The global stone carving tools market is witnessing steady expansion, driven by increased demand in construction, architectural restoration, and artisanal craftsmanship. According to a report by Mordor Intelligence, the Stone Market size was valued at USD 37.48 billion in 2024 and is projected to grow at a CAGR of 7.5% from 2024 to 2029, fueled by rising infrastructure development and heritage conservation efforts—sectors where sandstone remains a material of choice. As demand for precision and efficiency in carving soft stone like sandstone grows, so does the need for high-quality, durable tools. This has led to a surge in innovation among manufacturers specializing in sandstone carving equipment, ranging from handheld chisels to pneumatic hammers. Drawing on market trends and industry performance, the following list highlights the top nine manufacturers leading the charge in supplying reliable, precision-engineered sandstone carving tools to professionals worldwide.

Top 9 Sandstone Carving Tools Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Bybee Stone Company

Domain Est. 1996

Website: bybeestone.com

Key Highlights: Bybee Stone Company is an Indiana limestone fabricator specializing in custom fabrication of Indiana limestone for both new construction and restoration ……

#2 GranQuartz

Domain Est. 1997

Website: granquartz.com

Key Highlights: Shop by category: Diamond Blades, Polishing Pads & Sandpaper Cup, Wheels & Grinding Wheels, Router Bits & Profiling Tools, CNC Tooling & Equipment….

#3 Tabularasa mosaic tools and stonecarving supply

Domain Est. 1999

Website: tabvlarasa.com

Key Highlights: Rasps, chisels, hammers and diamond tools for stonecarvers. The best quality and right price · How to reach us · How to make a purchase…

#4 Supplier of tools for masons and carvers, construction and mining …

Domain Est. 1999

Website: miconproducts.com

Key Highlights: We are proud to sell the Rebit line of Swedish made high quality stone masonry tools and stone carving tools. In addition to these carbide stone masonry chisels ……

#5 Sculpture & Carving

Domain Est. 2000

Website: trowandholden.com

Key Highlights: Trow and Holden has worked to develop a wide range of tools that can meet the needs of all types of stone and the artists who work with them….

#6 2Sculpt

Domain Est. 2000

Website: 2sculpt.com

Key Highlights: We find the best stone carving tools & stone online: limestone, marble, travertine, calcite, and onyx. Shipping to US & internationally….

#7

Domain Est. 2000

Website: neolithicstone.com

Key Highlights: Specializing in sculpture stone and tools for the stone sculptor · We supply the most diverse and unique variety of carving stone · To sculptors throughout North ……

#8 Stone Tools and Suppliers

Domain Est. 2002

Website: carvingstudio.org

Key Highlights: Stone Suppliers · The Carving Studio and Sculpture Center · Colorado Alabaster Supply · The Compleat Sculptor · Gawet Granite and Marble · Green Mountain Soapstone….

#9 Auriou Tools For Stone

Domain Est. 2008

Website: forge-de-saint-juery.com

Key Highlights: 5–12 day delivery 28-day returnsStandard Carving Tools ; Standard Auriou Deer’s Foot Claw Chisel · €23.50 – €26.50 ; Standard Auriou Pointed Teeth Chisel · €33.00 ; Standard Auriou…

Expert Sourcing Insights for Sandstone Carving Tools

Sandstone Carving Tools Market Trends in 2026

By 2026, the market for sandstone carving tools is poised for significant evolution, driven by technological advancements, shifting artisanal demands, and broader industry dynamics. While sandstone remains a popular medium for sculptors, architects, and restoration specialists due to its workability and aesthetic appeal, the tools used to shape it are adapting to meet modern expectations for precision, efficiency, and sustainability.

Growing Demand in Restoration and Heritage Conservation

A major driver in the 2026 market is the increasing focus on architectural restoration and heritage preservation. As cities and cultural institutions invest in conserving historic sandstone buildings and monuments, there is rising demand for specialized carving tools that allow for precise, non-invasive restoration work. Artisans and contractors require chisels, rasps, and pneumatic hammers designed for delicate detail work, fueling innovation in ergonomic and precision-engineered tooling. This trend supports a niche but high-value segment of the market, particularly in Europe and North America.

