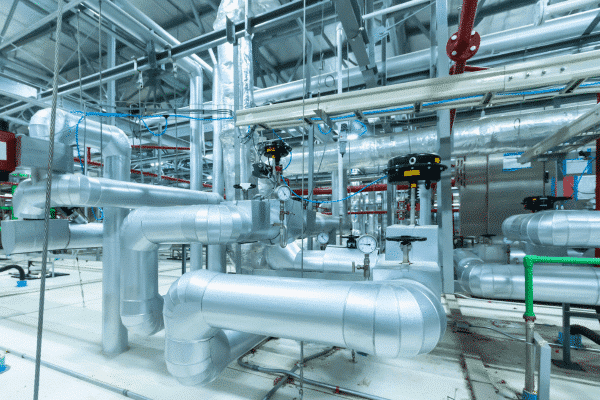

The global aluminum pipe market is experiencing steady growth, driven by increasing demand across industries such as construction, transportation, and renewable energy. According to Grand View Research, the global aluminum pipes and tubes market was valued at USD 56.7 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.3% from 2023 to 2030. This growth is fueled by aluminum’s lightweight, corrosion-resistant properties and its role in enhancing fuel efficiency and reducing carbon emissions in automotive and aerospace applications. Sch 40 aluminum pipes, known for their durability and standardized wall thickness, are increasingly specified in high-performance systems where strength and reliability are critical. As demand rises, a select group of manufacturers have emerged as leaders in producing high-quality Sch 40 aluminum pipe, combining advanced extrusion technologies, strict quality control, and global supply capabilities to meet evolving industry standards.

Top 8 Sch 40 Aluminum Pipe Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Unipipe

Domain Est. 2019 | Founded: 2011

Website: unipipesolutions.com

Key Highlights: Unipipe is a leading manufacturer and supplier of modular aluminum piping systems, trusted by industries worldwide since 2011….

#2 Aluminum Pipe

Domain Est. 1996

Website: easternmetal.com

Key Highlights: Pipe sizes up to 12″ SCH 40 are in stock and available for immediate shipment We feature high quality anodized marine grade pipe with a polished or brushed ……

#3 Seamless Aluminum Pipe

Domain Est. 1998

Website: continentalsteel.com

Key Highlights: Seamless Aluminum Pipe – Series 6061-T6 Schedule 40 ; Nominal Size · 4 inches101.6 mm ; O.D. · 4.500 inches114.3 mm ; I.D. · 4.026 inches102.2604 mm ; Wall Thickness ……

#4 Aluminum Pipe

Domain Est. 1998

Website: piercealuminum.com

Key Highlights: Pierce Aluminum supplies a full inventory of aluminumpipe products, as well as complete processing and fabrication services, at its 10 U.S. locations….

