The global scanner and visual communication modules (VCM) market is experiencing robust growth, driven by rising demand for automation, barcode recognition, and imaging technologies across retail, healthcare, logistics, and manufacturing sectors. According to a report by Grand View Research, the global barcode scanner market size was valued at USD 5.97 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 8.6% from 2023 to 2030. Similarly, Mordor Intelligence projects steady advancement in visual communication modules, fueled by increasing adoption of smartphones, security systems, and embedded vision technologies. As the demand for high-precision scanning and real-time data capture grows, manufacturers specializing in scanner and VCM technologies are scaling innovation and production capacity. In this competitive landscape, a select group of eight leading manufacturers distinguish themselves through technological excellence, market reach, and reliability—shaping the future of optical sensing and imaging solutions.

Top 8 Scanner Vcm Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Complete Ford IDS Package

Domain Est. 2002

Website: oemtools.com

Key Highlights: Experience the ultimate diagnostic tool for Ford vehicles – Ford IDS. Includes VCM-II hardware, Ford IDS software, and a Dell laptop….

#2 Scanner Optics VCM F1

Domain Est. 2023

Website: scanneroptics.com

Key Highlights: VCM F1 is a digital processing driver technology based on FPGA. The digital driver has excellent anti-interference ability and excellent dynamic performance….

#3 Ford VCM II with CFR Kit

Domain Est. 1995

#4 VCM Scanner with MPVI3 from HP Tuners

Domain Est. 1996

Website: aeswave.com

Key Highlights: In stock Rating 4.6 23 The VCM Scanner software allows you to create custom math parameters to monitor the difference between two PIDs. For example, you can create a custom math …

#5 IDS

Domain Est. 1998

Website: fordtechservice.dealerconnection.com

Key Highlights: IDS is enhanced WDS software that was modified to run on a standard laptop platform, and utilizes the VCM and VMM. Moving IDS to a laptop helps technicians by ……

#6 Supported Vehicles List

Domain Est. 2003

Website: hptuners.com

Key Highlights: View HP Tuners’ supported vehicles list from Ford, Stellantis, GM, Volkswagen Group, and more with credit and licensing details….

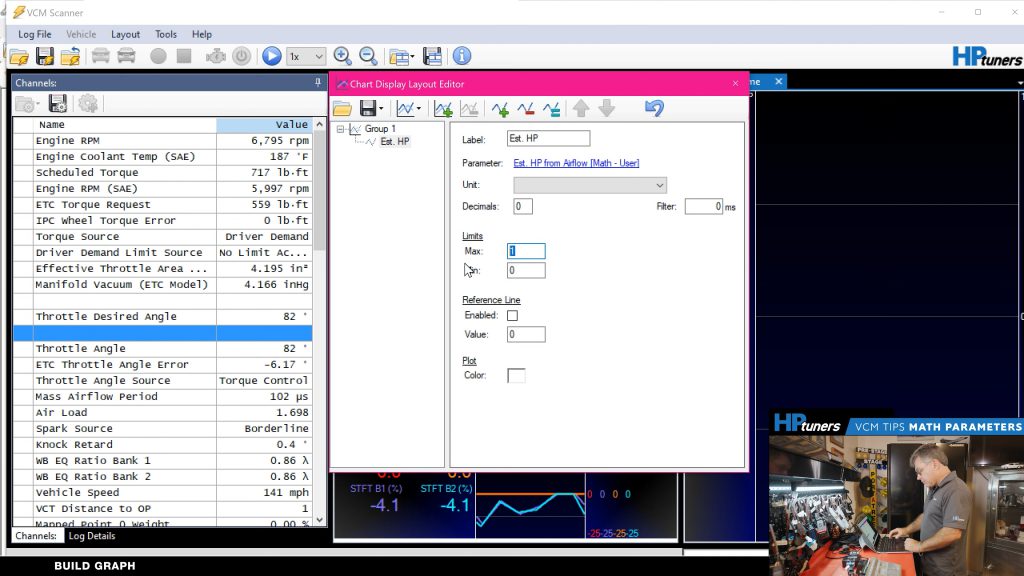

#7 Getting Started with VCM Scanner :

Domain Est. 2003

Website: support.hptuners.com

Key Highlights: You can quickly scan the vehicle’s performance and emissions behavior using the default VCM Scanner settings….

