The global market for landscaping and turf management tools is experiencing steady expansion, driven by rising residential and commercial development, increasing emphasis on aesthetic outdoor spaces, and growing demand for precision in turf maintenance. According to Grand View Research, the global lawn and garden tools market was valued at USD 14.9 billion in 2023 and is projected to grow at a compound annual growth rate (CAGR) of 4.3% from 2024 to 2030. A key segment within this market is specialty tools for sand leveling—critical in sports field construction, golf course maintenance, and synthetic turf installation. As demand for consistent surface grading intensifies, so does the need for high-quality sand leveling tools. This has spurred innovation among manufacturers focusing on durability, ergonomic design, and compatibility with various grading applications. Based on market presence, product range, customer reviews, and technological advancements, the following are ten leading manufacturers shaping the sand leveling tool industry.

Top 10 Sand Leveling Tool Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Sandvik Coromant

Domain Est. 1996

Website: sandvik.coromant.com

Key Highlights: Part of global industrial engineering group Sandvik, Sandvik Coromant is at the forefront of manufacturing tools, machining solutions and metal cutting…

#2 Leading AODD Pump Manufacturer

Domain Est. 2000

Website: sandpiperpump.com

Key Highlights: YOU’VE SELECTED THE BEST. Find training tools, literature, videos, and other resources to help you solve your most challenging pump-related problems….

#3 M-I SWACO, a Schlumberger Company

Domain Est. 1987

Website: slb.com

Key Highlights: … Sand Control · Perforating · Isolation Valves · Completion Accessories. Fluids, Cementing, and Tools. Back. Fluids, Cementing, and Tools · Clear ……

#4 60 Common Construction Tools

Domain Est. 1989

Website: autodesk.com

Key Highlights: A concrete sander is a leveling tool for smoothing out concrete surfaces. … Good construction tool brands sell reliable tools at a ……

#5 LESCO®: Upgrade What You Put Down

Domain Est. 1995

Website: siteone.com

Key Highlights: Supplier Self Service Portal · Partners Program. Tools & Resources. Business Resources · Spreader & Sprayer Calibration Settings · Catalogs · Events ……

#6 Sampling & Testing Tools

Domain Est. 1996 | Founded: 1942

Website: ams-samplers.com

Key Highlights: 3-day delivery · 30-day returnsSince 1942, we have been manufacturing high-quality sampling and testing tools with exceptional workmanship in the USA. Shop our official online sto…

#7 Sand Control

Domain Est. 1996

Website: weatherford.com

Key Highlights: From conventional sand screens to specialty screens such as our shunt-tube designs, we deliver tailor-engineered solutions that help you to increase tool ……

#8 Mirka

Domain Est. 1997

Website: mirka.com

Key Highlights: All Mirka power tools have a standard two-year warranty. Get an additional 1 year of warranty free of charge by registering your tool within 30 days of ……

#9 Kraft Tool Co

Domain Est. 1998

Website: krafttool.com

Key Highlights: 1-day deliveryKraft Tool Co.® and its brands have a long-standing presence in American manufacturing. Our signature brands include W. Rose™ masonry tools since 1798, Sands ……

