The global natural stone market, including sandstone, has experienced steady growth driven by rising demand in construction, architectural restoration, and landscaping. According to a report by Mordor Intelligence, the natural stone market was valued at USD 39.5 billion in 2022 and is projected to grow at a CAGR of 5.8% from 2023 to 2028. Sandstone, prized for its durability, aesthetic versatility, and thermal resistance, holds a significant share of this market, particularly in regions like Asia-Pacific and the Middle East where infrastructure development is accelerating. With increasing preference for sustainable and locally sourced building materials, sandstone manufacturers are expanding production capacities and adopting eco-friendly extraction techniques to meet evolving industry standards. As demand continues to climb, identifying leading players becomes crucial for stakeholders across construction and design sectors.

Top 9 Sandstone Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Stone Veneer Manufacturer

Domain Est. 2004

Website: estoneworks.com

Key Highlights: StoneWorks manufactures & installs beautiful stone veneer for builders & contractors. From project start to finish, we are your one source turnkey solution….

#2 Natural Stones: Granites, Marble, Limestones, Soapstone

Domain Est. 1997

Website: polycor.com

Key Highlights: Polycor is the World’s Leading Natural Stone Quarrier. Our mission is to strive together as one team to deliver excellence as a natural stone company….

#3 Vetter Stone

Domain Est. 1998

Website: vetterstone.com

Key Highlights: Vetter Stone’s Alabama Stone is a durable and striking limestone, quarried in Alabama, that has graced monumental buildings for over a century….

#4 Halquist Stone

Domain Est. 1998

Website: halquiststone.com

Key Highlights: Products · Stone Veneer · Landscape Stone · Bluestone Collection · Fieldstone Collection · Flagstone Collection · Paving/Paver Collection ……

#5 Apache Stone

Domain Est. 1999

Website: apachestone.com

Key Highlights: Explore Apache Stone vast selection of natural and manufactured stone veneer as well as masonry building supplies. Everything you need from one source!…

#6 Cleveland Quarries

Domain Est. 2001

Website: clevelandquarries.com

Key Highlights: Fully integrated fabrication facilities transform blocks of Berea Sandstone into a variety of products ranging from slabs to hand cut architectural details….

#7 Prestige Stone

Domain Est. 2007

Website: prestigestoneproducts.com

Key Highlights: Prestige Stone offers lightweight, affordable stone veneers that replicate the look of real stone with exceptional quality and care….

#8 Dunbar Stone Company

Domain Est. 2007

Website: dunbarstoneinc.com

Key Highlights: Dunbar Stone Company was founded by Robert (Bob) Dunbar back in 1945. The company has always had pride in the quality of stone they produce….

#9 Fond du Lac Natural Stone

Domain Est. 2020

Website: fdlnaturalstone.com

Key Highlights: Fond du Lac Natural Stone offers over 90 natural stone products harvested from the United States and abroad, offering a wide variety of colors, textures and ……

Expert Sourcing Insights for Sandstone

H2: Market Trends for Sandstone in 2026

As we approach 2026, the global sandstone market is undergoing significant transformation driven by shifts in construction demand, sustainability priorities, technological advancements, and regional economic developments. Sandstone, a durable and aesthetically valued natural stone, continues to hold relevance in architecture and landscaping, though its market dynamics are being reshaped by emerging trends.

1. Growth in Sustainable and Green Construction

Environmental awareness is a key driver influencing material selection in construction. Sandstone, as a naturally occurring and low-carbon footprint material compared to manufactured cladding products, is gaining favor in eco-conscious building projects. By 2026, green building certifications such as LEED and BREEAM are increasingly promoting the use of locally sourced natural stone, including sandstone, reducing transportation emissions. This trend is particularly strong in Europe and North America, where sustainability regulations are tightening.

2. Rising Demand in Residential and Luxury Architecture

The luxury residential segment is seeing a resurgence in the use of sandstone for façades, flooring, and interior finishes due to its unique textures and earthy color palettes. In markets like India, the Middle East, and parts of Southeast Asia, sandstone remains a preferred material for high-end villas and heritage-inspired designs. Rajasthan in India, one of the world’s largest sandstone producers, continues to export premium grades, benefiting from strong demand in international luxury markets.