#8 VCM Scanner

Website: vcmperformance.com.au

Key Highlights: With our scanning, logging, and diagnostic software, VCM Scanner, dive deep into your vehicle’s performance data with customizable charts, graphs, gauges, ……

Expert Sourcing Insights for Scanner Vcm

H2: 2026 Market Trends Outlook for Scanner VCM (Voice Coil Motor)

The global market for Voice Coil Motors (VCMs) used in scanning applications—commonly referred to as Scanner VCMs—is poised for significant transformation by 2026, driven by advancements in automation, precision imaging, and demand across key industries. This analysis outlines the major market trends expected to influence the Scanner VCM sector in the second half of 2026 (H2 2026), based on current technological trajectories, industry demand, and macroeconomic factors.

-

Increased Demand in Industrial Automation and Logistics

By H2 2026, the integration of Scanner VCMs in automated sorting systems, warehouse robotics, and logistics tracking is expected to grow significantly. The expansion of e-commerce and smart supply chains continues to drive the need for high-speed, accurate barcode and QR code scanning systems. VCMs, known for their fast response times and precise positioning, are increasingly preferred in next-generation scanning modules used in automated guided vehicles (AGVs) and mobile robots. -

Advancements in Miniaturization and Power Efficiency

OEMs are focusing on smaller, more energy-efficient scanning components. In H2 2026, Scanner VCMs are expected to benefit from innovations in micro-electromechanical systems (MEMS) and compact coil design. These improvements allow for integration into handheld scanners, wearable devices, and compact industrial sensors without sacrificing performance. This trend supports applications in healthcare (e.g., mobile patient identification scanners) and retail (e.g., compact point-of-sale systems). -

Growth in Healthcare and Biomedical Imaging

The healthcare sector is emerging as a high-growth area for Scanner VCMs, particularly in medical imaging devices such as optical coherence tomography (OCT) and portable diagnostic scanners. By H2 2026, increased investment in telemedicine and point-of-care diagnostics is expected to boost demand for reliable, fast-scanning mechanisms. VCMs offer the precision and stability required for real-time imaging, making them ideal for these sensitive applications. -

Rise of Smart Retail and Contactless Technology

Post-pandemic behavioral shifts continue to influence retail technology. Scanner VCMs are being deployed in contactless checkout systems, smart shelves, and inventory management tools. In H2 2026, the push for seamless, cashier-less shopping experiences—exemplified by smart stores—will further increase adoption. VCM-based laser scanners provide the speed and reliability needed for high-accuracy product recognition and real-time data capture. -

Integration with AI and IoT Ecosystems

Scanner VCMs are increasingly embedded within AI-powered and IoT-connected systems. By H2 2026, intelligent scanning systems will leverage real-time data from VCM-driven sensors to enable predictive maintenance, dynamic inventory updates, and enhanced user interfaces. This integration enhances operational efficiency and enables smarter decision-making across manufacturing, logistics, and retail sectors. -

Regional Market Shifts and Supply Chain Localization

Asia-Pacific, particularly China, South Korea, and Japan, remains a dominant hub for Scanner VCM manufacturing due to strong electronics supply chains and R&D capabilities. However, by H2 2026, there is a noticeable shift toward supply chain diversification. North America and Europe are investing in localized production of high-precision components, including VCMs, to reduce dependency on single-source suppliers and meet growing demand for customized scanning solutions. -

Sustainability and Material Innovation

Environmental regulations and corporate sustainability goals are influencing VCM design. By H2 2026, manufacturers are expected to adopt more recyclable materials, reduce rare-earth magnet dependency, and improve energy efficiency. These efforts align with broader ESG (Environmental, Social, and Governance) initiatives within the electronics industry.