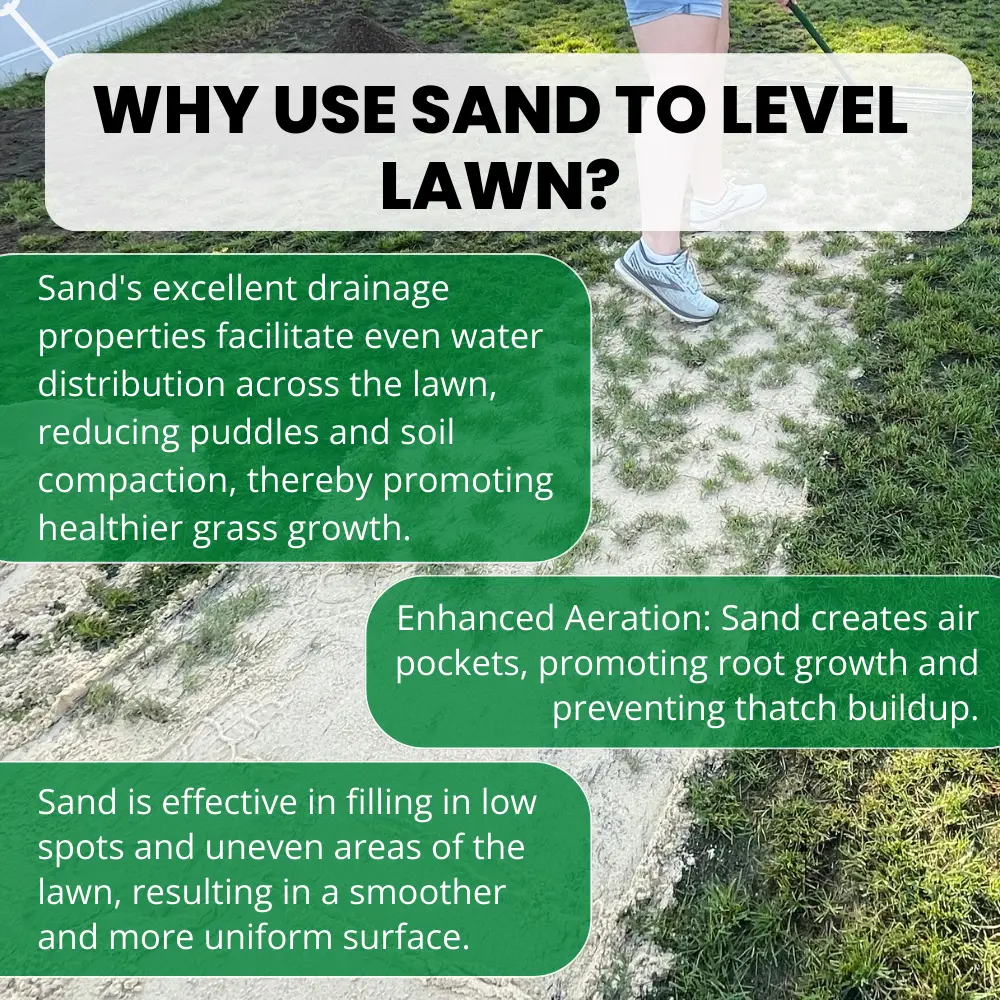

#10 Using Sand to Level a Lawn

Domain Est. 2019

Website: landzie.com

Key Highlights: … leveling tools on the market. Landzie makes it easy for you to maintain a … Sand can be a valuable tool in achieving this goal. Let’s explore the ……

Expert Sourcing Insights for Sand Leveling Tool

H2: Market Trends for Sand Leveling Tools in 2026

By 2026, the sand leveling tool market is poised for significant transformation, driven by technological advancements, evolving construction practices, and heightened demand for precision and efficiency. Here are the key trends shaping the industry:

1. Integration of Smart Technology and IoT

The future of sand leveling tools lies in digitalization. By 2026, expect widespread adoption of smart leveling tools equipped with sensors, Bluetooth connectivity, and real-time feedback systems. These tools will interface with mobile apps or construction management platforms to provide data on surface flatness, moisture levels, and compaction—enabling on-site corrections and improving quality control. GPS-guided screeds and laser-leveling systems integrated with autonomous machinery will become standard in large-scale projects.

2. Rise in Demand for Cordless and Battery-Powered Tools

Environmental regulations and a push for quieter, cleaner job sites are accelerating the shift from gas-powered to cordless electric tools. Sand rakes, vibratory screeds, and power trowels will increasingly feature high-capacity lithium-ion batteries, offering greater portability, reduced maintenance, and improved user comfort. This trend aligns with the broader electrification movement in the construction equipment sector.

3. Growth in Residential and DIY Applications

The booming residential construction and landscaping markets—particularly in North America and parts of Asia—will drive demand for user-friendly sand leveling tools. Lightweight, ergonomic designs with intuitive operation will cater to both professional landscapers and DIY enthusiasts. Retailers will see increased sales of compact, multifunctional tools suitable for paver installations, patio leveling, and backyard projects.

4. Emphasis on Ergonomics and Worker Safety

With rising awareness of occupational health, manufacturers will prioritize ergonomics in tool design. Features such as adjustable handles, vibration-reduction systems, and balanced weight distribution will become standard. This not only improves user experience but also reduces fatigue and musculoskeletal injuries—supporting compliance with OSHA and other safety regulations.

5. Sustainable Materials and Manufacturing Practices

Environmental sustainability will influence material choices and production methods. Tool manufacturers will increasingly use recycled metals and plastics, and adopt energy-efficient manufacturing processes. Additionally, modular and repairable designs will gain traction, extending product lifecycles and reducing waste—responding to both consumer demand and regulatory pressure.

