The global sandbag weights market has experienced steady growth, driven by rising demand across construction, flood control, military, and fitness sectors. According to a report by Mordor Intelligence, the global sandbags market was valued at approximately USD 420 million in 2023 and is projected to grow at a CAGR of over 4.5% from 2024 to 2029. This expansion is fueled by increased infrastructure development, climate-related flood mitigation efforts, and the growing popularity of functional fitness training. As industries seek durable, cost-effective, and versatile anchoring and ballast solutions, manufacturers of sandbag weights are scaling innovation in materials, durability, and design. With North America and Asia Pacific emerging as key regional markets, competition among manufacturers is intensifying—making it essential to identify industry leaders shaping this evolving landscape.

Top 10 Sandbag Weights Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sandbags

Domain Est. 1997

Website: sandbags.com

Key Highlights: Our filled sandbags are widely used as benches, trench breakers, padding and bedding during pipeline construction….

#2 Sand Filled Sandbag Training Weights

Domain Est. 1997

#3 RoadBags

Domain Est. 1998

#4 Workout Sandbags

Domain Est. 2003

#5 Ultimate Sandbags™ Sand & Water Systems

Domain Est. 2009

Website: ultimatesandbagtraining.com

Key Highlights: Free delivery 30-day returns…

#6 Precision Ballast Bags for Aerospace & Testing

Domain Est. 2010

Website: sandbagstore.com

Key Highlights: Free delivery 30-day returnsShop precision-weighted Cordura® sandbags for engineering, aerospace, and automotive testing. Durable, lab-safe ballast bags trusted by NASA, Boeing, …..

#7 Fitness Sandbags

Domain Est. 2010

Website: bellsofsteel.com

Key Highlights: Rating 4.9 (187) Seven Bells of Steel Fitness Sandbags, featuring durable Condura construction and white weight labels from 50 to 400 lbs, are arranged on a white background….

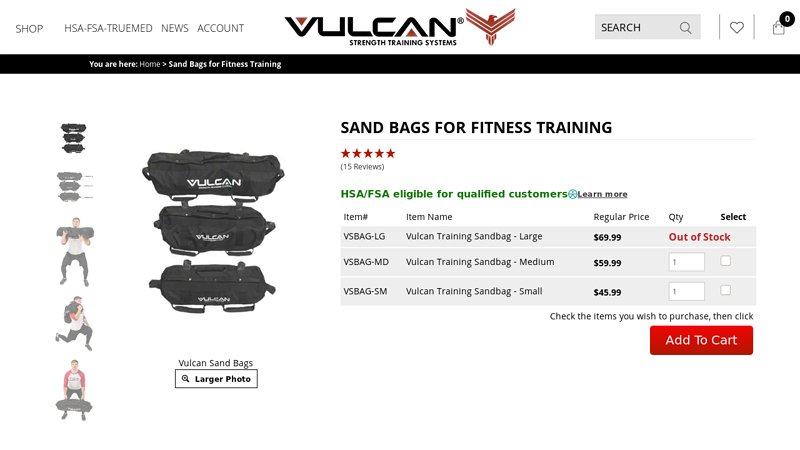

#8 Sand Bags for Fitness Training

Domain Est. 2011

#9 Innovated Fitness and Outdoor Products

Domain Est. 2018

Website: 2xsr.com

Key Highlights: Carefully crafted for rucking, fitness, hiking, and travel — this all-in-one, patent-pending 26L bag transforms from a rugged backpack to a weighted sandbag, ……

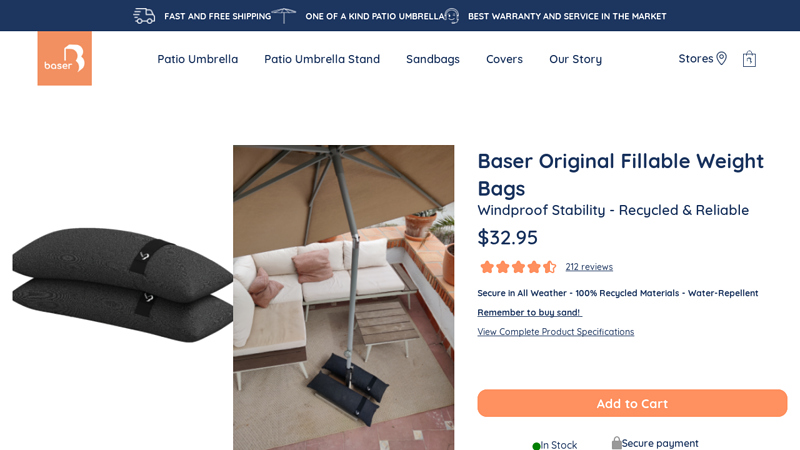

#10 Baser Original Fillable Weight Bags

Domain Est. 2018

Website: mybaser.com

Key Highlights: The Baser Original Sandbags are crafted from premium 7 oz/yd² solution-dyed ReSun™ fabric, made from 100% GRS Certified recycled plastic bottles. Each sandbag ……

Expert Sourcing Insights for Sandbag Weights

H2: Projected Market Trends for Sandbag Weights in 2026

The global sandbag weights market is poised for notable growth and transformation by 2026, driven by evolving fitness trends, increased home workout adoption, and a surge in demand for versatile, affordable training equipment. As consumers prioritize functional fitness and space-efficient solutions, sandbag weights are emerging as a staple in both professional and home gym environments.