Conclusion:

In H2 2026, the Scanner VCM market is expected to experience robust growth driven by technological innovation and expanding applications in automation, healthcare, and smart infrastructure. Companies that invest in miniaturization, energy efficiency, and integration with intelligent systems will be best positioned to capitalize on emerging opportunities. As demand becomes more global and application-specific, strategic partnerships and regional manufacturing will play a critical role in shaping market leadership.

Common Pitfalls Sourcing Scanner VCM (Quality, IP)

Sourcing Voice Coil Motors (VCMs) for scanning applications—such as laser scanning, barcode readers, or optical imaging systems—requires careful attention to both performance and legal considerations. Overlooking key aspects can lead to product failures, supply chain disruptions, or intellectual property (IP) risks. Below are common pitfalls related to quality and IP when sourcing Scanner VCMs.

Quality-Related Pitfalls

Inadequate Performance Specifications

Many suppliers provide generic or incomplete performance data, such as stroke range, response time, force output, and linearity. Relying on incomplete specs can result in VCMs that fail to meet system requirements, leading to poor scanning accuracy or slow response times.

Poor Mechanical and Thermal Stability

Scanner VCMs operate under dynamic conditions and are sensitive to temperature fluctuations and mechanical stress. Sourcing from manufacturers without robust thermal compensation or durable mechanical design can result in drift, hysteresis, or premature failure in real-world environments.

Inconsistent Manufacturing Tolerances

Low-cost or unqualified suppliers may lack strict quality control processes, leading to part-to-part variations. This inconsistency affects calibration, repeatability, and overall scanner system performance, especially in high-precision applications.

Lack of Environmental Robustness Testing

Scanner VCMs used in industrial or outdoor applications must withstand shock, vibration, humidity, and temperature extremes. Sourcing components without proper environmental validation increases the risk of field failures and reduces system reliability.

Insufficient Lifetime and Reliability Data

Long-term reliability data—such as mean time between failures (MTBF) or cycle life testing—is often missing or exaggerated. Without verified data, designers cannot accurately predict maintenance intervals or failure rates, leading to unexpected downtime.

Intellectual Property (IP) Pitfalls

Unlicensed or Infringing Designs

Some suppliers, particularly in less-regulated markets, may offer VCMs that copy patented technologies without proper licensing. Using such components exposes the buyer to legal liability, including injunctions or damages, especially when selling in IP-sensitive regions like the U.S. or EU.

Unclear IP Ownership in Custom Designs

When working with contract manufacturers on custom VCMs, failure to define IP ownership in contracts can lead to disputes. Suppliers may claim rights to design improvements or tooling, limiting your ability to switch vendors or scale production.

Reverse-Engineered Components

Certain VCMs may be reverse-engineered from established brands, potentially violating design patents or trade secrets. Even if the component functions well, using such parts can trigger IP litigation, especially if the original manufacturer detects market infringement.

Lack of Documentation and Compliance Certificates

Reputable suppliers provide IP compliance statements, design registration documents, and freedom-to-operate (FTO) analyses. Absence of such documentation increases the risk of unknowingly infringing on third-party patents.

Supply Chain Opacity

Complex supply chains with multiple intermediaries can obscure the true origin of components. This makes it difficult to verify whether the VCM design respects IP laws, especially when sub-tier suppliers are involved.

Best Practices to Avoid Pitfalls

- Validate supplier qualifications through audits, sample testing, and reference checks.

- Require full performance and reliability data under real operating conditions.

- Conduct IP due diligence, including patent landscape reviews and supplier warranties.

- Define IP ownership clearly in development and supply agreements.

- Work with reputable, transparent suppliers who provide traceability and compliance documentation.

By proactively addressing these quality and IP challenges, companies can ensure reliable scanner performance and mitigate legal and operational risks in their VCM sourcing strategy.

