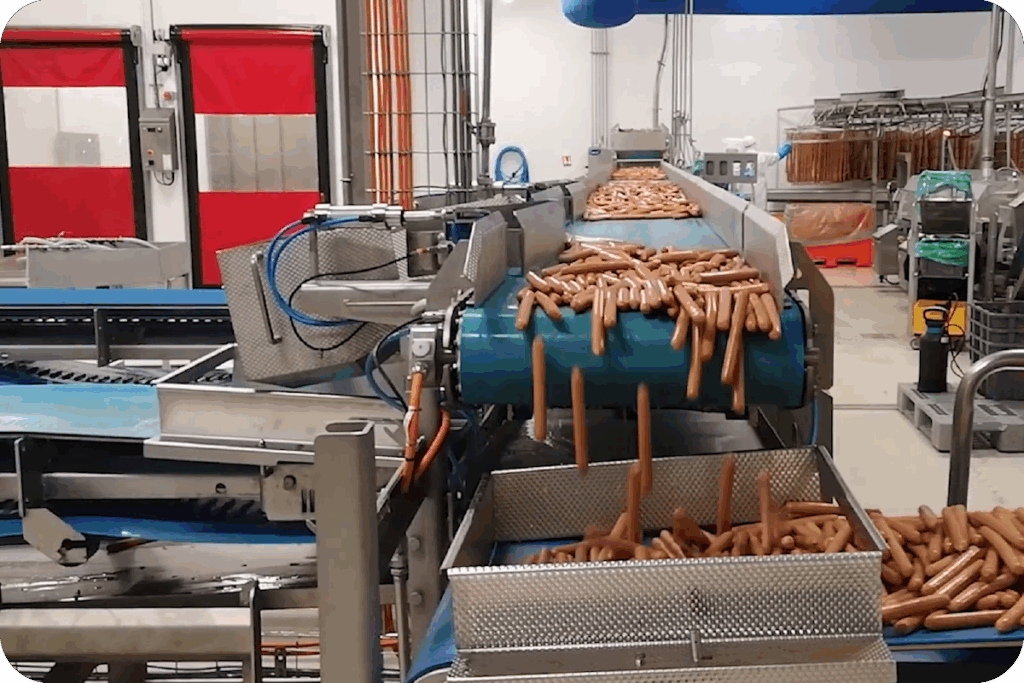

The global sausage processing equipment market is experiencing steady growth, driven by rising demand for processed meat products and increasing automation in food manufacturing. According to Grand View Research, the global meat processing equipment market was valued at USD 9.8 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 6.4% from 2023 to 2030. A key contributor to this expansion is the growing need for efficient, hygienic, and high-capacity sausage filling and portioning solutions across commercial and industrial meat processing facilities. Similarly, Mordor Intelligence projects a CAGR of over 5.8% for the meat processing equipment market through 2028, citing advancements in food safety standards and increased investment in scalable production technologies. As demand rises, sausage machine manufacturers are innovating to meet industry needs for precision, durability, and compliance with international food safety regulations. In this competitive landscape, seven manufacturers have emerged as leaders, combining engineering excellence with global reach to support the evolving needs of meat processors worldwide.

Top 7 Sausage Machine Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 The Sausage Maker #5

Domain Est. 1997

Website: usinger.com

Key Highlights: In stockLean choice beef, coarsely chopped, seasoned just right, then slowly smoked two days for a tantalizing aroma and robust flavor.Missing: machine manufacturer…

#2 HeBei XiaoJin Machinery Manufacturing Inc.

Domain Est. 2020 | Founded: 1986

Website: xiaojinmachinery.com

Key Highlights: HeBei XiaoJin Machinery Manufacturing Inc is founded in 1986. We have over 30 years experience in food processing machinery industry….

#3 Get Premium Meat Processing Equipment

Domain Est. 1996

#4 Sausage Processing Equipment Solutions for your business

Domain Est. 1996

Website: reiser.com

Key Highlights: Reiser is the industry’s leading supplier of sausage processing equipment, including sausage processing, sausage stuffing, and sausage linking equipment….