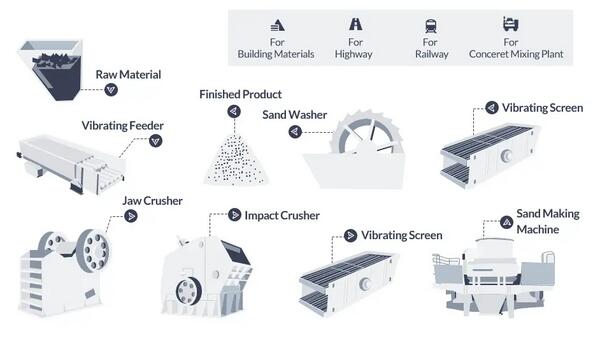

3. Technological Advancements in Processing and Finishing

Innovation in quarrying and stone processing technologies is enhancing the efficiency and precision of sandstone production. By 2026, computer-controlled cutting, water-jet technologies, and digital templating are enabling manufacturers to offer custom finishes (e.g., honed, flamed, bush-hammered) with reduced waste and improved consistency. These advancements are making sandstone more competitive against engineered stone alternatives.

4. Shift in Supply Chain Dynamics and Regional Production

Global supply chains for sandstone have been reorganized post-pandemic, with a growing emphasis on regional self-sufficiency. Countries like Turkey, Iran, and Brazil are expanding their sandstone quarrying operations to meet local and export demand, reducing reliance on traditional suppliers. Additionally, geopolitical factors are prompting construction firms to diversify sourcing, supporting a more distributed global production base.

5. Competitive Pressure from Alternative Materials

Despite its appeal, sandstone faces increasing competition from engineered quartz, porcelain tiles, and composite panels—materials that offer uniformity, lower maintenance, and often lower costs. However, sandstone retains a niche in high-value applications where authenticity and natural beauty are paramount. Marketing efforts by industry groups are emphasizing its recyclability and longevity to differentiate it in the marketplace.

6. Infrastructure and Public Projects Driving Institutional Demand

Governments in developing economies are investing heavily in infrastructure and urban beautification projects, where sandstone is used for cladding public buildings, monuments, and civic spaces. In India, for example, government-led initiatives to develop smart cities and renovate historical sites are expected to sustain demand for sandstone through 2026.

Conclusion

By 2026, the sandstone market is poised for moderate but steady growth, supported by its alignment with sustainability trends, enduring aesthetic value, and technological improvements in production. While challenges from synthetic alternatives persist, strategic positioning of sandstone as a premium, eco-friendly natural material is expected to secure its place in both traditional and modern architectural applications. Market players who invest in sustainable practices, value-added processing, and global distribution networks will be best positioned to capitalize on evolving demand.

Common Pitfalls Sourcing Sandstone: Quality and Intellectual Property (IP)

Sourcing sandstone for construction, architectural design, or artistic projects can present several challenges, particularly concerning material quality and intellectual property considerations. Being aware of these pitfalls helps ensure project success and legal compliance.

Poor Quality Control and Inconsistent Material Properties

One of the most frequent issues when sourcing sandstone is variability in quality across batches or quarries. Sandstone is a natural stone, and its composition can vary significantly based on geological origin. Buyers may encounter inconsistent color, grain size, hardness, porosity, and compressive strength, leading to mismatches in aesthetic and structural performance. Low-quality sandstone may also contain hidden flaws such as fissures, laminations, or high water absorption rates, which compromise durability—especially in exterior applications exposed to freeze-thaw cycles. Without rigorous testing and certification from suppliers, these defects may only become apparent after installation, resulting in costly replacements or structural failures.

Lack of Traceability and Certification

Many sandstone suppliers, particularly in less-regulated markets, do not provide verifiable documentation on the stone’s origin, extraction methods, or compliance with industry standards (e.g., ASTM, EN). This lack of traceability makes it difficult to ensure the stone meets required performance specifications or sustainability criteria. It also increases the risk of sourcing material from environmentally harmful or unethical operations. Without proper certification, architects and contractors may inadvertently violate building codes or green building standards like LEED or BREEAM.

Misrepresentation of Origin and Type

Sandstone is often marketed using misleading names that suggest a prestigious geographic origin (e.g., “Australian” or “Indian sandstone”) when the material may actually come from a different region or be a lookalike stone. This mislabeling can affect both aesthetic expectations and performance, as different types of sandstone have distinct physical properties. Buyers may end up with a product that doesn’t match design intent or fails to meet technical requirements, leading to disputes and project delays.

Intellectual Property Infringement in Design Elements

When sourcing custom-cut or patterned sandstone for architectural features (e.g., ornate facades, carved panels), there is a risk of unintentional intellectual property (IP) infringement. Some designs may be protected by copyright or design patents, especially if they are based on traditional motifs, registered patterns, or proprietary templates. If a supplier reproduces such designs without proper licensing—even if the buyer requests it—the end user could be held liable for infringement. This is particularly relevant when sourcing from overseas manufacturers with less stringent IP enforcement.

