The global scissor trailer jack market is experiencing steady growth, driven by increasing demand from the automotive and transportation sectors for reliable, heavy-duty lifting solutions. According to Grand View Research, the global automotive jack market size was valued at USD 1.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by rising commercial vehicle production, expanding logistics networks, and the need for efficient trailer maintenance and loading systems. As demand for durable and high-capacity scissor jacks rises—particularly in North America, Europe, and Asia-Pacific—manufacturers are investing in enhanced load capacity, corrosion resistance, and innovative design features. In this evolving landscape, the top eight scissor trailer jack manufacturers are leading the way through precision engineering, stringent quality standards, and a strong global distribution footprint.

Top 8 Scissor Trailer Jacks Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stillwell, Inc.

Domain Est. 2020

Website: stillwellinc.com

Key Highlights: Stillwell offers a wide variety of hydraulic trailer jacks to fit any application. The complete line up of Stillwell Jacks are sourced from US materials….

#2 BAL RV Products

Domain Est. 2020

Website: balrvproducts.com

Key Highlights: BAL RV Products – a brand of Norco Industries, Inc. – manufactures quality products for the RV industry, such as slideouts, trailer frames, chassis components….

#3 RV Scissor Jacks for Stable and Secure Leveling

Domain Est. 1996

#4 BendPak

Domain Est. 1997

Website: bendpak.com

Key Highlights: Upgrade your garage with the industry standard. Discover why pros choose BendPak for car lifts, parking lifts, pipe benders, and wheel service equipment….

#5 Trailer Jacks (TJ,FJ,NJ)

Domain Est. 1998

Website: vestil.com

Key Highlights: The Trailer Jack adjustable lift range provides easy hitching and unhitching of a loaded trailer. Use for a wide variety of lifting, leveling, ……

#6 Gray Manufacturing

Domain Est. 1998

Website: grayusa.com

Key Highlights: Gray Manufacturing is your shop equipment solution. Whether it’s with our air jacks or a portable auto lift, we’re minimizing customer downtime….

#7 Scissor Jacks

Domain Est. 1998

Website: support.lci1.com

Key Highlights: The intended use of the jacks is to stabilize, not level the unit. Can you use this jack to change your tire? This assembly by itself is not intended to ……

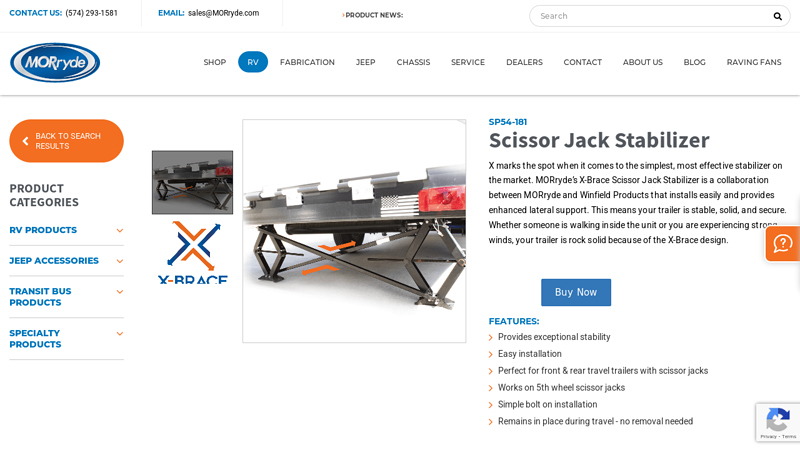

#8 Scissor Jack Stabilizer

Domain Est. 1998

Website: morryde.com

Key Highlights: FEATURES: Provides exceptional stability; Easy installation; Perfect for front & rear travel trailers with scissor jacks; Works on 5th wheel scissor jacks ……

Expert Sourcing Insights for Scissor Trailer Jacks

H2: Market Trends for Scissor Trailer Jacks in 2026

The scissor trailer jacks market is poised for steady growth and transformation by 2026, driven by advancements in material technology, increased demand in the recreational and commercial trailer sectors, and a growing emphasis on user safety and convenience. Key trends shaping the market include:

-

Rising Demand in the RV and Marine Industries

The recreational vehicle (RV) and marine trailer markets are expanding globally, particularly in North America and Europe. As consumers continue to prioritize outdoor lifestyles and leisure travel, the need for durable, reliable trailer jacks—including scissor models—will grow. Scissor jacks are favored for their compact design and stability, making them ideal for RVs, boat trailers, and utility trailers. -