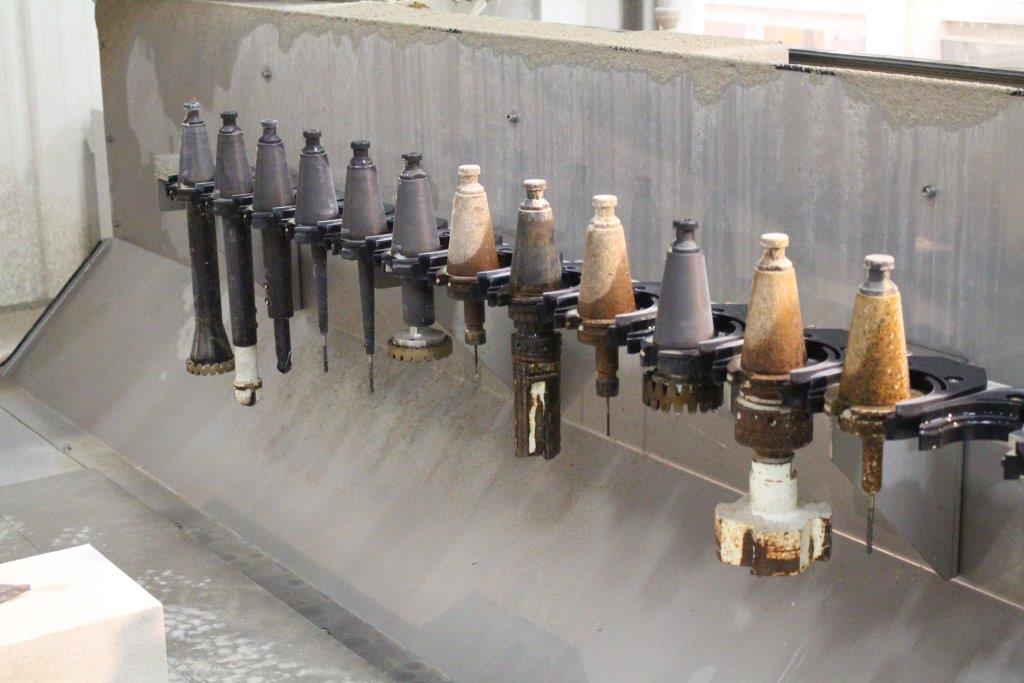

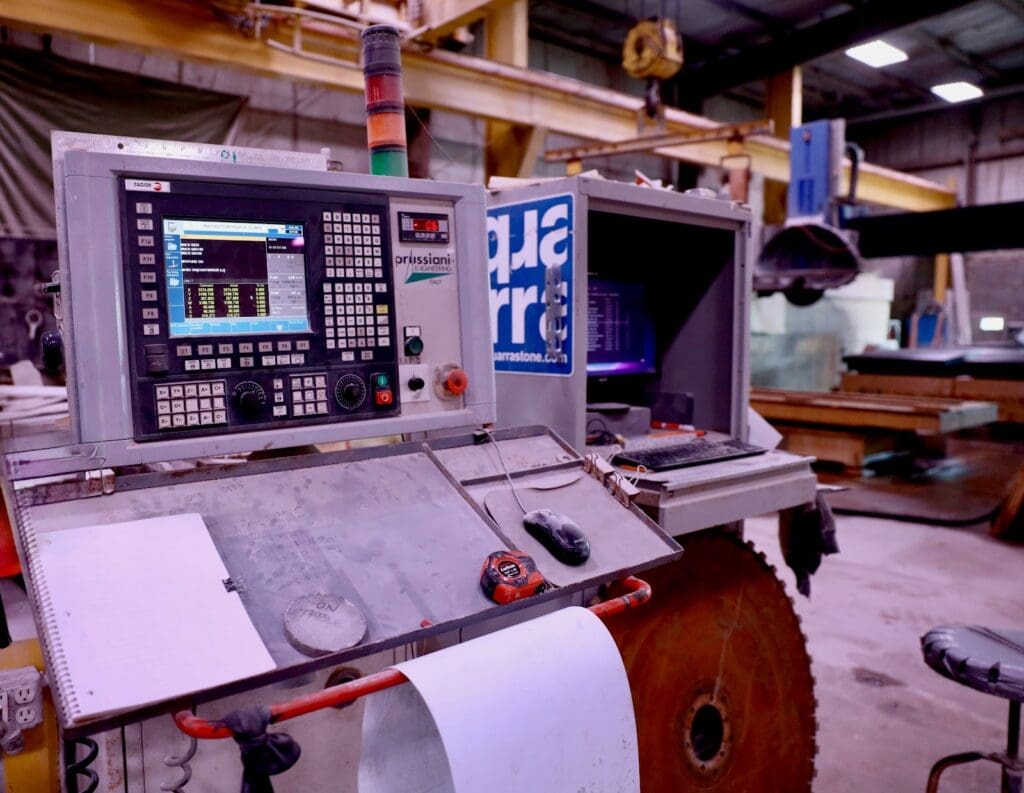

Integration of Power and Digital Technologies

The adoption of power-assisted and digitally guided tools continues to grow. By 2026, manufacturers are increasingly offering compact rotary tools, angle grinders with sandstone-specific attachments, and even small-scale CNC carving systems tailored for soft stone like sandstone. These tools enhance productivity for larger projects and enable complex designs that are difficult to achieve by hand. Additionally, the use of 3D scanning and modeling software is influencing tool design, with some companies developing tools optimized for digital workflow integration, allowing carvers to translate digital models into physical form more efficiently.