Inadequate Documentation of Custom Tooling and Molds

In projects requiring bespoke sandstone elements, custom molds or digital tooling (e.g., CNC designs) may be created at the buyer’s expense. A common pitfall is failing to secure IP rights over these designs in the supply contract. Without explicit agreements, suppliers may retain ownership or reuse the tooling for other clients, diluting the design’s uniqueness or leading to unauthorized replication. This undermines competitive advantage and brand exclusivity, particularly in high-end architectural or commercial developments.

Conclusion

To mitigate these risks, buyers should conduct thorough due diligence on suppliers, require material test reports and origin certifications, verify design rights, and include clear IP clauses in procurement contracts. Engaging with reputable quarries and legal advisors familiar with construction materials and IP law can help avoid costly quality issues and legal complications.

Logistics & Compliance Guide for Sandstone

This guide outlines the essential logistics and compliance considerations for the extraction, handling, transportation, and use of sandstone, ensuring adherence to regulatory standards and operational best practices.

Regulatory Compliance

Ensure all activities related to sandstone operations comply with local, national, and international regulations. Key areas include:

- Environmental Permits: Obtain necessary permits for quarrying, including Environmental Impact Assessments (EIA), water usage, and waste management plans.

- Mining Licenses: Secure valid mining or extraction rights from relevant governmental authorities.

- Health & Safety Regulations: Follow OSHA (or equivalent) standards for worker safety, including dust control, fall protection, and equipment operation.

- Transportation Regulations: Adhere to Department of Transportation (DOT) or local transport authority guidelines for load dimensions, weight limits, and hazardous material classifications (if applicable).

Quarrying & Extraction

Implement responsible and sustainable extraction practices:

- Conduct regular geological surveys to assess resource availability and quality.

- Minimize environmental disruption through phased extraction and site rehabilitation planning.

- Control dust and noise emissions using water sprays, barriers, and scheduled operations.

- Manage runoff and sediment with proper drainage and silt fences to prevent water pollution.

Handling & Storage

Proper handling reduces material degradation and ensures worker safety:

- Stack sandstone slabs or blocks on level, dry surfaces with adequate support to prevent cracking.

- Use protective padding between layers to avoid chipping and surface damage.

- Store indoors or under cover when possible to prevent moisture absorption and freeze-thaw damage.

- Label materials clearly with grade, origin, and compliance status.

Transportation

Plan logistics to ensure safe and efficient delivery:

- Use flatbed trucks or specialized stone carriers with secure tie-downs and edge protectors.

- Comply with axle weight limits and vehicle dimension regulations.

- Provide shipping documentation including material safety data sheets (MSDS), origin certificates, and customs forms (for cross-border transport).

- Insure shipments against damage, loss, or delay.

Quality Control & Certification

Maintain consistent product quality and traceability:

- Test samples for compressive strength, water absorption, and durability per ASTM or EN standards.

- Keep records of source location, batch numbers, and test results.

- Obtain certifications such as ISO 9001 (Quality Management) or environmental labels when applicable.

- Ensure compliance with building codes (e.g., ASTM C616 for dimension stone) for construction use.

Environmental & Sustainability Practices

Promote long-term ecological responsibility:

- Reclaim and rehabilitate quarried areas with native vegetation.

- Recycle process water and minimize freshwater usage.

- Reduce carbon footprint by optimizing transport routes and using fuel-efficient equipment.

- Report environmental performance metrics annually.

Documentation & Recordkeeping

Maintain accurate records to support audits and traceability:

- Keep logs of extraction volumes, sales, and inventory.

- Archive compliance permits, inspection reports, and training records.

- Store digital copies of all documentation with secure backup.

By following this guide, sandstone operations can achieve efficient logistics, regulatory compliance, and sustainable practices across the supply chain.

Conclusion for Sourcing Sandstone Supplier

After a thorough evaluation of potential sandstone suppliers, it is evident that selecting the right partner involves balancing quality, reliability, cost-efficiency, and sustainability. Key factors such as stone durability, color consistency, compliance with industry standards, and the supplier’s capacity for timely delivery have been carefully assessed. Direct engagement with quarries and verified track records of past projects further support the credibility of the chosen supplier.

Ultimately, the selected sandstone supplier demonstrates strong capabilities in providing high-quality, ethically sourced materials, backed by consistent performance and excellent customer service. Their ability to meet project specifications, adhere to environmental regulations, and offer competitive pricing positions them as a reliable long-term partner. Moving forward, establishing a formal supply agreement with clear terms and quality assurance protocols will ensure seamless procurement and successful project outcomes.