The global sand plaster market is experiencing steady growth, driven by rising construction activities and increasing demand for durable, cost-effective wall finishing solutions. According to a report by Mordor Intelligence, the global exterior wall coatings market—under which sand plaster is categorized—was valued at USD 42.5 billion in 2022 and is projected to grow at a CAGR of 5.8% from 2023 to 2028. Sand plaster, known for its weather resistance, textured finish, and thermal stability, remains a preferred choice in both residential and commercial construction, especially in regions with high humidity and extreme temperatures.

Asia Pacific currently dominates the market, fueled by rapid urbanization in countries like India and China, while increasing infrastructure investments in North America and the Middle East are further boosting demand. As sustainability becomes a priority, manufacturers are innovating with eco-friendly formulations and low-VOC products to meet evolving regulatory standards and consumer expectations.

In this competitive landscape, a select group of manufacturers have distinguished themselves through product quality, technological advancement, and global reach. Based on market presence, production capacity, and innovation, the following eight companies represent the leading sand plaster manufacturers shaping the industry today.

Top 8 Sand Plaster Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Quality Plaster Sand supplier and manufacturer

Domain Est. 2012

Website: doctorsand.com

Key Highlights: Doctor Sand offers High-quality plaster sand for flawless construction finishes. Get our premium plaster sand for smooth surfaces and flawless plastering….

#2 Sandtastik

Domain Est. 1997

Website: sandtastik.com

Key Highlights: For over 25 years Sandtastik Products has continued their commitment to manufacturing the most creative, safe, amazingly colorful quality products….

#3 American Clay

Domain Est. 2002

Website: americanclay.com

Key Highlights: Our natural earth plaster products, manufactured in Albuquerque, New Mexico, are a healthy and creative solution for beautiful interiors….

#4 Gold Bond® Two

Domain Est. 2020

Website: goldbondbuilding.com

Key Highlights: Gold Bond® Two-Way Hardwall Plaster is a basecoat gypsum neat plaster that forms a hard, durable base for the finish coats of another gypsum plaster….

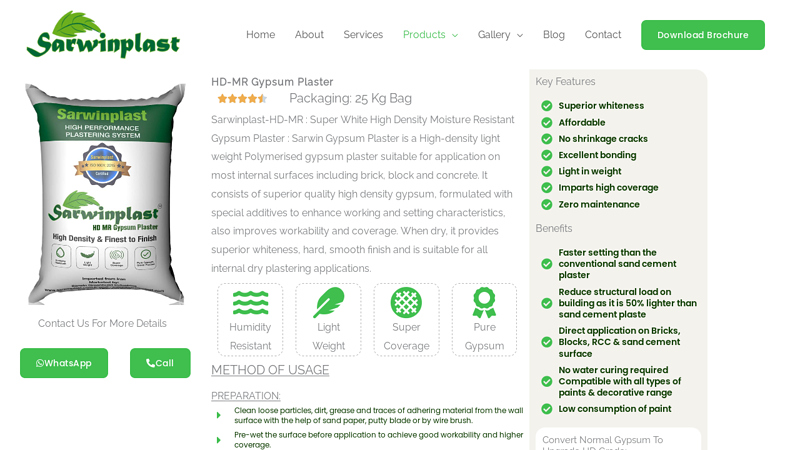

#5 HD MR Gypsum Plaster

Domain Est. 2020

Website: sarwinplast.com

Key Highlights: Key Features. Superior whiteness; Affordable; No shrinkage cracks; Excellent bonding · Benefits. Faster setting than the conventional sand cement plaster; Reduce ……

#6 Amundson Plaster and Paint

Domain Est. 2020

Website: amundsonplaster.com

Key Highlights: We install clay and lime plasters for health, durability and beauty unrivaled in other finishes. These materials are a binder in which pigment and aggregate ……

#7 Sand Finish, Granular Velvety Plaster

Domain Est. 2022

Website: earthausplaster.com

Key Highlights: Free delivery over $300 365-day returns…

#8 GYPSUM BRANDS

Website: saint-gobain.com

Key Highlights: OUR OFFER. We design, manufacture and supply plaster, dry lining and ceilings innovative products and systems that improve wellbeing in living spaces….