#5 Sausage Maker Supplies

Domain Est. 2012

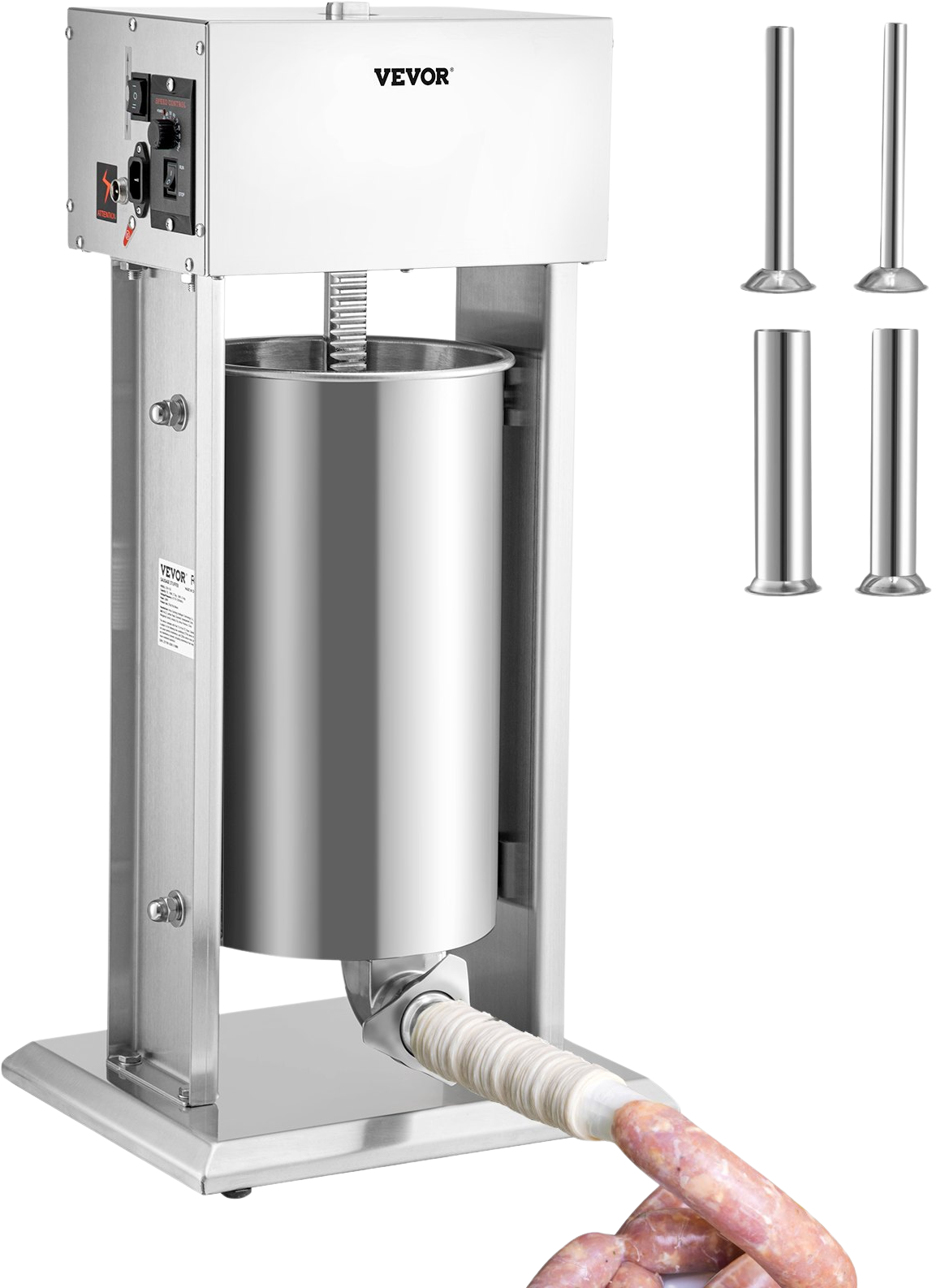

#6 Manual & Electric Sausage Stuffers

Domain Est. 2021

Website: hakkabros.com

Key Highlights: Free delivery 30-day returnsHakka manual and electric sausage stuffers for sausage making and food filling. Multiple models to support kitchen operations, retail sellers, and food …

#7 GARVEE Stainless Steel Upright Sausage Stuffing Machine

Domain Est. 2022

Website: garvee.com

Key Highlights: Rating 4.9 (9) Ideal for both indoor and outdoor use, this powerful sausage stuffing machine features adjustable speed and five tubes for versatile sausage making….

Expert Sourcing Insights for Sausage Machine

H2: 2026 Market Trends for Sausage Machines

The global sausage machine market is poised for significant transformation by 2026, driven by evolving consumer preferences, technological advancements, and shifts in food production practices. Key trends shaping the industry include automation, demand for specialty and plant-based sausages, sustainability, and regional market dynamics.