Logistics & Compliance Guide for Scanner VCM

This guide outlines the essential logistics procedures and compliance requirements for the transportation, handling, and deployment of the Scanner VCM (Vehicle Configuration Module). Adherence to these guidelines ensures regulatory compliance, product integrity, and operational efficiency.

Shipping and Handling

All Scanner VCM units must be shipped in their original protective packaging or equivalent certified packaging that meets ISTA 3A standards. Units should be palletized and secured with stretch wrap for freight transport. Always label shipments with proper handling indicators: “Fragile,” “This Side Up,” and “Protect from Moisture.” Avoid dropping, stacking heavy items on top, or exposing units to extreme temperatures during transit.

Import and Export Compliance

Ensure all international shipments comply with relevant export control regulations, including EAR (Export Administration Regulations) and any applicable ITAR requirements. The Scanner VCM may be subject to ECCN (Export Control Classification Number) 3A999. Complete and retain accurate export documentation, including commercial invoices, packing lists, and export declarations. Verify destination country restrictions and obtain required licenses prior to shipment.

Customs Clearance

Provide complete and accurate customs documentation to prevent delays. Include HS Code 8471.80 for automated data processing machines and associated equipment. Declare the correct value, country of origin (typically USA or as per manufacturing site), and end-use. Coordinate with a licensed customs broker to ensure smooth clearance and compliance with local import laws.

Product Certification and Standards

The Scanner VCM is certified to meet key international standards, including:

– FCC Part 15, Class B (USA)

– CE Marking (EMC Directive 2014/30/EU, RoHS Directive 2011/65/EU)

– UKCA (United Kingdom)

– PSE (Japan, for applicable models)

Ensure only certified configurations are distributed in each region. Do not modify hardware or firmware in a way that invalidates certifications.

Environmental and Safety Compliance

Dispose of packaging and electronic waste in accordance with local environmental regulations. The Scanner VCM contains electronic components subject to WEEE (Waste Electrical and Electronic Equipment) directives in the EU and equivalent laws elsewhere. Follow manufacturer guidelines for battery handling if applicable (e.g., for backup power modules).

Documentation and Recordkeeping

Maintain a compliance dossier for each shipment, including:

– Certificate of Conformity (CoC)

– Packing list and shipping manifest

– Export license (if required)

– Test reports for EMC and safety

– Software version and firmware audit logs

Retain all records for a minimum of five years to support audits and regulatory inquiries.

Field Deployment and Installation

Only trained and authorized personnel may install or configure the Scanner VCM. Follow the manufacturer’s installation manual to ensure proper setup and grounding. Conduct a post-installation verification to confirm operational compliance with site safety and data security policies.

Incident Reporting and Corrective Actions

Immediately report any logistics damage, compliance breach, or non-conforming product to the Logistics Compliance Officer. Initiate corrective and preventive actions (CAPA) as needed. Document all incidents and resolutions in the compliance management system.

Adhering to this guide ensures the secure, lawful, and efficient movement of Scanner VCM units across global supply chains.

Conclusion for Sourcing VCM (Voice Coil Motor) Scanners:

After a comprehensive evaluation of potential suppliers, technical specifications, cost structures, and supply chain reliability, sourcing VCM (Voice Coil Motor) scanners from qualified vendors presents a strategic opportunity to enhance the performance and responsiveness of scanning systems. VCM technology offers superior speed, precision, and energy efficiency compared to traditional scanning mechanisms, making it ideal for high-demand applications in industries such as automation, medical devices, and consumer electronics.

Key findings indicate that partnering with suppliers who demonstrate proven expertise in VCM design, offer consistent quality control, and provide scalable production capacity is critical. Additionally, considerations around lead times, total cost of ownership, and technical support post-purchase play a significant role in long-term success.

In conclusion, sourcing VCM scanners from carefully vetted suppliers not only improves product performance but also supports innovation and competitiveness. A strategic sourcing approach—balancing technical excellence, reliability, and cost-effectiveness—will ensure successful integration of VCM scanners into end applications, ultimately delivering enhanced value to customers and stakeholders.