Expert Sourcing Insights for Sand Plaster

2026 Market Trends for Sand Plaster

The sand plaster market is poised for steady growth and transformation by 2026, driven by evolving construction demands, sustainability imperatives, and regional development patterns. Key trends shaping the industry include:

Rising Demand in Emerging Economies

Infrastructure expansion and urbanization in regions like Asia-Pacific, the Middle East, and Africa are fueling demand for cost-effective, durable finishing materials. Countries such as India, Indonesia, and Nigeria are witnessing increased residential and commercial construction, where sand plaster remains a preferred choice due to its affordability and ease of application.

Emphasis on Sustainable and Eco-Friendly Materials

With growing environmental awareness, manufacturers are reformulating sand plaster products to incorporate recycled aggregates and low-carbon binders. Green building certifications like LEED and BREEAM are encouraging the use of sustainable plasters, pushing suppliers to develop eco-conscious alternatives without compromising performance.

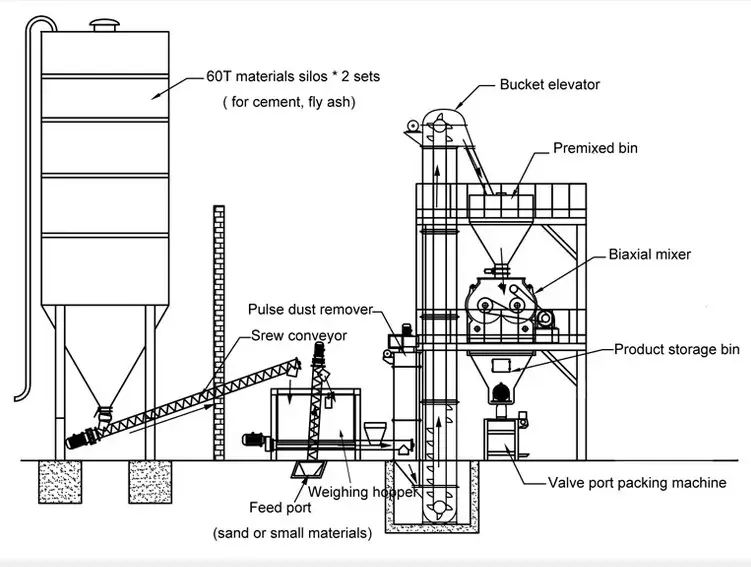

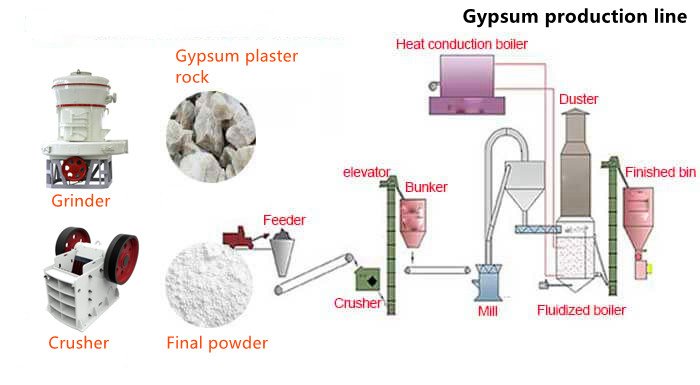

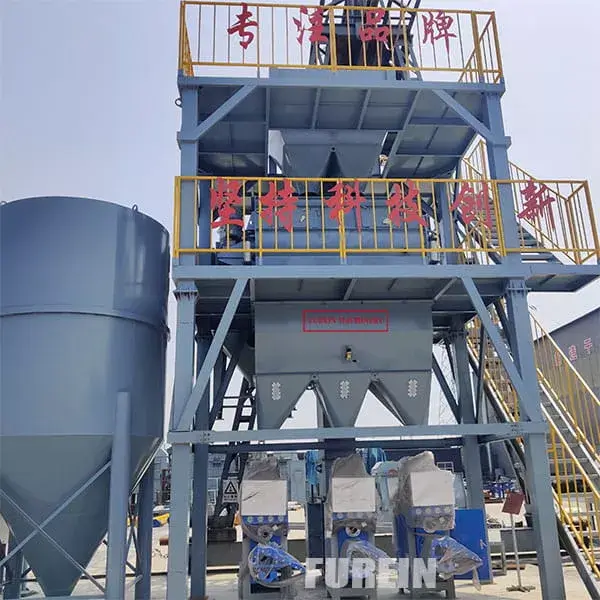

Technological Advancements in Application and Formulation

Innovations such as pre-mixed sand plasters, polymer-modified formulations, and automated application systems are improving workability, adhesion, and finish quality. These advancements reduce labor costs and application time, making sand plaster more attractive in competitive construction markets.

Integration with Energy-Efficient Building Envelopes

Sand plaster is increasingly being combined with insulation systems (e.g., ETICS – External Thermal Insulation Composite Systems) to enhance thermal performance. By 2026, demand is expected to rise for sand plasters that not only provide aesthetic finishes but also contribute to energy efficiency in buildings.

Shift Toward Aesthetic Customization

Architects and developers are favoring textured and colored finishes to achieve distinctive building façades. Sand plaster’s versatility allows for a range of surface textures and pigmentation, supporting design trends that prioritize visual appeal alongside functionality.

Supply Chain and Raw Material Challenges

Fluctuations in sand availability and quality, coupled with tightening regulations on sand mining, may impact production costs. By 2026, industry players will likely invest in alternative raw materials and regional sourcing strategies to ensure supply chain resilience.

