The global wood products market continues to expand steadily, driven by rising demand in residential construction, furniture, and interior design. According to a 2023 report by Mordor Intelligence, the global wood and wood products market was valued at approximately USD 530 billion and is projected to grow at a CAGR of over 5.8% from 2023 to 2028. This growth is fueled by increasing urbanization, sustainable building practices, and a resurgence in wood as a renewable, aesthetically pleasing material. In India, regional manufacturing hubs like Salem—renowned for its rich timber resources and legacy of craftsmanship—have emerged as key contributors to this upward trend. Situated in Tamil Nadu, Salem benefits from proximity to forested regions and well-established woodworking infrastructure, making it a hotspot for high-quality wood product manufacturing. Here, we spotlight the top six wood products manufacturers in Salem whose innovation, scale, and quality are not only meeting domestic demand but also aligning with global sustainability and design trends.

Top 6 Salem Wood Products Manufacturers 2026

(Ranked by Factory Capability & Trust Score)

#1 Koppers Inc.

Domain Est. 1995

Website: koppers.com

Key Highlights: We provide fully integrated, sustainability-based product, services, and solutions to infrastructure industries around the world….

#2 Salem Wood Products

Domain Est. 1996

Website: mapquest.com

Key Highlights: Salem Wood Products is a reputable company based in Salem, MO, specializing in the production and distribution of high-quality wood products….

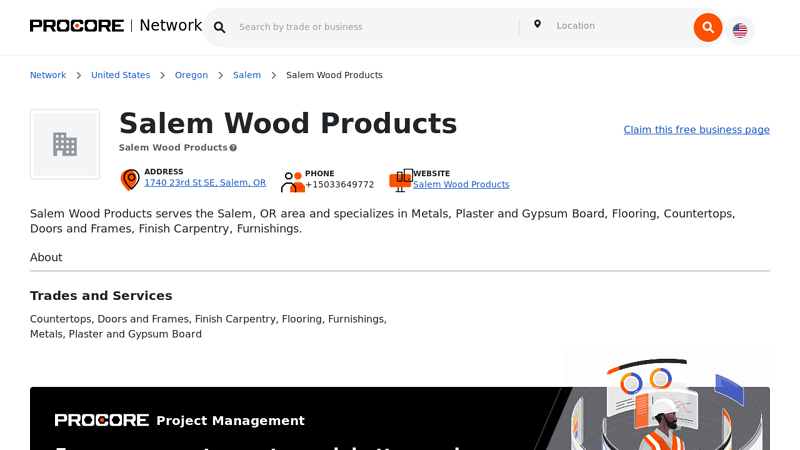

#3 Salem Wood Products

Domain Est. 1998

Website: procore.com

Key Highlights: Salem Wood Products is a construction company based in Salem, OR and specializes in Metals, Plaster and Gypsum Board, Flooring, Countertops, Doors and ……

#4 Salem Wood Shop

Domain Est. 2017

Website: salemwoodshop.com

Key Highlights: Unique and Long Lasting Gifts for your Home and Business. · How can we help? · Salem Wood Shop….

#5 Contact

Domain Est. 2021

Website: salemwood.co

Key Highlights: Salem Wood Co. builds custom furniture to suit your space and style. Anything from dining tables to sideboards to custom shelving….

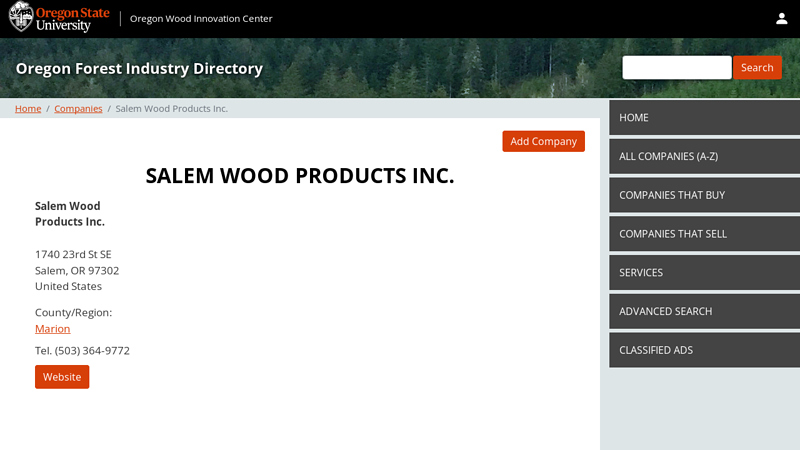

#6 Salem Wood Products Inc.

Domain Est. 2004

Website: orforestdirectory.com

Key Highlights: Salem Wood Products Inc. 1740 23rd St SE Salem, OR 97302 United States County/Region: Marion Tel. (503) 364-9772 Website…

Expert Sourcing Insights for Salem Wood Products

H2: Market Trends Analysis for Salem Wood Products in 2026

As Salem Wood Products positions itself for growth and adaptation in 2026, several key market trends are shaping the wood products industry, influencing demand, supply chains, technological adoption, and sustainability practices. This analysis outlines the most significant trends likely to impact Salem Wood Products in the coming years.