Sustainability and Material-Specific Tool Innovation

Environmental awareness is shaping product development. Consumers and professionals alike are favoring tools made from recycled or sustainably sourced materials, and there is growing interest in long-lasting, repairable tools that reduce waste. Simultaneously, toolmakers are refining blade compositions and abrasives specifically for sandstone’s unique grain structure, improving cutting efficiency while minimizing tool wear. Diamond-tipped tools, for example, are seeing enhanced formulations that balance cost-effectiveness and performance for soft stone applications.

Expansion of the DIY and Artisanal Craft Sector

The resurgence of interest in handmade crafts and home artisanship is expanding the consumer base for entry-level sandstone carving kits. By 2026, online marketplaces and educational platforms are driving demand for beginner-friendly tools, often bundled with instructional content. This democratization of carving is encouraging manufacturers to produce affordable, high-quality starter sets, increasing market accessibility while cultivating future professional users.

In conclusion, the 2026 sandstone carving tools market reflects a convergence of tradition and innovation. While hand tools remain essential, the integration of technology, emphasis on sustainability, and growth in both professional restoration and hobbyist segments are reshaping the landscape. Manufacturers who adapt to these trends—offering precision, durability, and digital compatibility—are well-positioned to lead in this evolving niche.

Common Pitfalls When Sourcing Sandstone Carving Tools (Quality and Intellectual Property)

Sourcing sandstone carving tools—whether for professional sculpting, restoration work, or artisanal crafts—requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to operational inefficiencies, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Tool Quality and Material Specifications

One of the most frequent issues when sourcing carving tools is receiving substandard products that fail to perform effectively on sandstone. Sandstone varies in hardness and composition, so tools must be durable and precisely engineered.

- Inadequate Hardness or Tempering: Tools made from low-grade steel or improperly heat-treated metals wear down quickly or chip when carving abrasive sandstone. This leads to frequent replacements and inconsistent results.

- Inconsistent Manufacturing Standards: Sourced tools may lack uniformity in edge geometry, balance, or handle ergonomics, impacting carving precision and user safety.

- Misrepresentation of Specifications: Suppliers may exaggerate tool hardness (e.g., claiming high-carbon steel when using softer alloys) or omit critical details like tempering processes.

Mitigation: Request material certifications, conduct sample testing, and source from manufacturers with verifiable quality control processes (e.g., ISO certifications). Engage only with suppliers who provide detailed technical specifications.

Counterfeit or Copycat Tools Infringing IP Rights

The artisan tool market is increasingly affected by counterfeit products that replicate patented designs, trademarks, or trade dress of reputable brands.

- Trademark Infringement: Imitation tools may use logos or branding confusingly similar to established brands (e.g., “Pfiel-style” chisels with misleading engravings), misleading buyers and diluting brand value.

- Design Patent Violations: Many high-end carving tools feature patented handle shapes, blade profiles, or mounting systems. Unauthorized copies may infringe these design rights, exposing buyers to legal risk if used commercially.

- Lack of IP Due Diligence: Buyers may unknowingly import or distribute tools that violate intellectual property laws, especially when sourcing from regions with lax IP enforcement.

Mitigation: Verify supplier legitimacy, request proof of IP compliance, and avoid unusually low-priced tools that may be counterfeit. Work with legal counsel to assess IP risks, particularly when importing tools for resale or commercial use.

Insufficient After-Sales Support and Warranty

Low-cost suppliers, particularly from overseas, may lack reliable customer service, spare parts availability, or warranty coverage.

- No Warranty or Replacement Policy: Defective tools cannot be returned or repaired, increasing long-term costs.

- Unavailability of Replacement Parts: Handles or blades may break, but suppliers do not offer replacements, rendering the entire tool unusable.

- Language and Time Zone Barriers: Communication challenges delay resolution of quality issues or order discrepancies.

Mitigation: Prioritize suppliers with clear warranty terms, responsive support channels, and a track record of honoring service commitments.

Inadequate Compliance with Safety and Import Regulations

Tools may fail to meet safety standards required in the destination market (e.g., CE marking in the EU or OSHA compliance in the U.S.).