6. Regional Market Expansion in Emerging Economies

Rapid urbanization in countries like India, Indonesia, and Nigeria will fuel infrastructure and housing development, increasing demand for sand leveling tools. Localized production and affordable, durable tool models tailored to regional conditions will be critical for market penetration. Government investments in smart cities and affordable housing will further boost this growth.

7. Consolidation and Innovation Among Key Players

The market will see increased competition and consolidation, with major construction tool brands acquiring niche innovators to expand their smart tool portfolios. R&D investments will focus on AI-assisted leveling, drone-assisted site surveys, and integration with Building Information Modeling (BIM) systems—positioning sand leveling as a data-driven phase of construction workflows.

In summary, the 2026 sand leveling tool market will be defined by intelligence, sustainability, and accessibility. Tools will no longer be simple hand implements but integral components of a connected, efficient, and precision-focused construction ecosystem.

Common Pitfalls When Sourcing a Sand Leveling Tool (Quality & Intellectual Property)

Sourcing a sand leveling tool—commonly used in construction, landscaping, or foundry applications—requires careful attention to both product quality and intellectual property (IP) considerations. Overlooking these aspects can lead to performance issues, legal risks, and reputational damage. Below are key pitfalls to avoid:

Poor Material Quality and Durability

One of the most frequent issues is sourcing tools made from substandard materials. Low-grade metals or plastics may bend, crack, or corrode quickly when exposed to sand, moisture, or outdoor elements. This reduces tool lifespan and compromises leveling accuracy. Always verify material specifications (e.g., hardened steel, anodized aluminum) and request physical samples or third-party test reports before bulk ordering.

Inconsistent Manufacturing Tolerances

A sand leveling tool must have precise dimensions to ensure uniform sand distribution. Tools produced with inconsistent tolerances—especially in the blade or frame—can create uneven surfaces, leading to project rework. Choose suppliers with documented quality control processes and insist on production samples to verify dimensional accuracy.

Lack of Ergonomic Design

Poorly designed handles or unbalanced weight distribution can lead to user fatigue and reduced efficiency. This is often overlooked during sourcing but significantly impacts productivity on job sites. Evaluate the tool’s ergonomics through user testing or detailed design reviews before finalizing a supplier.

Inadequate Finishes and Corrosion Protection

Sand and moisture accelerate corrosion, especially in tools used outdoors. Sourcing tools without proper surface treatments—such as powder coating, galvanization, or stainless steel components—leads to premature rust and degradation. Confirm the type and thickness of protective finishes and request corrosion resistance test data.

Ignoring Intellectual Property Rights

Many sand leveling tools incorporate patented designs, particularly in adjustable mechanisms, blade geometry, or modular components. Sourcing from manufacturers who replicate branded designs without licensing can expose your business to IP infringement claims, customs seizures, or legal penalties. Conduct due diligence by checking patent databases and requiring suppliers to provide proof of design freedom-to-operate.

Copycat Products with Misleading Branding

Some suppliers offer tools that closely mimic well-known brands in appearance and packaging, raising trademark and design patent concerns. These knockoffs often sacrifice quality and expose buyers to legal risk. Avoid suppliers who cannot clearly distinguish their product design from existing branded tools or who use ambiguous branding.

Insufficient IP Documentation from Suppliers

Reliable suppliers should be able to provide documentation proving their right to manufacture and export the tool, including design patents, utility models, or original design authorship. Failure to obtain such documentation increases your liability if IP disputes arise post-purchase.

Overlooking Design Registration in Target Markets

Even if a tool design is original, failing to register it in key markets (e.g., EU, US, China) leaves it vulnerable to imitation. When developing a custom sand leveling tool, ensure that design rights are secured before production to protect your investment and market exclusivity.

By addressing these quality and IP-related pitfalls proactively, businesses can source reliable, legally compliant sand leveling tools that meet performance standards and safeguard long-term interests.

Logistics & Compliance Guide for Sand Leveling Tool

This guide outlines the logistics considerations and compliance requirements for the distribution, use, and handling of the Sand Leveling Tool. Adherence to these guidelines ensures safe, efficient operations and regulatory compliance.