Shift Toward Lightweight and Corrosion-Resistant Materials

Manufacturers are increasingly using aluminum alloys and powder-coated steel to reduce weight and improve resistance to rust and environmental damage. This trend is especially relevant for marine applications where exposure to saltwater demands higher durability. By 2026, high-performance, low-maintenance materials are expected to dominate product offerings. -

Integration of Electric and Power-Assisted Features

While traditional manual scissor jacks remain popular due to their reliability and cost-effectiveness, there is a growing trend toward electric and power-assisted models. These innovations offer ease of use, particularly for users with physical limitations or those managing heavier trailers. The integration of battery-powered actuators and remote controls is expected to gain traction in premium segments by 2026. -

Focus on Ergonomics and User Safety

Enhanced ergonomics—such as foldable handles, improved leverage mechanisms, and anti-sway features—are becoming standard. Safety certifications and compliance with ANSI and ISO standards are increasingly influencing consumer purchasing decisions. Brands that prioritize user safety in design will likely gain competitive advantage. -

E-Commerce and Direct-to-Consumer Sales Growth

Online retail platforms are becoming a primary channel for trailer accessories. By 2026, manufacturers are expected to invest more in digital marketing, customer education, and direct sales models, enabling faster delivery and competitive pricing. Customer reviews and video demonstrations play a crucial role in influencing buying behavior. -

Sustainability and Circular Economy Practices

Environmental concerns are prompting manufacturers to adopt sustainable production methods, recyclable packaging, and longer product lifecycles. Some companies are exploring modular designs that allow for part replacement rather than full-unit disposal, aligning with circular economy principles. -

Regional Market Expansion

While North America remains the largest market, growth in Asia-Pacific—particularly in countries like Australia, Japan, and South Korea—is accelerating due to rising trailer ownership and infrastructure development. Localized manufacturing and distribution partnerships will be key for global brands aiming to capture emerging markets.

In summary, the 2026 scissor trailer jacks market will be shaped by innovation in materials and functionality, increasing consumer expectations for convenience and safety, and expanding global demand. Companies that adapt to these H2-driven trends—highlighting durability, smart features, and sustainability—will be well-positioned for long-term success.

Common Pitfalls When Sourcing Scissor Trailer Jacks (Quality, IP)

Sourcing scissor trailer jacks involves more than just finding the lowest price—overlooking key quality and intellectual property (IP) concerns can lead to safety risks, product failures, and legal complications. Here are common pitfalls to avoid:

Poor Material Quality and Construction

Many low-cost scissor trailer jacks are made from substandard steel or inadequately treated metals, leading to premature rust, deformation, or structural failure under load. Avoid suppliers who don’t disclose material specifications (e.g., carbon steel grade, galvanization type) or provide inconsistent welding and finish quality.

Inaccurate Load Capacity Ratings

Some manufacturers exaggerate lifting capacity or fail to specify dynamic vs. static load ratings. Always verify load claims through third-party test reports and ensure the jack is rated for your trailer’s GVWR with a safety margin (typically 1.5x the expected load).

Lack of IP Compliance and Risk of Infringement

Sourcing from suppliers that replicate patented designs (e.g., branded jack mechanisms or mounting systems) exposes your business to intellectual property litigation. Ensure suppliers have design rights or offer OEM/ODM solutions that don’t infringe on existing patents, especially from well-known brands.

Inadequate Corrosion Protection

Scissor jacks are exposed to harsh outdoor environments. Sourcing units without proper corrosion resistance—such as insufficient zinc plating, absence of powder coating, or poor seal integrity—results in rapid deterioration. Confirm IP (Ingress Protection) ratings for dust and moisture resistance, especially if used in coastal or off-road conditions.

Missing Safety and Certification Standards

Low-quality jacks may lack compliance with regional safety standards (e.g., ISO, CE, or DOT). Avoid suppliers who can’t provide documentation for compliance with relevant mechanical and safety regulations, as this can impact product liability and market access.

Inconsistent Manufacturing and Quality Control

Suppliers with poor QC processes may deliver inconsistent thread quality, misaligned components, or faulty gear mechanisms. Establish clear quality benchmarks and conduct regular factory audits or pre-shipment inspections to ensure batch-to-batch reliability.

Hidden Costs from Frequent Failures and Returns

While cheap jacks may reduce upfront costs, poor durability increases long-term expenses due to replacements, warranty claims, and reputational damage. Invest in reliable suppliers with proven track records and warranties that reflect confidence in product longevity.

By prioritizing material integrity, accurate specifications, IP compliance, and adherence to safety standards, you can avoid these pitfalls and source scissor trailer jacks that deliver performance, safety, and legal security.