-

Rising Demand in Home Fitness

The post-pandemic shift toward home-based workouts continues to fuel demand for compact, multi-functional fitness gear. Sandbag weights, known for their adaptability and low storage footprint, are gaining popularity among urban dwellers and remote workers. E-commerce platforms are expected to see a 30–40% year-on-year increase in sandbag sales by 2026, particularly in North America and Europe. -

Innovation in Design and Materials

Manufacturers are investing in ergonomic, durable designs using eco-friendly materials such as recycled fabrics and non-toxic fillers. Adjustable sandbags with modular weight inserts and smart features—like integrated tracking sensors—are expected to capture a growing share of the premium fitness equipment segment by 2026. -

Expansion in Commercial and Tactical Markets

Beyond consumer fitness, sandbag weights are increasingly used in military, law enforcement, and sports performance training due to their ability to simulate real-world resistance. This niche sector is projected to grow at a CAGR of 7.2% through 2026, particularly in government and institutional procurement. -

Regional Growth Dynamics

Asia-Pacific is expected to be the fastest-growing market, driven by rising disposable incomes, urbanization, and fitness awareness in countries like India and Indonesia. Meanwhile, North America will maintain dominance due to established fitness culture and strong online retail infrastructure. -

Sustainability and Customization Trends

Consumers are showing a preference for customizable, refillable sandbags that allow users to modify weight based on fitness levels. Brands emphasizing sustainability—offering biodegradable options or refill stations—are likely to gain competitive advantage.

In conclusion, the 2026 sandbag weights market will be shaped by innovation, digital integration, and sustainability. As functional training continues to gain momentum, sandbag weights are well-positioned to transition from niche equipment to mainstream fitness essential.

Common Pitfalls When Sourcing Sandbag Weights (Quality and Intellectual Property)

Sourcing sandbag weights—whether for fitness, flood control, military training, or industrial use—can present several challenges, particularly concerning product quality and intellectual property (IP) risks. Being aware of these pitfalls helps ensure you receive reliable, durable products while avoiding legal complications.

Poor Material Quality and Construction

One of the most frequent issues is receiving sandbags made from substandard materials. Low-quality fabrics such as thin, non-reinforced polyester or polypropylene can tear easily under stress or degrade quickly when exposed to UV light, moisture, or abrasion. Stitching that lacks double or triple reinforcement may fail during use, leading to spills and safety hazards. Additionally, poorly sealed seams or inadequate closure mechanisms (e.g., weak drawstrings or flimsy Velcro) compromise functionality.

Tip: Always request material specifications, durability test results (e.g., tear strength, UV resistance), and samples before bulk ordering.

Inconsistent Weight Accuracy

Sandbag weights often vary significantly from advertised values due to inconsistent filling processes or low manufacturing standards. This is especially problematic in fitness or training applications where precise load is essential for effective programming and safety.

Tip: Choose suppliers with quality control measures such as automated filling and weight verification systems. Include weight tolerance requirements in your purchase agreement.

Use of Non-Durable or Unsafe Fillers

Some manufacturers use low-cost, inconsistent, or hazardous fillers—such as contaminated soil, construction debris, or moisture-absorbing materials—that can add unpredictability to weight and promote mold or corrosion. Silica sand is generally preferred for its consistency and inert properties, but substitutes may be used to cut costs.

Tip: Specify the type of filler material (e.g., washed, kiln-dried silica sand) and confirm it’s sealed in a moisture-resistant inner liner.

Lack of IP Compliance and Design Infringement

When sourcing custom or branded sandbag weights, especially fitness equipment, there’s a risk of inadvertently purchasing products that infringe on patented designs or trademarks. Some suppliers, particularly in regions with weak IP enforcement, may copy patented features such as unique handle placements, multi-chamber systems, or proprietary closure mechanisms.

Tip: Conduct due diligence on the supplier’s design rights. Request proof of IP ownership or licensing for innovative features. Avoid designs that closely mimic well-known branded products.

Counterfeit or Misrepresented Products

Suppliers may misrepresent the origin, material composition, or performance claims of sandbags. For example, labeling a product as “military-grade” or “commercial durability” without certification or testing evidence is a red flag. Counterfeit fitness sandbags may even falsely bear brand names or logos.

