs, and lead times—is critical in making cost-effective sourcing decisions.

In conclusion, effective screw fastener sourcing supports operational efficiency, product reliability, and long-term cost savings. By implementing a structured sourcing process and staying informed about material and market trends, organizations can ensure they procure the right fasteners, at the right time, and at the right price.