1. Rising Demand for Sustainable and Certified Wood Products

Environmental consciousness continues to grow among consumers and commercial buyers alike. In 2026, demand for FSC (Forest Stewardship Council) and SFI (Sustainable Forestry Initiative)-certified wood products is expected to increase significantly. Salem Wood Products can capitalize on this trend by reinforcing its commitment to sustainable sourcing, transparent supply chains, and eco-friendly manufacturing. Companies emphasizing green credentials are likely to gain a competitive advantage in both residential and commercial markets.

2. Growth in Mass Timber and Engineered Wood Applications

The construction sector is increasingly adopting mass timber—such as cross-laminated timber (CLT) and glued laminated timber (glulam)—for mid- and high-rise buildings due to its strength, carbon sequestration benefits, and faster construction timelines. Salem Wood Products may benefit from investing in or expanding into engineered wood product lines, especially as building codes evolve to support taller wood structures in urban environments.

3. Supply Chain Resilience and Domestic Sourcing

Ongoing global supply chain volatility has driven a shift toward regional and domestic sourcing. In 2026, customers will continue to favor suppliers with reliable, localized supply chains. Salem Wood Products can strengthen its market position by securing long-term agreements with regional timber suppliers, investing in inventory optimization technologies, and minimizing dependence on imported raw materials.

4. Digitalization and Smart Manufacturing

The integration of Industry 4.0 technologies—such as IoT-enabled machinery, AI-driven demand forecasting, and real-time production monitoring—is transforming wood manufacturing. By 2026, companies that adopt smart manufacturing practices will achieve greater efficiency, reduced waste, and improved customization capabilities. Salem Wood Products should consider incremental digital upgrades to remain competitive and meet evolving customer expectations for speed and precision.

5. Labor Shortages and Automation

The wood products industry faces persistent challenges in attracting and retaining skilled labor. In response, automation and robotics are being increasingly deployed in sawmills, planing operations, and packaging. Salem Wood Products may explore automation solutions to mitigate labor gaps, enhance productivity, and maintain consistent product quality.

6. Impact of Housing and Construction Cycles

The U.S. housing market remains a key driver of demand for wood products. While 2026 may see moderate growth in residential construction—supported by demographic trends and urban infill development—volatility in interest rates and material costs could affect project starts. Salem Wood Products should remain agile, aligning production capacity with housing market indicators and diversifying into non-residential and renovation sectors to stabilize revenue.

7. Regulatory and Carbon Compliance Pressures

Environmental regulations, including carbon reporting requirements and building energy codes, are becoming more stringent. Wood, as a renewable and carbon-storing material, is well-positioned in this landscape. Salem Wood Products can leverage its low-carbon footprint as a marketing advantage and prepare for potential compliance mandates by tracking and reporting emissions across its operations.

Conclusion

In 2026, Salem Wood Products will operate in a dynamic environment defined by sustainability, technological innovation, and shifting market demands. By proactively addressing these trends—particularly in sustainable certification, engineered wood expansion, and operational digitization—the company can strengthen its market presence, enhance customer value, and drive long-term profitability. Strategic investments in people, technology, and environmental stewardship will be essential to thriving in the evolving wood products landscape.

Common Pitfalls When Sourcing Salem Wood Products (Quality, IP)

Sourcing wood products from Salem—known for its forestry heritage and wood manufacturing—can offer high-quality materials, but businesses must navigate several potential pitfalls related to quality control and intellectual property (IP). Being aware of these challenges helps ensure reliable supply chains and protects your brand.

Inconsistent Product Quality

One of the most frequent issues when sourcing wood products from Salem is inconsistency in quality across suppliers. While some manufacturers adhere to strict grading standards, others may cut corners to reduce costs. Buyers often encounter variations in wood grain, moisture content, finishing, and dimensional accuracy. These inconsistencies can lead to rework, delays, or customer dissatisfaction, especially in high-end furniture or architectural applications.

Lack of Standardized Grading and Certification

Not all Salem wood suppliers follow standardized grading systems (such as NHLA or WWPA), and some may misrepresent the grade of lumber. Additionally, claims of “sustainable” or “FSC-certified” wood are not always backed by valid documentation. Without third-party verification, buyers risk receiving subpar or illegally harvested materials, which can lead to compliance issues and reputational damage.

Misrepresentation of Wood Species

Some suppliers may mislabel wood species to pass off less expensive or more readily available types as premium varieties (e.g., selling alder as walnut or Douglas fir as old-growth pine). This misrepresentation affects both the aesthetic and structural integrity of the final product and may constitute fraud.

Intellectual Property Infringement Risks

When sourcing finished wood products—such as custom furniture, cabinetry, or architectural millwork—there’s a risk that designs may infringe on existing patents, trademarks, or copyrighted patterns. Some Salem manufacturers may replicate popular designs without securing proper IP rights, exposing the buyer to legal liability upon importing or selling the goods.