Tip: Work with reputable suppliers, verify certifications, and consider third-party inspections or audits, especially for overseas sourcing.

Inadequate Packaging and Logistics Damage

Poor packaging can lead to damage during shipping, especially if sandbags are stacked improperly or exposed to moisture. Bags without protective outer wrapping may arrive stained, torn, or with compromised integrity.

Tip: Specify packaging requirements, such as moisture barriers, reinforced cartons, and palletization standards, in your procurement agreement.

Limited After-Sales Support and Warranties

Many low-cost suppliers offer little to no warranty or customer support. If quality issues arise post-delivery, resolving them can be difficult, especially with international vendors.

Tip: Prioritize suppliers with clear return policies, warranties against manufacturing defects, and responsive customer service.

By addressing these common pitfalls proactively—through thorough vetting, clear specifications, and attention to both physical quality and IP integrity—you can mitigate risks and ensure a reliable supply of high-performing sandbag weights.

Logistics & Compliance Guide for Sandbag Weights

Proper logistics and compliance management are essential when shipping, storing, and distributing sandbag weights. This guide outlines key considerations to ensure safety, regulatory adherence, and operational efficiency.

Product Classification and Handling

Sandbag weights are typically classified as dense, heavy goods due to their material composition (usually sand or other granular fillers enclosed in durable fabric). They are often used for fitness, industrial stabilization, or flood control. Proper handling procedures include:

- Use mechanical lifting equipment (e.g., forklifts, pallet jacks) for loads over 50 lbs (22.7 kg) to prevent injury.

- Stack sandbags no higher than 6 feet (1.8 meters) on pallets to prevent toppling.

- Store in dry, well-ventilated areas to avoid moisture absorption and mold growth.

Packaging and Unit Load Configuration

To maintain integrity during transport:

- Sandbags should be double-stitched or heat-sealed to prevent leakage.

- Individually bagged weights should be shrink-wrapped or banded on skids.

- Use edge protectors and corner boards when stacking on pallets.

- Standard pallet sizes: 48” x 40” (1219 mm x 1016 mm) for North America; EUR/EPAL pallets (1200 mm x 800 mm) for Europe.

Transportation and Shipping Requirements

- Weight Limits: Adhere to local and international weight regulations per axle and vehicle. Sandbags can quickly exceed weight thresholds due to high density.

- Hazardous Materials: Sandbag weights are generally non-hazardous; however, verify filler material (e.g., silica sand may require safety data sheets if respirable dust is a concern).

- Freight Class (NMFC): In the U.S., sandbag weights typically fall under NMFC Class 70–85 based on density and packaging. Accurate classification ensures correct freight pricing.

- International Shipments: Declare contents clearly as “fabric sandbag weights, non-hazardous.” Include weight, quantity, and material composition on commercial invoices.

Regulatory and Safety Compliance

- OSHA (U.S.): Follow guidelines for manual handling and workplace safety. Provide training on proper lifting techniques.

- REACH & RoHS (EU): Ensure fabric and dyes comply with chemical restrictions, especially if marketed for consumer use.

- Customs Documentation: For cross-border shipments, include HS Code (e.g., 6307.90 for other made-up textile articles) and country of origin.

- DOT & IATA: Not regulated as hazardous goods under normal conditions, but confirm if filled with specialty materials (e.g., steel shot, non-silica granules).

Storage and Shelf Life

- Store indoors away from UV exposure to prevent fabric degradation.

- Rotate stock using FIFO (First In, First Out) method.

- Inspect periodically for tears, moisture, or pest infestation.

- Typical shelf life: 3–5 years when stored properly.

Environmental and Disposal Considerations

- Empty sandbags may be recyclable depending on fabric (polypropylene, cotton, etc.).

- Sand fill is generally inert but should not be dumped in waterways.

- Follow local regulations for disposal of industrial or contaminated sand.

Labeling and Marking

Each package or pallet must include:

– Product name and weight per unit

– Total net and gross weight

– Handling symbols (e.g., “This Side Up,” “Fragile” if applicable)

– Manufacturer or distributor information

– Batch/lot number for traceability

Adhering to this logistics and compliance guide ensures safe, efficient, and legally compliant handling of sandbag weights across the supply chain.

In conclusion, sourcing sandbag weights requires careful consideration of several key factors including material quality, durability, cost-effectiveness, and supplier reliability. Whether intended for fitness training, flood control, or industrial use, selecting the right sandbag weights involves balancing weight consistency, bag integrity, and filling material to meet specific needs. Evaluating multiple suppliers, comparing product specifications, and considering long-term usage can ensure a cost-efficient and reliable supply chain. By prioritizing trusted vendors and high-quality materials, organizations and individuals can achieve optimal performance and safety in their respective applications. Ultimately, a well-informed sourcing strategy leads to greater efficiency, reduced maintenance, and long-term satisfaction with the sandbag weight solution.