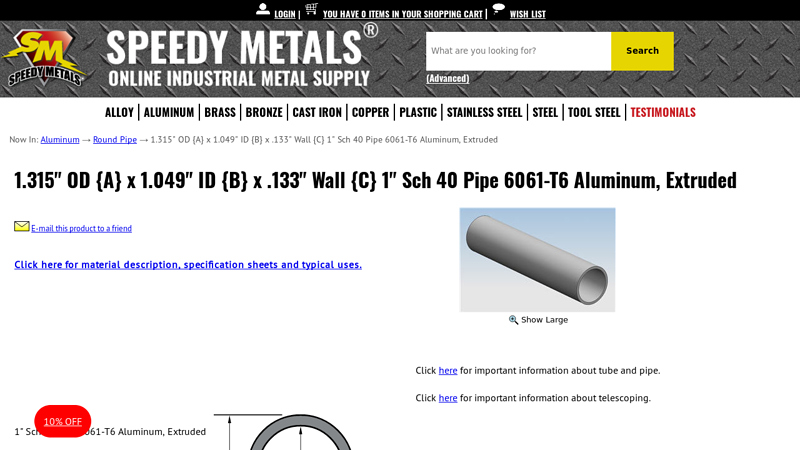

#5 Speedy Metals 1.315″ OD x 1.049″ ID x .133″ Wall 6061 Aluminum …

Domain Est. 2001

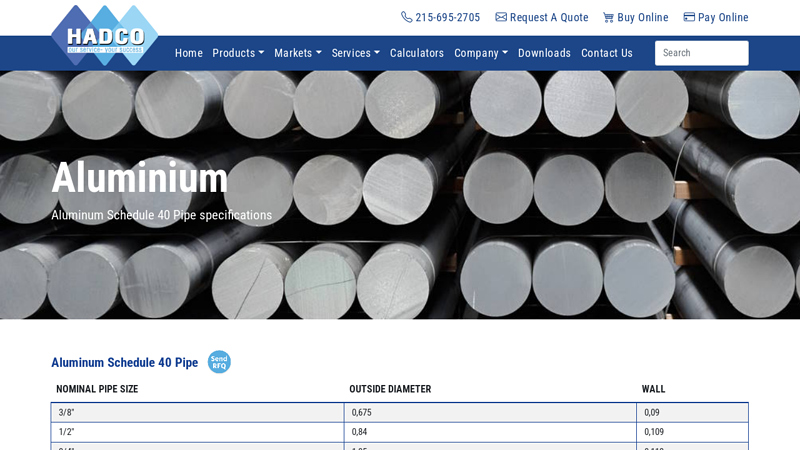

#6 Aluminum Schedule 40 Pipe specifications

Domain Est. 2006

Website: hadco-metal.com

Key Highlights: Aluminum Schedule 40 Pipe specifications. Aluminum Schedule 40 Pipe. Send RFQ. Hadco Metal Trading Co., LLC. Headquarters. 555 State Rd. Bensalem, PA 19020….

#7 Aluminum Seamless Bus Pipe

Domain Est. 2008

Website: aflglobal.com

Key Highlights: Seamless bus pipe is generally made of 6063-T6 alloy in ANSI Schedule 40 pipe because of its excellent mechanical and electrical properties. The 6061-T6 ……

#8 SCH40 SCH80 Aluminum Pipe Tube

Domain Est. 2017

Website: chalcoaluminum.com

Key Highlights: Chalco can provide high-quality 6061 6063 7075 5083 SCH40 SCH80 aluminum alloy seamless tubes, widely used in aircraft pipes, bicycle and other vehicle frames….

Expert Sourcing Insights for Sch 40 Aluminum Pipe

H2: Projected Market Trends for Schedule 40 Aluminum Pipe in 2026

The global market for Schedule 40 aluminum pipe is poised for significant evolution by 2026, driven by shifting industrial demands, material innovation, and sustainability priorities. As industries continue transitioning toward lightweight, corrosion-resistant, and energy-efficient materials, aluminum—particularly in standardized forms like Schedule 40—gains traction across key sectors.

-

Increased Adoption in Sustainable Infrastructure

By 2026, growing emphasis on green building and infrastructure is expected to boost demand for aluminum piping. Schedule 40 aluminum pipe, known for its durability and resistance to corrosion, is increasingly favored in water treatment, renewable energy systems (such as solar thermal and geothermal), and eco-friendly construction projects. Its recyclability—aluminum can be reused indefinitely without quality loss—aligns with global circular economy goals, enhancing its appeal over steel or PVC alternatives. -

Expansion in the Renewable Energy Sector

The renewable energy industry is a key growth driver. Aluminum pipes are used in heat exchange systems, solar panel support structures, and fluid transport in concentrated solar power (CSP) plants. As governments and private investors accelerate funding into clean energy, demand for lightweight, thermally efficient piping like Schedule 40 aluminum is projected to rise significantly, particularly in North America, Europe, and parts of Asia-Pacific. -

Technological Advancements in Manufacturing

Improvements in extrusion techniques and alloy development are expected to enhance the strength-to-weight ratio of Schedule 40 aluminum pipes. By 2026, manufacturers may offer high-strength aluminum alloys (e.g., 6061-T6 and 6063-T6) with performance closer to steel, expanding applications into higher-pressure industrial systems. Additive manufacturing integration and digital supply chain tools will also improve customization and delivery times. -

Competitive Pricing and Supply Chain Resilience

While aluminum prices remain sensitive to energy costs and geopolitical factors, the long-term trend suggests stable or declining costs due to improved refining efficiency and recycling rates. Companies are diversifying sourcing strategies to mitigate supply chain risks, with regional production hubs emerging in Mexico, Southeast Asia, and Eastern Europe to support localized demand. -

Regulatory and Code Acceptance

Building codes and industry standards are gradually adapting to recognize aluminum’s benefits. By 2026, wider acceptance in plumbing, HVAC, and industrial codes—particularly in seismic zones where aluminum’s flexibility is advantageous—will further drive adoption. Certification programs and performance testing will play a critical role in expanding market confidence. -

Competition with Alternative Materials

Despite growth, Schedule 40 aluminum faces competition from advanced composites and coated steel. However, aluminum’s non-toxicity, ease of installation, and low maintenance give it a competitive edge in sensitive environments such as food processing, pharmaceuticals, and marine applications.