Overall, the 2026 sand plaster market will be characterized by innovation, sustainability, and regional growth, positioning it as a vital component in modern construction despite increasing competition from alternative finishing systems.

Common Pitfalls When Sourcing Sand Plaster (Quality, IP)

Sourcing sand plaster involves several potential challenges, particularly when it comes to ensuring consistent quality and protecting intellectual property (IP). Overlooking these aspects can lead to project delays, increased costs, or legal complications. Below are common pitfalls to avoid:

Inconsistent Material Quality

One of the most frequent issues in sourcing sand plaster is variability in raw material quality. Sand sourced from different regions or suppliers can vary significantly in grain size, composition, and cleanliness. Impurities such as clay, salts, or organic matter can compromise adhesion, strength, and durability. Always request material certifications and conduct batch testing to ensure compliance with project specifications.

Lack of Standardized Mix Proportions

Suppliers may offer sand plaster mixes with inconsistent cement-to-sand ratios or undisclosed additives. Without clear formulation standards, the performance of the plaster—especially regarding crack resistance and workability—can be unpredictable. Ensure that mix designs are documented, verified, and consistently reproduced.

Poor Supplier Qualification

Engaging with unqualified or unvetted suppliers increases the risk of receiving substandard products. Some suppliers may lack proper quality control processes or fail to adhere to industry standards (e.g., ASTM, EN). Conduct thorough due diligence, including site visits and audits, before finalizing procurement.

Inadequate Testing and Certification

Failing to require third-party testing or relevant certifications (such as conformity to BS 1200 or equivalent) can expose projects to performance failures. Ensure that every batch is accompanied by test reports for compressive strength, setting time, and compatibility with substrates.

Intellectual Property Risks

When sourcing proprietary or customized sand plaster formulations, there is a risk of IP leakage. Suppliers might reverse-engineer unique blends or reuse formulations for competing clients. Always use non-disclosure agreements (NDAs) and clearly define IP ownership in contracts.

