The global scrap metal baler market is experiencing robust growth, driven by rising demand for efficient metal recycling solutions and increasing environmental regulations. According to a report by Mordor Intelligence, the scrap metal recycling market is projected to grow at a CAGR of over 6.8% from 2024 to 2029, bolstered by expanding industrialization and heightened focus on sustainable resource management. This surge in recycling activity has directly increased the demand for high-performance scrap metal balers—essential equipment used to compress loose metal waste into dense, transport-efficient bales. With the Asia-Pacific region leading in metal consumption and waste generation, and North America maintaining strong recycling infrastructure, manufacturers are innovating to meet evolving throughput, durability, and automation requirements. As industries prioritize cost-efficiency and environmental compliance, the role of advanced baler technology has become increasingly critical. Based on market presence, technological innovation, and global footprint, we’ve identified the top 8 scrap metal baler manufacturers shaping the future of metal recycling.

Top 8 Scrap Metal Baler Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

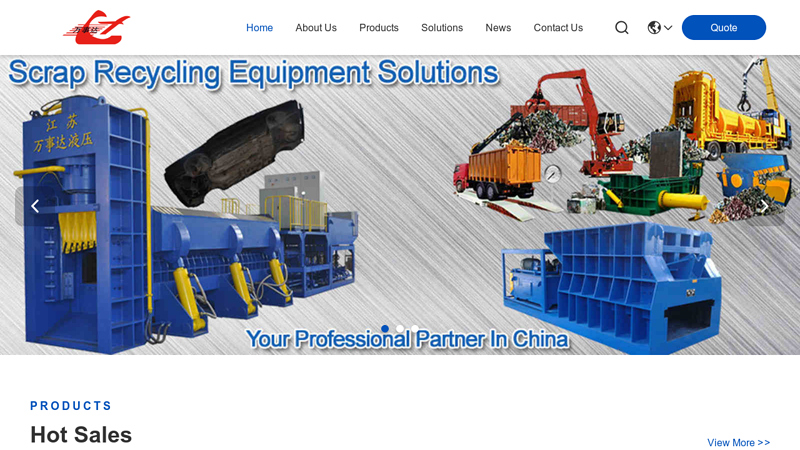

#1 Quality Scrap Metal Baler & Waste Paper Baler factory from China

Domain Est. 2016

Website: scrap-metalbaler.com

Key Highlights: China leading provider of Scrap Metal Baler and Waste Paper Baler, Jiangsu Wanshida Hydraulic Machinery Co., Ltd is Waste Paper Baler factory….

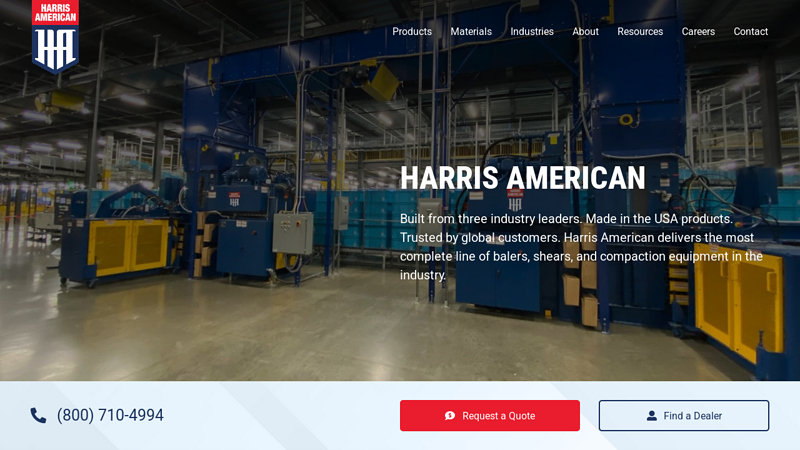

#2 Harris American Co. Balers, Shears & Compaction Equipment

Website: harrisamericanco.com

Key Highlights: Upgrade to industrial balers, shears, and compaction equipment from Harris American Co baler manufacturers. Made in America. Trusted around the globe….

#3 Lefort

Domain Est. 1997

Website: lefort.com

Key Highlights: The LEFORT® range of shear/balers includes static, portable, mobile and track-mounted versions with cutting forces of up to 2,000 tonnes. In detail….