In conclusion, the 2026 market for Schedule 40 aluminum pipe is expected to grow steadily, supported by sustainability trends, technological innovation, and expanding applications in high-growth industries. Strategic investment in R&D, recycling infrastructure, and market education will be key for suppliers aiming to capture emerging opportunities.

Common Pitfalls When Sourcing Schedule 40 Aluminum Pipe (Quality & IP)

Sourcing Schedule 40 aluminum pipe requires careful attention to both material quality and intellectual property (IP) considerations. Overlooking these areas can lead to project delays, safety risks, legal issues, and increased costs. Below are the most common pitfalls in both domains:

Quality-Related Pitfalls

-

Incorrect Alloy or Temper Specification

Assuming “aluminum pipe” is sufficient without specifying the exact alloy (e.g., 6061-T6) and temper can result in receiving substandard or unsuitable material. Different alloys vary significantly in strength, corrosion resistance, and weldability. Using a lower-grade alloy may compromise structural integrity. -

Tolerance and Dimensional Inaccuracy

Off-spec outer diameter (OD), wall thickness, or straightness can lead to fitment issues during installation, especially in pressurized systems or when connecting to flanges and fittings. Suppliers from non-certified mills may not adhere to ASTM B486 or ASME B36.10M standards. -

Poor Surface Finish or Defects

Surface imperfections such as scratches, dents, pits, or oxidation can accelerate corrosion, weaken the pipe, or contaminate sensitive processes (e.g., in food, pharmaceutical, or semiconductor applications). Visual inspection at delivery is essential. -

Inadequate Certification and Traceability

Failing to require mill test reports (MTRs) or certificates of conformance (CoC) leaves you without proof of compliance with required standards (e.g., ASTM B241). Lack of heat/lot traceability makes quality accountability impossible. -

Corrosion Resistance Mismatch

Not confirming the pipe’s suitability for the operating environment (e.g., marine, chemical exposure) can result in premature failure. Some aluminum alloys are prone to galvanic, pitting, or stress corrosion cracking in specific conditions. -

Weldability and Fabrication Issues

Unsuitable tempers or unverified material chemistry may lead to cracking or weak joints during welding. Confirming weld procedure specifications (WPS) compatibility before procurement prevents rework.

Intellectual Property (IP) Pitfalls

-

Infringement of Patented Designs or Processes

Sourcing aluminum pipe manufactured using patented forming, heat-treating, or coating methods without authorization exposes the buyer or end-user to IP litigation. This is particularly relevant with high-performance or specialty aluminum products. -

Counterfeit or Grey-Market Materials

Purchasing from unauthorized distributors or unclear supply chains increases the risk of receiving counterfeit materials falsely labeled as compliant. These may mimic certifications but lack proper IP licensing or quality controls. -

Unauthorized Use of Proprietary Specifications

Using a competitor’s or partner’s proprietary material specifications (e.g., custom alloy blends or processing techniques) in sourcing documents without permission can lead to trade secret or IP disputes. -

Lack of IP Clauses in Contracts

Failing to include clear IP indemnification clauses in procurement agreements leaves the buyer vulnerable if the supplier infringes third-party IP. Ensure contracts specify that the supplier warrants non-infringement. -

Export Control and Licensing Violations

Certain aluminum alloys and manufacturing technologies are subject to export controls (e.g., ITAR, EAR). Sourcing internationally without verifying compliance can result in legal penalties and shipment seizures.

By proactively addressing both quality standards and IP risks during procurement, organizations can ensure reliable performance, regulatory compliance, and legal protection when sourcing Schedule 40 aluminum pipe.

H2: Logistics & Compliance Guide for Schedule 40 Aluminum Pipe

Schedule 40 aluminum pipe is widely used in industrial, commercial, and transportation applications due to its lightweight, corrosion resistance, and structural integrity. Proper logistics and compliance practices are essential to ensure safe handling, transportation, and regulatory adherence. Below is a comprehensive guide to managing the logistics and compliance requirements for Schedule 40 aluminum pipe.

1. Material Classification & Specifications

- Material Type: Aluminum Alloy (typically 6061-T6 or 6063-T6)

- Schedule: Schedule 40 (standard wall thickness per ANSI/ASME B36.10M)

- Standards Compliance:

- ASTM B241: Standard Specification for Aluminum and Aluminum-Alloy Seamless Pipe and Seamless and Welded Tube

- ASME B36.10M: Welded and Seamless Wrought Steel Pipe (applicable dimensional standards adopted for aluminum)

- ISO 6303: Aluminum and aluminum alloys — Seamless round tubes

Ensure all material is certified and accompanied by Mill Test Reports (MTRs) verifying chemical composition and mechanical properties.