Inadequate Documentation for IP and Compliance

Suppliers might fail to provide clear documentation proving design ownership or licensing for proprietary patterns, joinery techniques, or branded finishes. This lack of transparency makes it difficult to defend against IP claims, especially in international markets with strict IP enforcement.

Supply Chain Opacity and Traceability Gaps

Many wood product suppliers in Salem source raw materials from multiple mills or private landowners without full traceability. This opacity increases the risk of inadvertently sourcing wood from protected areas or engaging in practices that violate environmental regulations, potentially leading to customs delays or import bans.

Conclusion

To mitigate these pitfalls, buyers should conduct thorough due diligence: verify certifications, request material samples, perform factory audits, and secure written IP indemnification agreements. Partnering with reputable, transparent suppliers and using third-party inspections can significantly reduce risks associated with quality and intellectual property when sourcing Salem wood products.

Logistics & Compliance Guide for Salem Wood Products

This guide outlines the essential logistics and compliance procedures for Salem Wood Products to ensure efficient operations, regulatory adherence, and sustainable business practices. All departments must follow these guidelines to maintain quality, legal compliance, and customer satisfaction.

Supply Chain Management

- Supplier Selection: Partner only with certified and reputable timber suppliers who comply with sustainable forestry practices (e.g., FSC or PEFC certification). Conduct annual supplier audits.

- Raw Material Sourcing: Ensure all wood materials are legally harvested with proper documentation (e.g., chain-of-custody certificates, logging permits).

- Inventory Control: Maintain accurate inventory records using barcode scanning and warehouse management software. Conduct quarterly physical audits.

Transportation & Distribution

- Shipping Methods: Utilize a mix of trucking (regional) and rail (long-distance) to optimize cost and reduce carbon footprint. Partner with carriers compliant with EPA emissions standards.

- Load Security: Secure all wood products with appropriate strapping and dunnage to prevent damage during transit.

- Delivery Scheduling: Coordinate deliveries to minimize lead times and avoid overstocking at customer sites. Provide real-time tracking to clients.

Regulatory Compliance

- Import/Export Regulations: For international shipments, comply with ISPM 15 standards for wood packaging material (e.g., heat-treated pallets). Maintain accurate customs documentation (commercial invoices, packing lists, certificates of origin).

- Environmental Regulations: Adhere to Clean Air Act and Clean Water Act standards in manufacturing processes. Manage sawdust and wood waste per local environmental codes.

- Labor & Safety Compliance: Follow OSHA guidelines in all facilities. Provide PPE, safety training, and maintain a documented safety program.

Documentation & Recordkeeping

- Shipping Documents: Prepare and retain all bills of lading, delivery confirmations, and freight invoices for a minimum of seven years.

- Compliance Records: Archive all sustainability certifications, audit reports, and regulatory filings in a secure digital system.

- Customer Documentation: Provide material safety data sheets (MSDS) and product compliance statements upon request.

Quality Assurance

- Incoming Inspection: Inspect all raw materials for moisture content, defects, and species accuracy upon receipt.

- In-Process Checks: Conduct regular quality checks during production to ensure dimensional accuracy and finish standards.

- Final Inspection: Perform 100% visual inspection on finished goods before shipment.

Sustainability & Corporate Responsibility

- Waste Reduction: Recycle wood scraps into mulch, biomass fuel, or secondary products. Aim for 90% waste diversion from landfills by 2026.

- Carbon Reporting: Annually measure and report carbon emissions from transportation and operations. Implement offset programs as needed.

- Community Engagement: Support local reforestation initiatives and maintain transparent communication with stakeholders.

Incident Response & Audits

- Non-Compliance Reporting: Establish a confidential reporting system for compliance issues. Investigate and resolve all reports within 14 days.

- Internal Audits: Conduct biannual audits of logistics and compliance procedures. Corrective action plans must be implemented within 30 days of findings.

- Regulatory Updates: Assign a compliance officer to monitor changes in trade, environmental, and transportation laws affecting wood products.

Adherence to this guide ensures Salem Wood Products operates efficiently, ethically, and in full compliance with all applicable laws and industry standards.

Conclusion on Sourcing Salem Wood Products

Sourcing wood products from Salem presents a compelling opportunity for businesses prioritizing quality, sustainability, and regional reliability. Salem, particularly in regions known for timber production such as Salem, Oregon, offers access to a diverse range of wood species, including Douglas fir, western red cedar, and other premium softwoods, all harvested from responsibly managed forests. The region’s strong forestry traditions, combined with modern milling technologies and adherence to environmental regulations, ensure consistent product quality and compliance with sustainability standards such as FSC or SFI certification.

Additionally, sourcing from Salem supports local economies, reduces transportation emissions due to geographic proximity (especially for West Coast operations), and enhances supply chain resilience. However, potential challenges such as seasonal availability, market price fluctuations, and logistical considerations should be carefully managed through long-term supplier relationships and thorough due diligence.

In conclusion, Salem wood products represent a reliable, eco-conscious, and high-performing choice for construction, furniture, and specialty wood applications. With proper planning and strategic partnerships, sourcing from Salem can deliver both economic and environmental benefits, aligning well with sustainable procurement goals and high-quality production standards.