#4 Metal recycling with LINDEMANN scrap metal balers

Domain Est. 2021

Website: lindemann-metalrecycling.com

Key Highlights: LINDEMANN’s wide range of scrap metal balers is designed for scrap yards and various industrial applications processing steel, aluminum, copper and other ……

#5 Scrap Metal Baler Manufacturer

Domain Est. 2022

Website: bsghgranulator.com

Key Highlights: Scrap metal baler machine is mainly designed for processing all kinds of metal scraps or used metals, compressing various metal scraps like various metal ……

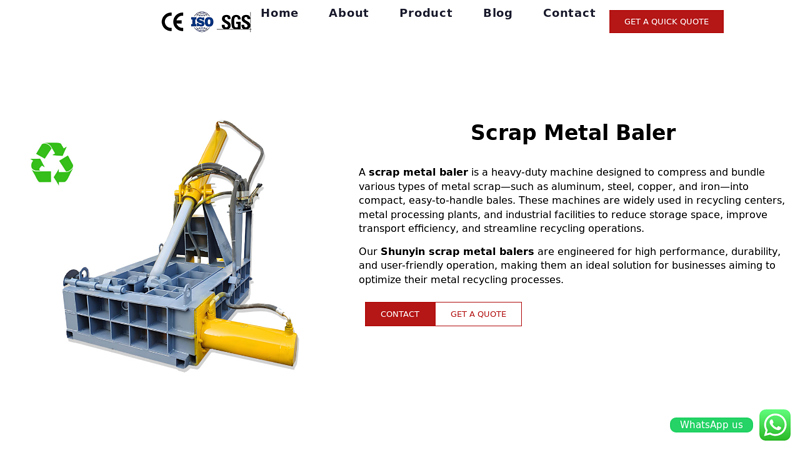

#6 Metal balers

Domain Est. 2024

Website: sybalingmachine.com

Key Highlights: A scrap metal baler is a heavy-duty machine designed to compress and bundle various types of metal scrap—such as aluminum, steel, copper, and iron—into ……

#7 Sierra International Machinery

Domain Est. 1996

Website: sierraintl.com

Key Highlights: Sierra is a worldwide leader in selling and supporting processing equipment to the recycled materials and waste industries, offering……

#8 Scrap Metal Baler

Domain Est. 2014

Website: enerpatrecycling.com

Key Highlights: Enerpat scrap metal baler is built to last, with brand spare parts for each machine, being with Schneider hydraulic system, Siemens motor, Hardox or Dillinger ……

Expert Sourcing Insights for Scrap Metal Baler

2026 Market Trends for Scrap Metal Balers

The global scrap metal baler market is poised for significant transformation by 2026, driven by evolving environmental regulations, technological advancements, and shifting dynamics in the recycling and manufacturing sectors. Key trends shaping the industry include:

Heightened Focus on Sustainability and Circular Economy

Governments worldwide are intensifying regulations to reduce landfill waste and promote resource efficiency, directly boosting demand for scrap metal recycling. The EU’s Circular Economy Action Plan and similar initiatives in North America and Asia are pushing industries to adopt closed-loop systems. Scrap metal balers, essential for compacting ferrous and non-ferrous metals into transportable bales, are becoming critical infrastructure in this shift. By 2026, compliance with environmental standards will be a primary driver for baler adoption, especially among auto recyclers, construction firms, and industrial manufacturers.

Technological Advancements and Automation

Baler manufacturers are integrating smart technologies to enhance efficiency and safety. Expect widespread adoption of IoT-enabled balers that offer real-time performance monitoring, predictive maintenance alerts, and remote diagnostics by 2026. Automation features such as auto-feed systems, programmable logic controllers (PLCs), and integration with material handling lines will reduce labor costs and increase throughput. These innovations will appeal to large-scale recyclers seeking to optimize operations and improve data transparency across the supply chain.

Rising Demand from Emerging Economies

Countries in Asia-Pacific (particularly India, Vietnam, and Indonesia) and Latin America are experiencing rapid industrialization and urbanization, leading to increased metal consumption and scrap generation. As these regions strengthen their recycling infrastructure, demand for cost-effective and durable scrap metal balers will surge. Localized manufacturing and the availability of compact, semi-automatic models will make balers more accessible to small and medium-sized recyclers in developing markets.