Insufficient Documentation of Formulation Rights

Ambiguity in who owns the plaster mix design—whether it’s the formulator, supplier, or client—can lead to legal disputes. Clearly specify in procurement agreements that any custom formulation developed for the project remains the property of the rightful owner, with usage rights appropriately licensed.

Overreliance on Verbal Agreements

Relying on verbal assurances about quality or IP protections leaves stakeholders vulnerable. All commitments regarding material specs, performance, and IP should be formally documented in written contracts with enforceable clauses.

By proactively addressing these pitfalls, stakeholders can ensure reliable supply, consistent quality, and robust protection of intellectual assets when sourcing sand plaster.

Logistics & Compliance Guide for Sand Plaster

Overview

Sand plaster, a common construction material composed of sand, cement, and lime, requires careful handling, storage, and transportation to ensure product quality and regulatory compliance. This guide outlines key logistics and compliance considerations for the safe and legal distribution of sand plaster.

Packaging and Storage

Sand plaster is typically supplied in moisture-resistant, durable bags (usually 25–40 kg) to prevent premature hydration. Store in a dry, well-ventilated, covered area off the ground on pallets. Avoid direct contact with moisture or rain, as exposure can lead to clumping and reduced performance. Ensure storage areas are free from contaminants and temperature extremes.

Transportation Requirements

Transport sand plaster in enclosed, weatherproof vehicles to protect against moisture and environmental exposure. Secure loads properly to prevent shifting during transit. Avoid stacking too high to prevent bag compression and potential rupture. Forklifts or pallet jacks should be used for loading and unloading to minimize manual handling risks.

Handling and Safety

Operators must wear appropriate personal protective equipment (PPE), including gloves, safety goggles, and dust masks, to avoid skin irritation and respiratory issues from cement dust. Follow safe lifting practices to reduce the risk of musculoskeletal injuries. In case of skin or eye contact, rinse immediately with water; seek medical attention if irritation persists.

Regulatory Compliance

Sand plaster may be subject to regional construction material standards and environmental regulations. Confirm compliance with local building codes (e.g., ASTM C926 in the U.S., EN 998-1 in the EU). Manufacturers must provide Safety Data Sheets (SDS) in accordance with GHS (Globally Harmonized System) standards. Ensure labeling includes product name, batch number, weight, manufacturer details, and hazard warnings.

Environmental and Disposal Considerations

Unused or hardened sand plaster should not be disposed of in drains or waterways due to potential alkalinity and sedimentation risks. Follow local waste management regulations for disposal of construction materials. Sweep up dry waste; avoid water-based cleanup to prevent slurry formation.

Documentation and Traceability

Maintain records of batch numbers, delivery dates, and storage conditions to support quality control and traceability. Distributors and contractors should verify expiration dates, as prolonged storage can reduce workability. Retain SDS and compliance certificates for audit purposes.

Emergency Procedures

In the event of a spill, contain dry material using non-sparking tools and place in sealed containers. Do not use water on large dry spills to avoid hazardous reactions. In case of fire, use dry media such as sand or Class D extinguishers; water may exacerbate certain cement-related reactions.

Conclusion for Sourcing Sand Plaster

In conclusion, sourcing sand plaster requires a careful evaluation of several key factors including material quality, supplier reliability, cost-effectiveness, and sustainability. High-quality sand plaster is essential for ensuring durability, aesthetic finish, and long-term performance of construction or renovation projects. It is important to source materials from reputable suppliers who adhere to industry standards and can provide consistent product specifications.

Additionally, considering local availability can reduce transportation costs and lead times, while also supporting regional economies and minimizing environmental impact. Conducting thorough site-specific assessments—such as determining the appropriate sand gradation, cement ratio, and additives—ensures compatibility with the project’s technical requirements.

Ultimately, a strategic and well-researched approach to sourcing sand plaster contributes to project efficiency, structural integrity, and overall success. By balancing quality, cost, and sustainability, stakeholders can make informed decisions that support both immediate application needs and long-term building performance.