- Unsafe Handle Materials or Construction: Poorly attached handles or brittle materials can cause injury during use.

- Non-Compliant Packaging or Labeling: Missing safety warnings or incorrect material labeling can result in customs delays or import bans.

- Environmental or Material Restrictions: Some steels or coatings may be restricted under environmental regulations (e.g., REACH, RoHS).

Mitigation: Confirm that tools meet relevant regional safety and environmental standards. Request compliance documentation before placing bulk orders.

By proactively addressing these quality and IP-related pitfalls, buyers can secure reliable, legal, and high-performing sandstone carving tools that support both craftsmanship and business integrity.

Logistics & Compliance Guide for Sandstone Carving Tools

Product Classification and HS Codes

Sandstone carving tools—such as chisels, mallets, points, and rasps—are typically classified under HS (Harmonized System) codes related to hand tools. The most common code is 8205.40, which covers “Other hand tools (for example, planes, spokeshaves, gouges, cold chisels, letter punches, riveting tools), not elsewhere specified or included.” Accurate classification is essential for customs clearance, duty assessment, and compliance with international trade regulations.

Import/Export Regulations

Exporters and importers must comply with the regulations of both origin and destination countries. Key considerations include:

– Export Controls: Verify if carving tools are subject to export restrictions, particularly if they contain materials such as cobalt or high-carbon steel that may be regulated.

– Import Duties and Tariffs: Duties vary by country; consult local customs authorities or use tariff lookup tools based on the correct HS code.

– Prohibited Items: Confirm that tool designs (e.g., resembling weapons) do not violate import restrictions in target markets.

Packaging and Labeling Requirements

Proper packaging ensures product safety during transit and compliance with international standards:

– Use durable, crush-resistant packaging to protect tool edges and handles.

– Clearly label packages with contents, weight, dimensions, and handling instructions (e.g., “Fragile,” “This Side Up”).

– Include bilingual labeling if shipping to non-English-speaking countries.

– Attach compliance labels such as CE (for EU) if applicable, especially for tools marketed as professional-grade.

Shipping and Transportation

Choose appropriate shipping methods based on volume, urgency, and destination:

– Air Freight: Best for urgent, low-volume shipments; subject to stricter size/weight limits.

– Ocean Freight: Cost-effective for bulk orders; ensure tools are containerized securely to prevent moisture damage.

– Ground Transport: Suitable for regional distribution; comply with domestic carrier regulations.

– Consider insuring shipments against loss or damage, particularly for high-value artisan tool sets.

Safety and Compliance Standards

Adhere to international safety and quality standards:

– CE Marking (EU): Required if tools are sold within the European Economic Area. Demonstrates compliance with health, safety, and environmental protection standards.

– REACH and RoHS (EU): Ensure tools are free from restricted hazardous substances (e.g., lead, cadmium).

– OSHA and ANSI (USA): While primarily for power tools, hand tools should still meet general safety expectations for workplace use.

– Product Liability: Maintain documentation proving design safety and manufacturing quality to mitigate legal risks.

Documentation for International Trade

Complete and accurate documentation is critical:

– Commercial Invoice

– Packing List

– Bill of Lading (BOL) or Air Waybill (AWB)

– Certificate of Origin (if claiming preferential tariffs under trade agreements)

– Export Declaration (as required by exporting country)

– Import License (if required by destination country)

Environmental and Ethical Considerations

- Source raw materials (e.g., steel, wood handles) from sustainable and ethically responsible suppliers.

- Comply with regulations on packaging waste (e.g., EU Directive 94/62/EC on packaging and packaging waste).

- Provide end-of-life disposal guidance to customers, especially for metal components.

Recordkeeping and Audit Preparedness

Maintain detailed records for at least five years, including:

– Product specifications and compliance certifications

– Supplier agreements and material sourcing documentation

– Shipping and customs records

– Customer complaints and corrective actions taken

Following this guide ensures smooth logistics operations and full compliance when distributing sandstone carving tools globally.

In conclusion, sourcing high-quality sandstone carving tools requires careful consideration of material durability, tool design, and supplier reliability. Selecting the right chisels, rasps, mallets, and abrasives tailored to the specific characteristics of sandstone ensures greater precision, efficiency, and longevity in carving projects. Whether purchasing from specialized stone carving suppliers, online marketplaces, or local artisans, it is essential to prioritize tools made from hardened steel with ergonomic handles for comfort and control. Additionally, investing in a well-rounded toolkit and maintaining tools properly will enhance performance and reduce wear over time. Ultimately, choosing the right tools from trusted sources lays the foundation for achieving detailed, professional results in sandstone sculpting and masonry work.