Growth in Non-Ferrous Metal Recycling

While ferrous metals remain dominant in baling operations, the rising value and demand for non-ferrous metals (e.g., aluminum, copper) are encouraging recyclers to invest in specialized balers capable of handling mixed or sensitive materials. By 2026, balers designed for high purity output and material segregation will see increased demand, driven by the automotive, aerospace, and electronics industries seeking sustainable raw materials.

Supply Chain Resilience and Localization

Ongoing global supply chain disruptions have prompted recyclers and manufacturers to prioritize equipment reliability and local service support. By 2026, baler producers will emphasize modular designs, easier maintenance, and regional service networks to minimize downtime. Additionally, companies may favor domestic or regional suppliers to reduce lead times and logistics costs, reshaping procurement strategies in the baler market.

In conclusion, the 2026 scrap metal baler market will be defined by innovation, regulatory pressure, and globalization of recycling efforts. Companies that embrace automation, sustainability, and market-specific solutions will be best positioned to capitalize on emerging opportunities.

Common Pitfalls When Sourcing a Scrap Metal Baler: Quality and Intellectual Property Concerns

Sourcing a scrap metal baler involves significant investment and long-term operational impact, making it crucial to avoid common pitfalls related to equipment quality and intellectual property (IP) issues. Overlooking these aspects can lead to downtime, safety hazards, legal disputes, and reduced return on investment.

Poor Build Quality and Material Selection

Many low-cost balers are constructed with substandard materials such as inferior-grade steel or undersized hydraulic components. This results in frequent breakdowns, reduced bale density, and shortened equipment lifespan. Buyers may unknowingly sacrifice durability for upfront cost savings, ultimately increasing total cost of ownership due to repairs and replacement parts.

Inadequate Hydraulic System Design

A poorly engineered hydraulic system—common in some imported or non-branded balers—can lead to overheating, leaks, and inconsistent bale compression. Systems lacking proper filtration, cooling, or pressure regulation are prone to premature failure, causing unplanned downtime and expensive maintenance.

Lack of Compliance with Safety Standards

Some balers, especially those from manufacturers in regions with lax regulations, may not meet international safety standards (e.g., CE, OSHA, or ISO). This exposes operators to serious injury risks and may result in legal liability or facility shutdowns during inspections.

Misrepresentation of Technical Specifications

Vendors may exaggerate key performance metrics such as bale density, cycle time, or motor power. Without third-party verification or onsite testing, buyers risk purchasing equipment that underperforms, reducing throughput and profitability.

Counterfeit or Clone Equipment (IP Infringement)

A growing concern is the proliferation of balers that replicate designs protected by intellectual property rights. These “clone” machines often copy patented features from reputable brands without authorization. While they may appear identical, they lack the engineering refinement, quality control, and safety testing of the original. Purchasing such equipment can expose the buyer to legal risks, especially in jurisdictions that enforce IP rights strictly.

Limited or No After-Sales Support and Spare Parts Availability

Many low-cost or IP-infringing balers come from manufacturers without established service networks. This leads to delays in spare parts delivery, lack of technical support, and difficulty in sourcing compatible components, resulting in prolonged downtime.

Absence of IP Documentation and Warranty Coverage

Reputable manufacturers provide documentation proving original design ownership and offer comprehensive warranties. Cloned or counterfeit balers often lack these, offering only vague or unenforceable warranty terms. This absence increases the buyer’s risk and reduces recourse in case of defects or performance issues.

Failure to Verify Manufacturer Authenticity

Buyers may assume a supplier is an original equipment manufacturer (OEM) when they are actually a reseller or distributor of copied designs. Conducting due diligence—such as checking patents, visiting manufacturing facilities, or requesting design documentation—is essential to avoid IP-related complications.

By carefully evaluating both the physical quality of the baler and the legitimacy of its design and origin, businesses can mitigate risks and ensure they invest in reliable, legally sound machinery that supports long-term operational success.