1. Increased Automation and Smart Technology Integration

By 2026, sausage machines are increasingly incorporating automation and IoT (Internet of Things) capabilities. Manufacturers are investing in smart equipment equipped with sensors, real-time monitoring, and predictive maintenance features. These innovations improve production efficiency, reduce labor costs, and ensure consistent product quality—critical for both large-scale meat processors and artisanal producers scaling operations.

2. Rising Demand for Specialty and Alternative Sausages

Consumer interest in diverse flavors, ethnic cuisines, and dietary-specific products is fueling demand for versatile sausage machines. Equipment capable of handling plant-based proteins, gluten-free mixtures, and exotic meat blends (e.g., venison, turkey, or duck) is gaining traction. The global rise in vegetarian and flexitarian diets is accelerating the need for machines that can efficiently process meat analogs made from pea protein, soy, and mycoprotein.

3. Focus on Hygiene, Cleanability, and Food Safety

Regulatory standards and heightened consumer awareness around food safety are pushing manufacturers to design sausage machines with improved hygiene features. Equipment made from food-grade stainless steel, with seamless surfaces and quick-disassembly components, is becoming standard. By 2026, compliance with HACCP and FDA regulations will be a key selling point, especially in North America and Europe.

4. Expansion in Emerging Markets

Asia-Pacific and Latin America are emerging as high-growth regions for sausage machine adoption. Urbanization, rising disposable incomes, and the expansion of organized food retail and foodservice sectors are driving demand. Local manufacturers are developing cost-effective, compact models tailored to small and medium-sized enterprises (SMEs), contributing to market diversification.

5. Sustainability and Energy Efficiency

Environmental concerns are influencing machinery design. By 2026, energy-efficient motors, water-saving cleaning systems, and recyclable components are becoming standard features. Producers are also favoring modular machines that reduce waste and allow for upgrades instead of full replacements, aligning with circular economy principles.

6. Customization and Modular Design

To cater to a fragmented market—from artisanal butchers to industrial food processors—manufacturers are offering modular sausage machines. These systems allow users to customize throughput, filling precision, and casing types. This flexibility supports product innovation and faster time-to-market for new sausage varieties.

Conclusion

The 2026 sausage machine market reflects broader trends in food technology: smarter, cleaner, and more adaptable equipment. Companies that invest in innovation, sustainability, and responsiveness to dietary shifts will be best positioned to capture growth in this dynamic sector.

Common Pitfalls When Sourcing Sausage Machines: Quality and Intellectual Property (IP) Risks

Sourcing sausage machines, especially from overseas suppliers, can present significant challenges related to both product quality and intellectual property protection. Being aware of these common pitfalls helps mitigate risks and ensures a reliable, legally sound procurement process.

Quality-Related Pitfalls

Inconsistent Build Materials and Standards

One of the most frequent issues is the use of substandard materials, such as non-food-grade stainless steel or inferior seals and gaskets. Suppliers may claim compliance with international standards (e.g., FDA, CE, or ISO), but actual machines may fall short. Always request material certifications and conduct third-party inspections before shipment.

Poor Manufacturing Tolerances and Assembly

Low-cost manufacturers may lack precision engineering, leading to misaligned parts, excessive vibration, or premature wear. This affects both performance and food safety. Prototype testing and on-site factory audits are essential to verify build quality.

Inadequate Motor and Drive System Performance

Some machines are equipped with underpowered motors or poorly designed gearboxes that overheat during continuous operation. This results in breakdowns and inconsistent filling. Verify motor specifications under real-world load conditions and assess thermal management features.

Lack of Validation in Real-World Conditions

Suppliers may demonstrate machines in ideal environments, masking issues like clogging, uneven stuffing, or cleaning difficulties. Request a trial run using your specific sausage mix and production conditions before finalizing the order.

Insufficient After-Sales Support and Spare Parts Availability

Even well-built machines require maintenance. Sourcing from suppliers without reliable technical support or a spare parts network can lead to prolonged downtime. Ensure service agreements and spare parts inventory are part of the procurement terms.

Intellectual Property (IP) Risks

Design and Technology Infringement

Many sausage machines, especially advanced models, incorporate patented technologies (e.g., vacuum systems, automated linking mechanisms). Sourcing from unscrupulous manufacturers may result in purchasing machines that infringe on existing IP rights, exposing your business to legal liability.