Logistics & Compliance Guide for Scissor Trailer Jacks

Product Overview

Scissor trailer jacks are mechanical lifting devices used to raise and stabilize trailers during hitching, unhitching, or maintenance. They are commonly mounted on the front (tongue) of utility, boat, and RV trailers. Understanding proper logistics and compliance is essential for safe and legal distribution and use.

Regulatory Compliance

Scissor trailer jacks must comply with relevant industry and safety standards to ensure structural integrity and operational safety. Key compliance considerations include:

- ASME B30.21 (Below-the-Hook Lifting Devices): While primarily for industrial lifting, aspects of mechanical design and load testing may apply.

- DOT Regulations (U.S.): Federal Motor Carrier Safety Administration (FMCSA) does not directly regulate jacks but requires trailers to be in safe operating condition. A malfunctioning jack could contribute to a violation during inspection.

- CSA B149 (Canada): For trailers used in Canada, compliance with Canadian Standards Association guidelines for trailer equipment may be referenced.

- Load Rating & Labeling: Jacks must be clearly marked with their maximum load capacity (e.g., 2,000 lbs, 3,500 lbs) and include manufacturer details, model number, and compliance symbols. This is required under general product safety regulations.

Load Capacity & Usage Guidelines

- Always match the jack’s rated capacity to the trailer’s tongue weight (typically 10–15% of total trailer weight).

- Never exceed the stated load rating.

- Use on level, stable ground to prevent tipping or collapse.

- Regularly inspect for wear, bent components, or damaged threads.

Packaging & Shipping

Proper packaging ensures product integrity during transit:

- Protective Packaging: Use corrugated cardboard boxes with internal supports or foam inserts to prevent movement.

- Labeling: Include handling labels such as “Fragile,” “This Side Up,” and “Do Not Stack,” along with the product weight and dimensions.

- Barcodes & SKUs: Apply scannable barcodes and include SKU numbers for inventory tracking.

- Hazard Classification: Scissor jacks are non-hazardous goods and do not require special handling under IATA, IMDG, or DOT hazardous materials regulations.

Import & Export Requirements

When shipping internationally:

- HS Code Classification: Use appropriate Harmonized System (HS) code. Common codes include:

- 8716.90 – Parts and accessories for trailers, including jacks.

- Country-Specific Standards: Verify compliance with local regulations (e.g., CE marking in the EU, RCM in Australia).

- Customs Documentation: Include commercial invoices, packing lists, and certificates of origin as needed.

- Tariffs & Duties: Be aware of import duties, which vary by country and trade agreements.

Storage Recommendations

- Store in a dry, indoor environment to prevent rust and corrosion.

- Elevate off the floor using pallets to avoid moisture exposure.

- Avoid extreme temperatures or direct sunlight, especially for models with plastic or painted components.

Quality Assurance & Testing

Manufacturers and distributors should implement quality control procedures:

- Load testing at 1.5x rated capacity during production sampling.

- Visual and functional inspections before packaging.

- Compliance with ISO 9001 standards for quality management systems (recommended).

Warranty & Customer Support

- Provide clear warranty terms (e.g., 1-year limited warranty against manufacturing defects).

- Include user manuals with installation, operation, and maintenance instructions.

- Offer multilingual support and accessible customer service channels.

Environmental & Disposal Considerations

- Scissor jacks are primarily made of steel and zinc-coated components; they are recyclable at end-of-life.

- No hazardous materials are typically involved, but follow local e-waste or metal recycling guidelines.

Conclusion

Ensuring compliance and efficient logistics for scissor trailer jacks involves adherence to safety standards, proper documentation, secure packaging, and awareness of international regulations. By following this guide, suppliers and distributors can ensure product reliability, legal compliance, and customer satisfaction.

In conclusion, sourcing scissor trailer jacks requires careful consideration of quality, durability, compatibility, and supplier reliability. These jacks play a critical role in supporting trailers during maintenance, storage, and loading, making it essential to select products made from robust materials such as galvanized or powder-coated steel to withstand heavy loads and harsh environmental conditions. Buyers should evaluate suppliers based on product certifications, customer reviews, warranty offerings, and after-sales support to ensure long-term performance and safety.

Additionally, understanding the specific requirements—such as weight capacity, mounting style, and lift height—helps in selecting the right scissor jack for the intended application. Whether sourcing locally or internationally, establishing partnerships with reputable manufacturers or distributors can lead to cost-effective solutions without compromising on quality. Ultimately, investing time in thorough research and due diligence when sourcing scissor trailer jacks ensures reliability, safety, and optimal value for both individual users and commercial operations.