Logistics & Compliance Guide for Scrap Metal Baler

Introduction

A scrap metal baler is essential equipment in recycling operations, compressing loose scrap metal into dense, manageable bales for efficient transport and sale. Proper logistics and compliance are critical to ensure safety, regulatory adherence, and operational efficiency. This guide outlines key considerations for the transportation, handling, and regulatory compliance associated with scrap metal balers.

Transportation and Delivery Logistics

Equipment Shipping Preparation

Before shipping a scrap metal baler, ensure it is properly secured and prepared for transport. Disconnect all power sources, drain hydraulic fluids if required, and remove loose parts. Use protective covers for hydraulic lines and electrical components. Provide detailed shipping documentation, including weight, dimensions, and center of gravity.

Carrier Requirements and Loading

Use a freight carrier experienced in handling heavy industrial machinery. Confirm the carrier has appropriate equipment (e.g., forklifts, cranes, flatbed trailers). Secure the baler using rated chains or straps to prevent movement during transit. Ensure the delivery site has unloading capabilities, including sufficient space and lifting equipment.

Site Access and Installation Planning

Evaluate the delivery route for overhead obstacles, weight restrictions, and access limitations. Coordinate with facility management to prepare the installation area—ensure proper foundation, power supply (voltage, phase, amperage), and ventilation. Schedule delivery during off-peak hours if site access is limited.

Regulatory Compliance

Environmental Regulations

Scrap metal balers may involve hydraulic fluids and lubricants regulated under environmental laws such as the U.S. Environmental Protection Agency (EPA) guidelines. Ensure containment systems are in place to prevent leaks. Follow proper disposal procedures for used hydraulic oil and filters in compliance with RCRA (Resource Conservation and Recovery Act).

Occupational Safety and Health Standards

Comply with OSHA (Occupational Safety and Health Administration) standards for machine guarding, lockout/tagout (LOTO), and worker training. Install emergency stop buttons, safety interlocks, and warning labels. Conduct routine safety inspections and maintain records of employee training on baler operation and maintenance.

Import/Export Compliance (if applicable)

For international shipments, ensure compliance with customs regulations, including accurate HS (Harmonized System) codes for scrap metal balers (typically 8474.20). Prepare commercial invoices, packing lists, and certificates of origin. Verify compliance with destination country standards (e.g., CE marking for Europe, CCC for China).

Electrical and Machine Safety Standards

Ensure the baler meets applicable safety standards such as ANSI Z245.5 (North America) or EN 16775 (Europe) for baler safety. Electrical components should comply with NFPA 70 (National Electrical Code) or IEC 60204-1. Retain all conformity certificates and technical files for audit purposes.

Operational Best Practices

Maintenance and Recordkeeping

Establish a preventive maintenance schedule for hydraulic systems, seals, and structural components. Keep detailed logs of inspections, repairs, and fluid changes. Retain records for compliance audits and warranty claims.

Waste Stream Management

Only bale approved materials—avoid contaminants such as hazardous waste, sealed containers, or mixed non-metallic materials. Segregate bales by metal type (ferrous, non-ferrous) to meet buyer specifications and recycling standards.

Training and Documentation

Provide comprehensive training for all operators and maintenance personnel. Maintain up-to-date Standard Operating Procedures (SOPs), safety manuals, and emergency response plans on-site.

Conclusion

Effective logistics and strict compliance are fundamental to the safe and legal operation of a scrap metal baler. By planning transportation carefully, adhering to environmental and safety regulations, and maintaining thorough documentation, facilities can minimize risks, avoid penalties, and ensure smooth recycling operations.

In conclusion, sourcing a scrap metal baler is a strategic investment that can significantly enhance operational efficiency, reduce transportation and storage costs, and improve overall profitability in scrap metal processing. By carefully evaluating key factors such as baler type, capacity, build quality, supplier reliability, and after-sales support, businesses can select a machine that aligns with their volume requirements and long-term goals. Additionally, considering energy efficiency, maintenance needs, and safety features ensures sustainable and safe operations. With the growing demand for recycled metals and increasing pressure to adopt environmentally responsible practices, acquiring the right scrap metal baler not only boosts productivity but also supports environmental sustainability. A well-informed sourcing decision ultimately positions a business for greater competitiveness and success in the recycling industry.