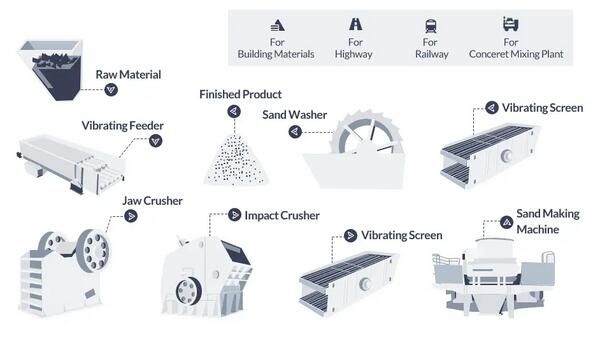

Product Overview

The Sand Leveling Tool is a manual or motorized device designed to evenly distribute and smooth sand surfaces, primarily used in construction, landscaping, and sports field maintenance. It is typically constructed from durable metals (e.g., steel or aluminum) and may include adjustable blades or vibrating mechanisms.

Packaging and Labeling Requirements

- Packaging: Units must be packed in robust, moisture-resistant corrugated cardboard or reusable crates to prevent damage during transit. Fragile components should be individually wrapped with foam or bubble wrap.

- Labeling: Each package must display:

- Product name and model number

- Weight and dimensions

- Handling instructions (e.g., “Fragile,” “This Side Up”)

- Manufacturer information and contact details

- Safety warnings and CE/UKCA marking (if applicable)

Shipping and Transportation

- Domestic Shipments: Use certified freight carriers experienced in handling industrial tools. Ensure proper palletization and strapping for stability.

- International Shipments: Comply with Incoterms (e.g., FOB, EXW) as agreed with the buyer. Provide commercial invoice, packing list, and bill of lading. Verify customs requirements for destination country.

- Hazardous Materials: The Sand Leveling Tool is non-hazardous; no special handling under IATA, IMDG, or ADR regulations is required.

Import and Export Compliance

- Export Controls: Verify that the product does not contain controlled materials or dual-use technologies. The Sand Leveling Tool is generally not subject to export restrictions under EAR or ITAR.

- Import Regulations: Confirm local import duties, VAT, and product conformity requirements (e.g., CE marking in the EU, UKCA in the UK).

- Documentation: Maintain records of export declarations, certificates of origin, and compliance certifications for a minimum of five years.

Regulatory and Safety Compliance

- CE Marking (European Union): The tool complies with the Machinery Directive 2006/42/EC and relevant EN standards (e.g., EN ISO 12100 for safety of machinery). Technical File and EC Declaration of Conformity must be available.

- UKCA Marking (United Kingdom): Post-Brexit, UKCA marking is required for tools sold in Great Britain. Compliance with UK supply of machinery regulations applies.

- OSHA (USA): While not directly regulated for consumer use, workplace use must follow OSHA guidelines for tool safety (29 CFR 1910.242).

- RoHS and REACH: Confirm that materials used comply with RoHS (restriction of hazardous substances) and REACH (chemical safety) regulations.

Storage and Handling

- Storage Conditions: Store in a dry, well-ventilated warehouse, protected from moisture and extreme temperatures. Keep off the ground on pallets.

- Handling: Use mechanical aids (e.g., forklifts) when moving heavy units. Train personnel in safe lifting techniques to prevent injury.

End-of-Life and Environmental Responsibility

- Recycling: The tool is largely recyclable (metal components). Provide end-user guidance on proper disposal in accordance with local WEEE (Waste Electrical and Electronic Equipment) directives where applicable.

- Environmental Impact: No lubricants or batteries are typically involved; minimal environmental footprint during use.

Quality Assurance and Documentation

- Maintain batch records, inspection reports, and conformity certificates.

- Conduct regular audits of logistics partners to ensure packaging and handling standards are met.

- Provide user manuals in local languages, including safety instructions and maintenance guidance.

Contact and Support

For compliance inquiries, logistics support, or documentation requests, contact:

[Company Name] Compliance & Logistics Department

Email: [email protected]

Phone: +1-800-XXX-XXXX

Conclusion:

After thorough evaluation of various options for a sand leveling tool, it is evident that selecting the right tool depends on the specific application, scale of the project, and desired efficiency. Manual tools such as leveling rakes and straight edges remain cost-effective and reliable for small to medium landscaping or paver projects, offering precision and ease of use. For larger-scale operations, motorized or vibrating screeds provide increased speed and consistency, reducing labor costs and improving surface uniformity.

Durability, material quality, and ergonomic design are key factors to consider when sourcing. Additionally, availability of replacement parts and compatibility with existing equipment can influence long-term usability. Sourcing from reputable suppliers ensures product reliability and access to technical support.

In conclusion, an appropriate sand leveling tool enhances project efficiency, ensures a smooth and level surface, and contributes to the overall quality and longevity of the installed hardscape. Careful consideration of project requirements and tool specifications will lead to an optimal sourcing decision.