Unauthorized Use of Branding or Logos

Some suppliers replicate well-known brand designs or logos without permission. Purchasing such equipment can inadvertently link your business to counterfeit products, damaging your reputation and inviting legal action from IP holders.

Reverse-Engineered Components

Suppliers may reverse-engineer proprietary components (e.g., augers, stuffing tubes) from premium brands. While these may appear identical, they often lack the performance and durability of original parts—and may violate patents or trade secrets.

Lack of IP Ownership Clarity in Custom Designs

If you commission a custom machine design, ensure the contract explicitly assigns IP rights to your company. Otherwise, the supplier may retain rights and reuse the design for competitors or block future modifications.

Weak Contractual Protections

Many sourcing agreements fail to include clauses protecting against IP infringement. Always include warranties stating that the supplier owns or has licensed all IP used in the machine, and that they will indemnify you against infringement claims.

By proactively addressing these quality and IP pitfalls—through due diligence, clear contracts, and third-party verification—businesses can source sausage machines that are both reliable and legally secure.

Logistics & Compliance Guide for Sausage Machine

This guide outlines the essential logistics and compliance considerations for the import, export, distribution, and operation of sausage machines in commercial and industrial environments.

Regulatory Compliance

Ensure all sausage machines meet relevant food safety and electrical safety standards based on the region of operation. In the United States, equipment must comply with FDA 21 CFR standards for food-contact surfaces and be certified by NSF International (NSF/ANSI Standard 2). In the European Union, adherence to the CE marking directive, including the Machinery Directive (2006/42/EC) and Regulation (EC) No 1935/2004 for food contact materials, is mandatory. Other regions may require national certifications such as CSA in Canada or CCC in China.

Import and Export Documentation

Prepare and maintain accurate documentation for international shipping, including commercial invoices, packing lists, bill of lading/airway bill, and certificates of origin. For regulated equipment, include compliance certifications (e.g., NSF, CE, ISO) and product specifications. Be aware of import duties, tariffs, and customs clearance requirements in the destination country. Use Harmonized System (HS) codes specific to food processing machinery (e.g., 8438.80 for machinery for preparing or making up meat products) to classify the sausage machine correctly.

Packaging and Handling

Package sausage machines in durable, weather-resistant materials to prevent damage during transit. Use wooden crates or reinforced cardboard with internal bracing to secure moving parts. Clearly label packages with handling instructions (e.g., “Fragile,” “This Side Up”) and include product identification, model number, and serial number. Protect electrical components and food-contact surfaces with plastic wrapping or protective caps.

Transportation Requirements

Use freight carriers experienced in handling industrial kitchen equipment. For sea freight, ensure containers are sealed and moisture-controlled to prevent rust. For air freight, optimize packaging for weight and dimensions to reduce costs. Coordinate delivery schedules with facility readiness, including access for heavy lifting equipment (e.g., forklifts or pallet jacks) at the destination.

Installation and Site Compliance

Verify that the installation site meets electrical, plumbing, and ventilation requirements specified by the manufacturer. Ensure grounding, voltage, and phase compatibility. Confirm that the facility’s health and safety policies comply with OSHA (in the U.S.) or equivalent local regulations. Train personnel on safe operation and lockout/tagout (LOTO) procedures before use.

Maintenance and Record-Keeping

Follow manufacturer-recommended maintenance schedules to ensure ongoing compliance and machine longevity. Keep detailed logs of inspections, repairs, and part replacements. Maintain copies of all compliance certificates, manuals, and warranty documentation on file for audits or regulatory inspections.

Disposal and End-of-Life

Dispose of decommissioned sausage machines in accordance with local environmental regulations. Recycle metal components and properly handle electrical parts to comply with e-waste directives (e.g., WEEE in the EU). Document disposal procedures to support sustainability and regulatory compliance efforts.

In conclusion, sourcing a sausage machine requires careful consideration of several key factors including production needs, machine type (manual, electric, or commercial-grade), capacity, durability, ease of cleaning, and budget. It is essential to evaluate suppliers based on reputation, warranty offerings, customer support, and compliance with food safety standards. By aligning the machine specifications with your operational requirements—whether for home use, small-scale production, or large commercial operations—you can ensure efficiency, consistency, and long-term cost-effectiveness. Proper research and due diligence in sourcing will lead to a reliable investment that enhances productivity and maintains product quality in sausage preparation.