2. Packaging & Handling

- End Protection: Use plastic or metal caps to protect pipe ends from damage and contamination.

- Bundling: Secure pipes into bundles using steel or nylon strapping. Typical bundle weights should not exceed crane or forklift lifting limits (usually under 5,000 lbs / 2,268 kg).

- Palletization: Use wooden or metal pallets rated for the load. Place dunnage between layers to prevent scratching.

- Labeling: Clearly label each bundle with:

- Alloy type and temper

- Dimensions (OD, wall thickness, length)

- Schedule (40)

- Heat number or batch ID

- Handling instructions (e.g., “Do Not Stack,” “Forklift Only”)

Avoid dragging or dropping pipes to prevent deformation or surface damage.

3. Storage Requirements

- Environment: Store indoors or under cover to avoid moisture, which may lead to surface oxidation or staining.

- Racking: Use horizontal racks with adequate support to prevent bending or sagging (support every 4–6 feet).

- Separation: Keep aluminum pipes separated from carbon steel or other metals to prevent galvanic corrosion.

- Ventilation: Ensure good airflow to minimize condensation in storage areas.

4. Transportation & Shipping

- Mode of Transport:

- Truck (flatbed or enclosed trailer): Most common for domestic shipments.

- Rail: For bulk shipments over long distances.

- Ocean Freight: For international transport; use containers with desiccants to prevent moisture buildup.

- Securing Loads:

- Use chains, straps, or load binders to secure bundles to the transport vehicle.

- Prevent shifting during transit to avoid damage or safety hazards.

- Documentation:

- Bill of Lading (BOL)

- Packing List

- Material Test Reports (MTRs)

- Certificate of Compliance (C of C)

- Commercial Invoice (for international shipments)

5. Regulatory & Compliance Considerations

- DOT (Department of Transportation): No hazardous material classification for aluminum pipe; standard cargo securement rules apply (49 CFR).

- Customs & International Trade:

- Harmonized System (HS) Code: Typically 7608.10 (Aluminum tubes, pipes, and hollow profiles).

- Country-of-Origin Marking: Required for imports (e.g., “Made in USA”).

- Anti-Dumping/Countervailing Duties: Verify if applicable based on source country.

- OSHA (Occupational Safety and Health Administration):

- Follow guidelines for safe material handling (e.g., proper lifting techniques, use of PPE).

- Ensure storage areas are free of trip hazards and properly marked.

- Environmental Regulations:

- Aluminum is recyclable; ensure waste or scrap is disposed of or recycled in compliance with local environmental laws (e.g., EPA guidelines).

6. Quality Assurance & Traceability

- Maintain full traceability through heat numbers and batch records.

- Conduct periodic inspections during logistics stages for damage or corrosion.

- Implement a Quality Management System (QMS) compliant with ISO 9001.

7. Special Considerations

- Temperature Sensitivity: While aluminum maintains strength at low temperatures, avoid prolonged exposure to high heat (>350°F / 177°C) during transport or storage.

- Coatings & Finishes: If pipes have anodized or painted finishes, take extra precautions to prevent scratching or chipping.

Adhering to this logistics and compliance guide ensures that Schedule 40 aluminum pipe is handled safely, meets regulatory standards, and arrives at its destination in optimal condition. Always consult specific project or customer requirements, which may exceed general guidelines.

Conclusion for Sourcing SCH 40 Aluminum Pipe:

After evaluating various suppliers, material specifications, cost considerations, and application requirements, sourcing SCH 40 aluminum pipe is a viable and advantageous option for projects requiring a lightweight, corrosion-resistant, and structurally sound piping solution. Aluminum’s natural resistance to oxidation, combined with the standardized wall thickness of Schedule 40, ensures reliable performance in applications such as structural support, pneumatic systems, marine environments, and specialty industrial uses.

Key findings indicate that while aluminum SCH 40 pipe may have a higher initial cost compared to steel alternatives, its durability in corrosive environments and reduced long-term maintenance can result in lower total cost of ownership. Additionally, sourcing from reputable suppliers who provide certified materials (e.g., ASTM B483 for aluminum pipe) ensures compliance with engineering standards and consistent quality.

In conclusion, with proper supplier vetting, attention to alloy selection (such as 6061-T6 for optimal strength and weldability), and confirmation of dimensional accuracy, SCH 40 aluminum pipe offers an excellent balance of performance, longevity, and ease of installation—making it a recommended choice for suitable applications. Future sourcing efforts should prioritize suppliers offering reliable lead times, material certifications, and competitive pricing to support project efficiency and integrity.